Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (5): 31-38.doi: 10.19964/j.issn.1006-4990.2023-0387

• Research & Development • Previous Articles Next Articles

Preparation and process optimization of porous silicon anode materials for lithium-ion battery

ZHAO Tianting1( ), ZHU Delun2, YANG Lin1, ZHOU Xinlei1

), ZHU Delun2, YANG Lin1, ZHOU Xinlei1

- 1.Taizhou Vocational and Technical College,Taizhou 318000,China

2.Shanghai University,Shanghai 200444,China

-

Received:2023-07-26Online:2024-05-10Published:2024-05-15

CLC Number:

Cite this article

ZHAO Tianting, ZHU Delun, YANG Lin, ZHOU Xinlei. Preparation and process optimization of porous silicon anode materials for lithium-ion battery[J]. Inorganic Chemicals Industry, 2024, 56(5): 31-38.

share this article

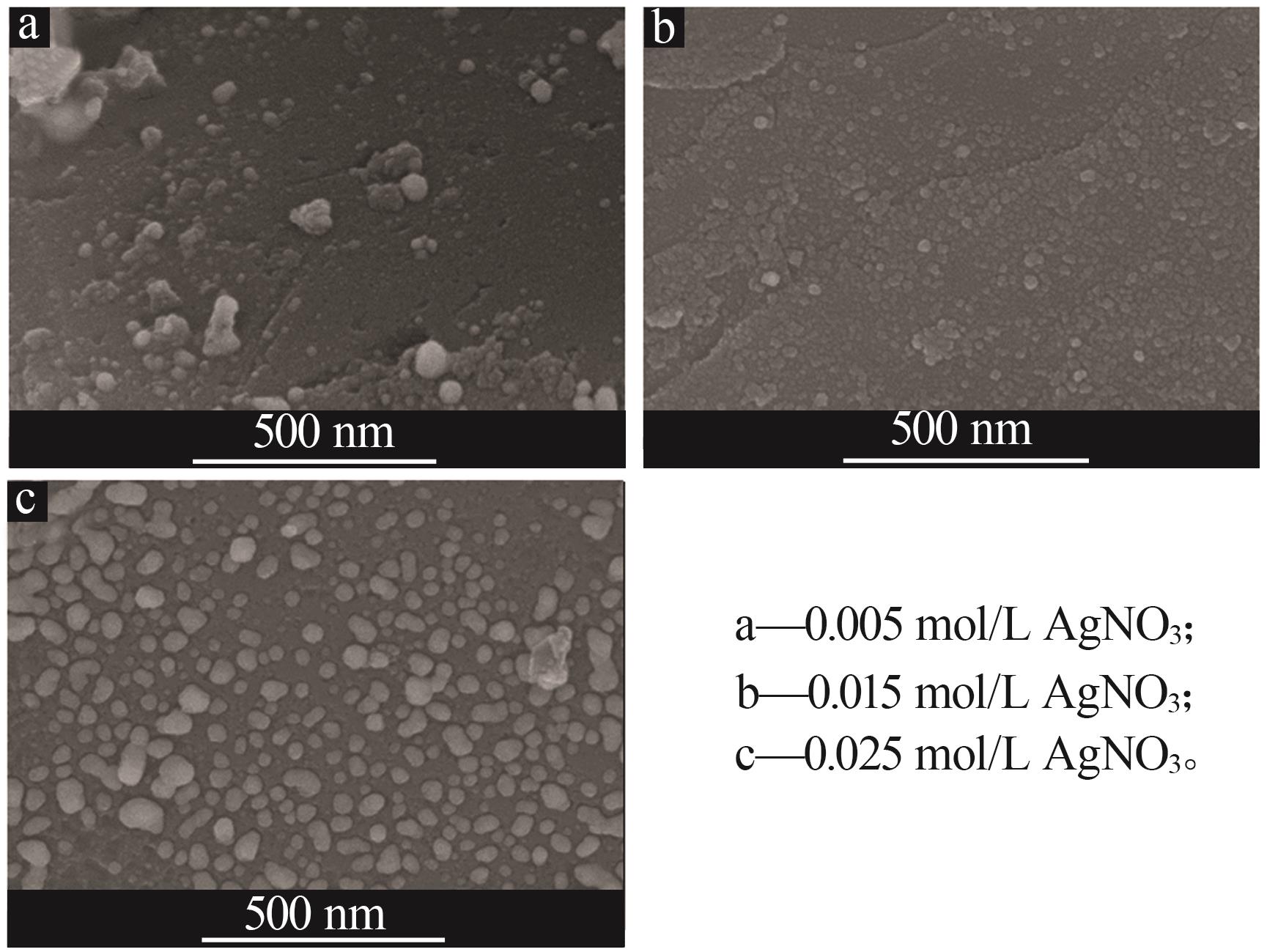

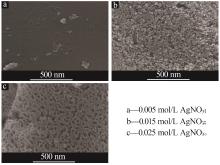

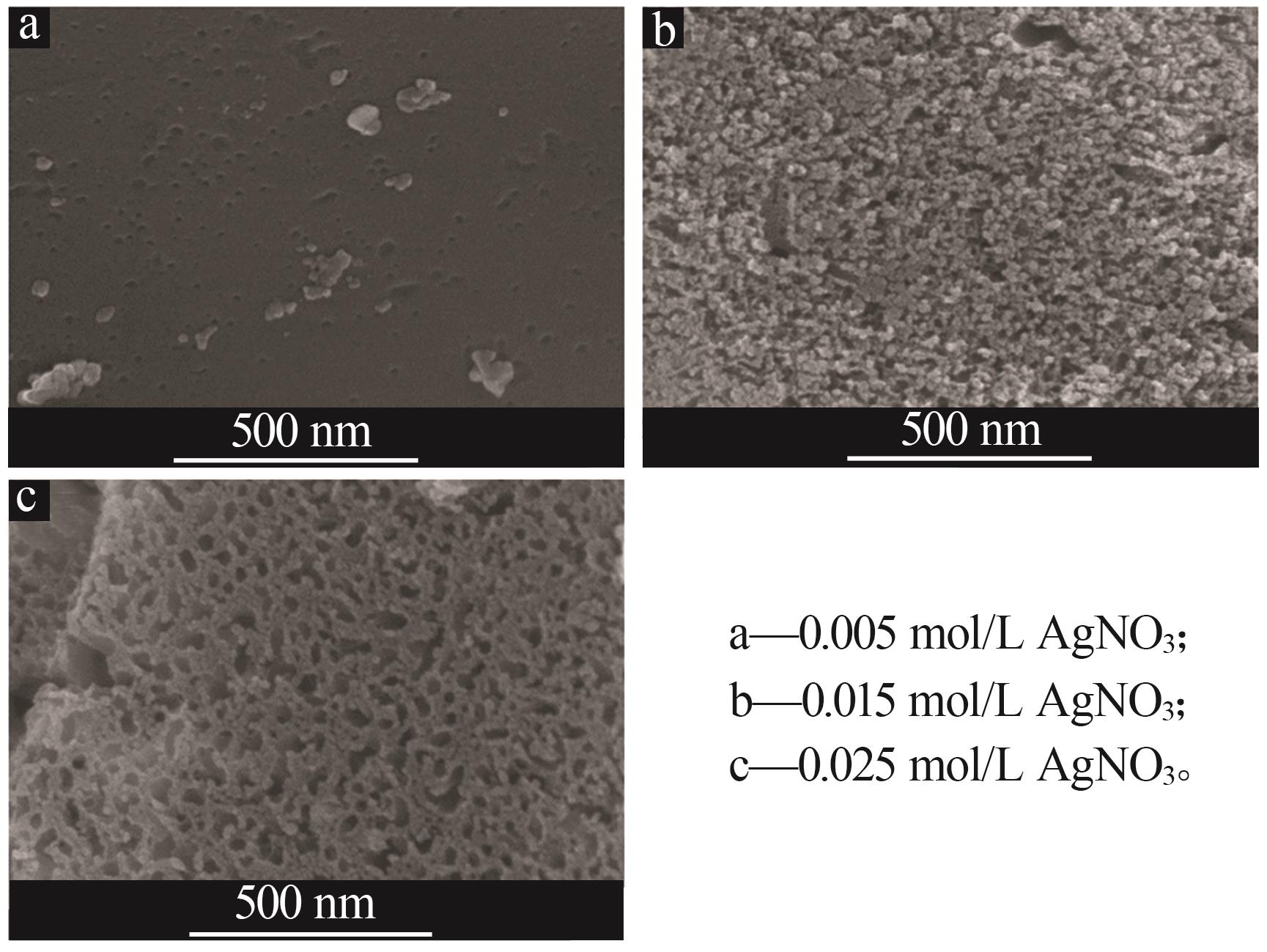

Table 1

Experimental parameters of sampleswith different AgNO3 concentrations"

样品 编号 | m(Si)/ g | 伽伐尼反应/ (102 mL) | 金属辅助化学刻蚀/ (102 mL) |

|---|---|---|---|

| A | 1 | 0.005 mol/L AgNO3+ 2 mol/L HF | 0.05 mol/L H2O2+ 0.15 mol/L HF |

| B | 1 | 0.015 mol/L AgNO3+ 2 mol/L HF | 0.05 mol/L H2O2+ 0.15 mol/L HF |

| C | 1 | 0.025 mol/L AgNO3+ 2 mol/L HF | 0.05 mol/L H2O2+ 0.15 mol/L HF |

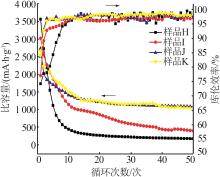

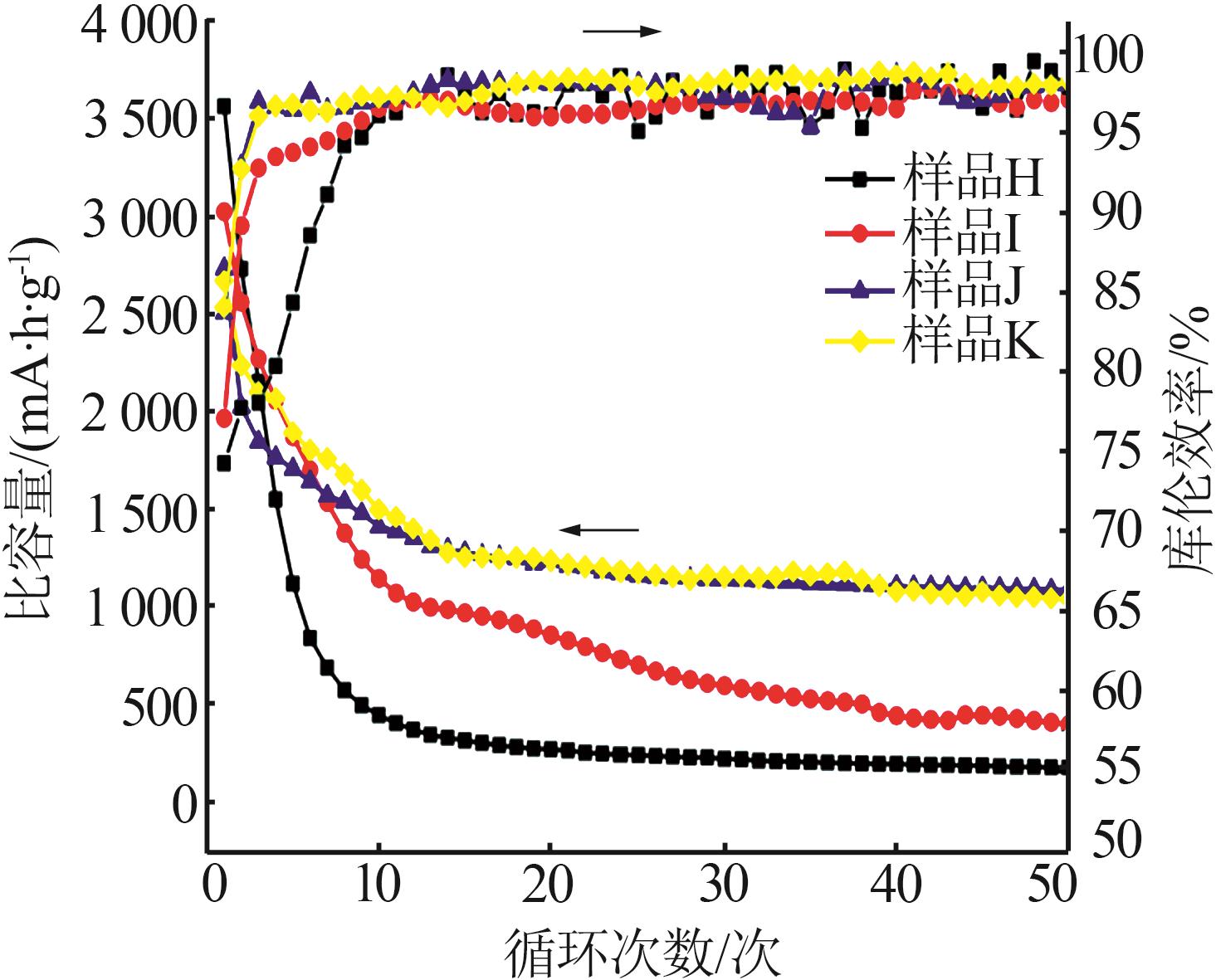

Table 2

Experimental parameters of samples with different concentration ratios of H2O2 and HF"

| 样品编号 | m(Si)/g | 伽伐尼反应/(102 mL) | 金属辅助化学刻蚀/(102 mL) | |

|---|---|---|---|---|

| H | 1 | 0.015 mol/L AgNO3 +2 mol/L HF | 0.35 mol/L H2O2+0.15 mol/L HF | 30 |

| I | 1 | 0.015 mol/L AgNO3 +2 mol/L HF | 0.15 mol/L H2O2+0.15 mol/L HF | 50 |

| J | 1 | 0.015 mol/L AgNO3 +2 mol/L HF | 0.064 mol/L H2O2+0.15 mol/L HF | 70 |

| K | 1 | 0.015 mol/L AgNO3 +2 mol/L HF | 0.017 mol/L H2O2+0.15 mol/L HF | 90 |

| 1 | 郭致昂,唐博,范保艳,等.低成本二氧化硅源镁热还原制备锂离子电池多孔硅负极材料的研究进展[J].功能材料,2022,53(1):1055-1063. |

| GUO Zhiang, TANG Bo, FAN Baoyan,et al.Research progress of porous silicon anodes using low-cost silica sources by magnesium thermal reduction for lithium-ion batteries[J].Journal of Functional Materials,2022,53(1):1055-1063. | |

| 2 | 况新亮,刘垂祥,熊朋.锂离子电池产业分析及市场展望[J].无机盐工业,2022,54(8):12-19,32. |

| KUANG Xinliang, LIU Chuixiang, XIONG Peng.Industry analysis and market prospect of lithium ion battery[J].Inorganic Chemicals Industry,2022,54(8):12-19,32. | |

| 3 | ZHU Hongzheng, SHIRAZ M H A, LIU Liang,et al.Atomic layer deposited aluminum oxynitride coating for high-performance Si anode in lithium-ion batteries[J].Applied Surface Science,2022,578:151982. |

| 4 | PENG Bo, XU Yaolin, MULDER F.Improving the performance of Si-based Li-ion battery anodes by utilizing phosphorene encapsulation[J].Acta Physico-Chimica Sinica,2017,33(11):2127-2132. |

| 5 | ZUO Xiuxia, ZHU Jin, MÜLLER-BUSCHBAUM P,et al.Silicon based lithium-ion battery anodes:A chronicle perspective review[J].Nano Energy,2017,31:113-143. |

| 6 | 朱思颖,李辉阳,胡忠利,等.锂离子电池氧化亚硅负极结构优化和界面改性研究进展[J].物理化学学报,2022,38(6):39-66. |

| ZHU Siying, LI Huiyang, HU Zhongli,et al.Research progresses on structural optimization and interfacial modification of silicon monoxide anode for lithium-ion battery[J].Acta Physico-Chimica Sinica,2022,38(6):39-66. | |

| 7 | 张炜,谢旭佳,叶嘉敏,等.基于表面改性纳米硅复合负极材料的制备及共性能[J].硅酸盐学报,2021,49(10):2123- 2129. |

| ZHANG Wei, XIE Xujia, YE Jiamin,et al.Preparation and performance of silicon nanoparticles composite anode material based on surface modification[J].Journal of the Chinese Ceramic Society,2021,49(10):2123-2129. | |

| 8 | LIN Ning, ZHOU Jianbin, WANG Liangbiao,et al.Polyaniline-assisted synthesis of Si@C/RGO as anode material for rechargeable lithium-ion batteries[J].ACS Applied Materials & Interfaces,2015,7(1):409-414. |

| 9 | 徐继文.纳米硅基负极材料研究进展[J].中国粉体工业,2022,28(3):14-17. |

| XU Jiwen.Research progress of nano-silicon based anode materials[J].China Powder Industry,2022,28(3):14-17. | |

| 10 | JIA Tianqi, ZHONG Geng, LV Yao,et al.Prelithiation strategies for silicon-based anode in high energy density lithium-ion battery[J].Green Energy and Environment,2023,8:1325-1340. |

| 11 | CHARTIER C, BASTIDE S, LÉVY-CLÉMENT C.Metal-assisted chemical etching of silicon in HF-H2O2 [J].Electrochimica Acta,2008,53(17):5509-5516. |

| 12 | BANG B M, LEE J I, KIM H,et al.High-performance macroporous bulk silicon anodes synthesized by template-free chemical etching[J].Advanced Energy Materials,2012,2(7):878-883. |

| 13 | PENG K, YAN Y, GAO S,et al.Dendrite-assisted growth of silicon nanowires in electroless metal deposition[J].Advanced Func- tional Materials,2003,13(2):127-132. |

| 14 | PENG Kuiqing, LU Aijiang, ZHANG Ruiqin,et al.Motility of metal nanoparticles in silicon and induced anisotropic silicon etching[J].Advanced Functional Materials,2008,18(19):3026-3035. |

| 15 | HUANG Zhipeng, GEYER N, WERNER P,et al.Metal-assisted chemical etching of silicon:A review[J].Advanced Materials,2011,23(2):285-308. |

| 16 | 郭人颂.基于金属辅助化学刻蚀的硅基X射线折射透镜可控制备工艺研究[D].上海:上海交通大学,2020. |

| GUO Rensong.Study on the controllable fabrication of silicon-based X-ray refractive lenses by metal assisted chemical etching[D].Shanghai:Shanghai Jiao Tong University,2020. |

| [1] | TIAN Peng, ZHANG Haoran, XU Jingang, MOU Chenxi, XU Qianjin, NING Guiling. Study on aluminum sol modified anode and cathode materials for lithium ion batteries [J]. Inorganic Chemicals Industry, 2024, 56(9): 44-53. |

| [2] | ZHOU Haitao, WEN Chengqin, ZHENG Ling, SUN Jie. Research on boron nitride modified film for cathode interface of metallic lithium battery [J]. Inorganic Chemicals Industry, 2024, 56(4): 85-89. |

| [3] | XU You, MA Luxiang, HAI Chunxi, DONG Shengde, XU Qi, HE Xin, PAN Wencheng, GAO Yawen, CHEN Ju, SUN Yanxia, ZHOU Yuan. Research progress and industrialization challenge of coal-based hard carbon anode materials for sodium ion batteries [J]. Inorganic Chemicals Industry, 2024, 56(11): 30-38. |

| [4] | FENG Zhun. Improvement of high temperature stability of high nickel single crystal cathode materials by B/Al/Zr synergistic strategy [J]. Inorganic Chemicals Industry, 2023, 55(8): 59-64. |

| [5] | TIAN Peng, XU Jingang, XU Qianjin, LIU Kunji, PANG Hongchang, NING Guiling. Preparation of nano-alumina slurry and its application in modifying lithium-ion battery cathode material [J]. Inorganic Chemicals Industry, 2023, 55(12): 43-49. |

| [6] | ZHANG Rui, WANG Zhenghao, CHEN Liang, GUO Xiaodong, LUO Dongmei. Synthesis of sodium titanate anode from industrial titanium liquid and its sodium storage performance [J]. Inorganic Chemicals Industry, 2023, 55(12): 66-73. |

| [7] | YU Jianguo,SUN Qing,QIU Shengbo,ZHANG Yiren,CHEN Jun. Lithium resources development supporting national new energy strategy development [J]. Inorganic Chemicals Industry, 2023, 55(1): 1-14. |

| [8] | TANG Di,WANG Junxiong,CHEN Wen,JI Guanjun,MA Jun,ZHOU Guangmin. Research status and prospect on direct regeneration of cathode materials from retired lithium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(1): 15-25. |

| [9] | XU Qianjin,XU Jingang,TIAN Peng,LIU Kunji,GAO Tingting,NING Guiling. Research progress of alumina coated cathode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(1): 46-55. |

| [10] | LIU Jinhang,YANG Zhipeng,CHEN Xiudong,LUO Yuxuan,YU Langhua,WANG Yawei,ZHAN Changchao,CAO Xiaohua. Preparation of new porous carbon and its lithium storage performance [J]. Inorganic Chemicals Industry, 2022, 54(9): 85-89. |

| [11] | MA Cunshuang,WAN Yanhua,XU Yongkai,CHEN Weihua. Preparation and sodium storage properties of ultra?thin N and S doped carbon coated FeS2 [J]. Inorganic Chemicals Industry, 2022, 54(6): 55-60. |

| [12] | ZHANG Xinyi,DI Yuli,DONG Qi,CHEN Xingyu,ZHANG Zhengdong. Research progress on preparation of Li3V2(PO4)3 cathode material for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(3): 38-44. |

| [13] | WU Zhaoguo,CAO Jun,YANG Zeheng. Preparation of LiNi0.8Co0.1Mn0.1O2 cathode materials with different morphologies based on hydrothermal/solvothermal method [J]. Inorganic Chemicals Industry, 2022, 54(2): 72-77. |

| [14] | YANG Wenyu,LIN Zhiya,FU Hong,YAN Wenyue,LIN Jianping,GUAN Guiqing. Study on surface potential of lithium iron phosphate based on kelvin probe technology [J]. Inorganic Chemicals Industry, 2022, 54(11): 65-70. |

| [15] | WANG Wei,LIU Wei,WU Yang,YANG Shenshen. Research progress on molybdenum disulfide-based anode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(10): 87-95. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||