Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (10): 151-158.doi: 10.19964/j.issn.1006-4990.2024-0064

• Catalytic Materials • Previous Articles Next Articles

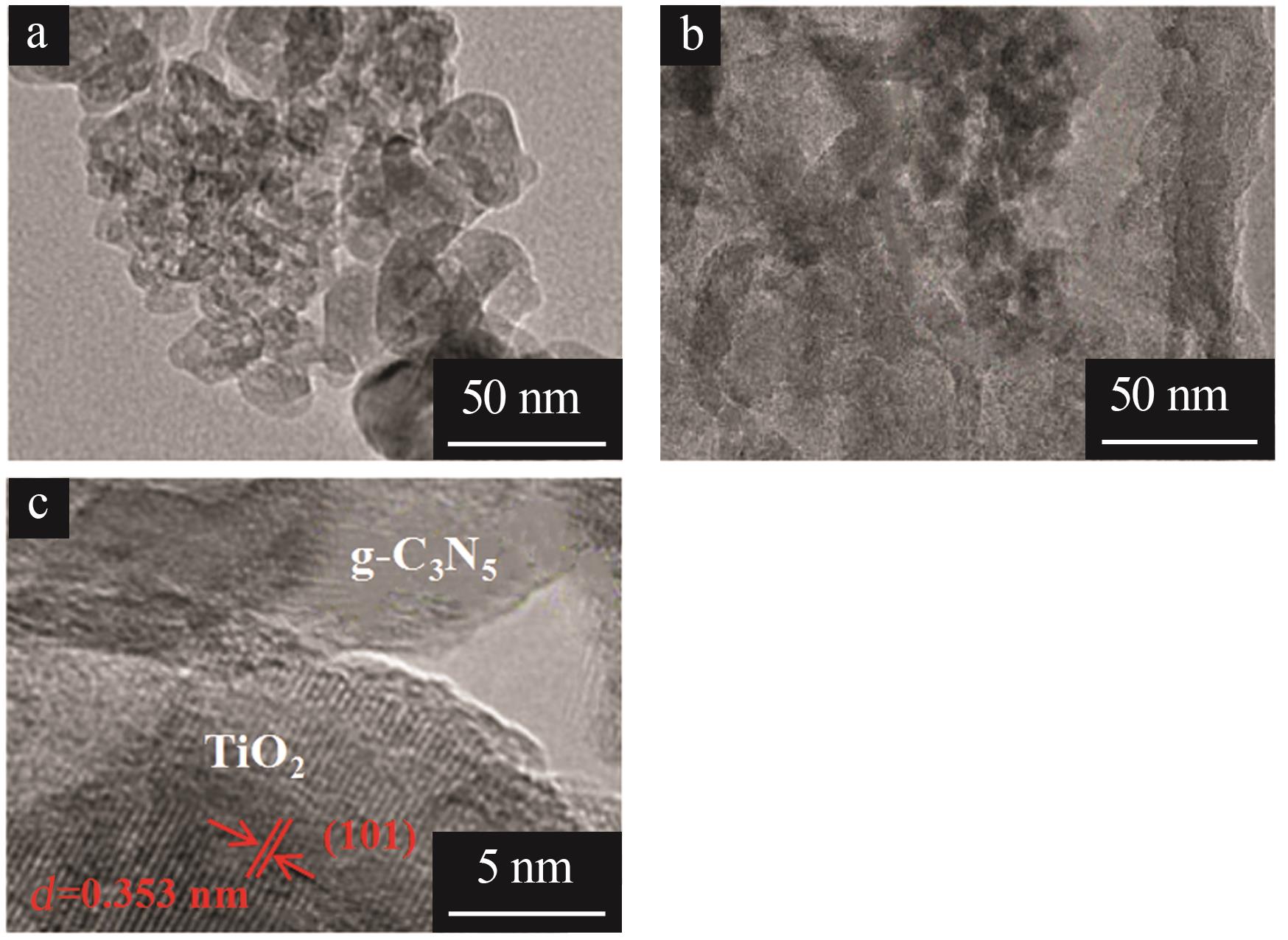

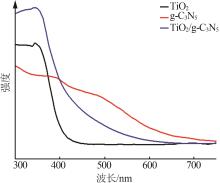

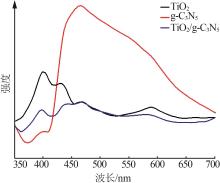

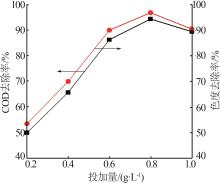

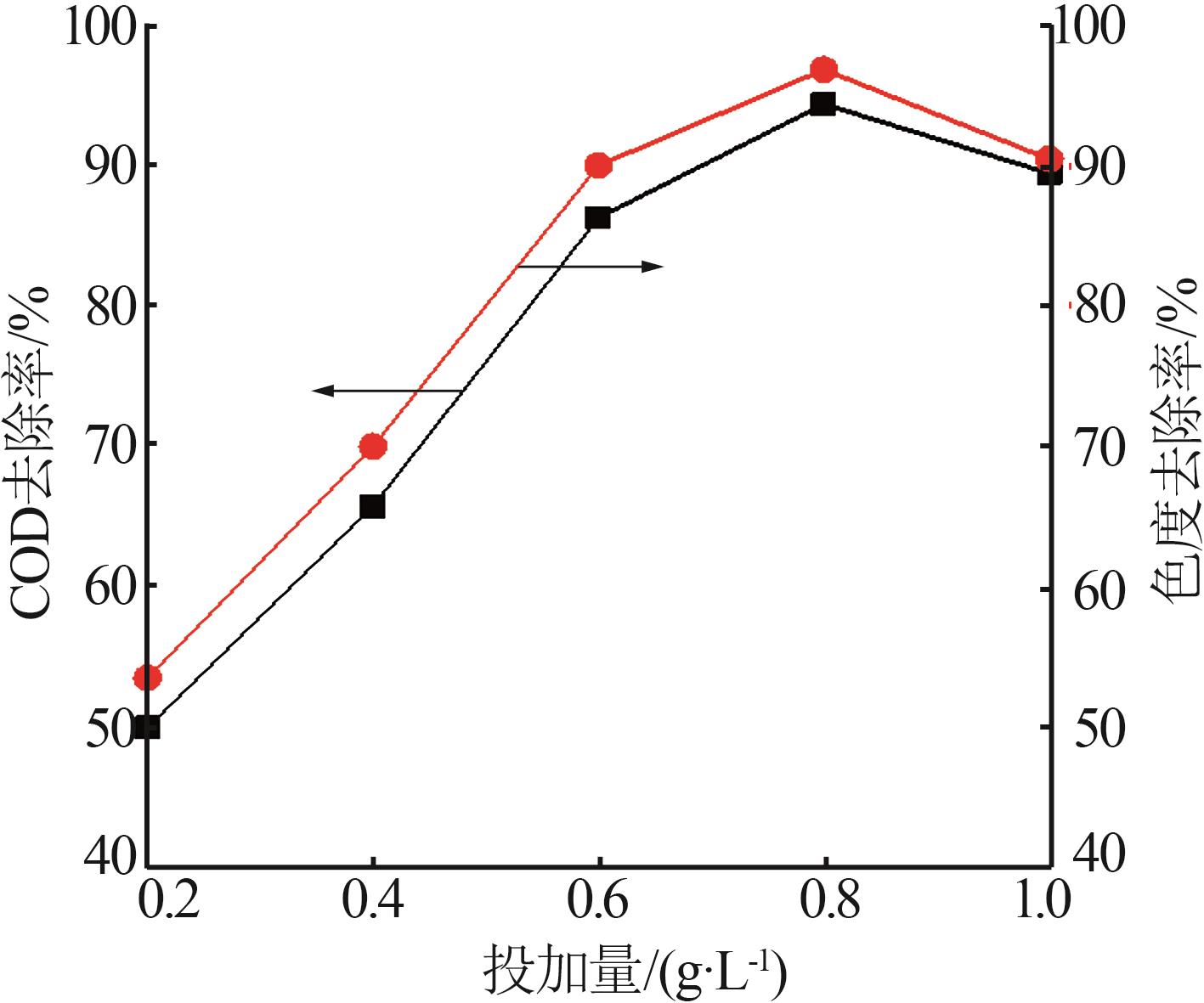

Treatment of printing wastewater by chemical coagulation-TiO2/g-C3N5 photocatalytic degradation

MA Yihong1( ), CHEN Xingtao1, TANG Lei2(

), CHEN Xingtao1, TANG Lei2( )

)

- 1.Zhongyifeng Construction Group Co. ,Ltd. ,Suzhou 218131,China

2.Nanjing Hydraulic Research Institute Materials & structural EngineeringDepartment,Nanjing 210029,China

-

Received:2024-01-30Online:2024-10-10Published:2024-03-19 -

Contact:TANG Lei E-mail:sm1211212023@163.com;leitang@nhri.cn

CLC Number:

Cite this article

MA Yihong, CHEN Xingtao, TANG Lei. Treatment of printing wastewater by chemical coagulation-TiO2/g-C3N5 photocatalytic degradation[J]. Inorganic Chemicals Industry, 2024, 56(10): 151-158.

share this article

| 1 | LIU Chang, CHU Yanyang, WANG Rong,et al.Preparation of lotus⁃leaf⁃like carbon cathode for the electro⁃Fenton oxidation process:Hydrogen peroxide production,various organics degradation and printing wastewater treatment[J].Journal of Water Process Engineering,2023,52:103596. |

| 2 | THUY N T, HOAN N X, VAN THANH D,et al.Application of electrocoagulation for printing wastewater treatment:From laboratory to pilot scale[J].Journal of Electrochemical Science and Tech⁃nology,2021,12(1):21-32. |

| 3 | XIONG Jiahui, LI Yaxin, PANG Conglin,et al.Removal of pollutants in banknote printing wastewater by mesoporous Fe/SiO2 prepared from rice husk pyrolytic residues[J].Environmental Science and Pollution Research,2019,26(16):16000-16013. |

| 4 | SAFWAT S M, HAMED A, ROZAIK E.Electrocoagulation/electroflotation of real printing wastewater using copper electrodes:A comparative study with aluminum electrodes[J].Separation Science and Technology,2019,54(1):183-194. |

| 5 | KHANNOUS L, ELLEUCH A, FENDRI I,et al.Treatment of printing wastewater by a combined process of coagulation and biosorption for a possible reuse in agriculture[J].Desalination and Water Treatment,2016,57(13):5723-5729. |

| 6 | 王艳辉,陈利科,钟云飞.基于MBR生物接触氧化的印刷废水处理工艺研究[J].数字印刷,2020(1):77-83. |

| WANG Yanhui, CHEN Like, ZHONG Yunfei.Research on printing wastewater treatment technology based on MBR biological contact oxidation[J].Printing and Digital Media Technology Study,2020(1):77-83. | |

| 7 | 环境保护部,国家质量监督检验检疫总局. 油墨工业水污染物排放标准: [S].北京:中国标准出版社,2010. |

| 8 | 陈淑意.高浓度印刷废水处理工程[J].节能,2020,39(10):99-102. |

| 9 | 潘碌亭,董恒杰,吴超,等.铁碳催化内电解-A/O工艺处理印刷线路板综合废水[J].环境工程,2017,35(4):40-44. |

| PAN Luting, DONG Hengjie, WU Chao,et al.Treatment of comprehensive wastewater from printed circuit board by iron carbon catalytic internal electrolysis combined with A/O process[J].Environmental Engineering,2017,35(4):40-44. | |

| 10 | 林志雄,姚林芬.SY-MBR在印刷行业生产废水处理工程应用[J].中国资源综合利用,2018,36(6):63-65. |

| LIN Zhixiong, YAO Linfen.Application of SY-MBR in wastewater treatment engineering in printing industry[J].China Resour⁃ces Comprehensive Utilization,2018,36(6):63-65. | |

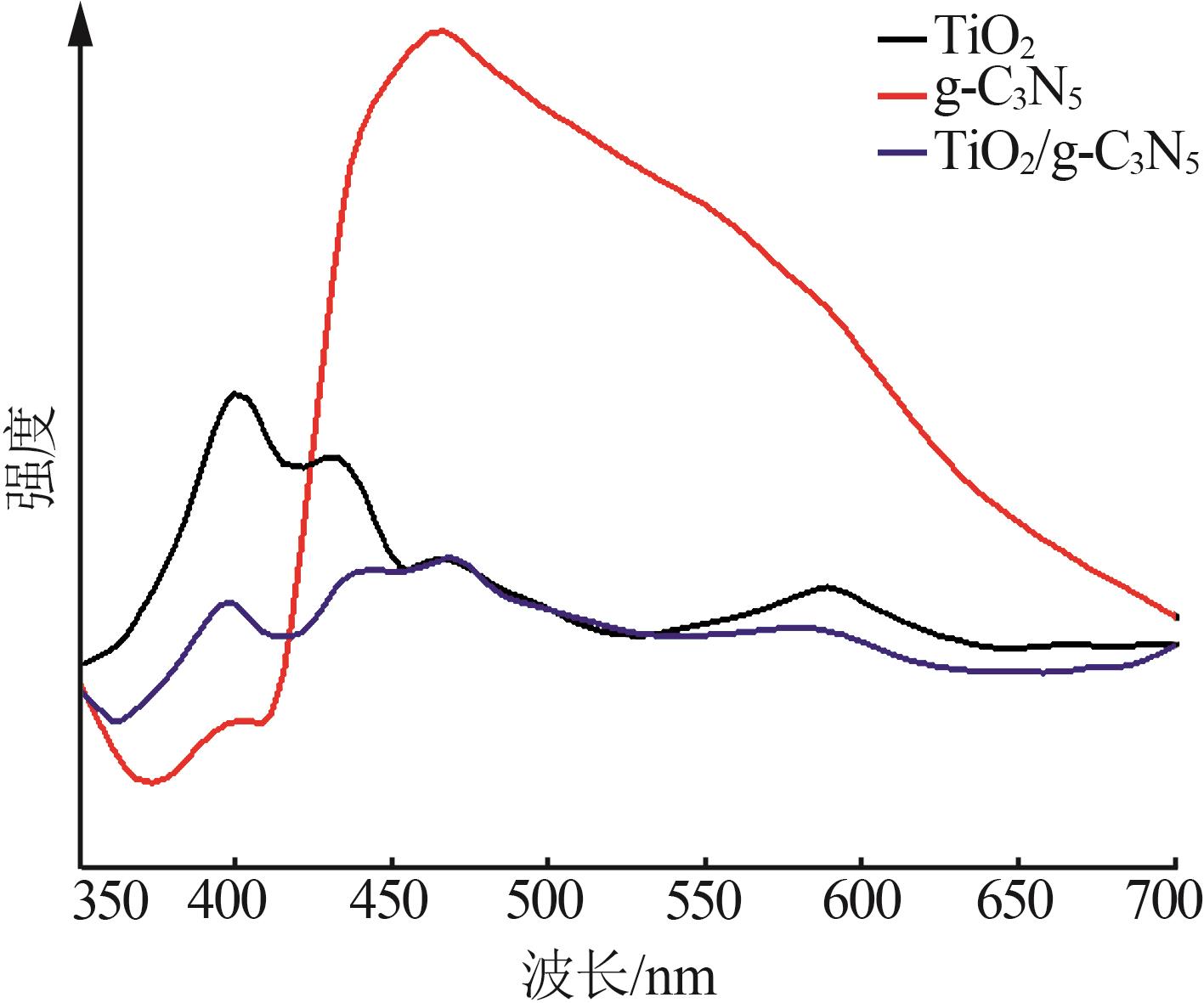

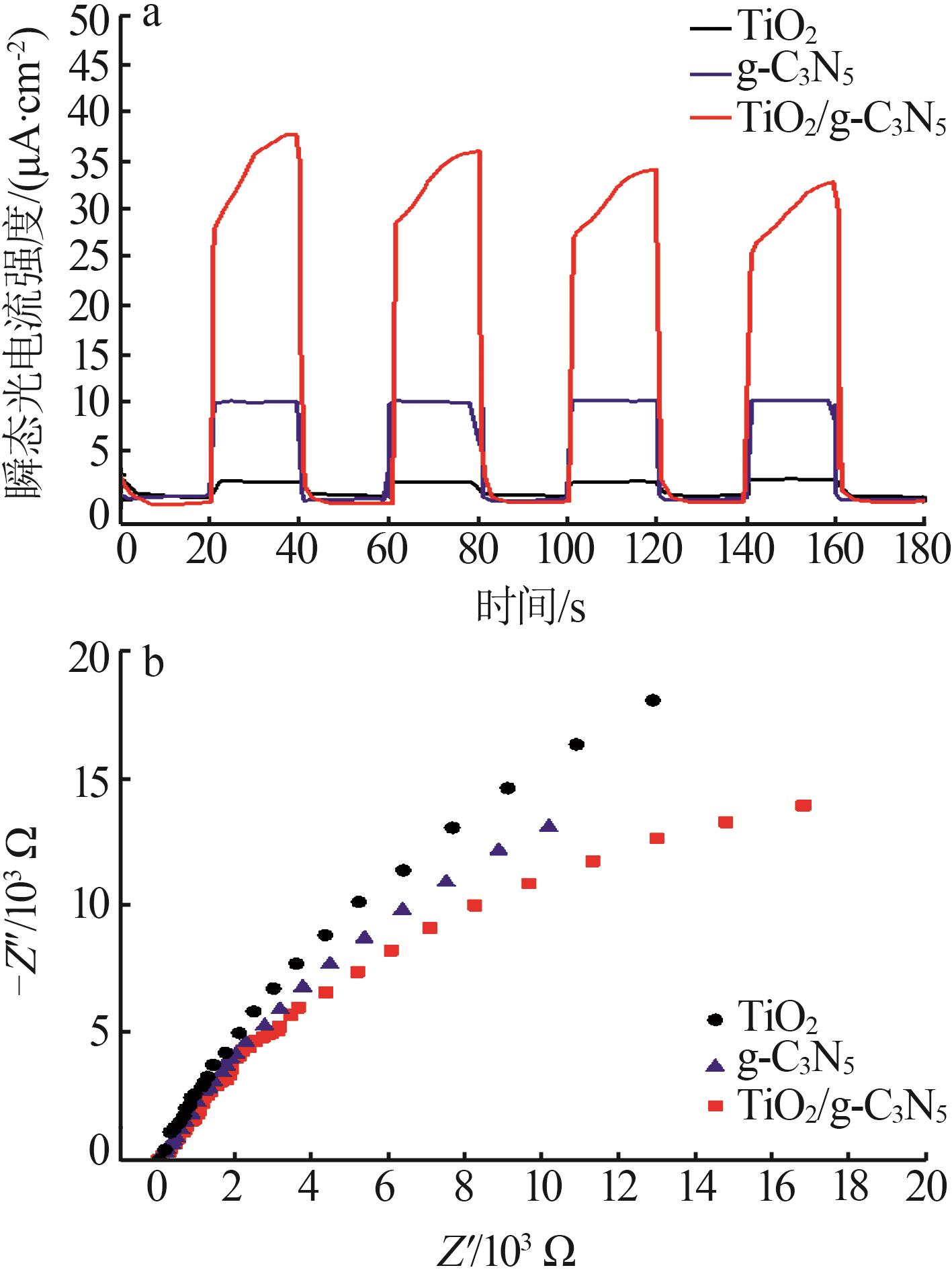

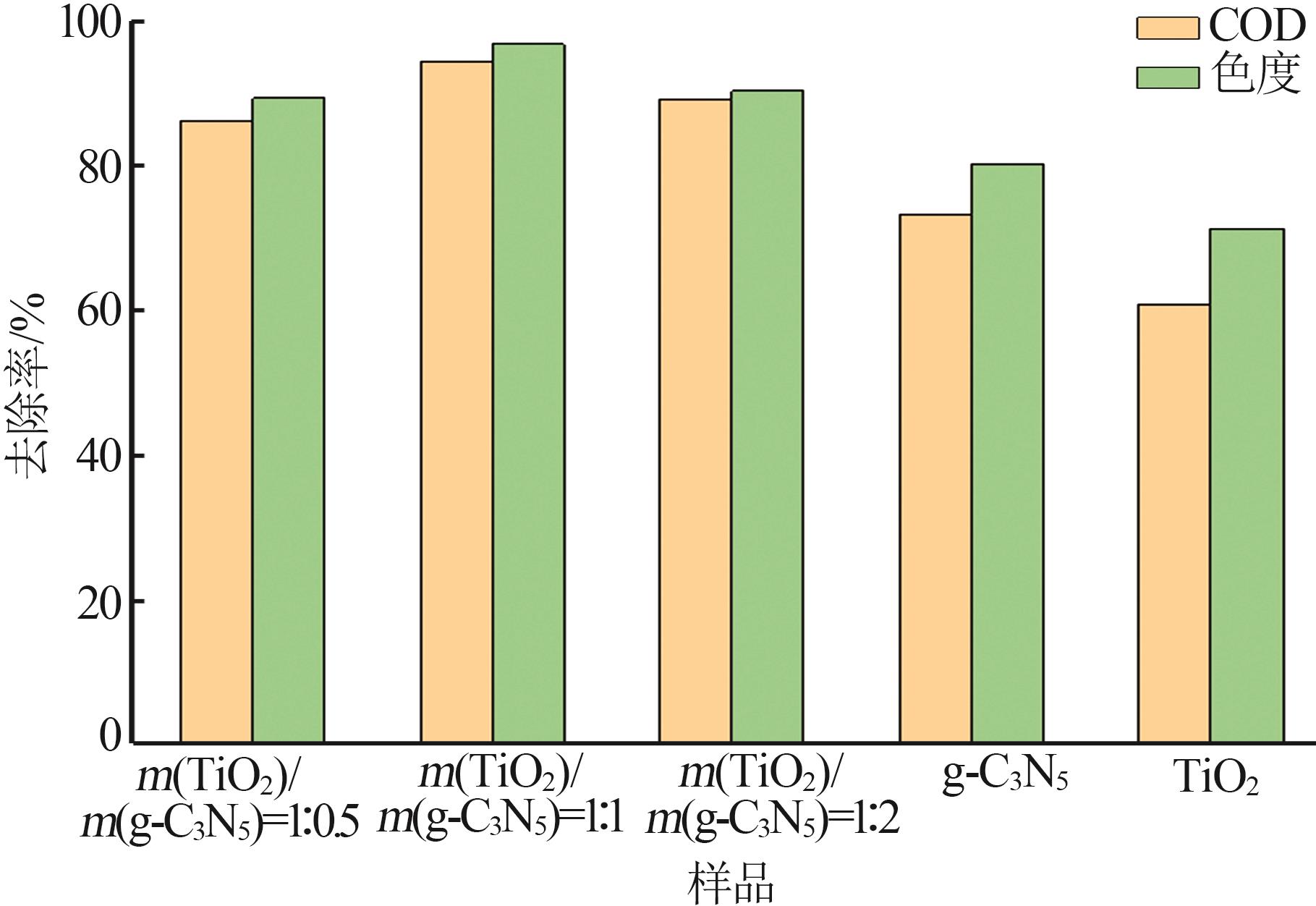

| 11 | 倪亭亭,王云钟,吴永明,等.印刷包装生产废水深度处理工程实例[J].水处理技术,2021,47(2):130-132,136. |

| NI Tingting, WANG Yunzhong, WU Yongming,et al.Engineering project of advanced treatment of printing and packaging production wastewater[J].Technology of Water Treatment,2021,47(2):130-132,136. | |

| 12 | 邹义龙,吴永明,万金保.印刷线路板生产废水处理的应用研究[J].工业水处理,2019,39(4):100-103. |

| ZOU Yilong, WU Yongming, WAN Jinbao.Application research on printed circuit board industrial wastewater treatment[J].Industrial Water Treatment,2019,39(4):100-103. | |

| 13 | LIU Sile, BU Yifu, CHENG Song,et al.Preparation of g-C3N5/g-C3N4 heterojunction for methyl orange photocatalytic degradation:Mechanism analysis[J].Journal of Water Process Engineering,2023,54:104019. |

| 14 | BEYHAQI A, AZIMI S M T, CHEN Zhihong,et al.Exfoliated and plicated g-C3N4 nanosheets for efficient photocatalytic organic degradation and hydrogen evolution[J].International Journal of Hydrogen Energy,2021,46(39):20547-20559. |

| 15 | 卜义夫,刘思乐,杜文娟,等.二硫化钼/石墨相氮化碳光催化降解印染废水研究[J].皮革科学与工程,2023,33(3):12-18. |

| BU Yifu, LIU Sile, DU Wenjuan,et al.Study on photocatalytic degradation of printing and dyeing wastewater by molybdenum disulfide/graphite carbon nitride[J].Leather Science and Engineering,2023,33(3):12-18. | |

| 16 | 杜瑞成,李燕,王霆,等.纳米TiO2光催化剂改性研究进展[J].化学通报,2023,86(10):1172-1180. |

| DU Ruicheng, LI Yan, WANG Ting,et al.Research progress in modification of nano-TiO2 photocatalyst[J].Chemistry,2023,86(10):1172-1180. | |

| 17 | 李权.掺杂金属离子对纳米二氧化钛光催化性能的影响[J].数字印刷,2020(3):172-179. |

| LI Quan.Effect of doping metal ions on photo catalytic properties of TiO2 nanoparticles[J].Digital Printing,2020(3):172-179. | |

| 18 | WANG Chun, JIAO Han, YANG Yinbo,et al.Dual⁃functional S-scheme Fe3O4/TiO2/g-C3N4 double⁃heterostructure bridged by TiO2 for collaborative removal of U(Ⅵ) and Sb(Ⅲ)[J].Journal of Cleaner Production,2023,426:139114. |

| 19 | ALBAIDANI K, TIMOUMI A, BELHADJ W,et al.Structural,electronic and optical characteristics of TiO2 and Cu-TiO2 thin films produced by sol-gel spin coating[J].Ceramics International,2023,49(22):36265-36275. |

| 20 | 郭湘立,冯艳文,郭勇.Ag-黑纳米TiO2-电气石可见光催化材料的制备与应用研究[J].涂料工业,2023,53(10):55-60,68. |

| GUO Xiangli, FENG Yanwen, GUO Yong.Preparation and application of plasma Ag-black nano TiO2-micro tourmaline visible light catalytic material[J].Paint & Coatings Industry,2023,53(10):55-60,68. | |

| 21 | 贾雪莹,王騊.TiO2纳米棒复合织物的制备及其光催化和抗菌性能[J].现代纺织技术,2022,30(3):136-142. |

| JIA Xueying, WANG Tao.Preparation of TiO2 nanorod composite fabric and its photocatalytic and antibacterial properties[J].Advanced Textile Technology,2022,30(3):136-142. | |

| 22 | 蒋琦,任姿旭,陈轲,等.S,N共掺杂TiO2纳米管作为钠离子电池负极的储钠性能[J].微纳电子技术,2023,60(8):1201-1210. |

| JIANG Qi, REN Zixu, CHEN Ke,et al.Sodium storage performance of S,N co⁃doped TiO2 nanotubes as anode for sodium ion batteries[J].Micronanoelectronic Technology,2023,60(8):1201-1210. | |

| 23 | 林博文,徐亦冬,余德密.MgAl-LDHs/TiO2复合光催化剂的制备及光催化性能[J].材料导报,2023,37(19):40-45. |

| LIN Bowen, XU Yidong, YU Demi.Preparation and photocatalytic performance of MgAl-LDHs/TiO2 composite photocataly⁃st[J].Materials Reports,2023,37(19):40-45. | |

| 24 | ZHANG Qingsong, XIAO Yang, YANG Liu,et al.Branched core⁃shell a-TiO2@N-TiO2 nanospheres with gradient⁃doped N for highly efficient photocatalytic applications[J].Chinese Chemical Letters,2023,34(4):107628. |

| 25 | YANG Xiande, QIN Yijin, WEI Liang,et al.Preparation of AgBr/g-C3N5 composite and its enhanced photodegradation for dyes[J].Inorganic Chemistry Communications,2023,155:110996. |

| 26 | SHEN Wanling, LI Yuanyuan, SHEN Changzhi,et al.Enhancing the photo⁃Fenton catalytic activity of g-C3N5 under visible light through Z-scheme heterojunction with ferric iron[J].Journal of Materials Research,2023,38(10):2775-2786. |

| 27 | THARUMAN S, BALAKUMAR V, VINODHINI J,et al.Visible light driven photocatalytic performance of 3D TiO2/g-C3N5 nanocomposite via Z-scheme charge transfer promotion for water purification[J].Journal of Molecular Liquids,2023,371:121101. |

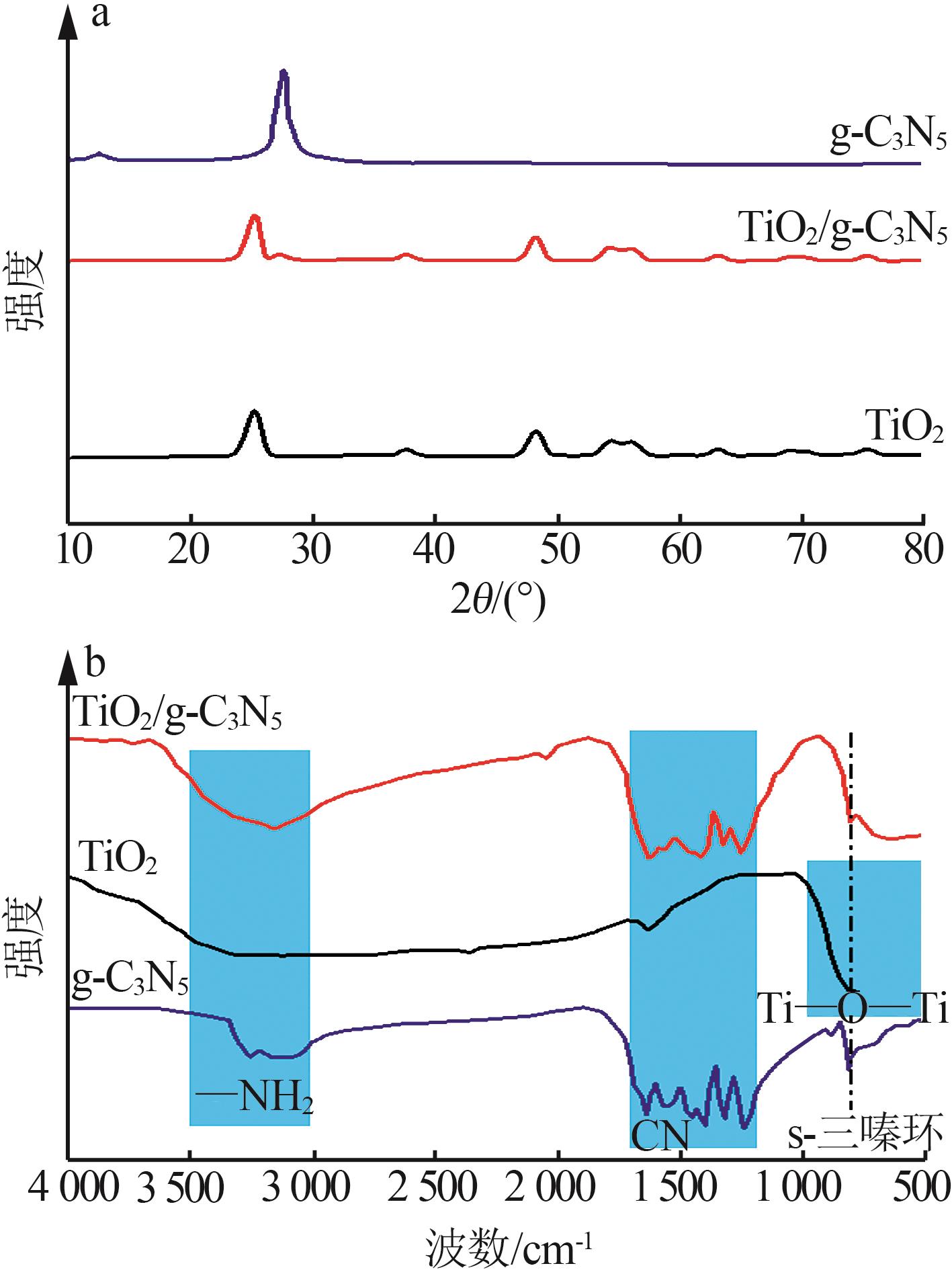

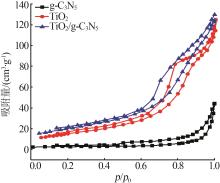

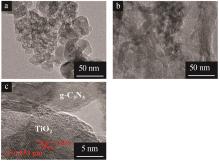

| 28 | LIU Sile, BU Yifu, CHENG Song,et al.Synthesis of TiO2/g-C3N5 heterojunction for photocatalytic degradation of methylene blue wastewater under visible light irradiation:Mechanism analysis[J].Diamond and Related Materials,2023,136:110062. |

| 29 | ZHANG Yuan, CUI Tianyi, ZHAO Jianbo,et al.Fabrication and study of a novel TiO2/g-C3N5 material and photocatalytic properties using methylene blue and tetracycline under visible light[J].Inorganic Chemistry Communications,2022,143:109815. |

| [1] | SHI Wangfang, ZHANG Yongsheng. Study on NO x degradation performance of concrete-based non-metallic boron doped nitrogen-rich carbon nitride [J]. Inorganic Chemicals Industry, 2025, 57(3): 116-123. |

| [2] | LI Zihan, ZHANG Jiaqi, LI Shizhuo, LI Xinyu, LIU Shaozhuo, WANG Yihao, HAO Yucui, LIU Jian, LI Yanhua. Study on synthesis and catalytic mechanism of CdS/g-C3N4 composite photocatalyst [J]. Inorganic Chemicals Industry, 2025, 57(3): 124-132. |

| [3] | SUN Qinghao, LI Keyan, GUO Xinwen. Study on photocatalytic benzyl alcohol oxidation coupled with hydrogen production over Pd/ZnIn2S4 nanosheets [J]. Inorganic Chemicals Industry, 2025, 57(1): 113-119. |

| [4] | LIU Guangming. Study on photocatalytic and mechanical properties of C3N5/NH2-MIL-125(Ti) modified concrete mortar [J]. Inorganic Chemicals Industry, 2025, 57(1): 120-128. |

| [5] | ZHANG Guoqiang, RONG Xilin, XIAO Zhenfang, XUE Ziran, CHENG Hao, FENG Jun, LIU Quan, LU Yao, HUANG Wenyi. Study on preparation and photocatalytic properties of bagasse carbon aerogels loaded with zinc oxide nanoparticles [J]. Inorganic Chemicals Industry, 2024, 56(8): 131-138. |

| [6] | WANG Yawen, WANG Fangfang, GENG Siyu, JU Jia, CHEN Lei, CHEN Changdong. Study on preparation and photocatalytic performance of SrTiO3-SrWO4 [J]. Inorganic Chemicals Industry, 2024, 56(7): 143-149. |

| [7] | LIU Min, HUANG Xiu, ZHANG Liyuan. Research progress of S-type heterojunction photocatalysts [J]. Inorganic Chemicals Industry, 2024, 56(7): 18-27. |

| [8] | LI Jiangpeng, ZHANG Huibin. Synergistic degradation of methylene blue by photo-Fenton and photocatalytic with 3D porous LaFeO3/CeO2/SrTiO3 [J]. Inorganic Chemicals Industry, 2024, 56(5): 141-148. |

| [9] | TANG Bei. Preparation of ZnO/g-C3N4 heterojunction photocatalytic material and its degradation of pyridine [J]. Inorganic Chemicals Industry, 2024, 56(4): 133-142. |

| [10] | HUANG Jianan, LU Xiaoyu, WANG Mitang. Effect of Ba-La co-doping on degradation of methylene blue dye by TaON [J]. Inorganic Chemicals Industry, 2024, 56(2): 146-151. |

| [11] | ZUO Guangling, WANG Minghui, PENG Yunying, DU Jia, YE Hongyong. Study on hnoneycomb-like LaVO4/Bi2O3 heterojunction for photocatalytic degradation of tetracycline hydrochloride [J]. Inorganic Chemicals Industry, 2024, 56(11): 158-164. |

| [12] | CUI Xiangdong, LIU Sile. Study on photoelectric performance analysis of g-C3N5 nanorods and removal of Cr(Ⅵ) and methylene blue [J]. Inorganic Chemicals Industry, 2024, 56(10): 159-168. |

| [13] | YAN Yu, ZHOU Wenyuan, YANG Yunfei, WU Junshu, WANG Jinshu, SUN Lingmin. Study on surface regulation of sodium ferric silicate photocatalyst and its enhanced Cr(Ⅵ) photoreduction properties [J]. Inorganic Chemicals Industry, 2024, 56(10): 141-150. |

| [14] | YANG Bo, LIANG Zhiyan, LIU Wenyuan, CAO Jiazhen, LIU Xinyue, XING Mingyang. Research progress of application of molybdenum-based catalytic materials for water pollution control [J]. Inorganic Chemicals Industry, 2023, 55(8): 1-12. |

| [15] | YU Hongchao, ZHANG Mengmeng, JIN Tianxiang. Research progress of microstructure and crystal surface effect of Ag3PO4 photocatalysts [J]. Inorganic Chemicals Industry, 2023, 55(8): 13-20. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||