Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (12): 18-25.doi: 10.19964/j.issn.1006-4990.2025-0021

• Research & Development • Previous Articles Next Articles

Study on coating modification and electrochemical performance investigation of graphite anode materials for lithium-ion batteries

LING Zheng1( ), SUN Lu1, TIAN Peng1,2, YE Junwei1,2(

), SUN Lu1, TIAN Peng1,2, YE Junwei1,2( )

)

- 1. School of Chemical Engineering,Dalian 116024,China

2. Liaoning Province Magnesium Special Functional;Material Preparation and Application Technology Engineering Laboratory,Dalian University of Technology,Dalian 116024,China

-

Received:2025-01-15Online:2025-12-10Published:2025-06-13 -

Contact:YE Junwei E-mail:Lz1763026070@mail.dlut.edu.cn;junweiye@dlut.edu.cn

CLC Number:

Cite this article

LING Zheng, SUN Lu, TIAN Peng, YE Junwei. Study on coating modification and electrochemical performance investigation of graphite anode materials for lithium-ion batteries[J]. Inorganic Chemicals Industry, 2025, 57(12): 18-25.

share this article

Table 1

Comparison of effects of alumina modified graphite anode materials by different methods"

| 负极材料 | 改性方法 | 首次库伦效率/% | 循环后比容量/(mA·h·g-1) | 循环容量保持率/% |

|---|---|---|---|---|

| MCMB-1[ | 双水解法 | 90.73 | 295.00 (0.2C,100次) | 98.57(0.2C,100次) |

| G05U[ | 溶胶-凝胶法 | 90.70 | 290.00(0.33C,50次) | 91.33(0.33C,50次) |

| 1% Al2O3(质量分数)[ | 溶胶-凝胶法 | 94.60 | 334.00(1.1C,100次) | 94.83(1.1C,100次) |

| 0.7%-Al-A(质量分数)[ | 溶胶浸渍-包覆法 | 385.06(0.1C,45次) | 93.45(0.1C,45次) | |

| BG/Al2O3-1.8[ | 高能球磨法 | 84.21 | 344.00(2.7C,500次) | 84.00(2.7C,500次) |

| AN-1[ | 溶胶-凝胶法 | 93.40 | 84.95(1C,200次) | |

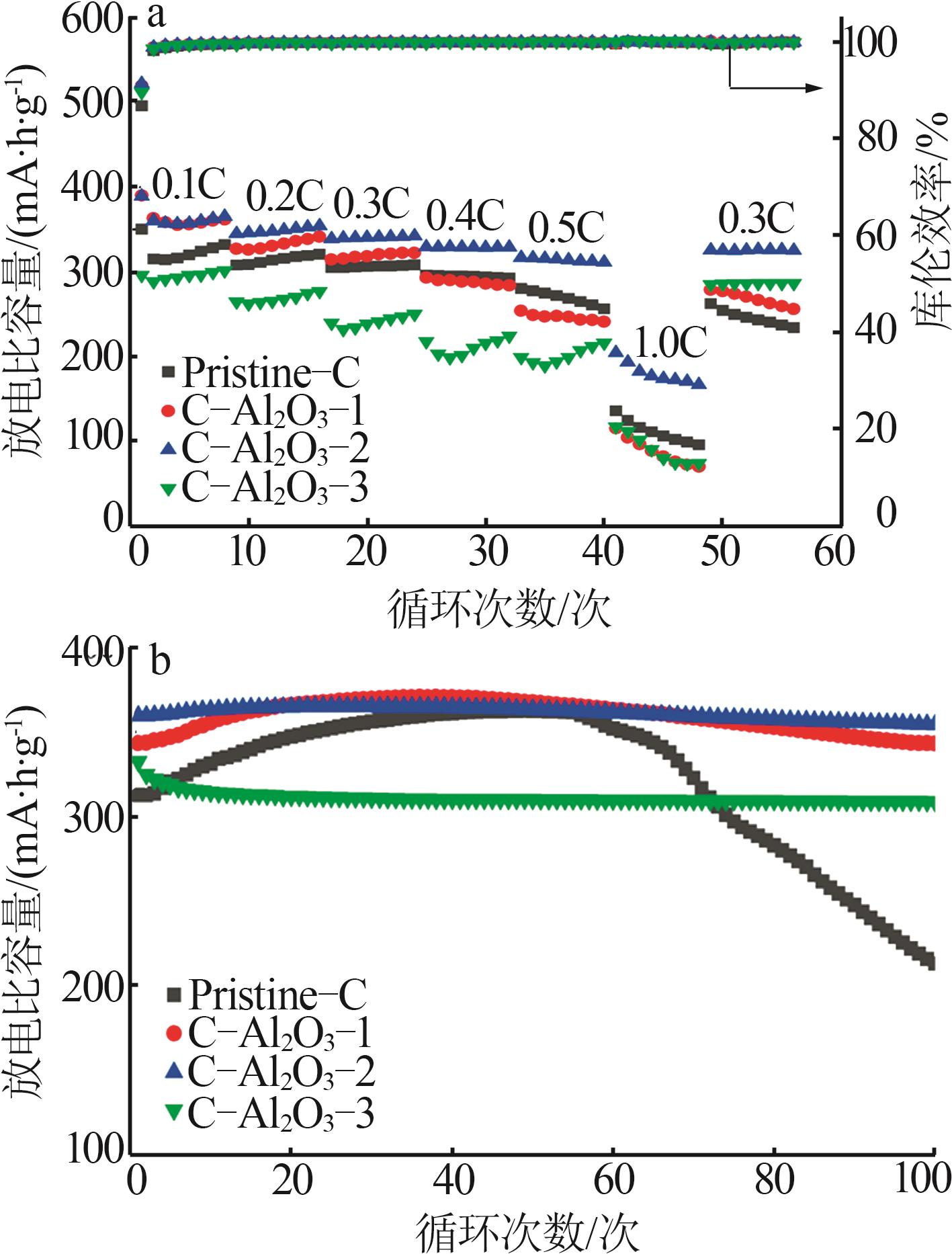

| C-Al2O3-2(本工作) | 沉淀法 | 91.64 | 354.37(0.1C,100次) | 98.59(0.1C,100次) |

| [1] | SAHU S R, RIKKA V R, HARIDOSS P,et al.A novel α-MoO3/single-walled carbon nanohorns composite as high-performance anode material for fast-charging lithium-ion battery[J].Advanced Energy Materials,2020,10(36):2001627. |

| [2] | XIE Jing, LU Yichun.A retrospective on lithium-ion batteries[J].Nature Communications,2020,11:2499. |

| [3] | LI Junhao, LIU Zhongqi, WANG Yifan,et al.Investigation of facial B2O3 surface modification effect on the cycling stability and high-rate capacity of LiNi1/3Co1/3Mn1/3O2 cathode[J].Journal of Alloys and Compounds,2020,834:155150. |

| [4] | SCHMUCH R, WAGNER R, HÖRPEL G,et al.Performance and cost of materials for lithium-based rechargeable automotive batteries[J].Nature Energy,2018,3(4):267-278. |

| [5] | GUO Jianguang, LU Shicheng, XIE Junran,et al.Preparation of mesophase pitch with domain textures by molecular regulation of ethylene tar pitch for boosting the performance of its carbon materials[J].Journal of Analytical and Applied Pyrolysis,2023,170:105932. |

| [6] | ZHANG Jie, ZHOU Chen, NAENEN V,et al.Facile synthesis of dual-phase lithium titanate nanowires as anode materials for lithium-ion battery[J].Journal of Alloys and Compounds,2021,875:160038. |

| [7] | DU Aimin, LI Hang, CHEN Xinwen,et al.Recent research progress of silicon-based anode materials for lithium-ion batteries[J].ChemistrySelect,2022,7(19):e202201269. |

| [8] | WU Chenghao, ZHU Guanjia, WANG Qiong,et al.Sn-based nanomaterials:From composition and structural design to their electrochemical performances for Li- and Na-ion batteries[J].Energy Storage Materials,2021,43:430-462. |

| [9] | PAN Yue, TONG Kun, TIAN Ruyu,et al.Advanced anode materials based on iron oxides for lithium-ion batteries[J].Nano,2023,18(6):2330004. |

| [10] | LEI Tongfei, WANG Yinwei, PAN Feng,et al.Nanofibrous carbon@cobaltous oxide composites for high electrochemical performance as anode materials of lithium-ion batteries[J].Ionics,2021,27(12):5097-5101. |

| [11] | WANG Zhijun, ZHANG Bingjie, ZHANG Yueyan,et al.A novel π-conjugated poly(biphenyl diimide) with full utilization of carbonyls as a highly stable organic electrode for Li-ion batteries[J].RSC Advances,2020,10(52):31049-31055. |

| [12] | 张珊珊,曾雨乐,张婷,等.锂离子电池正极预锂化技术研究进展[J].无机盐工业,2025,57(1):1-13,26. |

| ZHANG Shanshan, ZENG Yule, ZHANG Ting,et al.Research progress of cathode pre-lithiation technology for lithium-ion batteries[J].Inorganic Chemicals Industry,2025,57(1):1-13,26. | |

| [13] | GOODENOUGH J B, PARK K S.The Li-ion rechargeable battery:A perspective[J].Journal of the American Chemical Society,2013,135(4):1167-1176. |

| [14] | LIU Hanlin, YANG Wang, CHE Sai,et al.Silicon doped graphene as high cycle performance anode for lithium-ion batteri- es[J].Carbon,2022,196:633-638. |

| [15] | XIONG Dongbin, LI Xifei, BAI Zhimin,et al.Superior cathode performance of nitrogen-doped graphene frameworks for lithium ion batteries[J].ACS Applied Materials & Interfaces,2017,9(12):10643-10651. |

| [16] | ZHANG Chenzhen, MAHMOOD N, YIN Han,et al.Synthesis of phosphorus-doped graphene and its multifunctional applications for oxygen reduction reaction and lithium ion batteries[J].Advanced Materials,2013,25(35):4932-4937. |

| [17] | LI Qiuya, LI Bin, LV Dongjun,et al.Synthesis of copper naphthalocyanine/graphene oxide composites as anode materials for lithi-um-ion batteries[J].Physical Chemistry Chemical Physics,2023,25(45):31178-31187. |

| [18] | MÜLLNER S, HELD T, TICHTER T,et al.Impact of functional groups in reduced graphene oxide matrices for high energy anodes in lithium-ion batteries[J].Journal of the Electrochemical Society,2023,170(7):070523. |

| [19] | HE Yu, YU Xiqian, WANG Yanhong,et al.Alumina-coated patterned amorphous silicon as the anode for a lithium-ion battery with high coulombic efficiency[J].Advanced Materials,2011,23(42):4938-4941. |

| [20] | YAN Shuaipeng, XU Jiahao, BIAN Yuhan,et al.Effects of Al2O3 coating on electrochemical performance of MCMB material and LiNi0.5Mn1.5O4/MCMB full cells[J].Journal of Materials Science:Materials in Electronics,2023,34(4):271. |

| [21] | WANG Shidi, LI Yang, WANG Lijun,et al.PVA generated carbon-coated natural graphite anode material for enhanced performances of lithium-ion batteries[J].Ionics,2024,30(11):6845-6853. |

| [22] | FENG Tianyu, XU Youlong, ZHANG Zhengwei,et al.Low-cost Al2O3 coating layer as a preformed SEI on natural graphite powder to improve coulombic efficiency and high-rate cycling stability of lithium-ion batteries[J].ACS Applied Materials & Interfaces,2016,8(10):6512-6519. |

| [23] | JUNG Y S, CAVANAGH A S, RILEY L A,et al.Ultrathin direct atomic layer deposition on composite electrodes for highly durable and safe Li-ion batteries[J].Advanced Materials,2010,22(19):2172-2176. |

| [24] | JUNG Y S, CAVANAGH A S, DILLON A C,et al.Enhanced stability of LiCoO2 cathodes in lithium-ion batteries using surface modification by atomic layer deposition[J].Journal of the Electrochemical Society,2010,157(1):A75. |

| [25] | KIM D S, KIM Y E, KIM H.Improved fast charging capability of graphite anodes via amorphous Al2O3 coating for high power lithi-um ion batteries[J].Journal of Power Sources,2019,422:18-24. |

| [26] | 田朋,张浩然,徐金钢,等.氧化铝溶胶改性锂离子电池正负极材料的研究[J].无机盐工业,2024,56(9):44-53,116. |

| TIAN Peng, ZHANG Haoran, XU Jingang,et al.Study on aluminum sol modified anode and cathode materials for lithium ion batteries[J].Inorganic Chemicals Industry,2024,56(9):44-53, 116. | |

| [27] | DAN Jianglei, JIN Chenxin, WEN Lijun,et al.A double-layer-coated graphite anode material for high-rate lithium-ion batteri- es[J].Solid State Sciences,2023,141:107220. |

| [28] | SHI Qiang, HENG Shuai, QU Qunting,et al.Constructing an elastic solid electrolyte interphase on graphite:A novel strategy suppressing lithium inventory loss in lithium-ion batteries[J].Journal of Materials Chemistry A,2017,5(22):10885-10894. |

| [29] | ZOU Feng, CUI Zehao, NALLAN H C,et al.Long-term cycling of a Mn-rich high-voltage spinel cathode by stabilizing the surface with a small dose of iron[J].ACS Applied Energy Materials,2021,4(11):13297-13306. |

| [30] | ZHANG Jie, WANG Rui, YANG Xiaocheng,et al.Direct observation of inhomogeneous solid electrolyte interphase on MnO anode with atomic force microscopy and spectroscopy[J].Nano Letters,2012,12(4):2153-2157. |

| [31] | ALI Y, IQBAL N, SHAH I,et al.Mechanical stability of the heterogenous bilayer solid electrolyte interphase in the electrodes of lithium-ion batteries[J].Mathematics,2023,11(3):543. |

| [32] | LI Jialin, WANG Yanan, SUN Shuyu,et al.Understanding and regulating the mechanical stability of solid electrolyte interphase in batteries[J].Advanced Energy Materials,2025,15(4):2403845. |

| [33] | SHI Qiang, LIU Weijie, QU Qunting,et al.Robust solid/electrolyte interphase on graphite anode to suppress lithium inventory loss in lithium-ion batteries[J].Carbon,2017,111:291-298. |

| [34] | MA Huirong, YU Zhongrui, CHEN Jingjing,et al.Incorporating α-Al2O3 nanodots into expanded graphite anodes toward stable fast charging for lithium-ion batteries[J].ACS Applied Energy Materials,2023,6(3):1389-1395. |

| [35] | XU Tao, ZHOU Chengkun, ZHOU Haihui,et al.Synthesis of alumina-coated natural graphite for highly cycling stability and safety of Li-ion batteries[J].Chinese Journal of Chemistry,2019,37(4):342-346. |

| [1] | ZHANG Longhua, ZHANG Zhichao. Study on synergistic modification to improve structural stability of ternary cathode material LiNi0.9Co0.05Mn0.05O2 [J]. Inorganic Chemicals Industry, 2025, 57(9): 82-87. |

| [2] | LI Shuli, CHEN Shipeng, ZHANG Lingli, SHI Fanian. Defects,modification strategies and prospects of graphite anode materials for low temperature lithium-ion batteries [J]. Inorganic Chemicals Industry, 2025, 57(9): 21-29. |

| [3] | FU Tongtong, HE Ting, ZHOU Shiyu, GU Shuai. Study on self-driven leaching of spent lithium-ion batteries cathodes and anodes with galvanic cell structure [J]. Inorganic Chemicals Industry, 2025, 57(7): 35-43. |

| [4] | WANG Yiren, DUO Xinghong. Study on trimethyl phosphate-mixed salt flame retardant electrolytes performance [J]. Inorganic Chemicals Industry, 2025, 57(6): 85-92. |

| [5] | WANG Zhiyu, SONG Kun, SHEN Miao, SHEN Ping, XIAO Peiyao, YANG Chunming. Research progress of supercapacitors based on surface modified graphite felt composite materials [J]. Inorganic Chemicals Industry, 2025, 57(4): 11-21. |

| [6] | LUO Bingxin, WU Yani, LIU Zhenzhen, CHEN Xiaopan, PAN Wuxue, WANG Yuying, ZHOU Dongling, WEN Yanxuan. Effect of lithium supplementation on structure and properties of directly recycled waste ternary cathode materials [J]. Inorganic Chemicals Industry, 2025, 57(12): 26-33. |

| [7] | LI Yanqiang, WANG Dahui, CHEN Huaijing, PENG Xiaoping, SONG Xiaolong. Study on recovery of metals from spent NCA-type lithium-ion power batteries [J]. Inorganic Chemicals Industry, 2025, 57(10): 24-31. |

| [8] | ZHANG Shanshan, ZENG Yule, ZHANG Ting, LIN Sen, LIU Chenglin. Research progress of cathode pre-lithiation technology for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2025, 57(1): 1-13. |

| [9] | ZHANG Yanyan, LI Donghong, LIU Yonghe, ZHANG Yang, KANG Le, WANG Yi. Study on surface treatment of alumina filler [J]. Inorganic Chemicals Industry, 2025, 57(1): 77-82. |

| [10] | TIAN Peng, ZHANG Haoran, XU Jingang, MOU Chenxi, XU Qianjin, NING Guiling. Study on aluminum sol modified anode and cathode materials for lithium ion batteries [J]. Inorganic Chemicals Industry, 2024, 56(9): 44-53. |

| [11] | REN Xuechang, FENG Hao. Study on dissolution process of sintered clinker by aluminum ash alkali method with ultrasound irritation [J]. Inorganic Chemicals Industry, 2024, 56(6): 119-126. |

| [12] | ZHAO Tianting, ZHU Delun, YANG Lin, ZHOU Xinlei. Preparation and process optimization of porous silicon anode materials for lithium-ion battery [J]. Inorganic Chemicals Industry, 2024, 56(5): 31-38. |

| [13] | YANG En, SHEN Hongyan, LIU Youzhi. In situ modification of superfine magnesium hydroxide with silicon polyether [J]. Inorganic Chemicals Industry, 2024, 56(4): 42-49. |

| [14] | LI Yaguang, HAN Dongzhan, QI Lijuan. Recent research on pretreatment of waste lithium-ion batteries and electrolyte recovery technology [J]. Inorganic Chemicals Industry, 2024, 56(2): 1-10. |

| [15] | LIU Juan, JIANG Qinglai, ZHANG Yueyi. Study on Al-Zn co-doping of 4.6 V high voltage lithium cobalt oxide cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(11): 59-64. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||