Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (9): 106-113.doi: 10.19964/j.issn.1006-4990.2022-0685

• Environment·Health·Safety • Previous Articles Next Articles

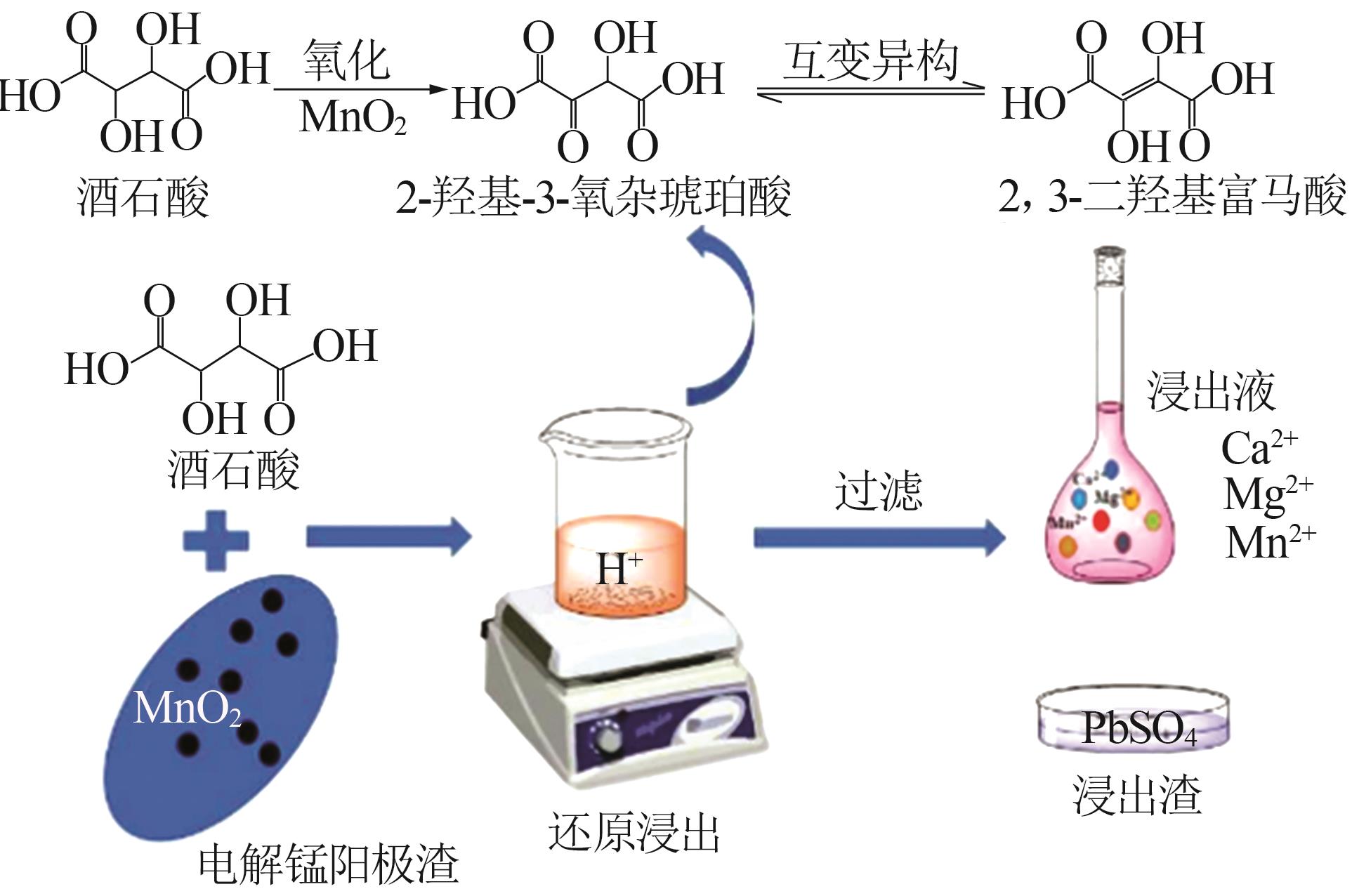

Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM

ZHANG Conghua( ), YAN Wenbin(

), YAN Wenbin( ), XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong

), XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong

- College of Chemistry and Chemical Engineering,Jishou University,Jishou 416000,China

-

Received:2022-11-18Online:2023-09-10Published:2023-09-19 -

Contact:YAN Wenbin E-mail:424547873@qq.com;jishouyanwenbin@163.com

CLC Number:

Cite this article

ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM[J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113.

share this article

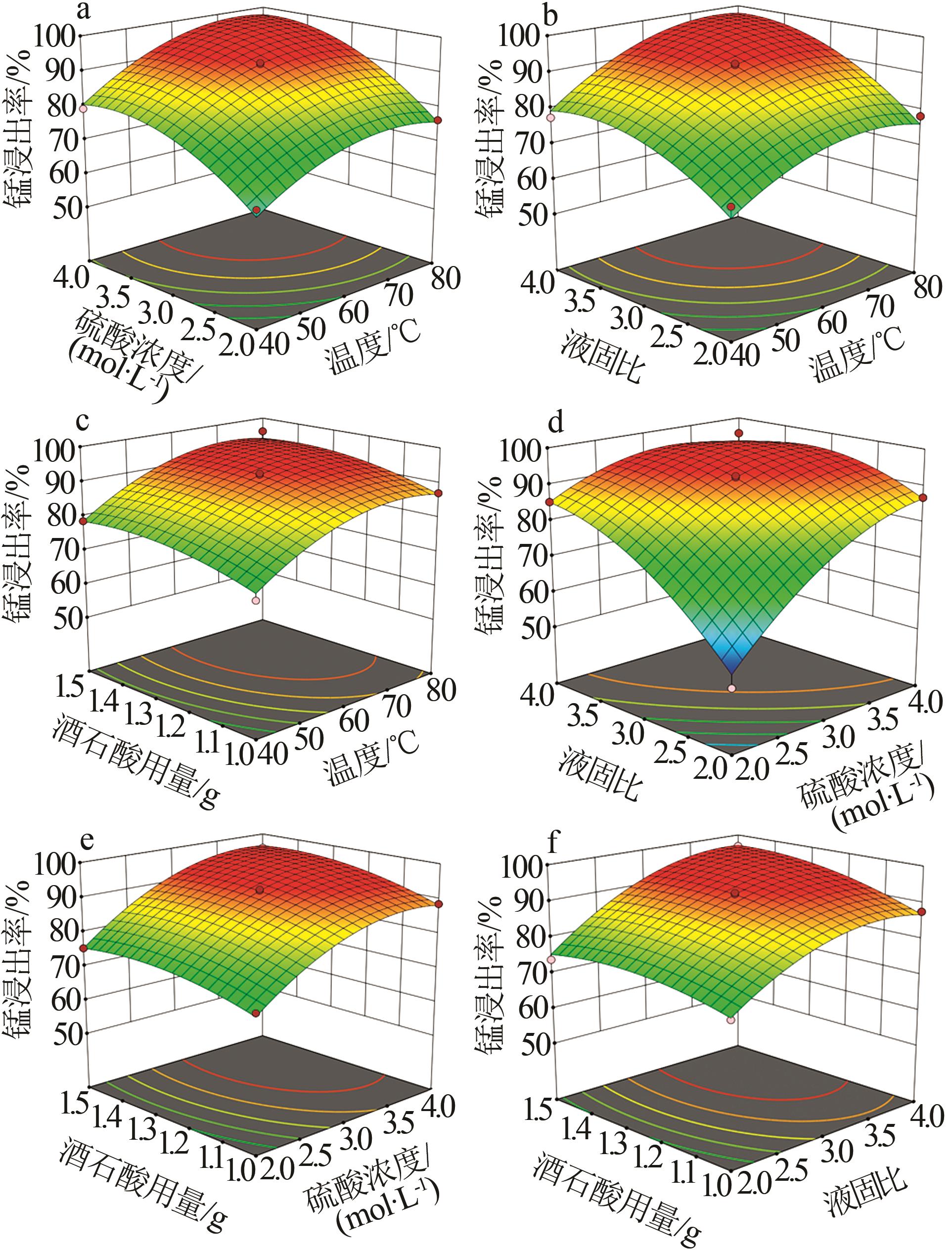

Table 3

Experimental results"

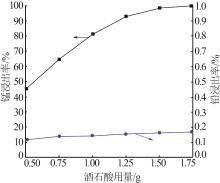

温度/ ℃ | 硫酸浓度/ (mol·L-1) | 液固比 | 酒石 酸用量/g | 锰浸 出率/% |

|---|---|---|---|---|

| 40 | 2 | 3 | 1.25 | 65.61 |

| 80 | 2 | 3 | 1.25 | 76.3 |

| 40 | 4 | 3 | 1.25 | 79.14 |

| 80 | 4 | 3 | 1.25 | 95.1 |

| 60 | 3 | 2 | 1 | 72.16 |

| 60 | 3 | 4 | 1 | 87.6 |

| 60 | 3 | 2 | 1.5 | 73.84 |

| 60 | 3 | 4 | 1.5 | 96.63 |

| 40 | 3 | 3 | 1 | 70.73 |

| 80 | 3 | 3 | 1 | 87.16 |

| 40 | 3 | 3 | 1.5 | 78.64 |

| 80 | 3 | 3 | 1.5 | 95.84 |

| 60 | 2 | 2 | 1.25 | 50.76 |

| 60 | 4 | 2 | 1.25 | 86.87 |

| 60 | 2 | 4 | 1.25 | 85.25 |

| 60 | 4 | 4 | 1.25 | 95.41 |

| 40 | 3 | 2 | 1.25 | 68.22 |

| 80 | 3 | 2 | 1.25 | 78.32 |

| 40 | 3 | 4 | 1.25 | 77.45 |

| 80 | 3 | 4 | 1.25 | 95.16 |

| 60 | 2 | 3 | 1 | 71.63 |

| 60 | 4 | 3 | 1 | 88.6 |

| 60 | 2 | 3 | 1.5 | 75.37 |

| 60 | 4 | 3 | 1.5 | 95.66 |

| 60 | 3 | 3 | 1.25 | 92.08 |

| 60 | 3 | 3 | 1.25 | 91.84 |

| 60 | 3 | 3 | 1.25 | 91.81 |

| 60 | 3 | 3 | 1.25 | 92.18 |

| 60 | 3 | 3 | 1.25 | 92.6 |

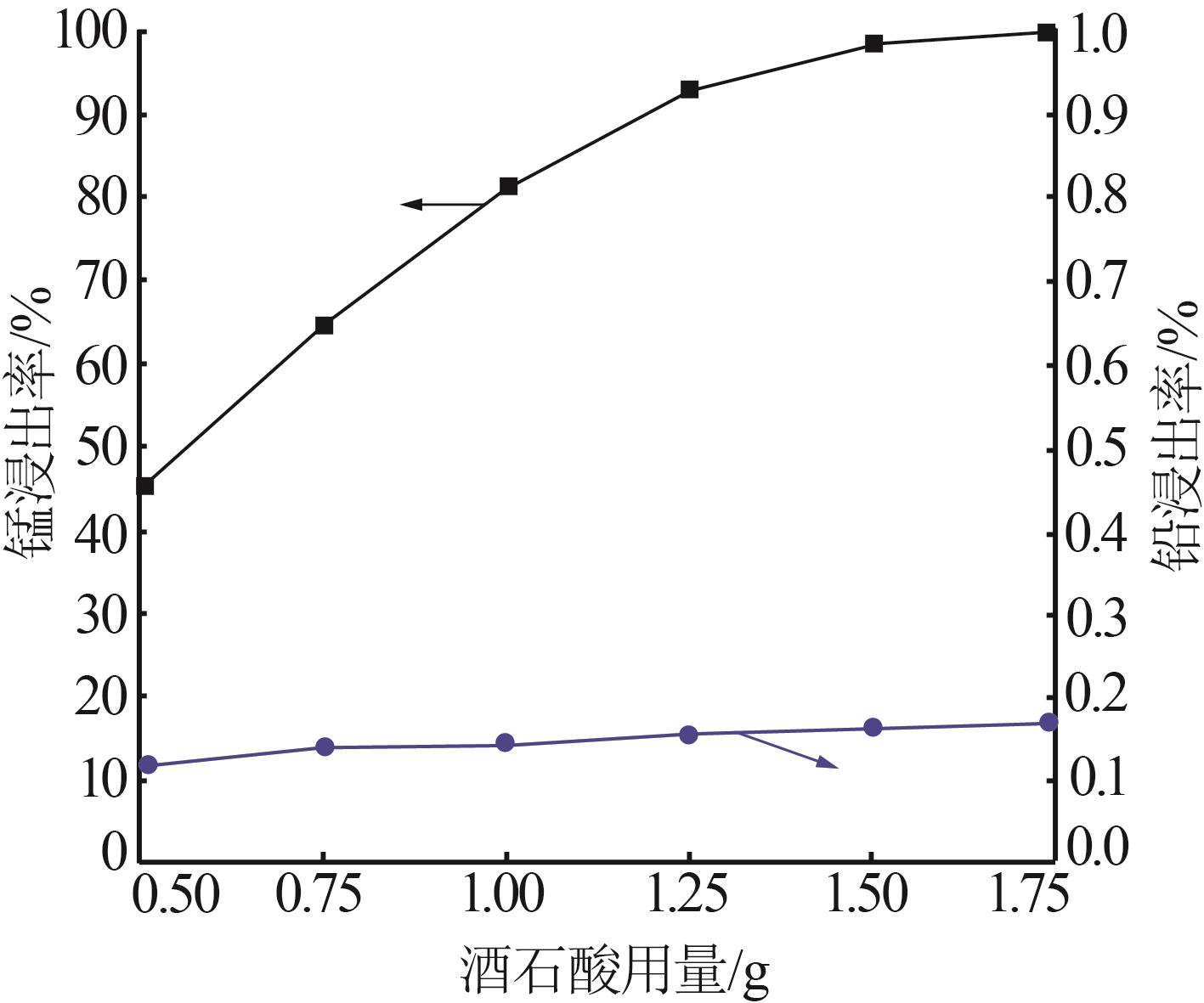

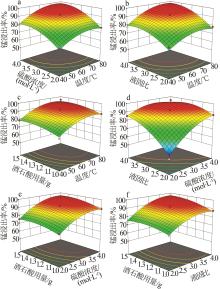

Table 4

Analysis of variance for response surface model for Mn leaching yield"

| 项目 | 均方和 | 自由度 | 均方 | F | P |

|---|---|---|---|---|---|

| 模型 | 3 617.20 | 14 | 258.37 | 46.54 | <0.000 1 |

| A-温度 | 646.65 | 1 | 646.65 | 116.49 | <0.000 1 |

| B-硫酸浓度 | 1 118.63 | 1 | 1 118.63 | 201.51 | <0.000 1 |

| C-液固比 | 959.98 | 1 | 959.98 | 172.93 | <0.000 1 |

| D-酒石酸用量 | 120.97 | 1 | 120.97 | 21.79 | 0.000 4 |

| AB | 6.94 | 1 | 6.94 | 1.25 | 0.282 2 |

| AC | 14.48 | 1 | 14.48 | 2.61 | 0.128 6 |

| AD | 0.148 2 | 1 | 0.148 2 | 0.026 7 | 0.872 5 |

| BC | 168.35 | 1 | 168.35 | 30.33 | <0.000 1 |

| BD | 2.76 | 1 | 2.76 | 0.496 4 | 0.492 6 |

| CD | 13.51 | 1 | 13.51 | 2.43 | 0.141 1 |

| A² | 252.24 | 1 | 252.24 | 45.44 | <0.000 1 |

| B² | 272.56 | 1 | 272.56 | 49.10 | <0.000 1 |

| C² | 252.24 | 1 | 252.24 | 45.44 | <0.000 1 |

| D² | 56.92 | 1 | 56.92 | 10.25 | 0.006 4 |

| 残差 | 77.72 | 14 | 5.55 |

| 1 | 孙宏伟,王杰,任军平,等.全球锰资源现状及对我国可持续发展建议[J].矿产保护与利用,2020,40(6):169-174. |

| SUN Hongwei, WANG Jie, REN Junping,et al.Current situation of global manganese resources and suggestions for sustain-able development in China[J].Conservation and Utilization of Mineral Resources,2020,40(6):169-174. | |

| 2 | 魏汉可,杨勇,罗豆,等.电解金属锰阳极泥的综合回收利用研究[J].中国锰业,2017,35(S1):55-58. |

| WEI Hanke, YANG Yong, LUO Dou,et al.A research on comprehensive recycling of electrolytic manganese anode slime[J].China′s Manganese Industry,2017,35(S1):55-58. | |

| 3 | 李涛,马国华.电解锰渣中锰组分的粉磨浸取工艺研究[J].无机盐工业,2021,53(2):66-70. |

| LI Tao, MA Guohua.Research on milling and leaching process of manganese in electrolytic manganese slag[J].Inorganic Chemicals Industry,2021,53(2):66-70. | |

| 4 | 孟小杰.国内电解金属锰生产用电解槽的发展探讨[J].中国锰业,2016,34(5):82-84. |

| MENG Xiaojie.The development of electrolytic cell of domestic EMM production[J].China′s Manganese Industry,2016,34(5):82-84. | |

| 5 | 马小霞,唐金晶,陶长元,等.电解金属锰渣中氨氮分析及处理技术进展[J].中国锰业,2016,34(1):1-4. |

| MA Xiaoxia, TANG Jinjing, TAO Changyuan,et al.Anlysis and advances in research of treatment technologies of amnonia nitrogen from EMM residue[J].China’s Manganese Industry,2016,34(1):1-4. | |

| 6 | 史菲菲,但智钢,姚扬,等.基于等标污染负荷的电解锰废水污染源解析[J].环境工程技术学报,2021,11(1):158-162. |

| SHI Feifei, DAN Zhigang, YAO Yang,et al.Wastewater pollution source apportionment of electrolytic manganese industry based on the equivalent pollution load method[J].Journal of Environmental Engineering Technology,2021,11(1):158-162. | |

| 7 | 黄屹,陈广义,田郁溟,等.中国锰业存在的主要问题及对策建议[J].地质与勘探,2021,57(2):294-304. |

| HUANG Yi, CHEN Guangyi, TIAN Yuming,et al.Main problems and countermeasures suggested for the manganese industry of China[J].Geology and Exploration,2021,57(2):294-304. | |

| 8 | 王志增,史菲菲,但智钢,等.电解锰企业环境影响评价存在的问题与改进研究[J].环境科学与管理,2016,41(3):170- 173. |

| WANG Zhizeng, SHI Feifei, DAN Zhigang,et al.Problems and suggestions for electrolytic manganese industry environmental impact assessment[J].Environmental Science and Management,2016,41(3):170-173. | |

| 9 | 伍永国.电解锰阳极渣回收制备一氧化铅和活性二氧化锰[D].吉首:吉首大学,2020. |

| WU Yongguo.Preparation of lead monoxide and active manganese dioxide by recovery of electrolytic manganese anode slag[D].Jis-hou:Jishou University,2020. | |

| 10 | 蔡启果,王海峰,王家伟,等.电解锰阳极渣矿物学特征分析与研究[J].矿产综合利用,2019(1):74-77. |

| CAI Qiguo, WANG Haifeng, WANG Jiawei,et al.Mineralogical properties of electrolytic manganese slag from guizhou[J].Multipurpose Utilization of Mineral Resources,2019(1):74-77. | |

| 11 | 石崇毅,陈奇志,史磊,等.硫铁矿—木炭湿法浸出高铁氧化锰矿的研究[J].有色金属(冶炼部分),2020(5):16-20. |

| SHI Chongyi, CHEN Qizhi, SHI Lei,et al.Hydro-leaching of manganese from iron-rich manganese dioxide ore with pyrite-charcoal[J].Nonferrous Metals(Extractive Metallurgy),2020(5):16-20. | |

| 12 | 覃兆财,明宪权,李春霞,等.亚硫酸铵还原浸出电解锰阳极泥中锰和硒的研究[J].有色金属(冶炼部分),2020(10):55-59. |

| QIN Zhaocai, MING Xianquan, LI Chunxia,et al.Leaching of manganese and selenium from electrolytic manganese anode slime with ammonium sulfite as reducing agent[J].Nonferrous Metals (Extractive Metallurgy),2020(10):55-59. | |

| 13 | 黎应芬,李祥,叶华,等.硫磺还原焙烧—酸浸法提取锰阳极泥[J].有色金属(冶炼部分),2017(8):13-15,24. |

| LI Yingfen, LI Xiang, YE Hua,et al.Recovery of manganese anode slimes by sulfur reduction roasting-acid leaching process[J].Nonferrous Metals(Extractive Metallurgy),2017(8):13-15,24. | |

| 14 | 陈升茂,廖英欢,傅佳,等.蔗糖还原浸出锰阳极泥中锰的研究[J].中国锰业,2015,33(3):20-23. |

| CHEN Shengmao, LIAO Yinghuan, FU Jia,et al.Reductive leaching in manganese from manganese anode mud by sucrose[J].China’s Manganese Industry,2015,33(3):20-23. | |

| 15 | 邱小龙,颜文斌,李学雷,等.乙醇还原浸出电解锰阳极渣中锰的研究[J].有色金属工程,2022,12(4):49-54. |

| QIU Xiaolong, YAN Wenbin, LI Xuelei,et al.Leaching of manganese from electrolytic manganese anode slag using ethanol as reductant[J].Nonferrous Metals Engineering,2022,12(4):49-54. | |

| 16 | 卢友志,苏李敏,赵义,等.单宁酸-硫酸体系浸出氧化锰矿中锰的研究[J].无机盐工业,2022,54(6):84-89. |

| LU Youzhi, SU Limin, ZHAO Yi,et al.Study on leaching of manganese from manganese dioxide ore with tannic acid-sulfuric acid system[J].Inorangic Chemicals Industry,2022,54(6):84-89. | |

| 17 | ALTINER M,TOP S, BOUCHEKRIT C,et al.Production of Mn3O4 nanoparticles from a manganiferous iron ore via reductive leaching,precipitation,and calcination[J].Hydrometallurgy,2022,208:105810. |

| 18 | 国家质量监督检验检疫总局,中国国家标准化管理委员会.锰矿石 锰含量的测定 电位滴定法和硫酸亚铁铵滴定法:GB/T 1506—2016[S].北京:中国标准出版社,2017. |

| 19 | 杨双平,周江峰,郭拴全,等.响应曲面法优化含钼废渣冶炼MoFe工艺[J].有色金属工程,2017,7(5):48-53. |

| YANG Shuangping, ZHOU Jiangfeng, GUO Shuanquan,et al.Optimization of preparing MoFe with molybdenum-containing waste residue by response surface methodology[J].Nonferrous Metals Engineering,2017,7(5):48-53. | |

| 20 | YANG Shangying, LI Ying, JIA Dongying,et al.The synergy of Box-Behnken designs on the optimization of polysaccharide extraction from mulberry leaves[J].Industrial Crops and Products,2017,99:70-78. |

| 21 | 杨升旺,刘殿文,庄故章,等.响应曲面法优化细粒氧化铜矿浸出工艺[J].中国矿业,2021,30(10):128-133. |

| YANG Shengwang, LIU Dianwen, ZHUANG Guzhang,et al.Acid leaching technology of fine-grained copper oxide optimized by RSM[J].China Mining Magazine,2021,30(10):128-133. | |

| 22 | 马致远,杨洪英.响应曲面法优化铜阳极泥微波浸出硒工艺[J].中南大学学报(自然科学版),2015,46(7):2391-2397. |

| MA Zhiyuan, YANG Hongying.Microwave assisted leaching of selenium from copper anode slime optimized by response surface methodology[J].Journal of Central South University(Science and Technology),2015,46(7):2391-2397. | |

| 23 | 刘伟,刘子龙,刘畅.响应曲面法优化低品位铜钼矿生物浸出工艺[J].中南大学学报(自然科学版),2021,52(9):3111-3120. |

| LIU Wei, LIU Zilong, LIU Chang.Optimization of bioleaching low-grade copper-molybdenum ore by response surface methodolo-gy[J].Journal of Central South University(Science and Technology),2021,52(9):3111-3120. | |

| 24 | 常伟.低品位软锰矿还原浸出过程及其动力学研究[D].长沙:中南大学,2014. |

| CHANG Wei.Study on reduction leaching process and kinetics of low-grade pyrolusite[D].Changsha:Central South University,2014. | |

| 25 | 付忠田,王允妹,胡筱敏.周期换向电凝聚法处理活性嫩黄X-6G模拟染料废水研究[J].环境工程,2016,34(5):54-58. |

| FU Zhongtian, WANG Yunmei, HU Xiaomin.Study on treatment of synthesized reactive brilliant yellow X-6G wastewater by periodical reverse electro-coagulation[J].Environmental Engineering,2016,34(5):54-58. |

| [1] | LI Chao, WANG Liping, GAO Guimei, ZHANG Yunfeng, HONG Yu, LIU Darui, XU Lijun, CUI Yongjie. Study on reaction mechanism of acid leaching lithium from circulating fluidized bed fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 101-107. |

| [2] | CHEN Xue, OUYANG Quansheng, SHAO Jiaojing. Recent research progress of lithium-sulfur batteries based on solid-solid reaction mechanism [J]. Inorganic Chemicals Industry, 2024, 56(9): 12-23. |

| [3] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [4] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [5] | HOU Zhanggui, WU Chongchong, ZHANG Siran. Research progress of CO2 conversion via Reverse Water-Gas Shift reaction [J]. Inorganic Chemicals Industry, 2024, 56(11): 105-115. |

| [6] | WANG Yingnan, SHENG Linlin, HUANG Juan, HUANG Zhanbin. Study on adsorption performance of lead from water by coal-fired slag [J]. Inorganic Chemicals Industry, 2023, 55(8): 109-115. |

| [7] | TENG Jiayang, FENG Qingge, ZHANG Xuan, QIN Fanghong, FENG Jinghang, HU Jiawen, CHEN Chaohong. Study on preparation of pseudo-boehmite from aluminum dross resource treatment [J]. Inorganic Chemicals Industry, 2023, 55(11): 130-138. |

| [8] | ZHANG Zhiqiang, CUI Kangping, CHEN Xing, LI Haiyang. Optimization of preparation of ultrafine chromium oxide by carbothermal reduction of sodium dichromate by response surface methodology [J]. Inorganic Chemicals Industry, 2023, 55(10): 136-144. |

| [9] | FANG Weicheng,CHENG Xingxing,SUN Changrong. Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology [J]. Inorganic Chemicals Industry, 2022, 54(9): 119-125. |

| [10] | FU Ziqi, ZHANG Cheng, SHENG Yong, JI Lijun. Study on preparation of phosphoric acid by leaching fluoride residue from wet-process phosphoric acid with organic solvents [J]. Inorganic Chemicals Industry, 2022, 54(7): 129-134. |

| [11] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| [12] | YANG Fengyu,DONG Hua,CHEN Botao. Research progress of reaction mechanism of lithium-rich manganese-based cathode materials [J]. Inorganic Chemicals Industry, 2022, 54(12): 19-27. |

| [13] | Li Fei,Zhou Jianmin,Li Chengyu,Xu Wentao,Zhang Xinyue,Li Xinwei,Wang Jun,Ji Zhiyong,Zhao Yingying,Guo Xiaofu,Yuan Junsheng. Study on mechanism and conditions of the new process of ammonium chloride conversion [J]. Inorganic Chemicals Industry, 2021, 53(3): 48-53. |

| [14] | Huang Jiming,Liu Runqing,Wu Sizhan,Song Juan. Optimization of extraction process of chlorination roasting-water leaching process for low-grade rhodochrosite by response surface methodology [J]. Inorganic Chemicals Industry, 2019, 51(3): 34-37. |

| [15] | CHEN Bo, SONG Xing-Fu, XU Yan-Xia, SUN Yu-Zhu, YU Jian-Guo. Optimization of preparation of calcium carbonate from continuous crystallization process of ammonium carbonate and conversion of calcium sulfate by response surface methodology [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(9): 18-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||