Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (4): 16-23.doi: 10.19964/j.issn.1006-4990.2023-0400

• Reviews and Special Topics • Previous Articles Next Articles

Preparation technology and research progress of fly ash ceramsite

ZHAO Feiyan1( ), ZHANG Xiaodong2(

), ZHANG Xiaodong2( ), DU Yanxia1, WANG Qiang1, LI Xiaoyan1

), DU Yanxia1, WANG Qiang1, LI Xiaoyan1

- 1.Haerwusu Open-pit Coal Mine, China Shenhua Energy Co., Ltd., Ordos 010300, China

2.Shenhua Zhungeer Energy Co., Ltd., Ordos 010300, China

-

Received:2023-08-07Online:2024-04-10Published:2024-04-18 -

Contact:ZHANG Xiaodong E-mail:10580193@ceic.com;10580172@ceic.com

CLC Number:

Cite this article

ZHAO Feiyan, ZHANG Xiaodong, DU Yanxia, WANG Qiang, LI Xiaoyan. Preparation technology and research progress of fly ash ceramsite[J]. Inorganic Chemicals Industry, 2024, 56(4): 16-23.

share this article

Table 1

Sintering reaction of fly ash ceramic particles"

| 序号 | 反应类型 | 反应式 | 反应温度/℃ |

|---|---|---|---|

| 1 | 碳的反应 | C+O2=CO2↑ 2C+O2=2CO↑ C+CO2=2CO↑ | 400~800 |

| 2 | 碳酸盐反应 | MgCO3=MgO+CO2↑ CaCO3=CaO+CO2↑ | 400~500 850~900 |

| 3 | 氧化铁分解 | 2Fe2O3=4FeO+O2↑ Fe2O3+FeO=Fe3O4 2Fe3O4=6FeO+O2↑ | 1 100 |

| 4 | 碳与铁反应 | 2Fe2O3+C=4FeO+CO2↑ 2Fe2O3+3C=4Fe+3CO2↑ Fe2O3+C=2FeO+CO↑ Fe2O3+3C=2Fe+3CO↑ | 1 000~1 300 |

| 5 | 水分蒸发 | 100 |

Table 2

Process comparison of fly ash sintered ceramsite and non fired ceramsite"

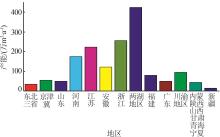

| 类型 | 介绍 | 单线规模/ (万m3·a-1) | 优势 | 劣势 | 国内代 表厂家 |

|---|---|---|---|---|---|

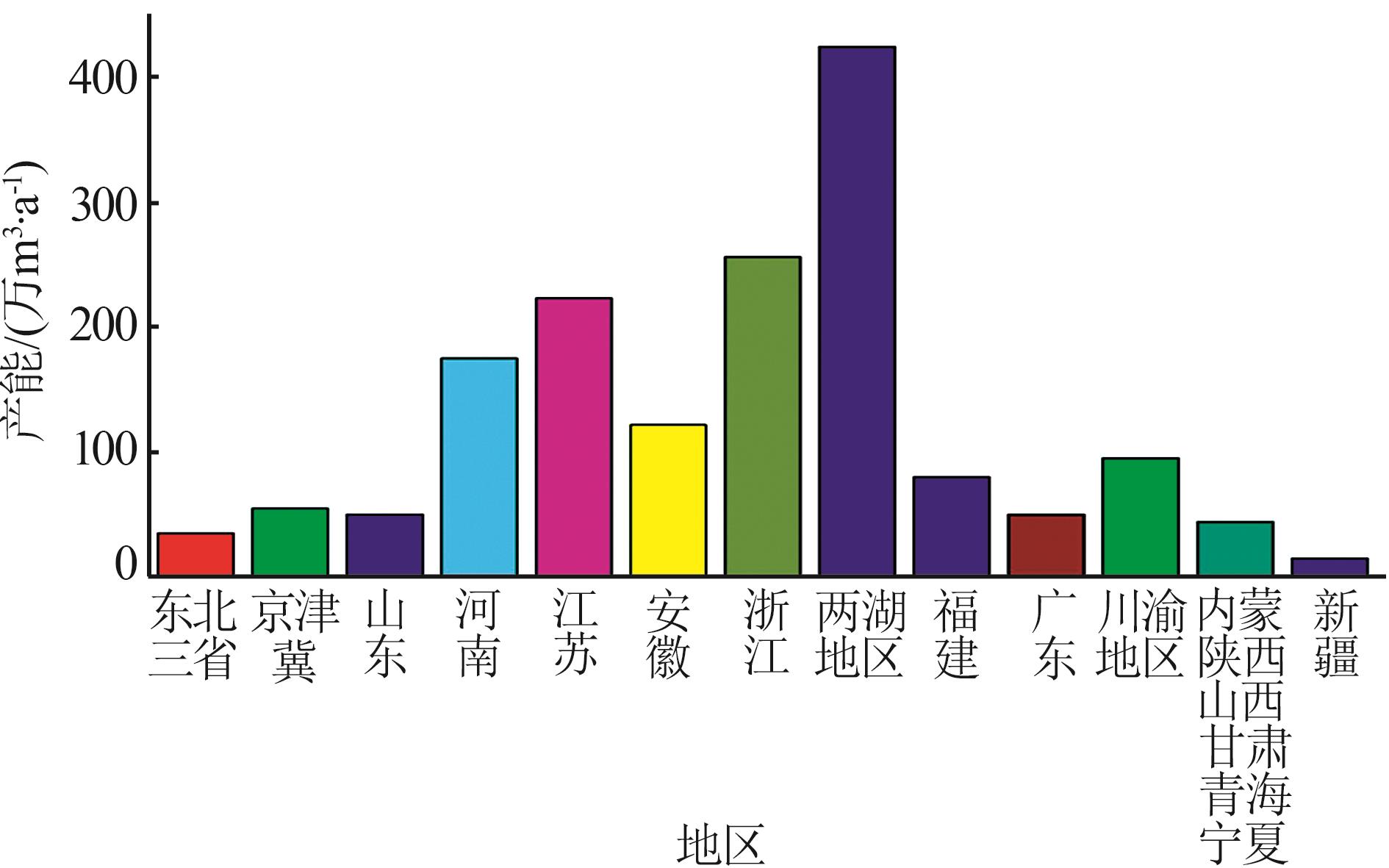

粉煤 灰烧 结陶 粒 | 陶粒密度通过调节膨胀组分含量进行控制,吨天然气消耗量为50~70 m3,吨产品能源造价超200元,适合生产高强陶粒 | 20~30 | 1)技术成熟,成本存在下降空间,可利用煤泥、生物质等作为补充能源可进一步降低生产成本;2)产品质量好,陶粒内气孔孔径差别小、分布均匀,通过改变原料比或生产工艺,生产不同等级陶粒,能够更好地适应市场需求;3)可实现连续生产,不受季节影响 | 1)生产成本高,吨产品能耗大;2)单线规模小,规模难以进一步扩大;3)粉煤灰黏结性能差,造粒成型需加入一定黏结剂;4)占地面积大 | 河南郑矿机器、山东恒远利废 |

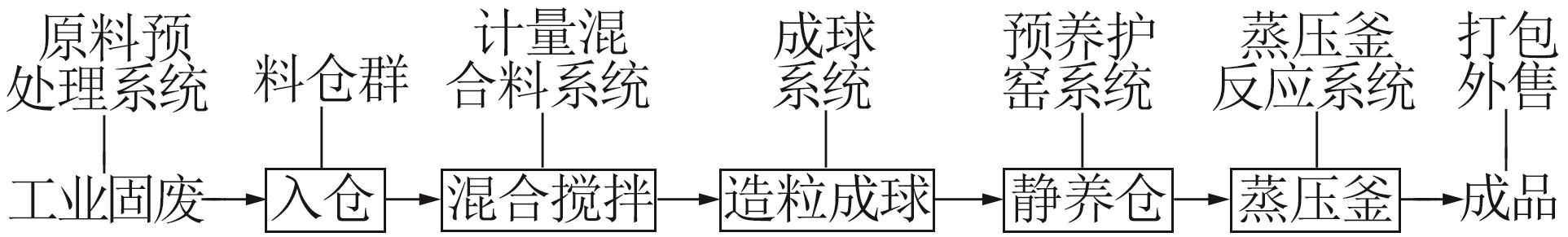

粉煤 灰免 烧陶 粒 | 产品采用硅、钙无机矿物元素为主要原料,经特殊工艺制备而成,密度介于500~1 000 kg/m3 | 10~20 | 1)养护代替了焙烧流程,能源消耗大大减少;2)零排放,废气、废水、废料场内循环利用;3)生产效率高,生产装备自动化程度高;4)占地面积小 | 1)成本相对较高,需要添加多种辅助材料,且粉煤灰添加量低;2)强度劣于烧结型陶粒,吸水率较高;3)规模放大能力不足;4)目前国内生产厂家较少,蒸压养护受温度影响较大 | 浙江中劲环保 |

| 1 | 张志明, 桂联政, 廖达琛, 等. 燃煤电厂粉煤灰高值化利用研究进展[J]. 能源环境保护, 2023, 37(4):1-11. |

| ZHANG Zhiming, GUI Lianzheng, LIAO Dachen, et al. Advances in high-value utilization of fly ash from coal-fired power plants[J]. Energy Environmental Protection, 2023, 37(4):1-11. | |

| 2 | 许欣, 武小燕, 陈敏洁, 等. 粉煤灰在矿坑生态化利用过程中的环境行为研究[J]. 有色金属(矿山部分), 2023, 75(1):73- 81. |

| XU Xin, WU Xiaoyan, CHEN Minjie, et al. Environmental behavior of fly ash during the process of ecological utilization of mine pits[J]. Nonferrous Metals(Mining Section), 2023, 75(1):73-81. | |

| 3 | 王丽萍, 李超. 粉煤灰资源化技术开发与利用研究进展[J]. 矿产保护与利用, 2019, 39(4):38-45. |

| WANG Liping, LI Chao. Research progress on development and utilization of fly ash resource technology[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4):38-45. | |

| 4 | 柴春镜, 宋慧平, 冯政君, 等. 粉煤灰陶粒的研究进展[J]. 洁净煤技术, 2020, 26(6):11-22. |

| CHAI Chunjing, SONG Huiping, FENG Zhengjun, et al. Research progress on the fly ash ceramsite[J]. Clean Coal Technology, 2020, 26(6):11-22. | |

| 5 | 张晓亚, 李佳丽, 冯丽娟, 等. 城市污泥陶粒制备技术与应用研究进展[J]. 无机盐工业, 2022, 54(9):28-38. |

| ZHANG Xiaoya, LI Jiali, FENG Lijuan, et al. Research progress on preparation technology and application of municipal sludge ceramsite[J]. Inorganic Chemicals Industry, 2022, 54(9):28-38. | |

| 6 | 齐元峰, 岳钦艳, 岳敏, 等. 用于水处理填料的超轻污泥-粉煤灰陶粒的研制[J]. 功能材料, 2010, 41(6):1097-1101,1105. |

| QI Yuanfeng, YUE Qinyan, YUE Min, et al. Preparation of ultra-lightweight ceramic from sewage sludge and fly ash used for fi-llers[J]. Journal of Functional Materials, 2010, 41(6):1097-1101,1105. | |

| 7 | 涂巍巍. 轻质高强粉煤灰陶粒的工厂制备[J]. 河南建材, 2018(6):139-140. |

| TU Weiwei. Factory preparation of lightweight and high strength fly ash ceramsite[J]. Henan Building Materials, 2018(6):139- 140. | |

| 8 | 王勇海, 梁效, 牛芳银, 等. 酸浸钒渣制备高强陶粒工艺[J]. 矿产综合利用, 2022(3):58-63. |

| WANG Yonghai, LIANG Xiao, NIU Fangyin, et al. Preparation process of high strength ceramsite from acid leaching vanadium tailing[J]. Multipurpose Utilization of Mineral Resources, 2022(3):58-63. | |

| 9 | 赵翔, 黄胜, 王亚举, 等. 用于水处理填料的超轻粉煤灰陶粒的研制[J]. 中国陶瓷, 2017, 53(6):59-65. |

| ZHAO Xiang, HUANG Sheng, WANG Yaju, et al. Preparation of ultra-lightweight fly-ash ceramic used for water treatment fillers[J]. China Ceramics, 2017, 53(6):59-65. | |

| 10 | 王志英. 煤矸石粉煤灰烧结陶粒制备及物化性能研究[D]. 太原: 山西大学, 2021. |

| WANG Zhiying. Preparation and physicochemical properties of sintered ceramsite produced from coal gangue and fly ash[D]. Taiyuan: Shanxi University, 2021. | |

| 11 | LIU Junzhe, LIU Rui, HE Zhimin, et al. Preparation and microstructure of green ceramsite made from sewage sludge[J]. Journal of Wuhan University of Technology:Mater.Sci.Ed., 2012, 27(1):149-153. |

| 12 | 朱万旭, 酆磊, 周红梅, 等. 新型免烧粉煤灰陶粒的研制及应用浅析[J]. 混凝土, 2017(5):59-62. |

| ZHU Wanxu, FENG Lei, ZHOU Hongmei, et al. Analysis on the development and application of a new type of ash haydite[J]. Concrete, 2017(5):59-62. | |

| 13 | 张睿泽, 陈阁翰, 顾春平, 等. 粉煤灰免烧陶粒的制备工艺研究[J]. 粉煤灰综合利用, 2022, 36(3):99-104. |

| ZHANG Ruize, CHEN Gehan, GU Chunping, et al. Development and performance test of fly ash non-fired ceramsite[J]. Fly Ash Comprehensive Utilization, 2022, 36(3):99-104. | |

| 14 |

NARATTHA C, CHAIPANICH A. Phase characterizations,physical properties and strength of environment-friendly cold-bonded fly ash lightweight aggregates[J]. Journal of Cleaner Production, 2018, 171:1094-1100.

doi: 10.1016/j.jclepro.2017.09.259 |

| 15 | 高淑燕. 高气孔率的免烧粉煤灰陶粒的制备及其隔热性能研究[D]. 柳州: 广西科技大学, 2019. |

| GAO Shuyan. Preparation of high-porosity sintering-free fly ash ceramsite and its thermal insulation properties[D]. Liuzhou: Guangxi University of Science and Technology, 2019. | |

| 16 | 胡广超, 张乐, 张添华, 等. 粉煤灰基功能陶粒研究进展[C]// 中国环境科学学会环境工程分会. 中国环境科学学会2022年科学技术年会—环境工程技术创新与应用分会场论文集(三), 2022:466-475. |

| 17 |

PATEL S K, MAJHI R K, SATPATHY H P, et al. Durability and microstructural properties of lightweight concrete manufactured with fly ash cenosphere and sintered fly ash aggregate[J]. Construction and Building Materials, 2019, 226:579-590.

doi: 10.1016/j.conbuildmat.2019.07.304 |

| 18 |

GESOĞLU M, ÖZTURAN T, GÜNEYISI E. Effects of fly ash properties on characteristics of cold-bonded fly ash lightweight aggregates[J]. Construction and Building Materials, 2007, 21(9):1869-1878.

doi: 10.1016/j.conbuildmat.2006.05.038 |

| 19 | 李瑞. 粉煤灰陶粒轻骨料混凝土性能试验研究[D]. 银川: 宁夏大学, 2015. |

| LI Rui. The experimental study on performance of fly ash ceramiste lightweight aggregate concrete[D]. Yinchuan: Ningxia University, 2015. | |

| 20 | 秦娟, 陈清林, 黄莹, 等. 多功能免烧陶粒吸附特性研究[C]// 中国环境科学学会环境工程分会. 中国环境科学学会2022年科学技术年会—环境工程技术创新与应用分会场论文集(二), 2022:230-236. |

| 21 | 屈湃, 王倩, 黎佳全, 等. 粉煤灰基免烧陶粒的表面沸石化及其对Cu2+吸附性能研究[J]. 现代技术陶瓷, 2022, 43(2):118-128. |

| QU Pai, WANG Qian, LI Jiaquan, et al. Study on surface zeolization and Cu2+ adsorption of fly ash based non-roasting ceramsi-te[J]. Advanced Ceramics, 2022, 43(2):118-128. | |

| 22 | 秦娟, 顾凯屹, 蔡琳, 等. 造纸白泥/粉煤灰环保陶粒对含磷废水的吸附及再生[C]// 中国环境科学学会环境工程分会. 中国环境科学学会2022年科学技术年会—环境工程技术创新与应用分会场论文集(一), 2022:92-98. |

| 23 | 酆磊. 绿色节能免烧结粉煤灰陶粒的研制与吸音性能研究[D]. 桂林: 广西科技大学, 2017. |

| FENG Lei. Preparation of green energy-saving unburned fly ash ceramsite and study on sound absorption property[D]. Guilin: Guangxi University of Science and Technology, 2017. | |

| 24 | 施云芬, 魏冬雪. 改性粉煤灰陶粒的制备及其吸附SO2性能研究[J]. 硅酸盐通报, 2012, 31(3):567-570. |

| SHI Yunfen, WEI Dongxue. Ceramsite sintered from modified fly ash and bentonite clay and its properties of adsorption of SO2 [J]. Bulletin of the Chinese Ceramic Society, 2012, 31(3):567- 570. | |

| 25 |

CHEN Xudong, LI Tiehu, REN Qiang, et al. Mullite whisker network reinforced ceramic with high strength and lightweight[J]. Journal of Alloys and Compounds, 2017, 700:37-42.

doi: 10.1016/j.jallcom.2017.01.075 |

| 26 |

LI Chaoxin, ZHOU Yi, TIAN Yuming, et al. Preparation and characterization of mullite whisker reinforced ceramics made from coal fly ash[J]. Ceramics International, 2019, 45(5):5613-5616.

doi: 10.1016/j.ceramint.2018.12.021 |

| 27 | 杜杰, 唐一博, 王俊峰, 等. 煤层压裂支撑剂的制备及性能研究[J]. 煤矿安全, 2018, 49(10):5-8,12. |

| DU Jie, TANG Yibo, WANG Junfeng, et al. Preparation and mechanisms of proppant for coal bed fracturing[J]. Safety in Coal Mines, 2018, 49(10):5-8,12. | |

| 28 |

CHEN Xudong, LI Tiehu, ZHAO Tingkai, et al. Effect of MnO2 on the properties of mullite-based ceramics[J]. Chemistry Letters, 2017, 46(3):327-329.

doi: 10.1246/cl.161012 |

| 29 | 姜龙. 燃煤电厂粉煤灰综合利用现状及发展建议[J]. 洁净煤技术, 2020, 26(4):31-39. |

| JIANG Long. Comprehensiveutilization situation of fly ash in coal-fired power plants and its development suggestions[J]. Clean Coal Technology, 2020, 26(4):31-39. |

| [1] | LIU Xinlong, YANG Zhenyu, HAO He, LIU Shuxin, WU Chenyang, WANG Xingli, MA Qingqing. Study on shaped 4A zeolite synthesized with aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 78-85. |

| [2] | LI Chao, WANG Liping, GAO Guimei, ZHANG Yunfeng, HONG Yu, LIU Darui, XU Lijun, CUI Yongjie. Study on reaction mechanism of acid leaching lithium from circulating fluidized bed fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 101-107. |

| [3] | LI Kuai, LI Zhaoshuai, DONG Tingxuan, LI Dan, GUO Shengwei, HAN Fenglan. Study on effect of wet magnetic separation on distribution of Fe and heavy metal in fly ash [J]. Inorganic Chemicals Industry, 2024, 56(4): 98-104. |

| [4] | LI Qiaoyun, HUANG Xiuxing, WEI Wenye, CHEN Zhen. Study on adsorption of methylene blue by activated carbon with acid/alkali synergistically modified fly ash [J]. Inorganic Chemicals Industry, 2024, 56(3): 131-136. |

| [5] | ZHAO Shiyong, XIAO Yuchen, MA Qingqing, YANG Zhenni, WANG Jizhen, FAN Xiaoping. Study on adsorption of Cu(Ⅱ) on 4A zeolite synthesized by aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2024, 56(10): 127-134. |

| [6] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [7] | SUN Zhigao, WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang. Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer [J]. Inorganic Chemicals Industry, 2023, 55(11): 139-146. |

| [8] | YANG Hongjun, WANG Min, GE Haiwen, QIAO Youmin, QIAO Ziyang. Study on recycling process of potassium from calcium aluminate fly ash [J]. Inorganic Chemicals Industry, 2023, 55(10): 121-127. |

| [9] | HE Wenchao,XUE Jing,WANG Wei. Research on strength and creep characteristics of concrete containing fly ash microbead [J]. Inorganic Chemicals Industry, 2023, 55(1): 124-128. |

| [10] | LIU Darui,XU Lijun,LI Shichun,CAO Kun,TU Ya,LI Wenqing,LIU Qingliang. Research progress of recovery of strategic metal lithium from fly ash [J]. Inorganic Chemicals Industry, 2023, 55(1): 56-63. |

| [11] | LEI Ming,ZHU Hanyu,LIU Zilong,CHEN Guopeng,YUAN Junsheng. Distribution and speciation of heavy metals in hardened solid of net slurry co?disposed by cement kiln [J]. Inorganic Chemicals Industry, 2022, 54(8): 107-113. |

| [12] | CUI Jiaxin,WANG Lianyong,LU Simeng,SUN Yanwen,WANG Rui,HE Yan,HAN Jianli. Research on performance of hydrothermally synthesized zeolite with fly ash from different producing areas [J]. Inorganic Chemicals Industry, 2022, 54(5): 96-100. |

| [13] | CUI Jiaxin,WANG Lianyong,LI Yao,HE Yan,WANG Rui,HAN Jianli. Preparation and properties characterization of water quenching slag-fly ash based 4A zeolite [J]. Inorganic Chemicals Industry, 2022, 54(4): 135-140. |

| [14] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| [15] | MA Yue,CHENG Yan. Effect of thermal treatment on structure and hydrophobicity of SiO2 aerogels derived from fly ash acid sludge [J]. Inorganic Chemicals Industry, 2022, 54(3): 109-112. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||