Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (9): 98-106.doi: 10.19964/j.issn.1006-4990.2024-0041

• Environment·Health·Safety • Previous Articles Next Articles

Study on leaching rate of calcium and magnesium from phosphorus tailings based on thermodynamic analysis and response surface method

TANG Dongwu1( ), YE Changwen1(

), YE Changwen1( ), DENG Jie2, AO Fang3

), DENG Jie2, AO Fang3

- 1.State Key Laboratory of Geological Hazard Prevention and Geological Environment Protection,Chengdu University of Technology,Chengdu 610059,China

2.Institute of Multipurpose Utilization of Mineral Resources,Chinese Academy of Geological Sciences,Chengdu 610041,China

3.China West Construction Academy of Building Materials Co. ,Ltd. ,Chengdu 610015,China

-

Received:2024-01-22Online:2024-09-10Published:2024-03-06 -

Contact:YE Changwen E-mail:1640674606@qq.com;yechwen123@sina.com

CLC Number:

Cite this article

TANG Dongwu, YE Changwen, DENG Jie, AO Fang. Study on leaching rate of calcium and magnesium from phosphorus tailings based on thermodynamic analysis and response surface method[J]. Inorganic Chemicals Industry, 2024, 56(9): 98-106.

share this article

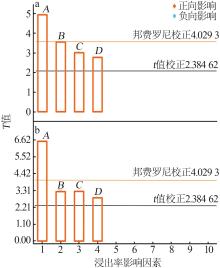

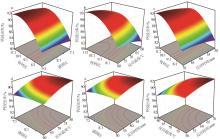

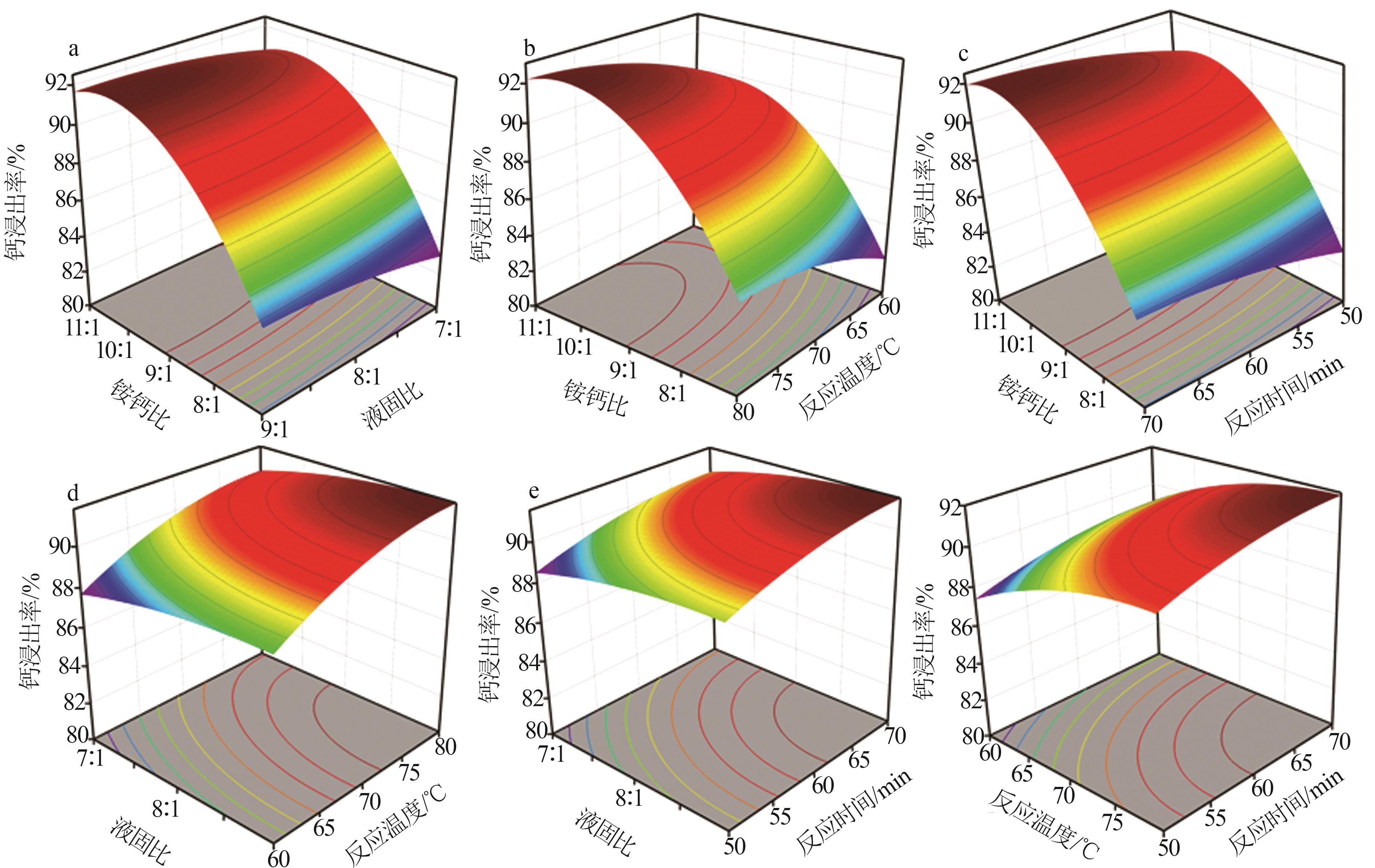

Table 3

Design and results of orthogonal experiment"

| 序号 | 铵钙比 | 液固比 | 反应温度/℃ | 反应时间/min | 钙浸出率/% | 镁浸出率/% |

|---|---|---|---|---|---|---|

| 1 | 9∶1 | 9∶1 | 60 | 60 | 88.99 | 83.35 |

| 2 | 9∶1 | 7∶1 | 70 | 70 | 90.21 | 82.87 |

| 3 | 9∶1 | 8∶1 | 60 | 50 | 87.33 | 81.92 |

| 4 | 9∶1 | 8∶1 | 70 | 60 | 90.77 | 84.89 |

| 5 | 7∶1 | 8∶1 | 80 | 60 | 84.79 | 74.56 |

| 6 | 7∶1 | 8∶1 | 60 | 60 | 81.99 | 73.61 |

| 7 | 9∶1 | 8∶1 | 60 | 70 | 89.04 | 83.38 |

| 8 | 7∶1 | 8∶1 | 70 | 70 | 84.54 | 74.67 |

| 9 | 11∶1 | 8∶1 | 60 | 60 | 89.45 | 85.11 |

| 10 | 11∶1 | 9∶1 | 70 | 60 | 91.45 | 86.14 |

| 11 | 9∶1 | 8∶1 | 80 | 50 | 90.13 | 82.88 |

| 12 | 9∶1 | 7∶1 | 80 | 60 | 90.46 | 82.83 |

| 13 | 11∶1 | 8∶1 | 70 | 70 | 91.99 | 86.19 |

| 14 | 9∶1 | 8∶1 | 70 | 60 | 90.77 | 83.75 |

| 15 | 9∶1 | 8∶1 | 70 | 60 | 90.78 | 83.79 |

| 16 | 9∶1 | 8∶1 | 70 | 60 | 90.79 | 83.77 |

| 17 | 9∶1 | 7∶1 | 60 | 60 | 87.66 | 81.89 |

| 18 | 7∶1 | 8∶1 | 70 | 50 | 82.82 | 73.21 |

| 19 | 11∶1 | 8∶1 | 80 | 60 | 92.25 | 86.06 |

| 20 | 9∶1 | 9∶1 | 70 | 50 | 89.83 | 82.96 |

| 21 | 9∶1 | 9∶1 | 70 | 70 | 91.54 | 84.44 |

| 22 | 9∶1 | 8∶1 | 80 | 70 | 91.84 | 84.32 |

| 23 | 11∶1 | 7∶1 | 70 | 60 | 90.61 | 84.68 |

| 24 | 9∶1 | 9∶1 | 80 | 60 | 91.81 | 84.31 |

| 25 | 7∶1 | 7∶1 | 70 | 60 | 83.15 | 73.18 |

| 26 | 9∶1 | 8∶1 | 70 | 60 | 90.79 | 83.78 |

| 27 | 11∶1 | 8∶1 | 70 | 50 | 90.28 | 84.71 |

| 28 | 9∶1 | 7∶1 | 70 | 50 | 88.51 | 81.52 |

| 29 | 7∶1 | 9∶1 | 70 | 60 | 84.49 | 74.64 |

| 1 | 荣一阳,叶国华,亢选雄,等.北方某铁尾矿浮磷试验研究[J].钢铁钒钛,2023,44(5):111-115. |

| RONG Yiyang, YE Guohua, KANG Xuanxiong,et al.Experimental study on phosphorus flotation of an iron tailings in Northern China[J].Iron Steel Vanadium Titanium,2023,44(5):111-115. | |

| 2 | 李鹏毅,张冬冬,宁平,等.磷尾矿资源化利用研究[J].化工矿物与加工,2019,48(2):66-70. |

| LI Pengyi, ZHANG Dongdong, NING Ping,et al.Study on resource utilization of phosphate tailings[J].Industrial Minerals & Processing,2019,48(2):66-70. | |

| 3 | 王昭.安徽磷矿资源调查评价与成矿规律探讨[J].西部资源,2023(2):83-86. |

| WANG Zhao.Investigation and evaluation of phosphate rock resources in Anhui Province and discussion on metallogenic regularity[J].Western Resources,2023(2):83-86. | |

| 4 | 胡宏,李艳.高镁磷尾矿渣制取磷镁复合肥料的试验研究[J].贵州化工,2009,34(2):20-21,25. |

| HU Hong, LI Yan.Production of P-Mg mixed fertilizer with high-Mg pHospHate gangue[J].Guizhou Chemical Industry,2009,34(2):20-21,25. | |

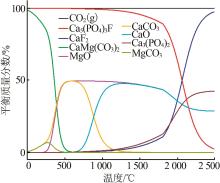

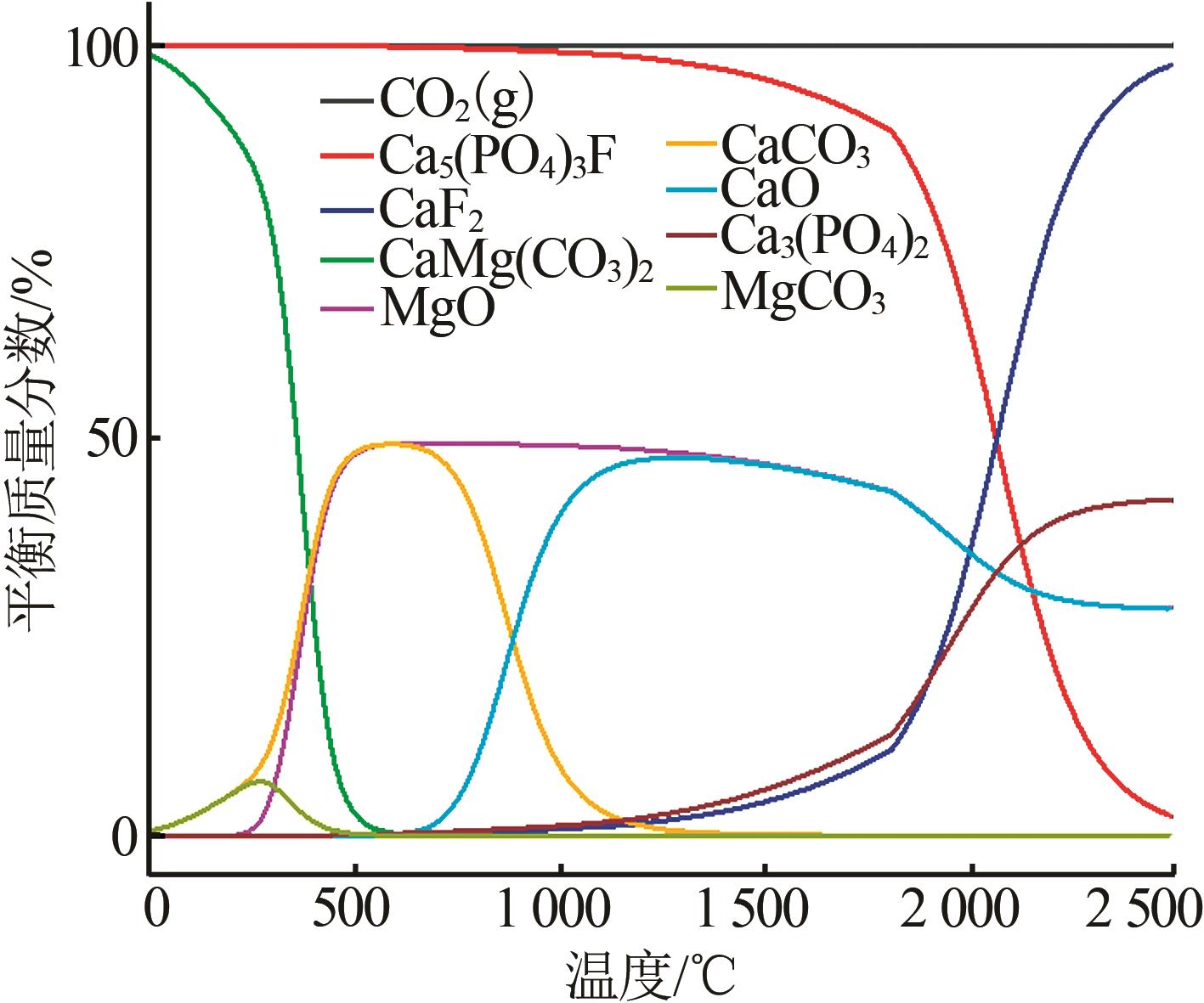

| 5 | 周强,武斌,陈葵,等.磷尾矿热分解动力学机理与煅烧工艺研究[J].无机盐工业,2023,55(3):47-54. |

| ZHOU Qiang, WU Bin, CHEN Kui,et al.Study on thermal decomposition kinetic mechanism and calcination process of phosphorus tailings[J].Inorganic Chemicals Industry,2023,55(3):47-54. | |

| 6 | 郑建国,于南树,刘永秀,等.磷酸活化磷尾矿制取聚合态钙镁磷肥的工艺条件研究[J].无机盐工业,2020,52(2):43-46. |

| ZHENG Jianguo, YU Nanshu, LIU Yongxiu,et al.Study on technological conditions of polymeric calcium magnesium phosphate fertilizer from phosphoric acid activated phosphate tailings[J].Inorganic Chemicals Industry,2020,52(2):43-46. | |

| 7 | 张家鑫,潘益,夏琰,等.磷尾矿副产物制备改性氢氧化镁的研究[J].武汉工程大学学报,2020,42(1):33-37. |

| ZHANG Jiaxin, PAN Yi, XIA Yan,et al.Study on preparation of modified magnesium hydroxide from phosphorus tailings by-products[J].Journal of Wuhan Institute of Technology,2020,42(1):33-37. | |

| 8 | 张汉泉,许鑫,胡超杰,等.磷化工固体废弃物综合利用技术现状[J].中国矿业,2021,30(4):50-55,63. |

| ZHANG Hanquan, XU Xin, HU Chaojie,et al.Current situation of comprehensive utilization technology of solid waste of phosphorus chemical[J].China Mining Magazine,2021,30(4):50-55,63. | |

| 9 | 周旺旺,刘意章,吴珊珊,等.高温活化磷尾矿钝化矿区污染土壤中阳离子态重金属研究[J].地球与环境,2024,52(2):166-175. |

| ZHOU Wangwang, LIU Yizhang, WU Shanshan,et al.Study on cationic heavy metals in contaminated soil of passivation mining area with activated phosphorus tailings at high temperature [J].Earth and Environment,2024,52(2):166-175. | |

| 10 | 李梦雨,汤建伟,刘咏,等.醋酸酸解磷尾矿制备醋酸钙镁融雪剂工艺研究[J].无机盐工业,2024,56(1):73-80. |

| LI Mengyu, TANG Jianwei, LIU Yong,et al.Study on preparation process of calcium magnesium acetate snowmelt agent from phosphorous tailings by acetic acid hydrolysis[J].Inorganic Chemicals Industry,2024,56(1):73-80. | |

| 11 | 黄洋.全量化高值利用磷尾矿制备轻质隔热耐高温材料[D].武汉:武汉科技大学,2023. |

| HUANG Yang.Preparation of lightweight thermal insulation and high temperature resistant materials by full quantification and high value utilization of phosphorus tailings[D].Wuhan:Wuhan University of Science and Technology,2023. | |

| 12 | 吴礼定,曾波,王生军.中低品位磷矿尾矿的综合利用研究进展[J].云南化工,2008,35(6):55-58. |

| WU Liding, ZENG Bo, WANG Shengjun.Comprehensive utilization of low and medium-grade phosphate rock tailings[J].Yunnan Chemical Technology,2008,35(6):55-58. | |

| 13 | ABDEL-HAKEEM M, EL-HABAAK G.The potential production of rock-based fertilizer and soil conditioner from phosphate mine wastes:A case study from Abu-Tartur Plateau in the Western Desert of Egypt[J].Journal of Cleaner Production,2021,329:129761. |

| 14 | 张守逊,吴雨瑶,郭永杰,等.磷尾矿综合利用研究现状[J/OL].化工矿物与加工,1-12.[2024-01-24].https://link.cnki.net/urlid/32.1492.TQ.20231222.1222.004. |

| ZHANG Shouxun, WU Yuyao, GUO Yongjie,et al.Research status of comprehensive utilization of phosphorus tailings[J/OL].Chemical Minerals and Processing,1-12.[2024-01-24.] https://link.cnki.net/urlid/32.1492.TQ.20231222.1222.004. | |

| 15 | 周旺旺,刘意章,吴珊珊,等.高温活化磷尾矿钝化矿区污染土壤中阳离子态重金属研究[J].地球与环境,2024,52(2):166-175. |

| ZHOU Wangwang, LIU Yizhang, WU Shanshan,et al.Study on cationic heavy metals in contaminated soil of passivation mining area with activated phosphorus tailings at high temperature [J].Earth and Environment,2024,52(2):166-175. | |

| 16 | YU Yaohui, DU Chuanming.Leaching of phosphorus from phosphate tailings and extraction of calcium phosphates:Toward comprehensive utilization of tailing resources[J].Journal of Environmental Management,2023,347:119159. |

| 17 | 田兴.反浮选磷尾矿的综合利用[D].武汉:武汉工程大学,2013. |

| TIAN Xing.Comprehensive utilization of phosphate tailings from reverse floatation[D].Wuhan:Wuhan Institute of Technology,2013. | |

| 18 | 周飞,杨林,曹建新.中低品位磷矿焙烧过程中白云石热分解动力学研究[J].硅酸盐通报,2019,38(5):1377-1383,1389. |

| ZHOU Fei, YANG Lin, CAO Jianxin.Research on thermal decomposition kinetics of dolomite during calcination of medium-low grade phosphate ore[J].Bulletin of the Chinese Ceramic Society,2019,38(5):1377-1383,1389. | |

| 19 | 苗俊艳,王艳语,许秀成.中低品位磷矿及磷尾矿的综合利用现状[J].硫磷设计与粉体工程,2019(6):11-13,27,4. |

| MIAO Junyan, WANG Yanyu, XU Xiucheng.Current utilization of medium-and low-rade phosphate ore and tailing[J].Sulphur Phosphorus & Bulk Materials Handling Related Engineering,2019(6):11-13,27,4. | |

| 20 | NIE Yunxiang, DAI Jinfeng, HOU Yidong,et al.An efficient and environmentally friendly process for the reduction of SO2 by using waste phosphate mine tailings as adsorbent[J].Journal of Hazardous Materials,2020,388:121748. |

| 21 | 周雪娜,关洪亮,何东升,等.磷尾矿综合利用研究进展[J].广州化工,2021,49(5):24-27. |

| ZHOU Xuena, GUAN Hongliang, HE Dongsheng,et al.Research progress on comprehensive utilization by phosphate tailings[J].Guangzhou Chemical Industry,2021,49(5):24-27. | |

| 22 | 范钧翔.磷尾矿制备矿山复垦基质土及高温活化研究[D].郑州:郑州大学,2022. |

| FAN Junxiang.Study on preparation of matrix soil for reclamation in mining area and high-temperature activation from phosphate tailings[D].Zhengzhou:Zhengzhou University,2022. | |

| 23 | 张立,尤大海,胡修权,等.磷尾矿与粉煤灰制备高强陶粒试验研究[J].非金属矿,2023,46(4):13-17. |

| ZHANG Li, YOU Dahai, HU Xiuquan,et al.Research on preparation of high strength ceramsite by using phosphorus tailings and fly ash[J].Non-Metallic Mines,2023,46(4):13-17. | |

| 24 | 姜立龙,李剑秋,杨林,等.高镁磷尾矿作为矿物掺合料应用于混凝土性能研究[J].无机盐工业,2024,56(1):90-95. |

| JIANG Lilong, LI Jianqiu, YANG Lin,et al.Study on performance of concrete with high-Mg phosphate tailing as mineral admixture[J].Inorganic Chemicals Industry,2024,56(1):90-95. | |

| 25 | 金铃子,张华丽.高镁磷尾矿处理氨氮废水的试验探究[J].广东化工,2022,49(15):145-147. |

| JIN Lingzi, ZHANG Huali.Experimental research on treatment of ammonia nitrogen wastewater by high magnesium phosphate tailings[J].Guangdong Chemical Industry,2022,49(15):145-147. | |

| 26 | 周佳琦,陈葵,武斌,等.磷尾矿煅烧及酸浸过程动力学研究[J].无机盐工业,2022,54(1):77-82,108. |

| ZHOU Jiaqi, CHEN Kui, WU Bin,et al.Study on kinetics of phosphate tailings calcination and acid leaching process[J].Inorganic Chemicals Industry,2022,54(1):77-82,108. | |

| 27 | 黄琴,廖秋实,田承涛,等.磷尾矿酸解后的氧化镁提浓技术[J].化工技术与开发,2023,52(4):75-77. |

| HUANG Qin, LIAO Qiushi, TIAN Chengtao,et al.Concentration of magnesium oxide after acid hydrolysis of phosphate tailings[J].Technology & Development of Chemical Industry,2023,52(4):75-77. | |

| 28 | 孙娜.我国磷尾矿综合利用现状及发展[J].当代化工研究,2019(3):2-3. |

| SUN Na.Present situation and development of comprehensive utilization of phosphorus tailings in China[J].Modern Chemical Research,2019(3):2-3. | |

| 29 | 陈博文,梅甫定,卢开华.用粗磷尾矿制备胶结充填材料[J].金属矿山,2015(10):184-188. |

| CHEN Bowen, MEI Fuding, LU Kaihua.Cemented paste backfilling material preparation using coarse phosphate tailings[J].Metal Mine,2015(10):184-188. | |

| 30 | 周坤,唐云,张群,等.磷尾矿制备磷酸铵镁试验研究[J].矿业研究与开发,2015,35(4):31-33. |

| ZHOU Kun, TANG Yun, ZHANG Qun,et al.Experimental study on the preparation of magnesium ammonium phosphate from phosphate tailings[J].Mining Research and Development,2015,35(4):31-33. | |

| 31 | 黄芳,王华,李军旗,等.萃取-反萃法综合回收磷矿浮选尾矿中磷和镁[J].环境科学与技术,2010,33(4):104-107,140. |

| HUANG Fang, WANG Hua, LI Junqi,et al.Recovering P and Mg from phosphate floatation tailings using extraction-stripping process[J].Environmental Science & Technology,2010,33(4):104-107,140. | |

| 32 | 孙娜,尤彩霞.磷尾矿制备氢氧化镁研究进展[J].河南科技,2019(10):126-127. |

| SUN Na, YOU Caixia.Progress of preparing magnesium hydroxide from phosphorus tailings[J].Henan Science and Technology,2019(10):126-127. | |

| 33 | 颜鑫,魏义兰.含钙镁废渣综合利用的现状及展望[J].无机盐工业,2022,54(1):7-11. |

| YAN Xin, WEI Yilan.Present situation and prospect of comprehensive utilization of waste residue containing calcium and magnesium[J].Inorganic Chemicals Industry,2022,54(1):7-11. | |

| 34 | 张娇,卢玉莲,张富强,等.磷尾矿处理过程中循环硝酸铵溶液中氮的测定[J].磷肥与复肥,2020,35(7):50-51. |

| ZHANG Jiao, LU Yulian, ZHANG Fuqiang,et al.Determination of nitrogen in circulating ammonium nitrate solution of phosphorus tailings treatment[J].Phosphate & Compound Fertilizer,2020,35(7):50-51. |

| [1] | SHI Yunpeng, GUO Ze, ZHANG Hanquan, LU Manman. Study on treatment of ammonia nitrogen wastewater by roasted phosphorus tailings [J]. Inorganic Chemicals Industry, 2025, 57(3): 94-100. |

| [2] | SONG Jiaxi, JI Renfei, CHEN Jun, LIN Sen, YU Jianguo. Research on characteristics analysis and pretreatment on deeply deactivated power battery ternary cathode materials [J]. Inorganic Chemicals Industry, 2025, 57(2): 44-49. |

| [3] | TANG Xuemei, WANG Meibo, XU Li, ZHANG Xujie, TAI Shijun, YI Xianmei, LIU Hongjuan, PAN Linyi. Study on whitening of phosphogypsum by low⁃temperature calcination [J]. Inorganic Chemicals Industry, 2024, 56(8): 110-115. |

| [4] | CHEN Junhui, LIU Xiang, HU Qingxi, TIAN Bangxin, CHEN Jiale. Study on leaching extraction of high purity potassium chloride from sintering machine head ash [J]. Inorganic Chemicals Industry, 2024, 56(6): 102-108. |

| [5] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [6] | LIU Hui, WANG Hongliang, YU Kun, GAO Shengnan. Effect of calcination on porous structure and electrochemical properties of air electrode [J]. Inorganic Chemicals Industry, 2024, 56(6): 80-86. |

| [7] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [8] | FANG Xiaoning, KUANG Fei, LIU Chenglin. Study on extraction of potassium from K-feldspar by roasting-leaching of mixed salts [J]. Inorganic Chemicals Industry, 2024, 56(5): 53-57. |

| [9] | WANG Shengchang, HAO Jianying, CHEN Jianing, TIAN Bo. Effect of calcination on properties of calcined gypsum prepared from desulphurization gypsum with potassium aluminum sulfate [J]. Inorganic Chemicals Industry, 2024, 56(4): 105-111. |

| [10] | QIAN Zhihui, ZHU Qin, MA Jiao, GUO Yujiao, XIANG Mingwu, GUO Junming. Study on preparation and electrochemical properties of nano-sized LiNi0.05Mn1.95O4 cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(4): 50-56. |

| [11] | YANG Kun, REN Qixia, DONG Yonggang, LIU Fei, YAO Mengqin, CAO Jianxin. Effect of calcination temperature on catalytic performance of ZnGaZrO x /SAPO-34 [J]. Inorganic Chemicals Industry, 2024, 56(2): 136-145. |

| [12] | WANG Baoming, WANG Xinglong, YANG Ying, ZHAO Bo, HUA Quanxian, LIU Yong, LIU Pengfei, SHEN Bo, DING Junxiang, TANG Jianwei. Current status and research progress of comprehensive utilization of phosphorus tailings [J]. Inorganic Chemicals Industry, 2024, 56(10): 1-11. |

| [13] | ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM [J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113. |

| [14] | LI Qiang, YOU Xiaomin, SHE Xuefeng, JIANG Zeyi, XUE Qingguo, WANG Jingsong. Effect of calcination temperature and carbon structure on compressive strength of CaO-containing carbon pellets [J]. Inorganic Chemicals Industry, 2023, 55(9): 43-49. |

| [15] | WANG Yingnan, SHENG Linlin, HUANG Juan, HUANG Zhanbin. Study on adsorption performance of lead from water by coal-fired slag [J]. Inorganic Chemicals Industry, 2023, 55(8): 109-115. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||