Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (6): 92-103.doi: 10.19964/j.issn.1006-4990.2022-0704

• Environment·Health·Safety • Previous Articles Next Articles

Study on full element recycling process of retired ternary power lithium battery

- Central Research Institute of Shanghai Electric Group Co.,Ltd.,Shanghai 200070,China

-

Received:2022-12-01Online:2023-06-10Published:2023-06-14

CLC Number:

Cite this article

LU Junhao. Study on full element recycling process of retired ternary power lithium battery[J]. Inorganic Chemicals Industry, 2023, 55(6): 92-103.

share this article

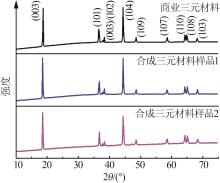

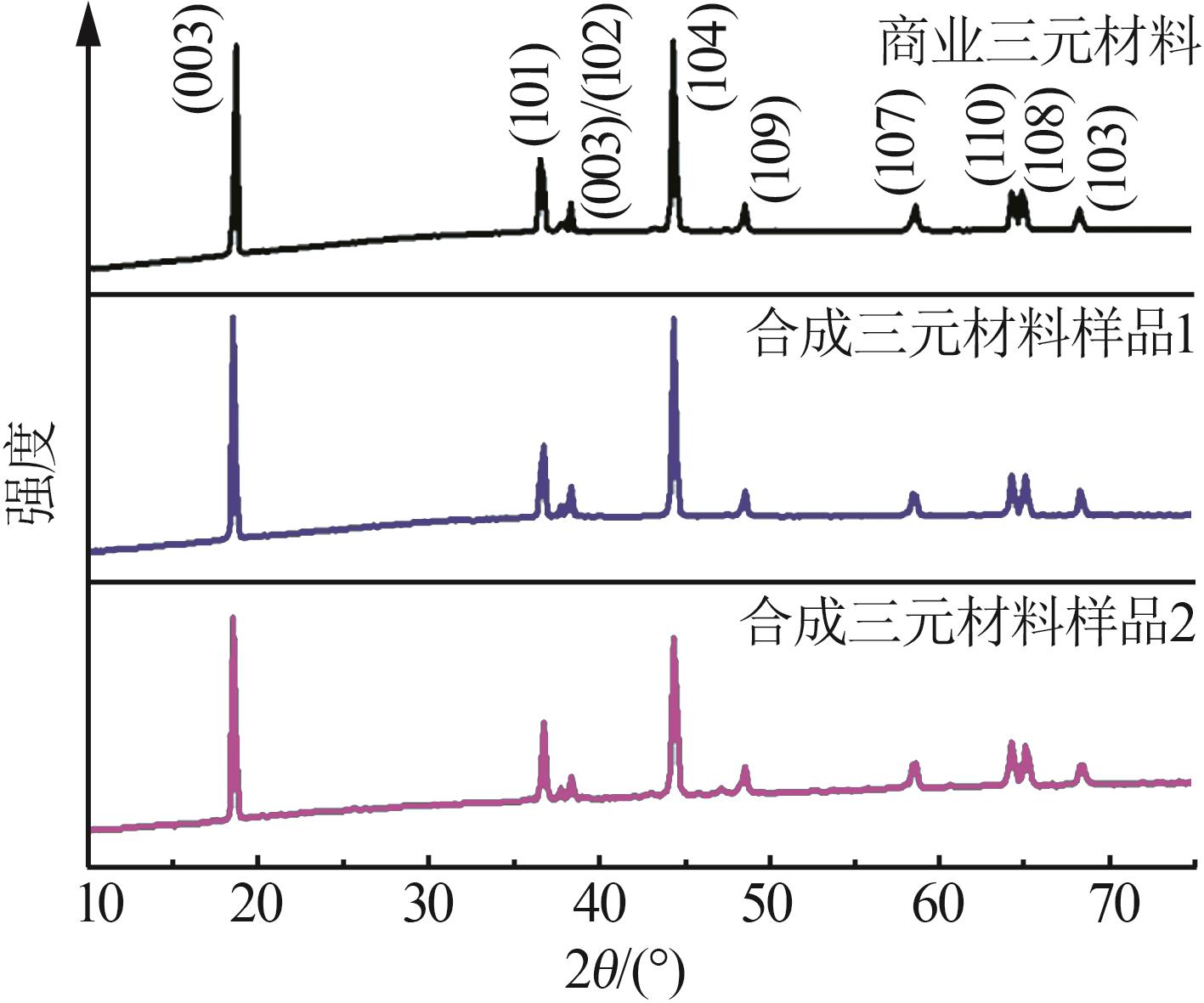

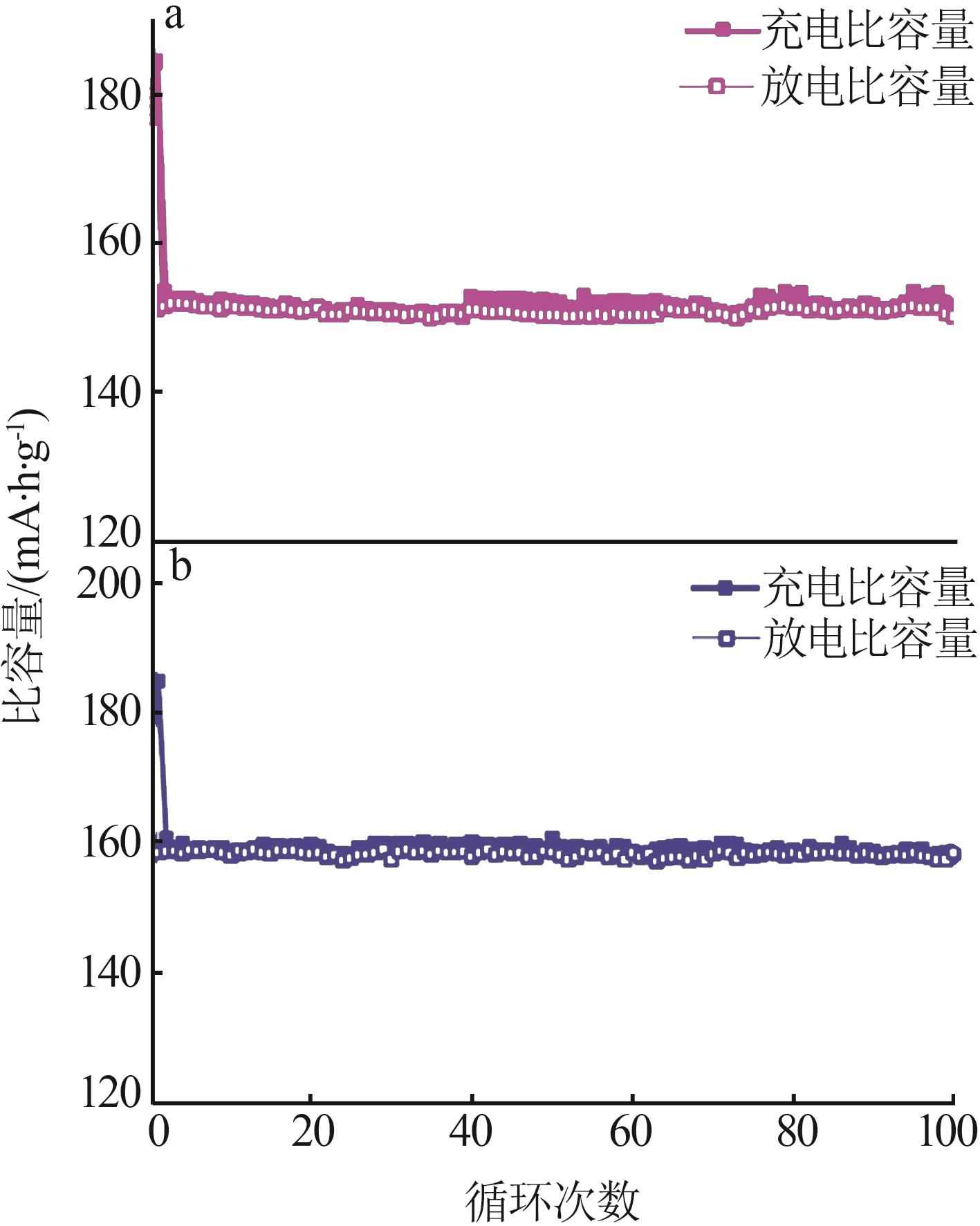

Table 10

Comparison of physical and electrochemical properties of synthetic cathode materials with industry standards"

| 项目 | 振实密度/ (g∙cm-3) | 粒度分布 | 比表面积/ (m2∙g-1) | 首次放电 比容量/ (mA∙h∙g-1) | 首次充放 电效率/% | 平台容量 比率/% |

|---|---|---|---|---|---|---|

| YS/T 798—2012《镍钴锰酸锂》 | ≥1.8 | D10≥2.0 μm;D50为5~10 μm;D90≤30.0 μm | ≤1.0 | ≥140 | ≥85 | ≥50 |

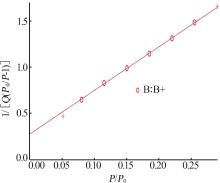

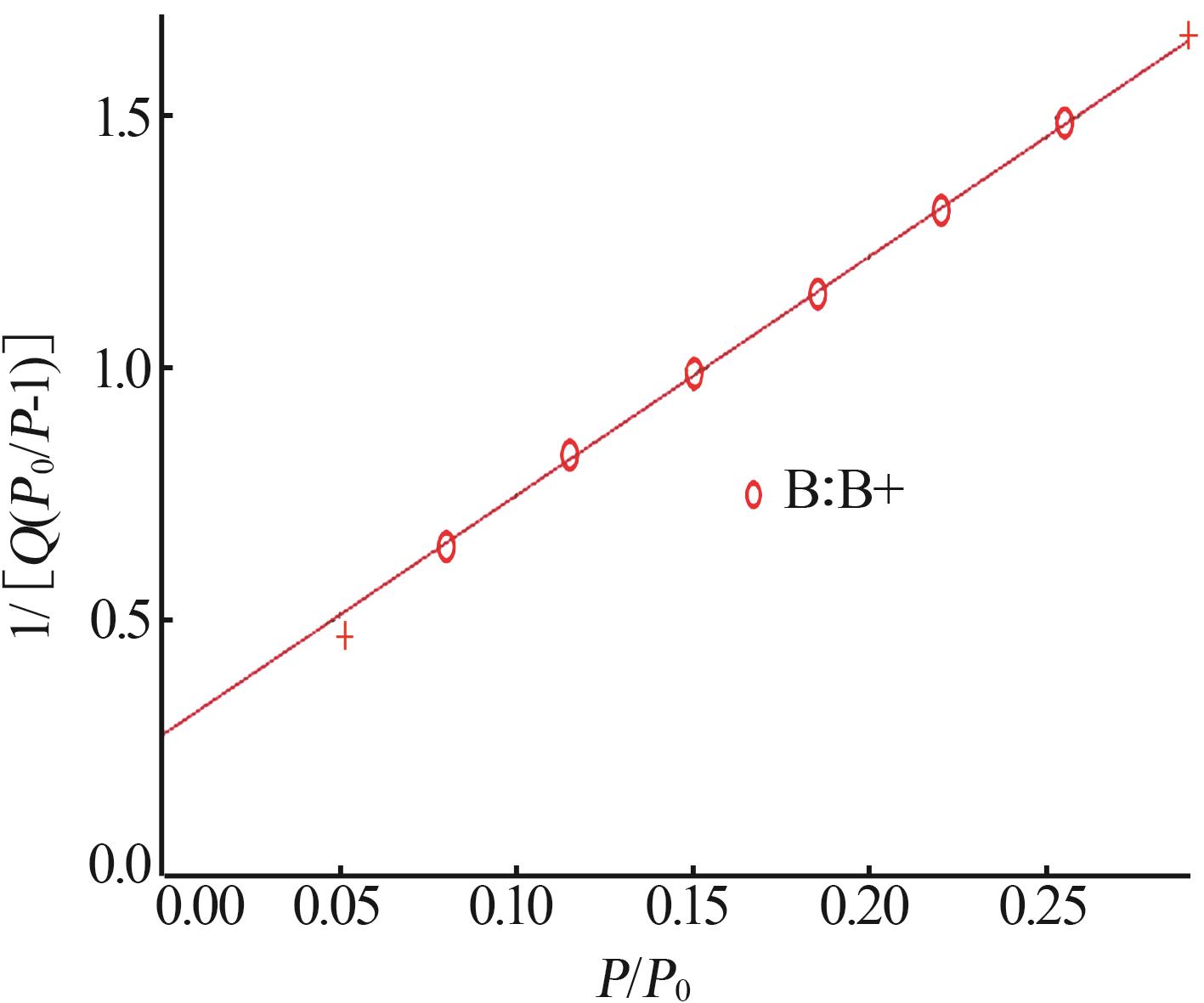

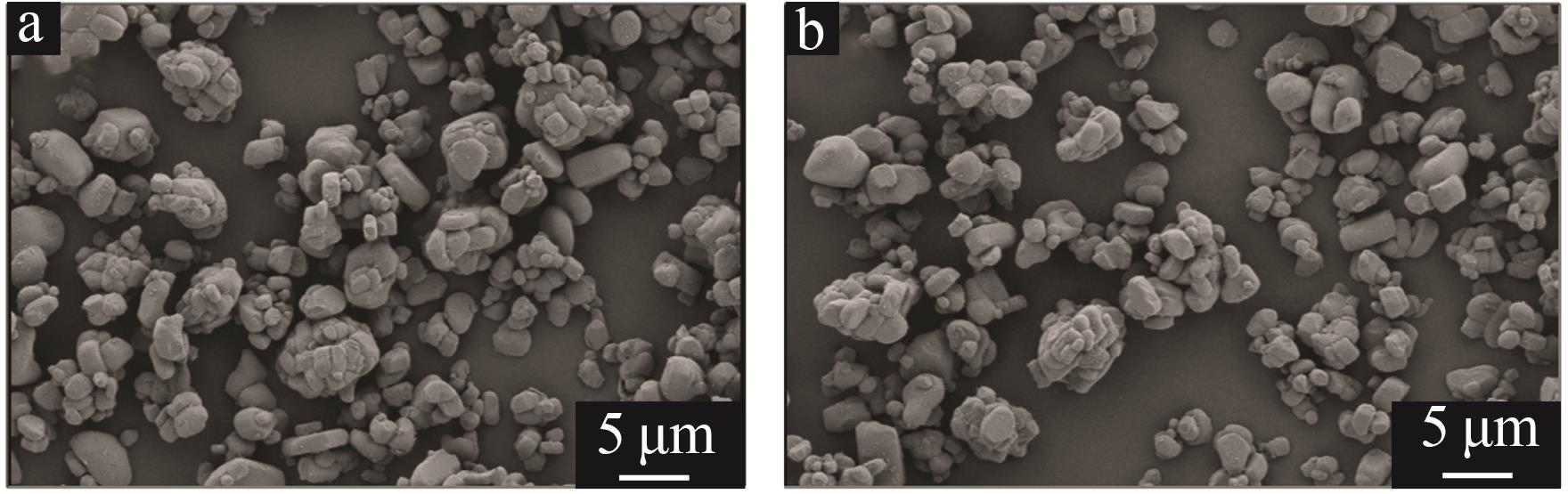

| 所合成正极材料 | 2.5 | D10为3.26 μm;D50为 5.91 μm;D90为10.2 μm | 0.872 4±0.005 1 | 156.2 | 85.2 | 93.4 |

Table 10

| 1 | 焦芬,史柯,覃文庆,等.废旧镍钴锰电池回收工艺及污染控制概述[J].矿冶工程,2021,41(5):153-158. |

| JIAO Feng, SHI Ke, QIN Wenqin,et al.A Review on recycling of spent NCM batteries and pollution control[J].Mining and Metallurgical Engineering,2021,41(5):153-158. | |

| 2 | 周蕾,袁永顺,李璐,等.废旧锂离子电池制备锂离子筛及其应用研究进展[J].无机盐工业,2022,54(8):33-39. |

| ZHOU Lei, YUAN Yongshun, LI Lu,et al.Research progress on preparation and application of lithium ion sieve from spent lithium ion batteries[J].Inorganic Chemicals Industry,2022,54(8):33-39. | |

| 3 | YANG Yue, OKONKWO E G, HUANG Guoyang,et al.On the su-stainability of lithium ion battery industry:A review and perspective[J].Energy Storage Materials,2021,36:186-212. |

| 4 | HOSSAIN R, KUMAR U, SAHAJWALLA V.Selective thermal transformation of value added cobalt from spent lithium-ion batteries[J].Journal of Cleaner Production,2021,293:126140. |

| 5 | HU Juntao, ZHANG Jialing, LI Hongxu,et al.A promising approach for the recovery of high value-added metals from spent lithium-ion batteries[J].Journal of Power Sources,2017,351:192-199. |

| 6 | HU Xianfeng, MOUSA E, TIAN Yang,et al.Recovery of Co,Ni,Mn,and Li from Li-ion batteries by smelting reduction-Part I:alaboratory-scale study[J].Journal of Power Sources,2021,483:228936. |

| 7 | ATIA T A, ELIA G, HAHN R,et al.Closed-loop hydrometallurgical treatment of end-of-life lithium ion batteries:Towards zerowaste process and metal recycling in advanced batteries[J].Journal of Energy Chemistry,2019,35:220-227. |

| 8 | CHEN Xiangping, CAO Ling, KANG Duozhi,et al.Recovery of valuable metals from mixed types of spent lithium ion batteries.Part Ⅱ:Selective extraction of lithium[J].Waste Management,2018,80:198-210. |

| 9 | GUO Mingming, LI Kan, LIU Lizhong,et al.Resource utilization of spent ternary lithium-ions batteries:Synthesis of highly active manganesebased perovskite catalyst for toluene oxidation[J].Journal of the Taiwan Institute of Chemical Engineers,2019,102:268-275. |

| 10 | XIN Yayun, GUO Xingming, CHEN Shi,et al.Bioleaching of valuable metals Li,Co,Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery[J].J Clean Prod,2016,116:249-258. |

| 11 | 陈亮,唐新村,张阳,等.从废旧锂离子电池中分离回收钴镍锰[J].中国有色金属学报,2011,21(5):1192-1198. |

| CHEN Liang, TANG Xincun, ZHANG Yang,et al.Separation and recovery of Ni,Co and Mn from spent lithium-ion batteries[J].The Chinese Journal of Nonferrous Metals,2011,21(5):1192-1198. | |

| 12 | NGUYEN V N H, LEE M S.Separation of Co(Ⅱ),Ni(Ⅱ),Mn(Ⅱ) and Li(Ⅰ) from synthetic sulfuric acid leaching solution of spent lithium ion batteries by solvent extraction[J].Journal of Chemical Technology & Biotechnology,2021,96(5):1205-1217. |

| 13 | 丁颖.废旧氢镍、镉镍电池正极材料回收中镍和钴、镁分离的萃取串级研究[J].能源研究与管理,2013(4):36-41. |

| DING Yin, Cascade studies on separation of Nickel,Cobalt and Magnesium during process for recovery of the spent MH-Ni and Cd-Ni batteries anode material[J].Energy Research and Management,2013(4):36-41. |

| [1] | PEI Hongchang, YUE Maowen, LIU Jianlu, LI Zhongfang, CHEN Xiaoyu. Research progress of comprehensive development and efficient utilization of seawater [J]. Inorganic Chemicals Industry, 2024, 56(2): 21-29. |

| [2] | CHEN Haixia, YAN Hong, SUN Yunlong, MA Guoqiang. Research progress of lithium resource extraction technology [J]. Inorganic Chemicals Industry, 2024, 56(1): 9-22. |

| [3] | FU Yu, DENG Mi, HUANG Donggen, WAN Jinbao. Research progress of lithium extraction technology from salt lake brine [J]. Inorganic Chemicals Industry, 2023, 55(9): 9-16. |

| [4] | LU Nana, QIN Yaru, MA Shuqing, WANG Qihui, LIU Bing, SHI Chenglong. Study on extraction of lithium from simulated old brine of salt lake by pyridine ionic liquid system [J]. Inorganic Chemicals Industry, 2023, 55(7): 45-50. |

| [5] | ZHOU Qinglie, WANG Baoqi, ZHANG Zhiye, ZHANG Yinghu, WANG Jian, YANG Lin. Development of new process of removing metal cations from wet-process phosphoric acid by extraction [J]. Inorganic Chemicals Industry, 2023, 55(3): 84-91. |

| [6] | ZHU Ruisong, CAO Jing, LIU Taoran, LI Yingwen, GAO Fei, HU Xuesheng. Research progress of lithium extraction technology and industrialization of unconventional brines in global [J]. Inorganic Chemicals Industry, 2023, 55(11): 1-11. |

| [7] | HU Yue, MO Hengliang, LI Tianyu, PENG Wenjuan, SUN Guangdong, XIAO Hongkang, CHEN Yili, LI Suoding, TANG Yang. Study on spinning molding and performance of Ti-based lithium ion sieve powder and PVDF resin [J]. Inorganic Chemicals Industry, 2023, 55(11): 58-63. |

| [8] | HU Guangshou, LI Huping, ZHOU Wanchun, LI Xiangdong, MA Xuhua. Study on origin of tetravalent cerium in extraction and separation of rare earth [J]. Inorganic Chemicals Industry, 2023, 55(11): 64-69. |

| [9] | JI Ying, ZHANG Ying, HOU Xuechao, ZHU Xiaofeng, JIANG Run, PENG Wenjuan, SUN Guangdong, LÜ Long. Application research of titanium adsorbent of carbonate-type salt lake in Tibet [J]. Inorganic Chemicals Industry, 2023, 55(11): 70-77. |

| [10] | LAI Xianrong, CHEN Zhouqin, SUN Hao, YANG Chao. Pilot study on lithium extraction by adsorption from raw brine of magnesium sulfate subtype salt lakes in Tibet [J]. Inorganic Chemicals Industry, 2023, 55(11): 86-92. |

| [11] | PENG Chenxi, LIU Jun. Research progress of layered transition metal oxides cathode materials for sodium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(10): 1-12. |

| [12] | LI Huifang, WANG Xiao, BAI Youpeng, ZHANG Shixiang. Study on extraction of lithium from low grade high clay leaching solution by solvent extraction [J]. Inorganic Chemicals Industry, 2023, 55(10): 63-69. |

| [13] | LIN Yuqing,ZHANG Yiren,QIU Yulong,ZHANG Jiayu,YU Jianguo. Progress and prospect of membrane technology in lithium extraction from salt lake brine [J]. Inorganic Chemicals Industry, 2023, 55(1): 33-45. |

| [14] | LIU Darui,XU Lijun,LI Shichun,CAO Kun,TU Ya,LI Wenqing,LIU Qingliang. Research progress of recovery of strategic metal lithium from fly ash [J]. Inorganic Chemicals Industry, 2023, 55(1): 56-63. |

| [15] | WANG Ping. Quantitative analysis of linkage between lithium supply and demand and lithium price [J]. Inorganic Chemicals Industry, 2022, 54(9): 1-13. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||