Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (11): 64-69.doi: 10.19964/j.issn.1006-4990.2022-0743

• Research & Development • Previous Articles Next Articles

Study on origin of tetravalent cerium in extraction and separation of rare earth

HU Guangshou( ), LI Huping(

), LI Huping( ), ZHOU Wanchun, LI Xiangdong, MA Xuhua

), ZHOU Wanchun, LI Xiangdong, MA Xuhua

- Gansu Rare Earth New Material Limited-Liability Company,Baiyin 730922,China

-

Received:2022-12-09Online:2023-11-10Published:2023-11-16 -

Contact:LI Huping E-mail:422696923@qq.com;649128876@qq.com

CLC Number:

Cite this article

HU Guangshou, LI Huping, ZHOU Wanchun, LI Xiangdong, MA Xuhua. Study on origin of tetravalent cerium in extraction and separation of rare earth[J]. Inorganic Chemicals Industry, 2023, 55(11): 64-69.

share this article

| 1 | 黄伟光,胡贤君,李景芬.稀土永磁材料的发展趋势[J].功能材料与器件学报,2022,28(6):513-517. |

| HUANG Weiguang, HU Xianjun, LI Jingfen.Developing of rare-earth permanent magnetic materials[J].Journal of Functional Materials and Devices,2022,28(6):513-517. | |

| 2 | 申立汉.稀土永磁材料国内外标准对比研究[J].中国有色金属,2022(12):42-45. |

| SHEN Lihan.Comparative study on domestic and foreign standards of rare earth permanent magnet materials[J].China Nonferrous Metals,2022(12):42-45. | |

| 3 | 董睿.稀土永磁材料在信息技术中的运用研究[J].世界有色金属,2021(19):166-167. |

| DONG Rui.Application of rare earth permanent magnet materials in information technology[J].World Nonferrous Metals,2021(19):166-167. | |

| 4 | 邹婧玲.乘风破浪:稀土永磁新时代发展浅析[J].中国有色金属,2021(17):46-49. |

| ZOU Jingling.Riding the wind and breaking the waves:Analysis on the development of rare earth permanent magnet in the new era[J].China Nonferrous Metals,2021(17):46-49. | |

| 5 | 胡胜龙,刘秋生,刘静,等.我国永磁材料行业现状及其发展趋势[J].磁性材料及器件,2021,52(4):83-87. |

| HU Shenglong, LIU Qiusheng, LIU Jing,et al.Present situation and development trend of permanent magnet materials in China[J].Journal of Magnetic Materials and Devices,2021,52(4):83-87. | |

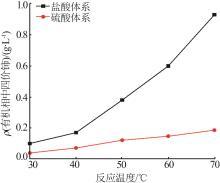

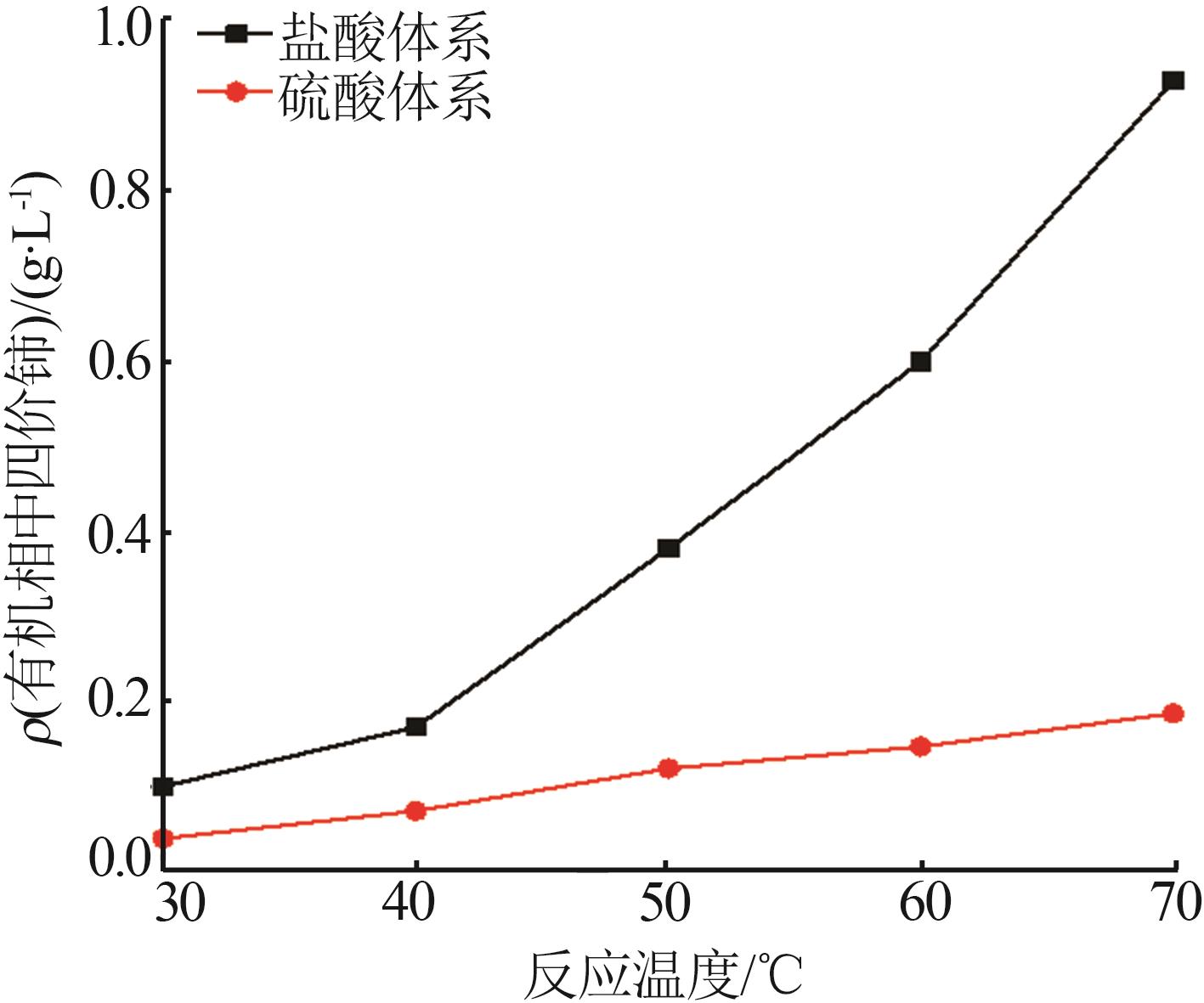

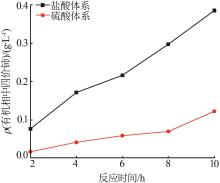

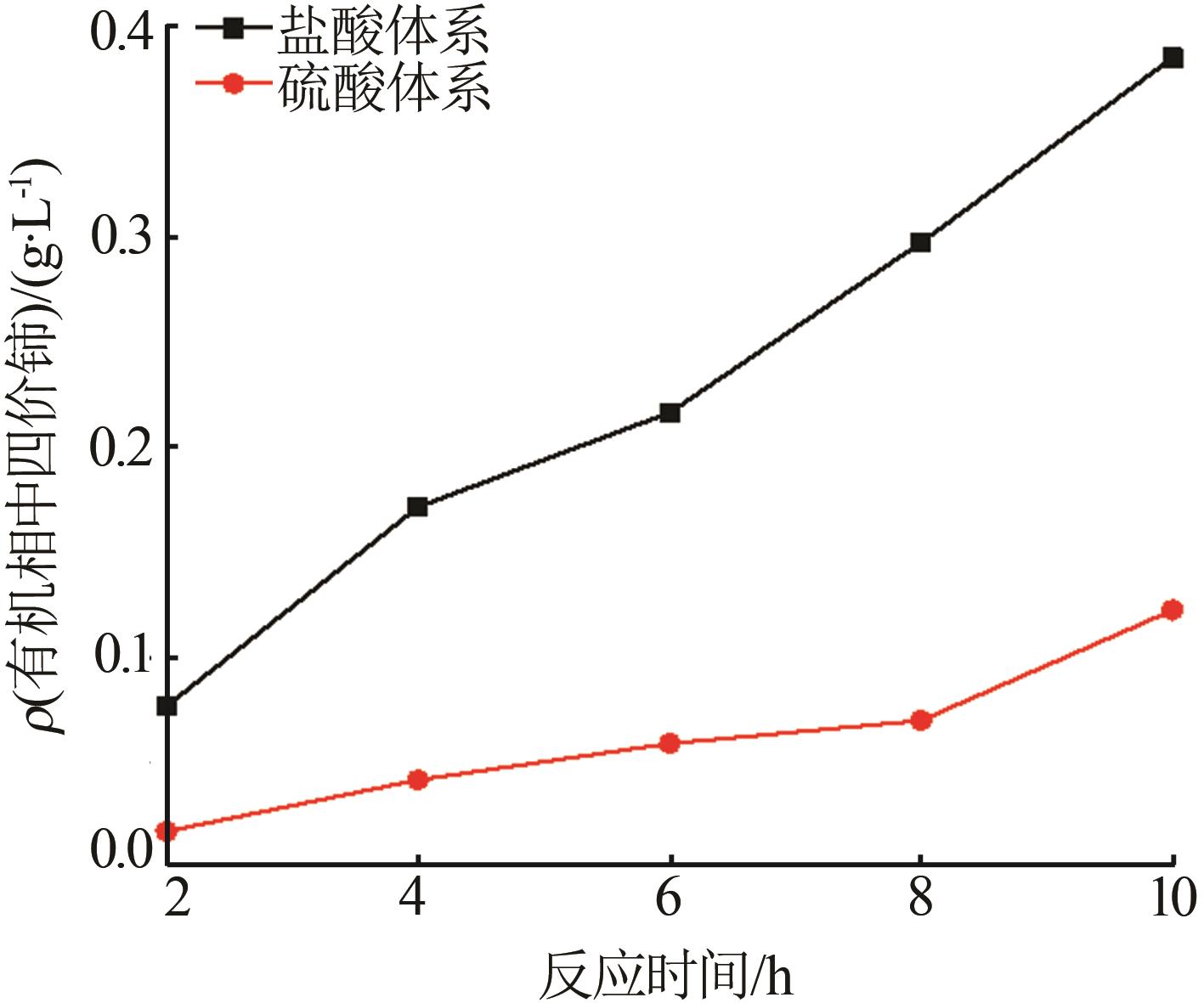

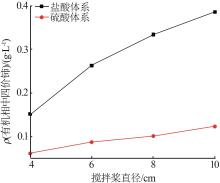

| 6 | 刘营,龙志奇,黄文梅,等.从含氟硫酸稀土溶液中萃取铈过程产生第三相的原因[J].中国稀土学报,2001,19(4):320-323. |

| LIU Ying, LONG Zhiqi, HUANG Wenmei,et al.The third phase precipitated from organic phase in solvent extraction Ce4+ from fluorine-bearing rare earth sulfate solution[J].Journal of the Chinese Rare Earth Society,2001,19(4):320-323. | |

| 7 | 龙志奇,黄小卫,黄文梅,等.二(2-乙基己基)磷酸从含氟稀土硫酸溶液中萃取铈的机制[J].中国稀土学报,2000,18(1):18-20. |

| LONG Zhiqi, HUANG Xiaowei, HUANG Wenmei,et al.Ce4+ extraction mechanism from rare earth sulfate solution containing fluorine with DEHPA[J].Journal of the Chinese Rare Earth Society,2000,18(1):18-20. | |

| 8 | 张虎军,欧阳森林,谢耀,等.一种高铈镨钕稀土料液除铈的方法:中国,115232965B[P].2023-05-09. |

| 9 | 王良士.非皂化萃取分离稀土、钍、氟过程机制及调控技术研究[D].北京:北京有色金属研究总院,2014. |

| WANG Liangshi.Mechanism and process control technology on the separation and purification of rare earths,thorium and fluorine without saponification[D].Beijing:Beijing General Research Institute of Nonferrous Metals,2014. | |

| 10 | 帅庚洪.氟碳铈矿氧化焙烧—盐酸浸出过程反应机理研究[D].北京:北京有色金属研究总院,2017. |

| SHUAI Genghong.Study on reaction mechanism of the process involving oxidation roasting and hydrochloric acid leaching of bastnaesite[D].Beijing:Beijing General Research Institute of Nonferrous Metals,2017. | |

| 11 | 张栋梁.混合型稀土精矿中三价/四价铈的酸浸行为及其氟、钙资源转化的基础研究[D].北京:北京化工大学,2019. |

| ZHANG Dongliang.Basic research on acid leaching behavior of Ce3+/Ce4+ in mixed rare earth concentrates and conversion of fluoride and calcium resources[D].Beijing:Beijing University of Chemical Technology,2019. | |

| 12 | 刘建刚,刘建军,方斌,等.硫酸介质中铈的电解氧化及提铈工业试验研究[C]//中国稀土学会第四届学术年会论文集.北京,2000:164-168. |

| 13 | 孙军,区海锋,杨桂林.萃取稀土(铈)过程中乳化的消除方法:中国,1027547C[P].1995-02-01. |

| 14 | 杨幼明,曹建明,徐耗祥,等.一种稀土料液除铈及非稀土杂质的方法:中国,111996396A[P].2020-11-27. |

| 15 | 饶向东,李炳伟,南胜刚,等.一种降低氯化镨钕中铈含量的方法、一种氧化镨钕的制备方法:中国,114162846A[P].2022-03-11. |

| 16 | 张兆兵.氧化萃取法提铈工艺中P204萃取能力下降因素分析[C]//第九届全国稀土化学与湿法冶金学术会议专辑.广州,2005:108-111. |

| 17 | 朱红伟,姜杰,孙冰,等.双氧水氧化工艺安全研究策略[J].无机盐工业,2021,53(1):77-81. |

| ZHU Hongwei, JIANG Jie, SUN Bing,et al.Strategy on safety of hydrogen peroxide oxidation process[J].Inorganic Chemicals Industry,2021,53(1):77-81. | |

| 18 | 张其昕,刘佑襁.稀土原料中铈的分离及纯氧化铈的制备[J].福建师范学院学报,1963(2):45-54. |

| ZHANG Qixin, LIU Youqiang.The separation of cerium from rare earth raw materials and the preparation pure ceriun dioxide[J].Journal of Fujian Normal University,1963(2):45-54. | |

| 19 | 董福柱,韩学印.高纯氧化铈的提取工艺研究[J].稀土,1997,18(1):70-72. |

| DONG Fuzhu, HAN Xueyin.Study on extraction technology of high purity cerium oxide[J].Chinese Rare Earths,1997,18(1):70-72. | |

| 20 | 方建章,王向德,万印华,等.氧化还原乳状液膜法自轻稀土中分离铈的研究[J].膜科学与技术,1997,17(5):52-59. |

| FANG Jianzhang, WANG Xiangde, WAN Yinhua,et al.Study on the seperation of Ce from light rare earths by oxidation-reduction emulsion liquid membrane method[J].Membrane Science and Technology,1997,17(5):52-59. | |

| 21 | 张永华,李婷婷,邢全生.盐酸体系中制备氢氧化铈的工艺研究[J].包钢科技,2020,46(2):34-37. |

| ZHANG Yonghua, LI Tingting, XING Quansheng.Technical study on preparing cerium hydroxide in hydrochloric acid system[J].Science & Technology of Baotou Steel,2020,46(2):34-37. | |

| 22 | 邓少刚,郭丽潇,武明亮,等.四价铈再生工艺研究进展[J].无机盐工业,2018,50(4):15-18,48. |

| DENG Shaogang, GUO Lixiao, WU Mingliang,et al.Research progress in regeneration technology of cerium with valence 4[J].Inorganic Chemicals Industry,2018,50(4):15-18,48. | |

| 23 | 郝先库,张瑞祥,刘海旺,等.还原萃取法制备荧光级氧化铕萃取剂自保护工艺:中国,1715427A[P].2006-01-04. |

| 24 | 牟保畏.包头稀土精矿碱饼中铈的氧化研究[D].呼和浩特:内蒙古大学,2011. |

| MOU Baowei.Study on oxidation of cerium in alkaline cake of Baotou rare earth concentrate[D].Hohhot:Inner Mongolia University,2011. | |

| 25 | 潘延波,刘敬军,黄志钰,等.Ce3+的臭氧氧化动力学研究[J].高校化学工程学报,2014,28(5):998-1003. |

| PAN Yanbo, LIU Jingjun, HUANG Zhiyu,et al.Kinetics study on the ozonation process of Ce3+ [J].Journal of Chemical Engineering of Chinese Universities,2014,28(5):998-1003. | |

| 26 | 韩健.氮气氧气在溶气水中的溶解过程研究[J].西安文理学院学报(自然科学版),2017,20(4):87-91. |

| HAN Jian.Study on the dissolution process of oxygen and nitrogen in dissolved water[J].Journal of Xi′an University (Natural Science Edition),2017,20(4):87-91. | |

| 27 | 徐光宪,袁承业.稀土的溶剂萃取[M].北京:科学出版社,2010. |

| 28 | 张宇旭.混合氯化稀土选择性沉淀铈元素工艺条件的研究[D].包头:内蒙古科技大学,2020. |

| ZHANG Yuxu.Study on process conditions for selective precipitation of Ce elements by mixed rare earth chloride[D].Baotou:Inner Mongolia University of Science & Technology,2020. | |

| 29 | 任秀莲,魏琦峰.混合稀土中铈的氧化分离法及其应用[J].阴山学刊,1995,8(S1):58-62. |

| REN Xiulian, WEI Qifeng.Oxidation separation method of cerium in mixed rare earth and its application[J].Yin Shan Acadimic Journal,1995,8(S1):58-62. | |

| 30 | 包钢冶金研究所湿法二组.铈(Ⅲ)的湿法加压空气氧化[J].稀土,1974(1):1-5. |

| Baotou Steel Metallurgical Research Institute wet method Group 2.Wet air oxidation of cerium(Ⅲ)[J].Chinese Rare Earths,1974(1):1-5. | |

| 31 | 王猛,徐旸,赵龙胜,等.稀土采选冶绿色标准现状及发展趋势分析[J].中国稀土学报,2022,40(6):1021-1031. |

| WANG Meng, XU Yang, ZHAO Longsheng,et al.Analysis on current situation and development trend of green standards for rare earth mining,benefication and metallurgy[J].Journal of the Chinese Society of Rare Earths,2022,40(6):1021-1031. | |

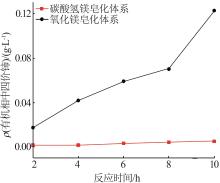

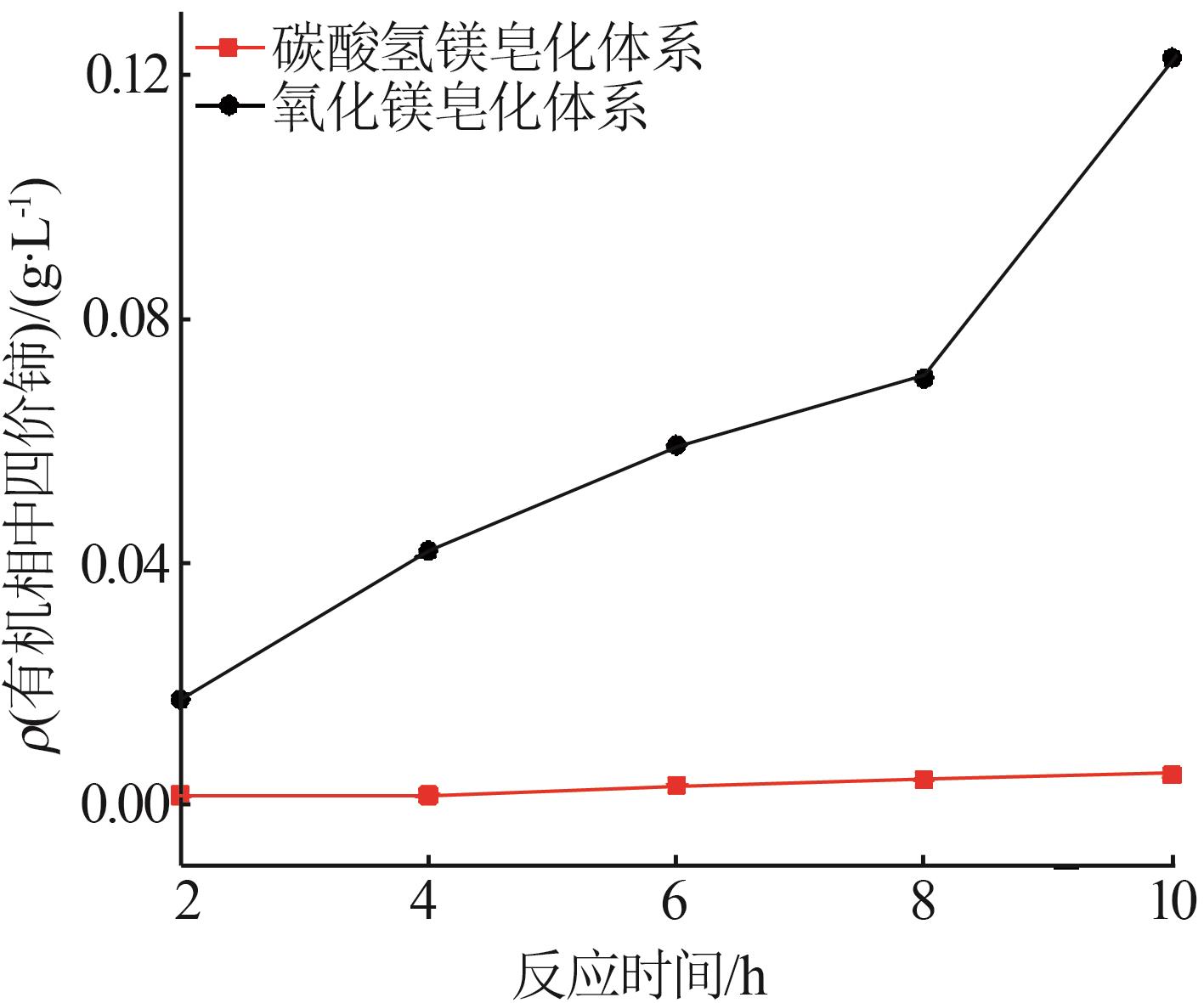

| 32 | 王斌,李虎平,胡广寿,等.不同镁盐在硫酸萃取体系下皂化P507的对比[J].世界有色金属,2019(7):252-253. |

| WANG Bin, LI Huping, HU Guangshou,et al.Comparison of P507 saponified by different magnesium salts in sulfuric acid extraction system[J].World Nonferrous Metals,2019(7):252-253. | |

| 33 | 吕昊.碳酸氢镁介稳溶液应用于萃取分离稀土过程中的基础研究[D].北京:北京有色金属研究总院,2018. |

| Hao LÜ.Basic research on the application of magnesium bicarbonate solution in the extraction and separation of rare earth[D].Beijing:Beijing Nonferrous Metals Research Institute,2018. | |

| 34 | 冯宗玉,王猛,赵龙胜,等.稀土元素萃取分离提纯技术发展现状与展望[J].中国稀土学报,2021,39(3):469-478. |

| FENG Zongyu, WANG Meng, ZHAO Longsheng,et al.Development status and prospect of rare earth extraction and separation technology[J].Journal of the Chinese Society of Rare Earths,2021,39(3):469-478. |

| [1] | LIU Xinlong, YANG Zhenyu, HAO He, LIU Shuxin, WU Chenyang, WANG Xingli, MA Qingqing. Study on shaped 4A zeolite synthesized with aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 78-85. |

| [2] | LI Chao, WANG Liping, GAO Guimei, ZHANG Yunfeng, HONG Yu, LIU Darui, XU Lijun, CUI Yongjie. Study on reaction mechanism of acid leaching lithium from circulating fluidized bed fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 101-107. |

| [3] | KONG Lingjie, LI Guangbi, XIE Jiahao, YANG Xinhui, BAI Xiaoqin. Research progress on lithium extraction technology from salt lake brine [J]. Inorganic Chemicals Industry, 2025, 57(1): 14-26. |

| [4] | ZHOU Wanji, LI Sixia. Study on extraction lithium from brine with high magnesium using ionic liquid/metal salt extraction system [J]. Inorganic Chemicals Industry, 2024, 56(9): 54-59. |

| [5] | MA Shuqing, LI Changwen, SHI Chenglong, QIN Yaru. Kinetic study of lithium extraction from solution with iron-based ionic liquid system [J]. Inorganic Chemicals Industry, 2024, 56(9): 60-66. |

| [6] | WANG Yong, LI Jixia, ZHANG Guisheng, WANG Pengfei, WANG Benlei. Determination of rhodium for catalyst solution of 2-Propylheptanol [J]. Inorganic Chemicals Industry, 2024, 56(9): 142-146. |

| [7] | JIAN Chengzong, JIANG Ziwen, QUAN Xuejun, LI Gang. Eco⁃friendly extraction of chromium from calcium⁃free roasting slag of chromite ore [J]. Inorganic Chemicals Industry, 2024, 56(7): 118-125. |

| [8] | AI Xin, DONG Qi, DOU Yefan, LI Enze, CHENG Huaigang, PAN Zihe. Research progress of functionalization and modification of crown ether and its application in metal ion separation [J]. Inorganic Chemicals Industry, 2024, 56(6): 14-25. |

| [9] | PEI Hongchang, YUE Maowen, LIU Jianlu, LI Zhongfang, CHEN Xiaoyu. Research progress of comprehensive development and efficient utilization of seawater [J]. Inorganic Chemicals Industry, 2024, 56(2): 21-29. |

| [10] | FU Yu, ZHANG Boshuang, YANG Jianmao, LIU Jianyun. Research progress of lithium manganese oxide materials in electrochemical lithium extraction applications [J]. Inorganic Chemicals Industry, 2024, 56(12): 62-69. |

| [11] | YUAN Shuai, FANG Yangfei, YANG Xiangguang, ZHANG Yibo. Study on synthesis of rare earth-doped CeO2 and its CMP properties [J]. Inorganic Chemicals Industry, 2024, 56(12): 35-41. |

| [12] | QUAN Jiayuan, FU Chunyan, DENG Bicheng, HUANG Yabin, KUANG Wangqiang, KUANG Shengting, LIAO Wuping. Study on selective electrosorption of thorium by carbon material containing aminophosphonate functional group [J]. Inorganic Chemicals Industry, 2024, 56(12): 42-50. |

| [13] | ZHAO Shiyong, XIAO Yuchen, MA Qingqing, YANG Zhenni, WANG Jizhen, FAN Xiaoping. Study on adsorption of Cu(Ⅱ) on 4A zeolite synthesized by aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2024, 56(10): 127-134. |

| [14] | XIA Guiying, YANG Liuchun, YUAN Zhiye. Study on direct leaching of rare earth elements from phosphogypsum with sulfuric acid [J]. Inorganic Chemicals Industry, 2024, 56(1): 107-113. |

| [15] | JIN Shengshi, LIU Kaijie, LIU Qiuwen, ZHANG Yibo, YANG Xiangguang. Study on catalytic performance of phosphoric acid modified CeO2 nanorod supported Pt catalyst for propane combustion [J]. Inorganic Chemicals Industry, 2024, 56(1): 141-148. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||