Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (3): 84-91.doi: 10.19964/j.issn.1006-4990.2022-0262

• Industrial Techniques • Previous Articles Next Articles

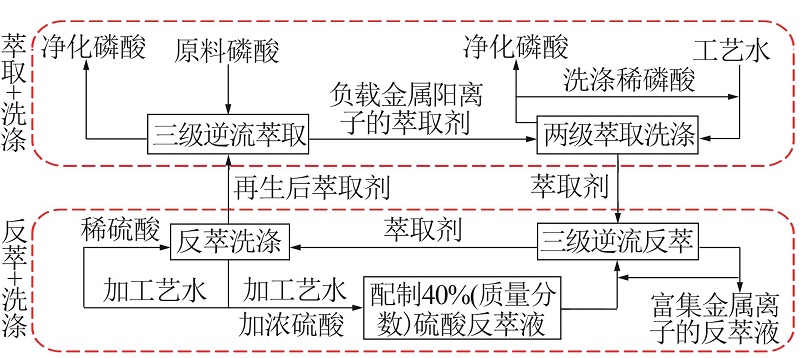

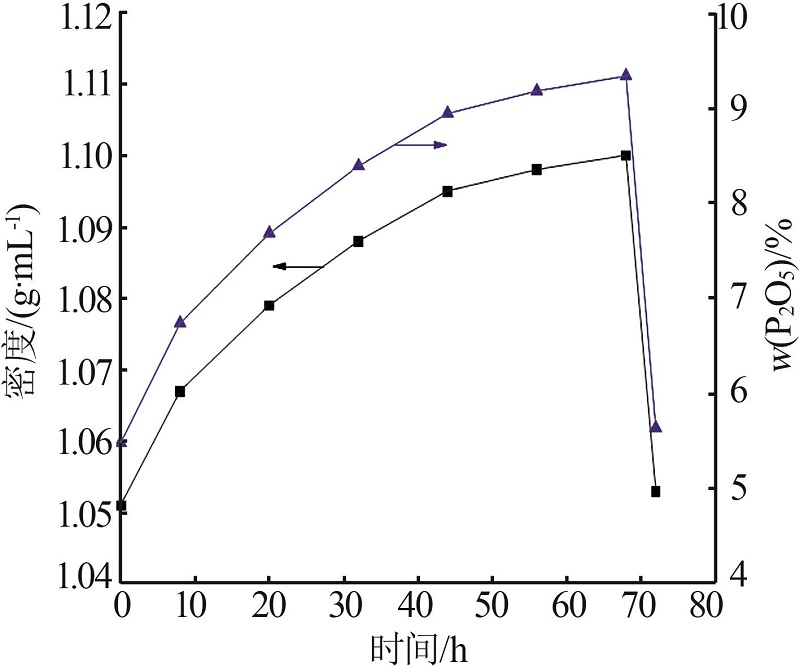

Development of new process of removing metal cations from wet-process phosphoric acid by extraction

ZHOU Qinglie1( ), WANG Baoqi1, ZHANG Zhiye1, ZHANG Yinghu2, WANG Jian2, YANG Lin1(

), WANG Baoqi1, ZHANG Zhiye1, ZHANG Yinghu2, WANG Jian2, YANG Lin1( )

)

- 1. School of Chemical Engineering, Sichuan University, Chengdu 610065, China

2. YUNTIANHUA Group, Kunming 650228, China

-

Received:2022-06-07Online:2023-03-10Published:2023-03-17 -

Contact:YANG Lin E-mail:346086995@qq.com;18980632893@163.com

CLC Number:

Cite this article

ZHOU Qinglie, WANG Baoqi, ZHANG Zhiye, ZHANG Yinghu, WANG Jian, YANG Lin. Development of new process of removing metal cations from wet-process phosphoric acid by extraction[J]. Inorganic Chemicals Industry, 2023, 55(3): 84-91.

share this article

| 1 | 郑东钥,唐盛伟,吕莉.盐酸分解高硅混合型胶磷矿工艺研究[J].无机盐工业,2021,53(2):81-83,104. |

| ZHENG Dongyao, TANG Shengwei,Li LÜ.Study on process of hydrochloric acid leaching high silicon mixed phosphate ore[J].Inorganic Chemicals Industry,2021,53(2):81-83,104. | |

| 2 | 张苏江,易锦俊,孔令湖,等.中国磷矿资源现状及磷矿国家级实物地质资料筛选[J].无机盐工业,2016,48(2):1-5,17. |

| ZHANG Sujiang, YI Jinjun, KONG Linghu,et al.Current status of phosphorite-ore resources in China and screening for national-class physical geological data of phopshorite[J].Inorganic Chemicals Industry,2016,48(2):1-5,17. | |

| 3 | 傅忠德.浅谈湿法磷酸的生产方法[J].化学工程与装备,2010(7):138-139. |

| FU Zhongde.Talking about the production method of wet-process phosphoric acid[J].Chemical Engineering & Equipment,2010(7):138-139. | |

| 4 | 匡国明.湿法磷酸工艺路线的探讨[J].无机盐工业,2013,45(4):1-4. |

| KUANG Guoming.Discussion on process routes of wet-process phosphoric acid[J].Inorganic Chemicals Industry,2013,45(4):1-4. | |

| 5 | 李维红.湿法磷酸装置管道除垢技术进展[J].磷肥与复肥,2022,37(1):47-48. |

| LI Weihong.Development of pipeline descaling technology in wet-process phosphoric acid plant[J].Phosphate & Compound Fertilizer,2022,37(1):47-48. | |

| 6 | 杨林军,张志炳,张允湘,等.湿法磷酸过滤管道系统氟硅酸钾(钠)结垢沉积模型[J].化工学报,2003,54(10):1407-1412. |

| YANG Linjun, ZHANG Zhibing, ZHANG Yunxiang,et al.Modeling of potassium(sodium) fluosilicate scale formation in wet-process phosphoric acid production[J].Journal of Chemical Industry and Engineering (China),2003,54(10):1407-1412. | |

| 7 | 王永贵,朱志华,陈坦,等.湿法磷酸中继沉淀盐的组成与防治[J].磷肥与复肥,2009,24(2):30-32,92. |

| WANG Yonggui, ZHU Zhihua, CHEN Tan,et al.The components of post precipitation salts from WPA and its prevention and control[J].Phosphate & Compound Fertilizer,2009,24(2):30-32,92. | |

| 8 | 路超,张伟,刘杰,等.氧化-沉淀法净化湿法磷酸的研究[J].无机盐工业,2011,43(9):49-51. |

| LU Chao, ZHANG Wei, LIU Jie,et al.Study on purification of wet-process phosphoric acid by oxidation and precipitation methods[J].Inorganic Chemicals Industry,2011,43(9):49-51. | |

| 9 | 陈爱梅.熔融悬浮结晶法提纯湿法磷酸[D].上海:华东理工大学,2012. |

| CHEN Aimei.Purification of phosphoric acid by melt suspension crystallization[D].Shanghai:East China University of Science and Technology,2012. | |

| 10 | 吴惠芳,周骏宏,方进.三聚氰胺复盐结晶法净化湿法磷酸萃余酸制磷酸氢二钠的研究[J].现代化工,2015,35(6):81-82,84. |

| WU Huifang, ZHOU Junhong, FANG Jin.Melamine salt crystallization process for purifying wet-process phosphoric acid raffinate to prepare disodium hydrogen phosphate[J].Modern Chemical Industry,2015,35(6):81-82,84. | |

| 11 | 李新柱,郭宗端,贾亮,等.甲醇沉淀法净化湿法磷酸制备工业级磷酸一铵[J].无机盐工业,2016(2):40-41,67. |

| LI Xinzhu, GUO Zongduan, JIA Liang,et al.Preparation of industrial mono-ammonium phosphate from wet process phosphoric acid purified by methanol precipitation method[J].Inorganic Chemicals Industry,2016(2):40-41,67. | |

| 12 | 朱芳,周贵云,陈建钧,等.氢氧化钠中和法净化湿法磷酸的研究[J].磷肥与复肥,2017,32(5):11-13. |

| ZHU Fang, ZHOU Guiyun, CHEN Jianjun,et al.Study on purification of wet-process phosphoric acid by neutralization from sodium hydroxide[J].Phosphate & Compound Fertilizer,2017,32(5):11-13. | |

| 13 | ZHUANG Haibo, ZHONG Yanjun, YANG Lin,et al.Adsorption equilibrium and kinetics studies of divalent manganese from phosphoric acid solution by using cationic exchange resin[J].Chinese Journal of Chemical Engineering,2020,28(11):2758-2770. |

| 14 | LENG Xinke, ZHONG Yanjun, XU Dehua,et al.Mechanism and kinetics study on removal of Iron from phosphoric acid by cation exchange resin[J].Chinese Journal of Chemical Engineering,2019,27(5):1050-1057. |

| 15 | FEKI M, AYEDI H F.Purification of wet process phosphoric acid by solvent extraction with methyl isobutyl ketone:Systematic study of impurity distribution[J].Separation Science and Technology,1998,33(16):2609-2622. |

| 16 | HMAMOU M, AMMARY B, BELLAOUCHOU A,et al.Liquid-liquid extraction of zinc from phosphoric acid solution by acid di (2-ethylhexyl) phosphoric[J].Materials Today:Proceedings,2020,24:1-6. |

| 17 | 冉瑞泉,金央,刘辉,等.溶剂萃取法净化盐酸法湿法磷酸的研究进展[J].无机盐工业,2021,53(7):18-22. |

| RAN Ruiquan, JIN Yang, LIU Hui,et al.Research progress purification of solvent extraction of wet-process phosphoric acid by hydrochloric acid route[J].Inorganic Chemicals Industry,2021,53(7):18-22. | |

| 18 | HU Jiashi, ZOU Dan, CHEN Ji,et al.A novel synergistic extraction system for the recovery of scandium(Ⅲ) by Cyanex272 and Cyanex923 in sulfuric acid medium[J].Separation and Purification Technology,2020,233.Doi:10.1016/j.seppur.2019.115977. |

| 19 | 杜怀明,罗容珍,刘兴勇,等.萃余酸净化利用的现状与展望[J].四川理工学院学报:自然科学版,2011,24(1):94-97. |

| DU Huaiming, LUO Rongzhen, LIU Xingyong,et al.Purifying application and expection of raffinate of wet-process phosphoric acid[J].Journal of Sichuan University of Science & Engineering:Natural Science Edition,2011,24(1):94-97. | |

| 20 | 罗珍,曾波,罗康碧,等.湿法磷酸萃取净化副产萃余酸利用研究进展[J].化工矿物与加工,2014,43(12):60-63. |

| LUO Zhen, ZENG Bo, LUO Kangbi,et al.Progress on research of utilization of extraction residual acid by-product of extraction purification of wet-process phosphoric acid[J].Industrial Minerals & Processing,2014,43(12):60-63. | |

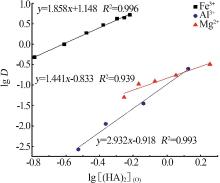

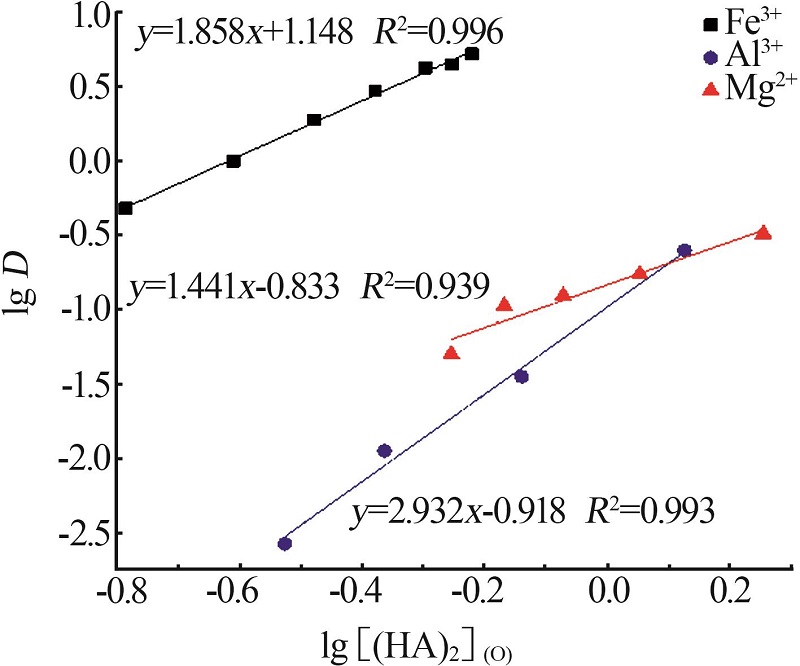

| 21 | JIN Yang, MA Yujing, WENG Yanling,et al.Solvent extraction of Fe3+ from the hydrochloric acid route phosphoric acid by D2EHPA in kerosene[J].Journal of Industrial and Engineering Chemistry,2014,20(5):3446-3452. |

| 22 | 余静,刘代俊,杜怀明,等.反胶团萃取磷酸溶液中的镁[J].高校化学工程学报,2008,22(3):401-406. |

| YU Jing, LIU Daijun, DU Huaiming,et al.Reverse micelles extraction of magnesium from phosphoric acid solution[J].Journal of Chemical Engineering of Chinese Universities,2008,22(3):401-406. | |

| 23 | 黄懿,张志业,王辛龙,等.溶剂萃取法脱除湿法磷酸中锰离子的实验研究[J].磷肥与复肥,2018,33(4):5-7. |

| HUANG Yi, ZHANG Zhiye, WANG Xinlong,et al.Study on removal of manganese from WPA by solvent extraction method[J].Phosphate & Compound Fertilizer,2018,33(4):5-7. | |

| 24 | 李云巧,于志辉,崔婷,等.磷钼酸喹啉重量法测定溶液中磷的不确定度评定[J].计量技术,2005(6):52-54. |

| LI Yunqiao, YU Zhihui, CUI Ting,et al.Evaluation of uncertainty in the determination of phosphorus in solution by Quinoline phosphomolybdate gravimetric method[J].Measurement Technique,2005(6):52-54. | |

| 25 | 黄可龙,舒万艮.酸性有机磷萃取剂的研究及其应用[J].湖南有色金属,1987,3(2):35-39. |

| HUANG Kelong, SHU Wangen.Study and application of acidic organophosphorus extractant[J].Hunan Nonferrous Metals,1987,3(2):35-39. | |

| 26 | TSAKIRIDIS P E.Solvent extraction of aluminium in the presence of cobalt,nickel and magnesium from sulphate solutions by Cyanex 272[J].Hydrometallurgy,2005,80(1/2):90-97. |

| 27 | 金丹,付海玲,吴剑华,等.SK静态混合器内停留时间分布的影响因素分析[J].石油化工高等学校学报,2011,24(3):70-74. |

| JIN Dan, FU Hailing, WU Jianhua,et al.Analysis for the effect of factors on residence time distribution in kenics static mixer[J].Journal of Petrochemical Universities,2011,24(3):70-74. | |

| 28 | 杨林.萃取法脱除湿法磷酸金属阳离子中试研究取得成功[J].磷肥与复肥,2020,35(12):19. |

| YANG Lin.The pilot study on the removal of metal cations from wet process phosphoric acid by extraction was successful[J].Phosphate & Compound Fertilizer,2020,35(12):19. |

| [1] | LIU Xinlong, YANG Zhenyu, HAO He, LIU Shuxin, WU Chenyang, WANG Xingli, MA Qingqing. Study on shaped 4A zeolite synthesized with aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 78-85. |

| [2] | LI Yongxiang, YANG Xiaolong, LU Zhonghai, MA Hang, WAN Banglong, LI Yundong. Research progress of flame retardant application of ammonium poly-phosphate [J]. Inorganic Chemicals Industry, 2024, 56(5): 20-30. |

| [3] | HUANG Tao, HUANG Zili, XIAO Shuo, ZHENG Jiemiao, LIU Xiaofeng, WU Jilong. Experimental study on preparation of polyferric chloride from iron tailings acid leaching solution [J]. Inorganic Chemicals Industry, 2024, 56(2): 121-126. |

| [4] | ZHANG Li, ZHANG Dan, PAN Hongyan, DONG Yonggang, LI Wenfei, QIN Hong. Study on preparation of low ash activated carbon by phosphoric acid method [J]. Inorganic Chemicals Industry, 2024, 56(2): 95-103. |

| [5] | CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, ZUO Shuo, QIN Donglan, ZHOU Na, WANG Jiaqin. Study on agglomeration phenomenon and regulation method of lithium carbonate crystal prepared from potassium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(10): 47-54. |

| [6] | ZHU Jian, DONG Guangfeng, CHEN Peng, JIA Feifei, MA Songliang, LIU Zhongjian, XIANG Xiaocheng. Study on influence mechanism of particle size composition of potassium mixed salt on its conversion flotation [J]. Inorganic Chemicals Industry, 2024, 56(10): 64-69. |

| [7] | ZHANG Ying, LI Jun, JIN Yang, HUANG Meiying. Study on pyrolysis regeneration of activated carbon for Tributyl phosphate decolorization [J]. Inorganic Chemicals Industry, 2024, 56(1): 59-66. |

| [8] | ZHAO Yan, HAO Xuewei, SHI Hainan, LI Jiahui, LI Keyan, GUO Xinwen. Study on photocatalytic CO2 reduction performance of Cu-doped TiO2/PCN heterojunction [J]. Inorganic Chemicals Industry, 2023, 55(8): 21-27. |

| [9] | REN Teng, LI Shengdong, WANG Dexi, CHU Fuzhou, SHAO Lixin. Numerical simulation analysis of influence of jet position on mixing effect of carbonization reactor [J]. Inorganic Chemicals Industry, 2023, 55(7): 109-114. |

| [10] | ZHAO Liping, WANG Fei. Effect of amine-functionalized graphene oxide on mechanical properties of cement composites [J]. Inorganic Chemicals Industry, 2023, 55(3): 66-70. |

| [11] | LIU Xueting, MAO Lingfeng, HU Yun, PENG Xi, FAN Xuemei, CHEN Yanlei, LIU Wenkui. Synergistic dispersion of SiO2 by dispersant and supershear [J]. Inorganic Chemicals Industry, 2023, 55(3): 71-77. |

| [12] | WANG Jinji, ZHAO Liang, ZHANG Menghui, XU Hanlu, DONG Hui. Numerical simulation of thermal characteristics in magnesium chloride pilot pyrolysis furnace [J]. Inorganic Chemicals Industry, 2023, 55(12): 140-145. |

| [13] | SUN Zhigao, WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang. Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer [J]. Inorganic Chemicals Industry, 2023, 55(11): 139-146. |

| [14] | TAN Ying, LI Chongyi, YU Xiaoguang, LIAO Hongguang, YAN Xin. Bimetal doped SBA-15 catalytic synthesis of bisphenol F and its isomers regulation [J]. Inorganic Chemicals Industry, 2023, 55(11): 147-152. |

| [15] | LI Huifang, WANG Xiao, BAI Youpeng, ZHANG Shixiang. Study on extraction of lithium from low grade high clay leaching solution by solvent extraction [J]. Inorganic Chemicals Industry, 2023, 55(10): 63-69. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||