| 1 |

PENG Hao, GUO Jing, LV Liping,et al.Recovery of chromium by calcium-roasting,sodium-roasting,acidic leaching,alkaline leaching and sub-molten technology:A review[J].Environmental Chemistry Letters,2021,19(2):1383-1393.

|

| 2 |

QI Tiangui, LI Yaomin, WANG Peng,et al.Effect of sodium aluminate on chromium spinels oxidation in chromite lime-free roasting process[J].Transactions of Nonferrous Metals Society of China,2023,33(8):2497-2510.

|

| 3 |

田仪娟,晏超群,程治良,等.柑桔皮与铬渣共热解毒六价铬[J].无机盐工业,2021,53(12):129-134.

|

|

TIAN Yijuan, YAN Chaoqun, CHENG Zhiliang,et al.Detoxification of Cr(Ⅵ) from chromite ore processing residue by pyrolysis with citrus peel[J].Inorganic Chemicals Industry,2021,53(12):129-134.

|

| 4 |

PENG Zhiwei, WANG Liancheng, GU Foquan,et al.Recovery of chromium from ferronickel slag:A comparison of microwave roasting and conventional roasting strategies[J].Powder Technology,2020,372:578-584.

|

| 5 |

ESCUDERO-CASTEJÓN L, TAYLOR J, SÁNCHEZ-SEGADO S,et al.A novel reductive alkali roasting of chromite ores for carcinogen-free Cr6+-ion extraction of chromium oxide(Cr2O3):A clean route to chromium product manufacturing![J].Journal of Hazardous Materials,2021,403:123589.

|

| 6 |

BEUKES J P, DU PREEZ S P, VAN ZYL P G,et al.Review of Cr(Ⅵ) environmental practices in the chromite mining and smelting industry:Relevance to development of the Ring of Fire,Canada[J].Journal of Cleaner Production,2017,165:874-889.

|

| 7 |

DHAL B, THATOI H N, DAS N N,et al.Chemical and microbial remediation of hexavalent chromium from contaminated soil and mining/metallurgical solid waste:A review[J].Journal of Hazardous Materials,2013,250/251:272-291.

|

| 8 |

UNCETA N, SÉBY F, MALHERBE J,et al.Chromium speciation in solid matrices and regulation:A review[J].Analytical and Bioanalytical Chemistry,2010,397(3):1097-1111.

|

| 9 |

ZHAO Qing, LIU Chengjun, YANG Dapeng,et al.A cleaner method for preparation of chromium oxide from chromite[J].Process Safety and Environmental Protection,2017,105:91-100.

|

| 10 |

WANG Lanbin, XU Yangming, TIAN Hong,et al.Co-treatment of chromite ore processing residue and pyrolusite for simultaneous detoxification and resource utilization[J].Journal of Environmental Chemical Engineering,2023,11(3):109785.

|

| 11 |

KUMAR P, PATRA S K, TRIPATHY S K,et al.Efficient utilization of nickel rich chromite ore processing tailings by carbothermic smelting[J].Journal of Cleaner Production,2021,315:128046.

|

| 12 |

TIAN Yijuan, QUAN Xuejun, LI Gang,et al.A cleaner method for preparation of chromium oxide from chromite ore[J].Process Safety and Environmental Protection,2022,158:87-97.

|

| 13 |

吴俊,程雯,全学军,等.铬铁矿无钙焙烧渣的酸浸解毒及浸出行为[J].无机盐工业,2019,51(7):64-67.

|

|

WU Jun, CHENG Wen, QUAN Xuejun,et al.Acid leaching detoxification and leaching behavior of chromite ore processing residue[J].Inorganic Chemicals Industry,2019,51(7):64-67.

|

| 14 |

温婧,姜涛,余唐霞,等.钒铬渣锰盐焙烧酸浸过程中钒、铬的分离行为[J].中国有色金属学报,2021,31(4):977-983.

|

|

WEN Jing, JIANG Tao, YU Tangxia,et al.Separation of vanadium and chromium from vanadium-chromium slag by manganese salt roasting[J].The Chinese Journal of Nonferrous Metals,2021,31(4):977-983.

|

| 15 |

ZHANG Jing, XIE Wenyu, CHU Shasha,et al.Sufficient extraction of Cr from chromium ore processing residue(COPR) by selective Mg removal[J].Journal of Hazardous Materials,2022,440:129754.

|

| 16 |

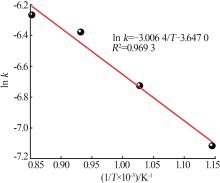

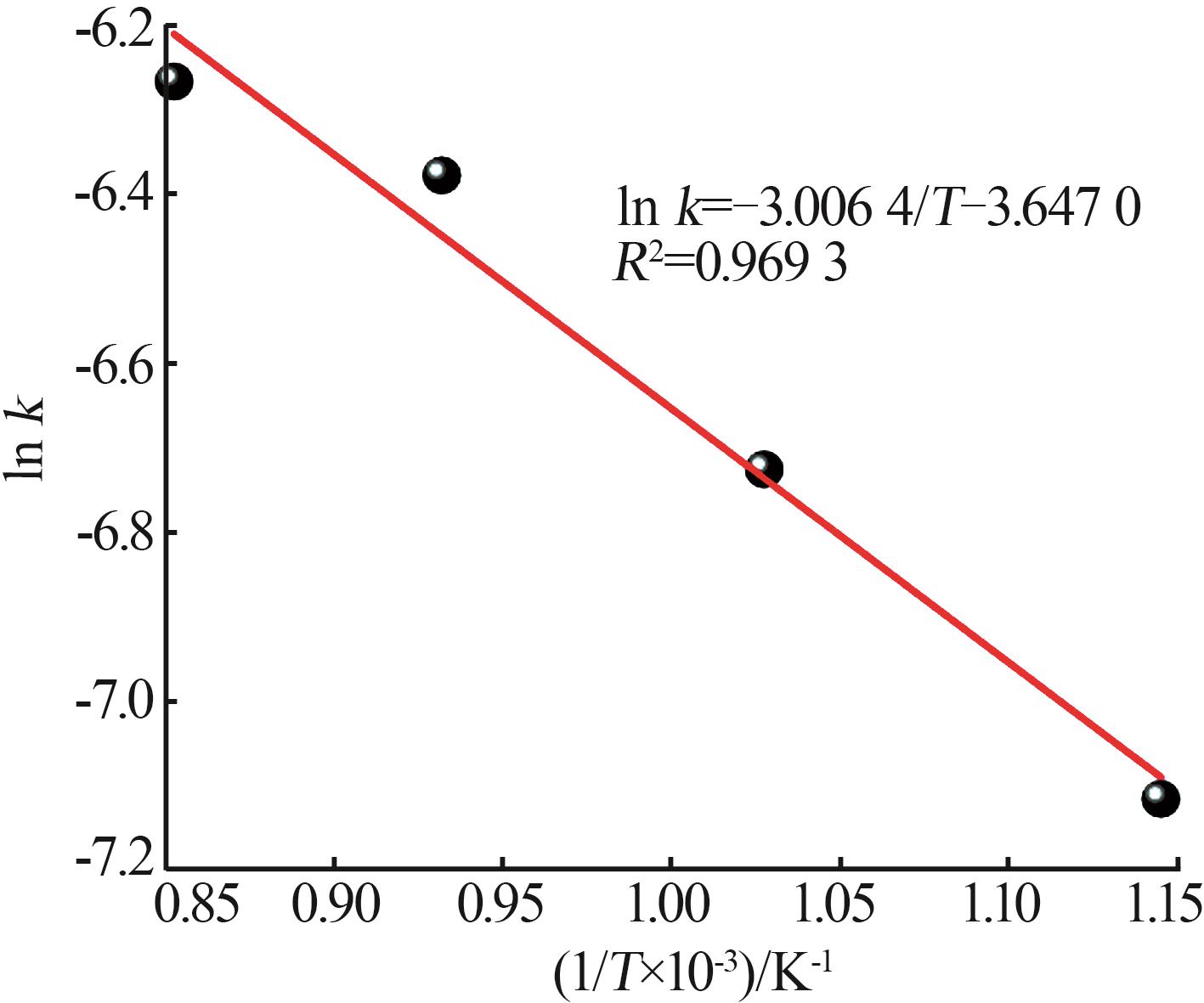

ZHANG Xingran, LI Gang, WU Jun,et al.Leaching of valuable elements from the waste chromite ore processing residue:A kinetic analysis[J].ACS Omega,2020,5(31):19633-19638.

|

| 17 |

叶鹏,全学军,秦险峰,等.铬铁矿无钙焙烧渣盐酸浸出[J].化工学报,2019,70(11):4428-4436.

|

|

YE Peng, QUAN Xuejun, QIN Xianfeng,et al.Leaching of chromite ore processing residue from non-calcium roasting with hydrochloric acid[J].CIESC Journal,2019,70(11):4428-4436.

|

| 18 |

宋艳,杨志平,康绍辉,等.铬渣中六价铬的浸出及还原试验研究[J].湿法冶金,2017,36(5):380-383.

|

|

SONG Yan, YANG Zhiping, KANG Shaohui,et al.Leaching and reduction of hexavalent chromium in chromium residue[J].Hydrometallurgy of China,2017,36(5):380-383.

|

| 19 |

庆朋辉,董玉明,王兴润,等.铬铁矿无钙焙烧铬渣的深度提铬与无害化处理[J].无机盐工业,2020,52(6):63-67,104.

|

|

QING Penghui, DONG Yuming, WANG Xingrun,et al.Chromium extraction and detoxification of processing residue from lime-free roasting process of chromite ore[J].Inorganic Chemicals Industry,2020,52(6):63-67,104.

|

| 20 |

FANG Haixing, LI Hongyi, XIE Bing.Effective chromium extraction from chromium-containing vanadium slag by sodium roasting and water leaching[J].ISIJ International,2012,52(11):1958-1965.

|

| 21 |

WANG Bo, YANG Qiaowen.Optimization of roasting parameters for recovery of vanadium and tungsten from spent SCR catalyst with composite roasting[J].Processes,2021,9(11):1923.

|

| 22 |

ZENG Xi, WANG Fang, ZHANG Huifeng,et al.Extraction of vanadium from stone coal by roasting in a fluidized bed reactor[J].Fuel,2015,142:180-188.

|

| 23 |

GILLIGAN R, NIKOLOSKI A N.The extraction of vanadium from titanomagnetites and other sources[J].Minerals Engineering,2020,146:106106.

|

| 24 |

LI Y, NI H, ZHOU Y,et al.Kinetic study of titanium-bearing electric arc furnace molten slag treated by molten sodium hydroxide[J].Minerals & Metallurgical Processing,2017,34(1):44-52.

|

| 25 |

赵昌明,翟玉春,刘岩,等.红土镍矿在NaOH亚熔盐体系中的预脱硅[J].中国有色金属学报,2009,19(5):949-954.

|

|

ZHAO Changming, ZHAI Yuchun, LIU Yan,et al.Pre-desilication of laterite in NaOH sub-molten salt system[J].The Chinese Journal of Nonferrous Metals,2009,19(5):949-954.

|

), JIANG Ziwen, JIAN Chengzong, QUAN Xuejun(

), JIANG Ziwen, JIAN Chengzong, QUAN Xuejun( )

)