Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (11): 74-82.doi: 10.19964/j.issn.1006-4990.2024-0532

• Environment·Health·Safety • Previous Articles Next Articles

Study on preparation and phosphorus adsorption of phosphate tailings ceramic particles by response surface method

HOU Daiwen1( ), LIANG Huan1(

), LIANG Huan1( ), XING Lijing1, LIU Hai1, ZHANG Huali1, TIAN Chengtao2, SHI Tongshan3

), XING Lijing1, LIU Hai1, ZHANG Huali1, TIAN Chengtao2, SHI Tongshan3

- 1. National Engineering Research Center for Phosphorus Resources Development and Utilization,Wuhan Institute of Technology,Wuhan 430074,China

2. Hubei Sanning Chemical Co.,Ltd.,Yichang 443200,China

3. Wengfu(Group) Limited liability Company,Guiyang 550002,China

-

Received:2024-10-09Online:2025-11-10Published:2025-08-01 -

Contact:LIANG Huan E-mail:2573258640@qq.com;zfslianghuan@163.com

CLC Number:

Cite this article

HOU Daiwen, LIANG Huan, XING Lijing, LIU Hai, ZHANG Huali, TIAN Chengtao, SHI Tongshan. Study on preparation and phosphorus adsorption of phosphate tailings ceramic particles by response surface method[J]. Inorganic Chemicals Industry, 2025, 57(11): 74-82.

share this article

Table 2

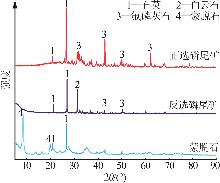

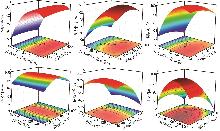

Performance parameters of FPTC and its phosphorus adsorption rate under different addition amounts of reverse-flotation phosphorus tailings"

| 编号 | 反选磷尾矿添加量/% | 孔隙率/% | 堆积密度/ (g·cm-3) | 抗压强度/MPa | 磷的吸 附率/% |

|---|---|---|---|---|---|

| FPTC-1 | 0 | 55.02 | 0.816 | 2.85 | 39.40 |

| FPTC-2 | 20 | 56.60 | 0.753 | 2.51 | 59.70 |

| FPTC-3 | 40 | 59.98 | 0.648 | 2.13 | 98.20 |

| FPTC-4 | 60 | 61.30 | 0.625 | 2.11 | 98.60 |

| FPTC-5 | 80 | 61.91 | 0.614 | 0.75 | 90.00 |

Table 3

Performance parameters of FPTC and its phosphorus adsorption rate under different calcination temperatures"

| 编号 | 焙烧 温度/℃ | 孔隙率/ % | 堆积密度/ (g·cm-3) | 抗压强度/MPa | 磷的吸 附率/% |

|---|---|---|---|---|---|

| FPTC-6 | 450 | 59.67 | 0.824 | 1.25 | 57.00 |

| FPTC-7 | 650 | 59.97 | 0.815 | 1.49 | 68.40 |

| FPTC-8 | 850 | 62.25 | 0.723 | 1.79 | 91.46 |

| FPTC-9 | 950 | 62.75 | 0.758 | 2.13 | 98.80 |

| FPTC-10 | 1 050 | 55.01 | 0.952 | 2.16 | 97.56 |

Table 6

Results of response surface experiment"

实验 序号 | A/% | B/℃ | C/℃ | D/min | 磷的吸附率/% |

|---|---|---|---|---|---|

| 1 | 70 | 400 | 950 | 40 | 99.30 |

| 2 | 70 | 400 | 900 | 60 | 97.51 |

| 3 | 70 | 350 | 950 | 60 | 99.24 |

| 4 | 60 | 400 | 950 | 60 | 99.45 |

| 5 | 60 | 400 | 900 | 80 | 95.73 |

| 6 | 60 | 450 | 900 | 60 | 96.74 |

| 7 | 60 | 400 | 1 000 | 80 | 95.44 |

| 8 | 70 | 450 | 950 | 60 | 99.20 |

| 9 | 60 | 400 | 950 | 60 | 99.45 |

| 10 | 50 | 400 | 900 | 60 | 90.31 |

| 11 | 60 | 400 | 950 | 60 | 99.45 |

| 12 | 60 | 450 | 1 000 | 60 | 97.88 |

| 13 | 50 | 450 | 950 | 60 | 91.68 |

| 14 | 50 | 400 | 1 000 | 60 | 90.57 |

| 15 | 50 | 400 | 950 | 80 | 91.22 |

| 16 | 60 | 350 | 950 | 40 | 98.70 |

| 17 | 60 | 400 | 950 | 60 | 99.45 |

| 18 | 60 | 350 | 900 | 60 | 96.71 |

| 19 | 70 | 400 | 1 000 | 60 | 96.80 |

| 20 | 60 | 450 | 950 | 80 | 97.60 |

| 21 | 60 | 400 | 900 | 40 | 97.32 |

| 22 | 70 | 400 | 950 | 80 | 97.99 |

| 23 | 60 | 450 | 950 | 40 | 99.23 |

| 24 | 50 | 350 | 950 | 60 | 92.40 |

| 25 | 50 | 400 | 950 | 40 | 92.04 |

| 26 | 60 | 350 | 950 | 80 | 97.73 |

| 27 | 60 | 400 | 1 000 | 40 | 98.55 |

| 28 | 60 | 350 | 1 000 | 60 | 97.63 |

| 29 | 60 | 400 | 950 | 60 | 99.45 |

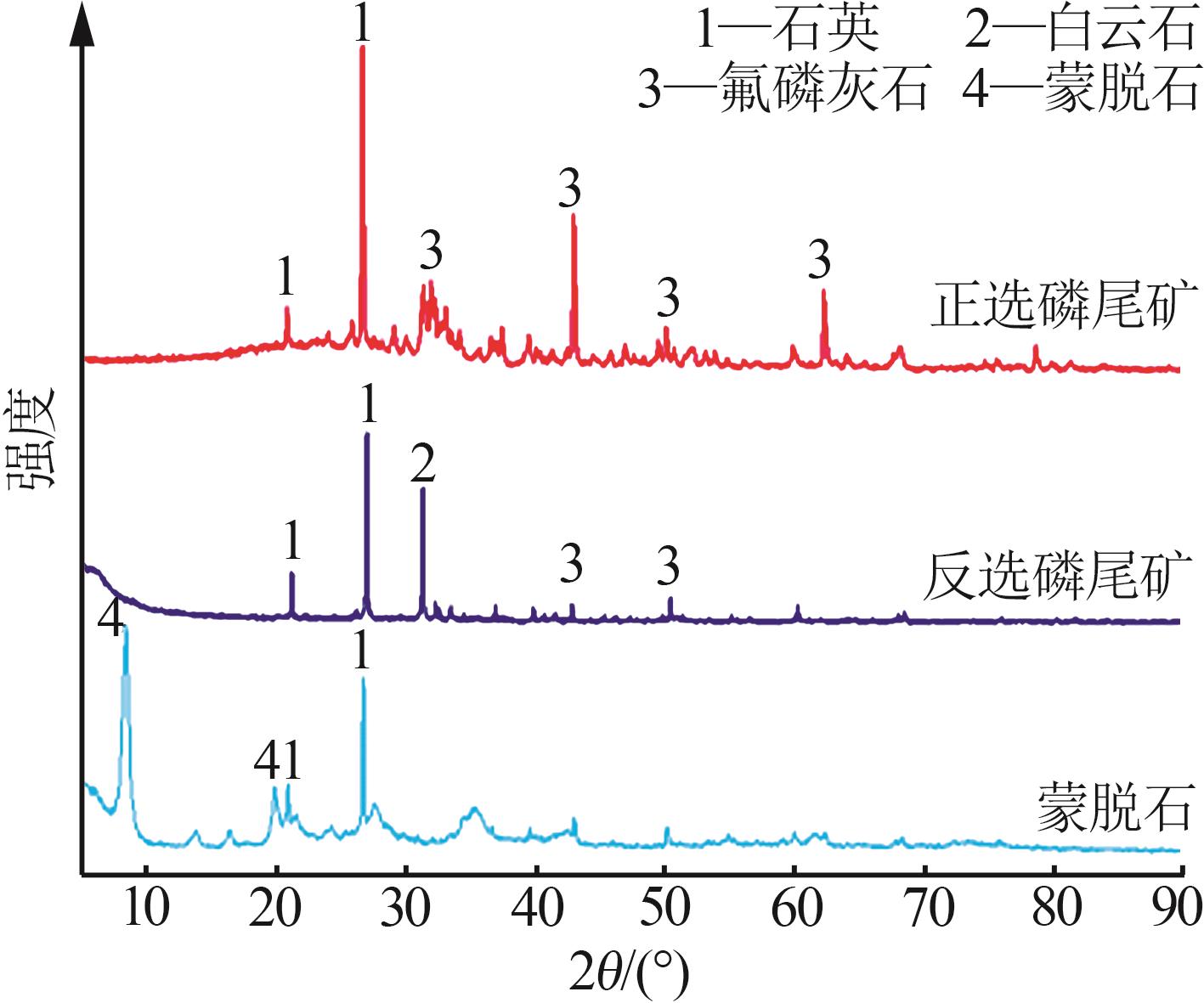

Table 7

Analysis of variance results of response surface regression model"

方差 来源 | 平方和 | 自由度 | 均方 | F值 | P值 | 显著性 |

|---|---|---|---|---|---|---|

| 模型 | 252.17 | 14 | 18.01 | 117.85 | <0.000 1 | ♣♣ |

| A | 145.74 | 1 | 145.74 | 953.57 | <0.000 1 | ♣♣ |

| B | 0.001 4 | 1 | 0.001 4 | 0.008 8 | 0.953 7 | |

| C | 0.54 | 1 | 0.54 | 3.55 | 0.080 7 | |

| D | 7.41 | 1 | 7.41 | 50.87 | <0.000 1 | ♣♣ |

| AB | 0.12 | 1 | 0.12 | 0.76 | 0.399 1 | |

| AC | 0.24 | 1 | 0.24 | 1.54 | 0.235 1 | |

| AD | 0.06 | 1 | 0.06 | 0.39 | 0.541 0 | |

| BC | 0.012 | 1 | 0.012 | 0.079 | 0.782 5 | |

| BD | 0.11 | 1 | 0.11 | 0.71 | 0.412 8 | |

| CD | 0.58 | 1 | 0.58 | 3.78 | 0.072 3 | |

| A2 | 83.56 | 1 | 83.56 | 546.72 | <0.000 1 | ♣♣ |

| B2 | 0.51 | 1 | 0.51 | 3.31 | 0.090 4 | |

| C2 | 25.25 | 1 | 25.25 | 165.19 | <0.000 1 | ♣♣ |

| D2 | 3.80 | 1 | 3.80 | 24.86 | 0.000 2 | ♣♣ |

| 残差 | 2.14 | 14 | 0.15 | |||

| 失拟项 | 2.14 | 10 | 0.21 | |||

| 纯误差 | 0 | 4 | 0 | |||

| 总和 | 254.31 | 28 | ||||

| 相关系数 | 0.950 9 | |||||

决定相 关系数 | 0.983 2 |

| [1] | 王文浩,王春连,王连训,等.中国磷矿成因类型、成矿规律及重点找矿方向[J].中国地质,2025,52(1):43-60. |

| WANG Wenhao, WANG Chunlian, WANG Lianxun,et al.Origin types,metallogenic regularity and prospecting direction of phosphate deposits in China[J].Geology in China,2025,52(1):43-60. | |

| [2] | 苗俊艳,齐帅亮,侯翠红,等.磷矿资源绿色全量利用技术研究现状及突破思路[J].化学与生物工程,2024,41(5):1-8. |

| MIAO Junyan, QI Shuailiang, HOU Cuihong,et al.Research status and breakthrough ideas of green full utilization technology of phosphate ore resources[J].Chemistry & Bioengineering,2024,41(5):1-8. | |

| [3] | 张立,张晋,张朝宏,等.轻质多孔陶粒的制备及其磷吸附性能研究[J].非金属矿,2024,47(2):80-84. |

| ZHANG Li, ZHANG Jin, ZHANG Chaohong,et al.Research on preparation of light porous ceramsites and their phosphate adsorption properties[J].Non-Metallic Mines,2024,47(2):80-84. | |

| [4] | 邢丽静,梁欢,田承涛,等.白云石质磷尾矿制备多孔陶粒对含磷废水吸附特性研究[J].水处理技术,2023,49(12):101-107,131. |

| XING Lijing, LIANG Huan, TIAN Chengtao,et al.Study on the adsorption characteristics of porous ceramsite prepared from dolomitic phosphorus tailings for phosphorous wastewater[J].Technology of Water Treatment,2023,49(12):101-107,131. | |

| [5] | 李沧,程霄智,矫辰,等.赤泥-钢渣基免烧陶粒的制备及除磷特性研究[J].水处理技术,2024,50(10):38-43. |

| LI Cang, CHENG Xiaozhi, JIAO Chen,et al.Study on preparation and phosphorus removal characteristics of red mud and steel slag based non-sintered ceramsite[J].Technology of Water Treatment,2024,50(10):38-43. | |

| [6] | 唐婧,罗胜元.碱浸和污泥强化对钢渣陶粒除磷效果的影响[J].钢铁钒钛,2024,45(1):96-103. |

| TANG Jing, LUO Shengyuan.Effect of alkali leaching and sludge strengthening on phosphorus removal of steel slag ceramics[J].Iron Steel Vanadium Titanium,2024,45(1):96-103. | |

| [7] | LV Na, LI Xiufen, QI Xiguang,et al.Calcium-modified granular attapulgite removed phosphorus from synthetic wastewater containing low-strength phosphorus[J].Chemosphere,2022,296:133898. |

| [8] | 冯宇博,梁欢,田承涛,等.La2O3负载非金属矿物基陶粒制备及其除磷性能研究[J].环境污染与防治,2023,45(9):1218-1222,1228. |

| FENG Yubo, LIANG Huan, TIAN Chengtao,et al.Preparation of La2O3 loaded non-metallic mineral based ceramsite and its phosphorus removal performance[J].Environmental Pollution & Control,2023,45(9):1218-1222,1228. | |

| [9] | EDWARDS D J, MEE R W.Fractional Box-Behnken designs for one-step response surface methodology[J].Journal of Quality Technology,2011,43(4):288-306. |

| [10] | RAHMATABADI D, SOLTANMOHAMMADI K, PAHLAVANI M,et al.Shape memory performance assessment of FDM 3D printed PLA-TPU composites by Box-Behnken response surface methodology[J].The International Journal of Advanced Manufacturing Technology,2023,127(1):935-950. |

| [11] | 章聪华,颜文斌,肖佳俊,等.响应面法优化酒石酸还原浸出电解锰阳极渣工艺[J].无机盐工业,2023,55(9):106-113. |

| ZHANG Conghua, YAN Wenbin, XIAO Jiajun,et al.Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM[J].Inorganic Chemicals Industry,2023,55(9):106-113. | |

| [12] | 石成龙,马淑清,秦亚茹,等.响应面法优化磷酸三丁酯-丁酸乙酯体系协同提锂工艺研究[J].无机盐工业,2022,54(10):37-41. |

| SHI Chenglong, MA Shuqing, QIN Yaru,et al.Study on optimization of synergistic lithium extraction process of tributyl phospha-te-ethyl butyrate system by response surface method[J].Inorganic Chemicals Industry,2022,54(10):37-41. | |

| [13] | 李亚娇,赵艺伟,鞠恺,等.基于响应面法的粉煤灰氨含量测定过程浸提条件优化研究[J].无机盐工业,2022,54(4):145-151. |

| LI Yajiao, ZHAO Yiwei, JU Kai,et al.Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method[J].Inorganic Chemicals Industry,2022,54(4):145-151. | |

| [14] | 方伟成,程星星,孙常荣.响应曲面法优化污泥/粉煤灰复合陶粒滤料的制备[J].无机盐工业,2022,54(9):119-125, 142. |

| FANG Weicheng, CHENG Xingxing, SUN Changrong.Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology[J].Inorganic Chemicals Industry,2022,54(9):119-125,142. | |

| [15] | 侯黎爽,谷守玉,侯翠红,等.响应面法优化焦磷酸钠螯合锌的制备工艺研究[J].无机盐工业,2020,52(7):30-35,93. |

| HOU Lishuang, GU Shouyu, HOU Cuihong,et al.Optimization of preparation process of sodium pyrophosphate chelates zinc by response surface analysis[J].Inorganic Chemicals Industry,2020,52(7):30-35,93. |

| [1] | LI Jun, ZHOU Zhaoan, LIU Xiaowen, MAO Anzhang, ZHOU Aiqing. Study on optimization of COD and fluoride removal on waste salt carbonization process by response surface method [J]. Inorganic Chemicals Industry, 2025, 57(4): 105-110. |

| [2] | SHI Yunpeng, GUO Ze, ZHANG Hanquan, LU Manman. Study on treatment of ammonia nitrogen wastewater by roasted phosphorus tailings [J]. Inorganic Chemicals Industry, 2025, 57(3): 94-100. |

| [3] | HU Zhenrong, ZHANG Manman, SHI Chenglong, PENG Jiaoyu, ZHOU Yannan, DONG Yaping, LI Wu. Study on crystallization process and kinetic of macallisterite in concentrated MgCl2-xNa2O·yB2O3-H2O solution [J]. Inorganic Chemicals Industry, 2025, 57(10): 64-74. |

| [4] | WANG Li, YAN Xiaohong, KE Guopeng, MEI Jiaxin, CHEN Mingyue, LIU Jingyong. Research progress of ceramsite prepared by sintering heavy metal-contaminated soil [J]. Inorganic Chemicals Industry, 2025, 57(1): 27-35. |

| [5] | TANG Dongwu, YE Changwen, DENG Jie, AO Fang. Study on leaching rate of calcium and magnesium from phosphorus tailings based on thermodynamic analysis and response surface method [J]. Inorganic Chemicals Industry, 2024, 56(9): 98-106. |

| [6] | CHEN Junhui, LIU Xiang, HU Qingxi, TIAN Bangxin, CHEN Jiale. Study on leaching extraction of high purity potassium chloride from sintering machine head ash [J]. Inorganic Chemicals Industry, 2024, 56(6): 102-108. |

| [7] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [8] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [9] | ZHAO Feiyan, ZHANG Xiaodong, DU Yanxia, WANG Qiang, LI Xiaoyan. Preparation technology and research progress of fly ash ceramsite [J]. Inorganic Chemicals Industry, 2024, 56(4): 16-23. |

| [10] | WANG Baoming, WANG Xinglong, YANG Ying, ZHAO Bo, HUA Quanxian, LIU Yong, LIU Pengfei, SHEN Bo, DING Junxiang, TANG Jianwei. Current status and research progress of comprehensive utilization of phosphorus tailings [J]. Inorganic Chemicals Industry, 2024, 56(10): 1-11. |

| [11] | ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM [J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113. |

| [12] | WANG Yingnan, SHENG Linlin, HUANG Juan, HUANG Zhanbin. Study on adsorption performance of lead from water by coal-fired slag [J]. Inorganic Chemicals Industry, 2023, 55(8): 109-115. |

| [13] | CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling. Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM [J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123. |

| [14] | LIU Guanfa, ZENG Chaocong, WANG Zekai, ZENG Xiangrong, HUANG Wanfu. Study on preparation of high strength sintered ceramsite from tungsten smelting slag and its property [J]. Inorganic Chemicals Industry, 2023, 55(8): 132-139. |

| [15] | WU Yulin, WU Junhu, YANG Xiushan, XU Dehua, ZHANG Zhiye. Study on optimization of decalcification process of calcium and magnesium nitrate solution by response surface method [J]. Inorganic Chemicals Industry, 2023, 55(6): 50-56. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||