Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (5): 45-51.doi: 10.19964/j.issn.1000-4990.2022-0395

• Research & Development • Previous Articles Next Articles

Leaching process and kinetics of phosphorus-potassium ore decomposition by nitric acid

WANG Haosen( ), REN Bingchen, XU Dehua(

), REN Bingchen, XU Dehua( ), YANG Xiushan, ZHANG Zhiye(

), YANG Xiushan, ZHANG Zhiye( )

)

- Ministry of Education Research Center for Comprehensive Utilization and Clean Processing Engineering of PhosphorusResources,College of Chemical Engineering,Sichuan University,Chengdu 610065,China

-

Received:2022-06-30Online:2023-05-10Published:2023-05-15

CLC Number:

Cite this article

WANG Haosen, REN Bingchen, XU Dehua, YANG Xiushan, ZHANG Zhiye. Leaching process and kinetics of phosphorus-potassium ore decomposition by nitric acid[J]. Inorganic Chemicals Industry, 2023, 55(5): 45-51.

share this article

| 1 | 王武强.肥料产业趋势与展望:中国肥料产业科技发展报告发布[J].中国农村科技,2017(1):55-57. |

| WANG Wuqiang.Trends and prospects of fertilizer industry—Report on the development of science and technology in fertilizer industry in China[J].China Rural Science & Technology,2017(1):55-57. | |

| 2 | 何宾宾,魏立军,谢德龙,等.中国湿法磷加工产业现状与可持续发展[J].无机盐工业,2020,52(1):1-4,16. |

| HE Binbin, WEI Lijun, XIE Delong,et al.Current situation and sustainable development of wet process phosphorus processing industry in China[J].Inorganic Chemicals Industry,2020,52(1):1-4,16. | |

| 3 | 谭慧婷,孙伟,崔玉照,等.钾矿资源现状与杂卤石的开发应用分析[J].无机盐工业,2022,54(6):23-30. |

| TAN Huiting, SUN Wei, CUI Yuzhao,et al.Present situation of potash resources and analysis of development and application of polyhalite[J].Inorganic Chemicals Industry,2022,54(6):23-30. | |

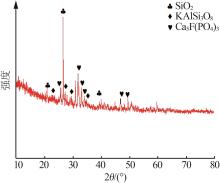

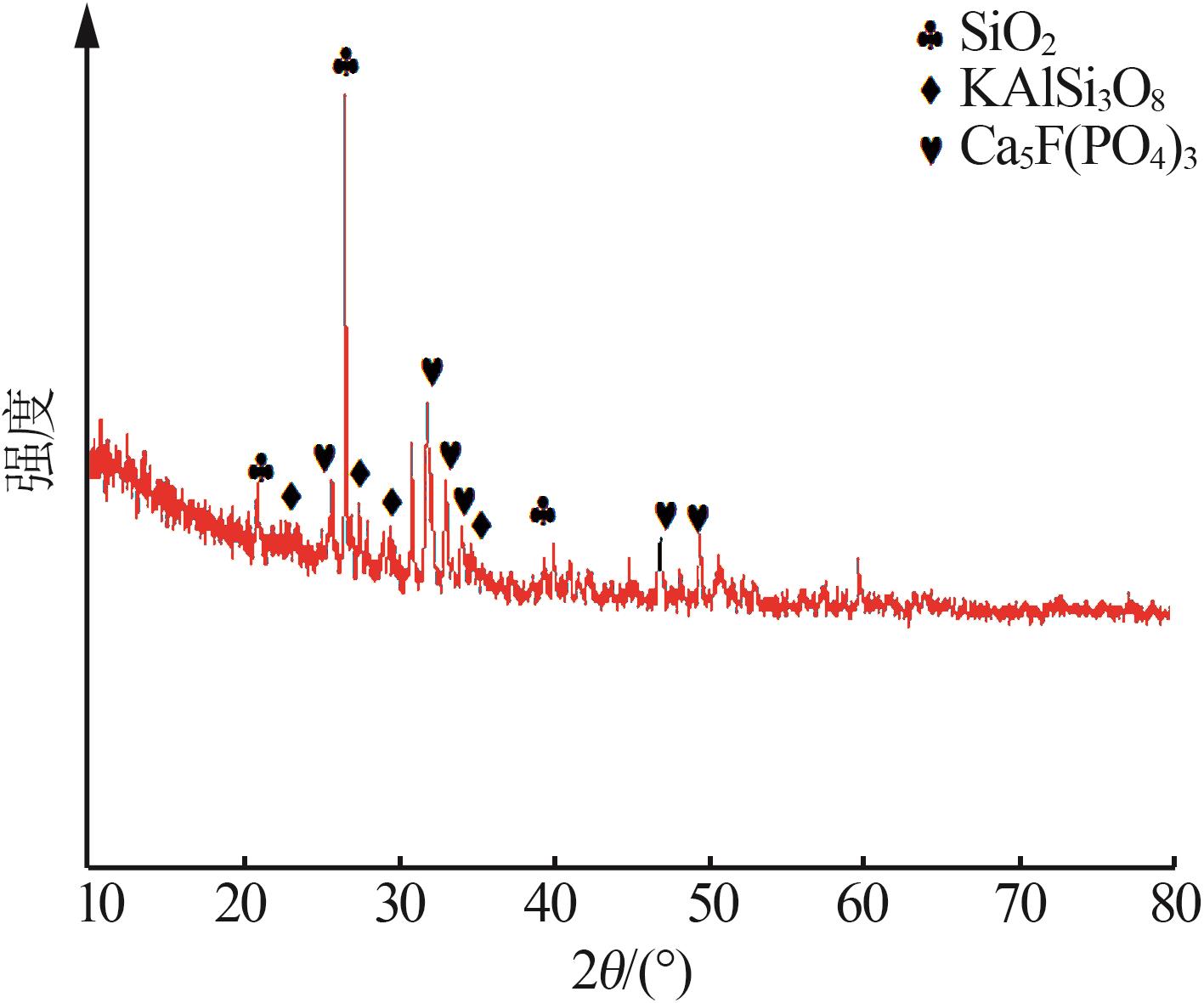

| 4 | 吕莉,张允湘.汉源磷钾矿矿石性质及工艺特性研究[J].矿产综合利用,2004(2):28-31. |

| Li LÜ, ZHANG Yunxiang.Mineralogical compositions and technological characteristics of phosphate-potassium ore,Hanyuan[J].Multipurpose Utilization of Mineral Resources,2004(2):28-31. | |

| 5 | 段欢,王存文,覃远航,等.宜昌磷钾矿反应特性和发泡特性研究[J].化工矿物与加工,2013,42(9):9-11. |

| DUAN Huan, WANG Cunwen, QIN Yuanhang,et al.Study on reaction and foaming characterstics of Yichang phosphate potassium ores[J].Industrial Minerals & Processing,2013,42(9):9-11. | |

| 6 | 宋超,刘全军,高利坤.低品位磷钾矿浮选提高磷品位试验研究[J].非金属矿,2019,42(3):55-57. |

| SONG Chao, LIU Quanjun, GAO Likun.Flotation experiment on the upgrade of phosphorus from low grade phosphate and potash feldspar compound ore[J].Non-Metallic Mines,2019,42(3):55-57. | |

| 7 | 朱排场,李绪,李防,等.宜昌某磷矿工艺矿物学研究及浮选实验[J].矿业研究与开发,2018,38(6):85-88. |

| ZHU Paichang, LI Xu, LI Fang,et al.Process mineralogy research and flotation experiment in a phosphate mine of Yichang[J].Mining Research and Development,2018,38(6):85-88. | |

| 8 | 贺方杰.磷钾伴生矿低温浸出液制备N、P、K复合肥及硫酸钙晶须的工艺研究[D].武汉:武汉工程大学,2015. |

| HE Fangjie.Study on preparation of NPK compound fertilizer and calcium sulfate whisker by using acid-leaching solution of phosphate-potassium associated ore obtained at low temperature[D].Wuhan:Wuhan Institute of Technology,2015. | |

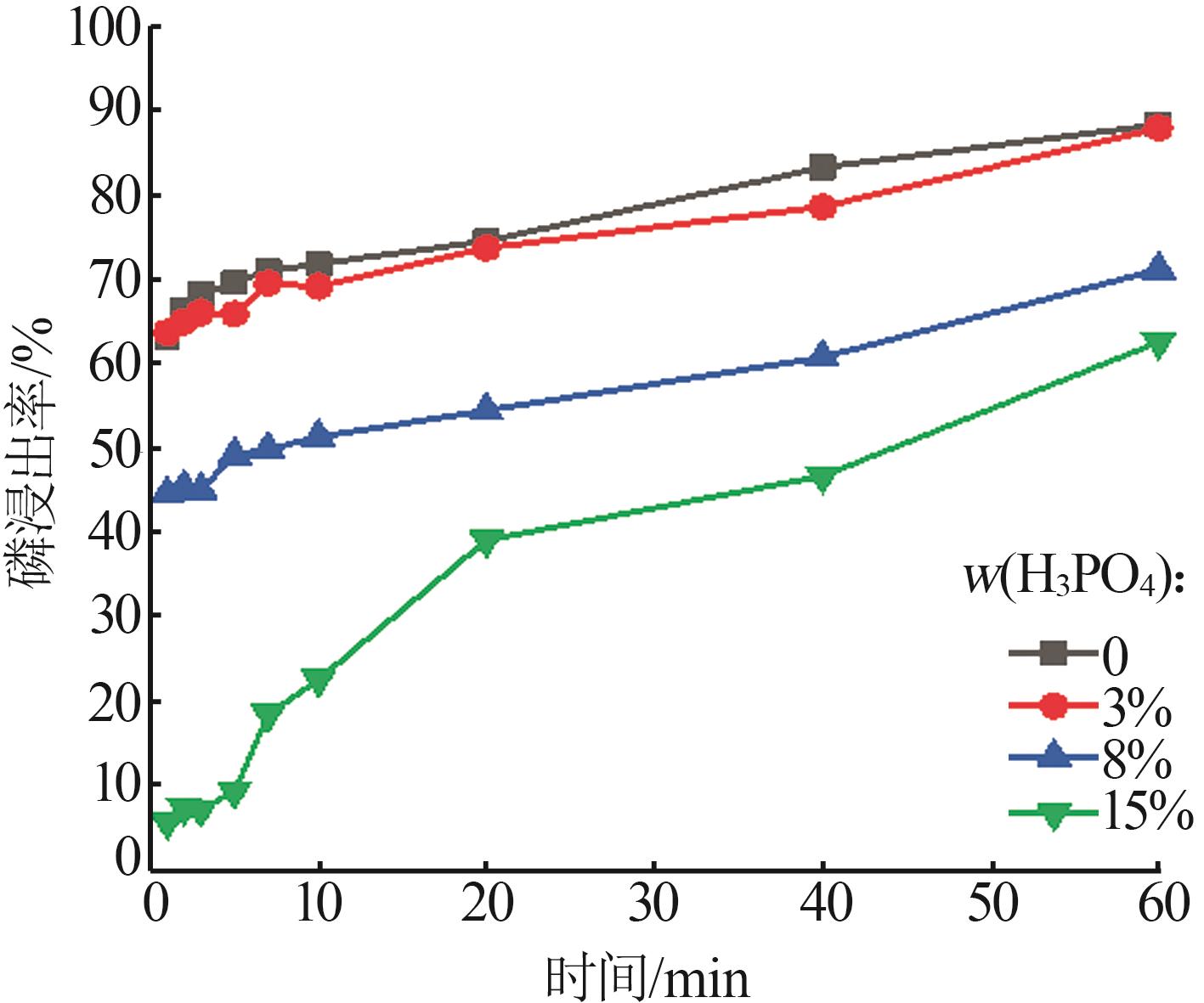

| 9 | 张光旭,彭宇,张平,等.磷酸法分解磷钾矿过程中钾硅分解率的研究[J].无机盐工业,2015,47(1):39-41. |

| ZHANG Guangxu, PENG Yu, ZHANG Ping,et al.Decomposition rate of potassium and silicon from low grade phosphate-potassium ore with phosphoric acid[J].Inorganic Chemicals Industry,2015,47(1):39-41. | |

| 10 | 吕莉,唐盛伟,罗洪波,等.磷钾伴生矿酸解提取磷钾的过程研究[J].矿产综合利用,2018(1):66-69,54. |

| Li LÜ, TANG Shengwei, LUO Hongbo,et al.Extraction of phosphorus and potassium by acid from a complex phosphoric miner-al[J].Multipurpose Utilization of Mineral Resources,2018(1):66-69,54. | |

| 11 | 周俊锋.磷钾伴生矿低温酸浸动力学及过程强化研究[D].武汉:武汉工程大学,2019. |

| ZHOU Junfeng.Low-temperature acid leaching of phosphorus-potassium associated ore:Kinetics and process intensification[D].Wuhan:Wuhan Institute of Technology,2019. | |

| 12 | 孙雪飞,王为国,王存文.低品位磷钾矿与磷酸共浸提取磷和钾工艺研究[J].化工矿物与加工,2011,40(1):6-10. |

| SUN Xuefei, WANG Weiguo, WANG Cunwen.Extraction of phosphate and potassium from leaching solution of low grade phosphate and potassium ore with phosphoric acid[J].Industrial Minerals & Processing,2011,40(1):6-10. | |

| 13 | 张爽,吕仁亮,王为国,等.低温酸浸磷钾伴生矿提钾工艺研究[J].现代化工,2015,35(5):96-100. |

| ZHANG Shuang, Renliang LÜ, WANG Weiguo,et al.Potassium extraction from phosphorus-potassium associated ore at low temperature[J].Modern Chemical Industry,2015,35(5):96-100. | |

| 14 | 杜学兰.磷钾伴生矿磷酸—盐酸混酸提钾研究[D].武汉:武汉工程大学,2016. |

| DU Xuelan.Potassium extraction from phosphorus-potassium associated ore in the mixed solutions of phosphoric acid and hydrochloric acid[D].Wuhan:Wuhan Institute of Technology,2016. | |

| 15 | 宋小霞,胡宏,彭卓飞,等.湿法磷酸生产中结垢问题的研究[J].磷肥与复肥,2018,33(10):28-31. |

| SONG Xiaoxia, HU Hong, PENG Zhuofei,et al.Research on scaling problems in WPA production[J].Phosphate & Compound Fertilizer,2018,33(10):28-31. | |

| 16 | 王励生,廖华书,万先达.硝酸分解磷矿反应动力学的研究[J].成都科技大学学报,1981,13(1):107-112. |

| WANG Lisheng, LIAO Huashu, WAN Xianda.Reaction kinetics of decomposing phosphate by nitric acid[J].Advanced Engineering Sciences,1981,13(1):107-112. | |

| 17 | 罗征,杨静,马鸿文,等.氟化物助剂分解钾长石制取硫酸钾研究评述[J].化工矿物与加工,2018,47(8):65-70. |

| LUO Zheng, YANG Jing, MA Hongwen,et al.Research review of preparation of potassium sulfate from K-feldspar with fluoride as additive agent[J].Industrial Minerals & Processing,2018,47(8):65-70. | |

| 18 | 周佳琦,陈葵,武斌,等.磷尾矿煅烧及酸浸过程动力学研究[J].无机盐工业,2022,54(1):77-82,108. |

| ZHOU Jiaqi, CHEN Kui, WU Bin,et al.Study on kinetics of phosphate tailings calcination and acid leaching process[J].Inorganic Chemicals Industry,2022,54(1):77-82,108. | |

| 19 | LI Zhili, XIE Zhihao, DENG Jie,et al.Leaching kinetics of rare earth elements in phosphoric acid from phosphate rock[J].Metals,2021,11(2):239. |

| [1] | TAN Shanyi, WEN Huizi, HE Shuyu, ZHANG Liwen, CHEN Shaohua, XI Benjun. Study on leaching behavior and kinetics of phosphorus from phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(2): 105-112. |

| [2] | ZENG Yijun, JIANG Ziwen, JIAN Chengzong, QUAN Xuejun. Study on deep extraction of chromium from calcium-free roasting slag of chromite ore [J]. Inorganic Chemicals Industry, 2025, 57(1): 90-96. |

| [3] | MA Shuqing, LI Changwen, SHI Chenglong, QIN Yaru. Kinetic study of lithium extraction from solution with iron-based ionic liquid system [J]. Inorganic Chemicals Industry, 2024, 56(9): 60-66. |

| [4] | FANG Fan, YAO Benlin, XIAO Yiqun, JIA Yanhong, CHEN Hui, LI Bin, HE Hui. Research progress on dissolution behavior and mechanism of uranium dioxide in nitric acid [J]. Inorganic Chemicals Industry, 2024, 56(9): 34-43. |

| [5] | ZOU Yang, LU Zhiyan, HU Zhilin, SUN Ze. Study on metastable zone width and primary nucleation kinetics for cooling crystallization of KNO3 [J]. Inorganic Chemicals Industry, 2024, 56(9): 67-74. |

| [6] | CHENG Ziyang, CHEN Guofu. Early hydration kinetics research of nano-SiO2 and cement composite cementitious materials [J]. Inorganic Chemicals Industry, 2024, 56(7): 80-87. |

| [7] | ZHANG Yu, ZHAO Guiyan, TIAN Yongchang, QIU Xiaokui, SUN Jiali, XU Lixin. Reaction kinetics of ethylenediamine hydrochloride with calcium hydroxide [J]. Inorganic Chemicals Industry, 2024, 56(5): 64-69. |

| [8] | ZHAO Shiyong, XIAO Yuchen, MA Qingqing, YANG Zhenni, WANG Jizhen, FAN Xiaoping. Study on adsorption of Cu(Ⅱ) on 4A zeolite synthesized by aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2024, 56(10): 127-134. |

| [9] | XIANG Mengqi, MENG Hua, WANG Ye, MENG Xianzhang, BAI Yuhang, WANG Yujunyao, ZHANG Yidan. Study on kinetic of iron leaching from titanium gypsum and its cyclic acid leaching process [J]. Inorganic Chemicals Industry, 2024, 56(1): 114-120. |

| [10] | YUAN Jinghua, WU Junhu, YANG XiuShan, XU Dehua, ZHANG Zhiye. Research on process of production ammonium dihydrogen phosphate by ammonia purification of nitro-phosphoric acid [J]. Inorganic Chemicals Industry, 2023, 55(9): 50-56. |

| [11] | ZHOU Shiqi, WANG Tao, JING Fangli, LUO Shizhong. Study on performance of magnesium nitrate-modified carbon molecular sieve for separation of nitrogen/methane [J]. Inorganic Chemicals Industry, 2023, 55(9): 75-80. |

| [12] | FAN Fangfang, TONG Zhongkai, ZUO Weiyuan. Study on adsorption of tetracycline from wastewater by calcium modified peanut shell biochar [J]. Inorganic Chemicals Industry, 2023, 55(6): 109-115. |

| [13] | MA Dianpu, PU Youfu, LI Jun, CHEN Lishi, LIU Hengyu, QIN Deqing, FU Zewei, PENG Jubo. Preparation of high purity ultrafine tin dioxide particles by liquid oxidation-spray drying method [J]. Inorganic Chemicals Industry, 2023, 55(4): 54-59. |

| [14] | ZHOU Qiang, WU Bin, CHEN Kui, JI Lijun, WU Yanyang. Study on thermal decomposition kinetic mechanism and calcination process of phosphorus tailings [J]. Inorganic Chemicals Industry, 2023, 55(3): 47-54. |

| [15] | TIAN Xiaoli, LI Zhixun, FENG Runtang, ZHANG Jie, ZHENG Quanfu, SHI Xuwu, DU Yongbin. Study on thermal decomposition behavior of Tibetan Kamado microcrystalline magnesite [J]. Inorganic Chemicals Industry, 2023, 55(3): 60-65. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||