Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (10): 95-102.doi: 10.19964/j.issn.1006-4990.2024-0128

• Environment·Health·Safety • Previous Articles Next Articles

Study on removal process of total organic carbon from industrial waste salts by pyrolysis

LI Hongyuan1,2( ), ZHANG Jianhua1,2(

), ZHANG Jianhua1,2( )

)

- 1.Key Laboratory of Industrial Biotechnology Ministry of Education,Jiangnan University,Wuxi 214122,China

2.School of Biotechnology,Jiangnan University,Wuxi 214122,China

-

Received:2024-03-05Online:2024-10-10Published:2024-11-05 -

Contact:ZHANG Jianhua E-mail:1015778146@qq.com;jhzh882@163.com

CLC Number:

Cite this article

LI Hongyuan, ZHANG Jianhua. Study on removal process of total organic carbon from industrial waste salts by pyrolysis[J]. Inorganic Chemicals Industry, 2024, 56(10): 95-102.

share this article

Table 5

Response surface ANOVA for high sodium chloride waste salt"

| 方差来源 | 平方和 | 自由度 | 均方 | F值 | Prob>F | 显著性 |

|---|---|---|---|---|---|---|

| 模型 | 72.75 | 9 | 8.08 | 1 593.83 | <0.000 1 | 显著 |

| A-温度 | 45.13 | 1 | 45.13 | 8 897.89 | <0.000 1 | 显著 |

| B-时间 | 3.00 | 1 | 3.00 | 591.80 | <0.000 1 | 显著 |

| C-堆积厚度 | 0.66 | 1 | 0.66 | 130.39 | <0.000 1 | 显著 |

| AB | 0.49 | 1 | 0.49 | 96.62 | <0.000 1 | 显著 |

| AC | 0.090 | 1 | 0.090 | 17.75 | 0.004 0 | 显著 |

| BC | 0.20 | 1 | 0.20 | 39.93 | 0.000 4 | 显著 |

| A2 | 22.23 | 1 | 22.23 | 4 382.45 | <0.000 1 | 显著 |

| B2 | 0.31 | 1 | 0.31 | 61.65 | 0.000 1 | 显著 |

| C2 | 0.063 | 1 | 0.063 | 12.46 | 0.009 6 | 显著 |

| 残差 | 0.035 | 7 | 5.07 | |||

| 失拟性 | 7.50 | 3 | 2.50 | 0.36 | 0.788 0 | 不显著 |

| 纯误差 | 0.028 | 4 | 7.00 | |||

| 总和 | 72.78 | 16 |

Table 6

Response surface ANOVA for high sodium sulfate salt"

| 方差来源 | 平方和 | 自由度 | 均方 | F值 | Prob>F | 显著性 |

|---|---|---|---|---|---|---|

| 模型 | 71.72 | 9 | 7.97 | 1 412.17 | <0.000 1 | 显著 |

| A-温度 | 44.65 | 1 | 44.65 | 7 912.88 | <0.000 1 | 显著 |

| B-时间 | 2.65 | 1 | 2.65 | 468.73 | <0.000 1 | 显著 |

| C-堆积厚度 | 0.66 | 1 | 0.66 | 117.18 | <0.000 1 | 显著 |

| AB | 0.36 | 1 | 0.36 | 63.80 | <0.000 1 | 显著 |

| AC | 0.063 | 1 | 0.063 | 11.08 | 0.012 6 | 显著 |

| BC | 0.16 | 1 | 0.16 | 28.35 | 0.001 1 | 显著 |

| A2 | 22.13 | 1 | 22.13 | 3 921.53 | <0.000 1 | 显著 |

| B2 | 0.42 | 1 | 0.42 | 75.22 | <0.000 1 | 显著 |

| C2 | 0.036 | 1 | 0.036 | 6.38 | 0.039 4 | 显著 |

| 残差 | 0.039 | 7 | 5.64 | |||

| 失拟性 | 0.028 | 3 | 9.16 | 3.06 | 0.154 4 | 不显著 |

| 纯误差 | 0.012 | 4 | 3.00 | |||

| 总和 | 71.76 | 16 |

Table 7

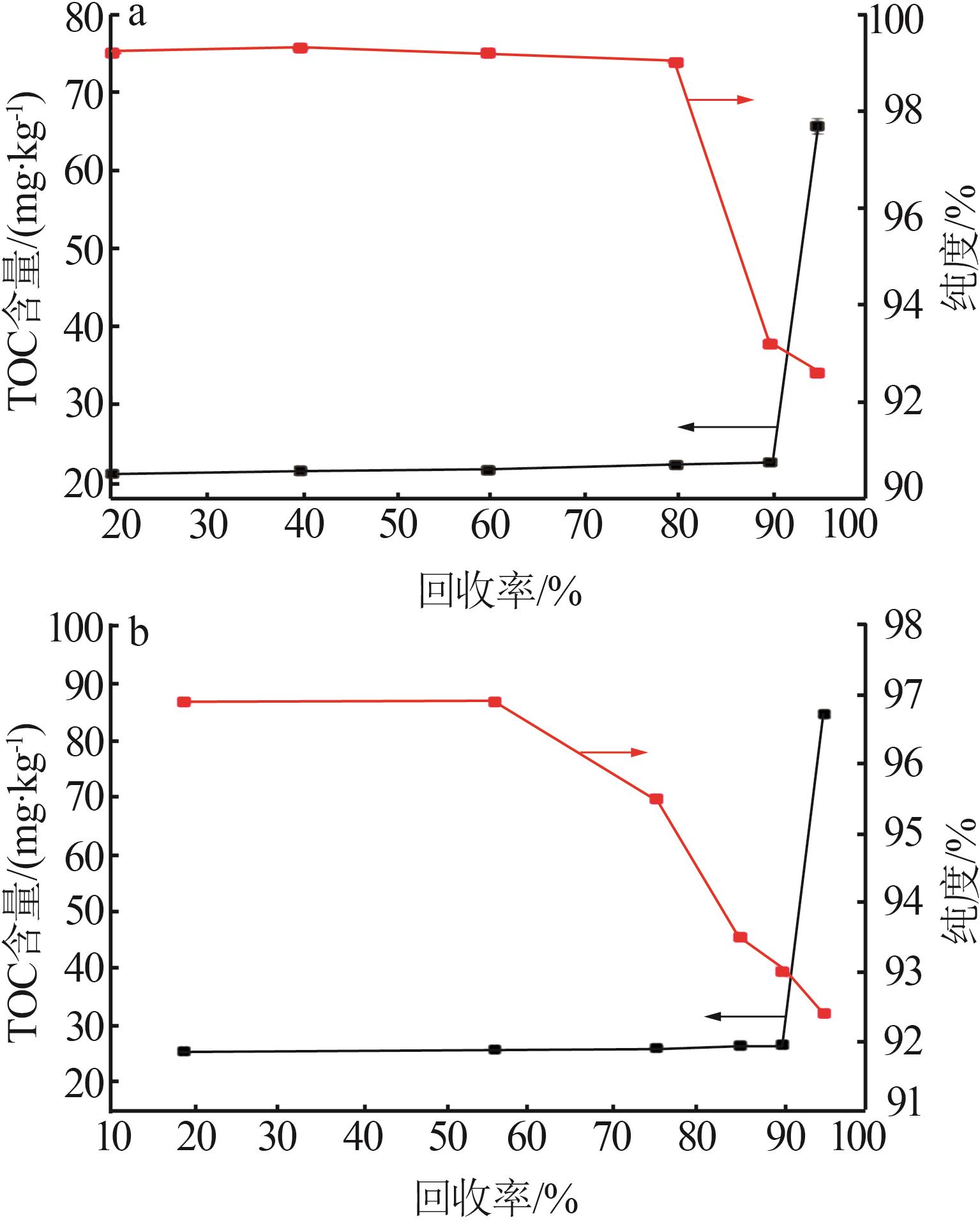

Comparison of national standard and recycled products of sodium chloride 10-2g/g"

| 项目日晒工业盐 | 氯化钠含量 | 水分含量 | 水不溶物含量 | 钙镁离子总量 | 硫酸根含量 | |

|---|---|---|---|---|---|---|

GB/T 5462—2015 《工业盐》 | 优级 | ≥96.2 | ≤2.80 | ≤0.20 | ≤0.30 | ≤0.50 |

| 一级 | ≥94.8 | ≤3.80 | ≤0.30 | ≤0.40 | ≤0.70 | |

| 二级 | ≥92.0 | ≤6.00 | ≤0.40 | ≤0.60 | ≤1.00 | |

| 40%回收率产品 | 99.2±0.2 | 0.74±0.20 | 0.01±0.01 | 0.02±0.01 | 0.01±0.01 | |

| 90%回收率产品 | 93.2±0.2 | 2.72±0.02 | 2.38±0.02 | 0.47±0.01 | 1.33±0.02 | |

| 1 | 彭伊敏,梅明.氯化钠型有机工业废盐处理及资源化利用研究进展[J].云南化工,2023,50(9):19-22. |

| PENG Yimin, MEI Ming.Research progress on sodium chloride organic industrial waste salt treatment and resource utilization[J].Yunnan Chemical Technology,2023,50(9):19-22. | |

| 2 | 马秀梅,何培花.工业废盐的尴尬与出路[J].化工设计,2023,33(4):15-17,35. |

| MA Xiumei, HE Peihua.Embarrassment and outlet of industrial waste salt[J].Chemical Engineering Design,2023,33(4):15-17,35. | |

| 3 | 张鹏,潘琦,彭莉,等.工业废盐处理处置现状及趋势[J].环境卫生工程,2022,30(5):67-71,82. |

| ZHANG Peng, PAN Qi, PENG Li,et al.Present situation and trend of industrial waste salt treatment and disposal[J].Environmental Sanitation Engineering,2022,30(5):67-71,82. | |

| 4 | 蒋太波.废盐热化学处理技术的应用[J].浙江化工,2023, 54(6):39-43. |

| JIANG Taibo.Application of waste salt thermochemical treatment technology[J].Zhejiang Chemical Industry,2023,54(6):39-43. | |

| 5 | 舒军政,张智芳,王魁,等.高级氧化法净化工业废盐[J].当代化工,2023,52(2):285-290. |

| SHU Junzheng, ZHANG Zhifang, WANG Kui,et al.Purification of industrial waste salt by advanced oxidation method[J].Contemporary Chemical Industry,2023,52(2):285-290. | |

| 6 | 汤子怡,汤亚飞,王顺.热处理有机化工废盐的工业盐制备[J].武汉工程大学学报,2023,45(1):71-75. |

| TANG Ziyi, TANG Yafei, WANG Shun.Production of industrial salt by heat treatment of organic chemical waste salt[J].Journal of Wuhan Institute of Technology,2023,45(1):71-75. | |

| 7 | 卢诗谣,赵颖颖,袁俊生.不同有机物对氯化钠溶解度和介稳区的影响[J].化工进展,2017,36(9):3210-3216. |

| LU Shiyao, ZHAO Yingying, YUAN Junsheng.Study on effects of different organic compounds on solubility and metastable zone of sodium chloride[J].Chemical Industry and Engineering Progress,2017,36(9):3210-3216. | |

| 8 | 岳培恒.含有机物结晶盐的热处理试验研究[J].煤炭加工与综合利用,2018(12):61-65. |

| YUE Peiheng.Experimental study on heat treatment of crystalline salt containing organic matter[J].Coal Processing & Comprehensive Utilization,2018(12):61-65. | |

| 9 | 胡卫平,贺周初,朱文新,等.农药副产废盐渣的无害化处理及利用[J].精细化工中间体,2013,43(3):48-50. |

| HU Weiping, HE Zhouchu, ZHU Wenxin,et al.Innocuous treatment and recycling of waste salts formed in pesticides producti⁃on[J].Fine Chemical Intermediates,2013,43(3):48-50. | |

| 10 | 李唯实,徐亚,雷国元,等.典型农药废盐热处理特性及适用性[J].环境科学研究,2018,31(10):1779-1786. |

| LI Weishi, XU Ya, LEI Guoyuan,et al.Thermal treatment characteristics and adaptability of typical pesticide waste salts[J].Research of Environmental Sciences,2018,31(10):1779-1786. | |

| 11 | 周海云,鲍业闯,包健,等.工业废盐处理处置现状研究进展[J].环境科技,2020,33(2):70-75. |

| ZHOU Haiyun, BAO Yechuang, BAO Jian,et al.Research progress on status quo of industrial waste salt treatment and dispo⁃sal[J].Environmental Science and Technology,2020,33(2):70-75. | |

| 12 | 罗鹏,徐琴琴,刘润杰,等.用超临界二氧化碳萃取技术脱除废水中有机物[J].环境科技,2011,24(3):5-11. |

| LUO Peng, XU Qinqin, LIU Runjie,et al.Removal of organics from wastewater using supercritical carbon dioxide extraction tec⁃hnology[J].Environmental Science and Technology,2011,24(3):5-11. | |

| 13 | 郭小玲.工业废盐处理综述[J].江西化工,2021,37(1):1-3. |

| GUO Xiaoling.Review on treatment of industrial waste salt[J].Jiangxi Chemical Industry,2021,37(1):1-3. | |

| 14 | 樊锐,刘玉坤.工业废盐资源化处置现状及分析[J].环境与发展,2020,32(8):52-53. |

| FAN Rui, LIU Yukun.Current situation and analysis of industrial waste salt resource disposal[J].Environment & Development,2020,32(8):52-53. | |

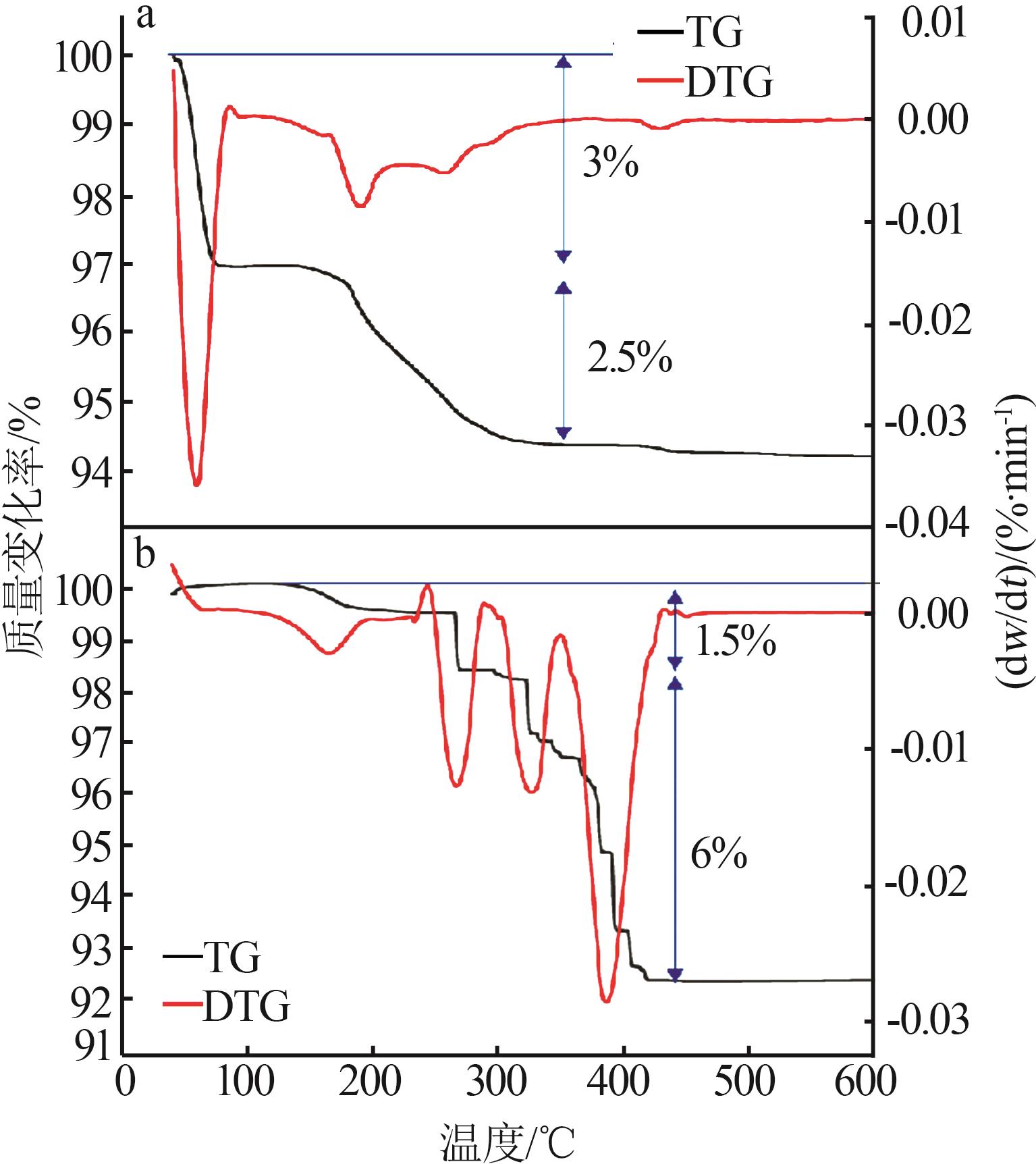

| 15 | 杨文振,熊萍,孙秀云,等.医药废硫酸钠盐燃烧特性及低温炭化除杂研究[J].无机盐工业,2021,53(9):76-82. |

| YANG Wenzhen, XIONG Ping, SUN Xiuyun,et al.Study on combustion characteristics of waste pharmaceutical Na2SO4 and impurity removal by low⁃temperature carbonization[J].Inorganic Chemicals Industry,2021,53(9):76-82. | |

| 16 | XI Shaobo, WEI Xiaolan, DING Jing,et al.The removal of organic contaminants from industrial waste salts by pyrolysis and potential use for energy storage[J].Journal of Cleaner Production,2023,425:138931. |

| 17 | BAO Huanjun, WU Meirong, MENG Xiangsong,et al.Application of electrochemical oxidation technology in treating high⁃salinity organic ammonia⁃nitrogen wastewater[J].Journal of Environmental Chemical Engineering,2023,11(5):110608. |

| 18 | 刘莲莲,夏莹,付晓燕.离子色谱法同时测定水中常见阴离子和草甘膦的方法研究[J].环境保护与循环经济,2022,42(2):83-86. |

| LIU Lianlian, XIA Ying, FU Xiaoyan.Study on simultaneous determination of common anions and glyphosate in water by ion chromatography[J].Environmental Protection and Circular Eco⁃ | |

| nomy,2022,42(2):83-86. | |

| 19 | 胡月,张文珍,李彦刚,等.腈纶废水有机物的紫外高级氧化去除机制及反应动力学模拟[J].环境科学学报,2024,44(3):61-70. |

| HU Yue, ZHANG Wenzhen, LI Yangang,et al.Removal of organics in acrylic fiber wastewater by ultraviolet⁃based advanced oxidation processes:Mechanism and kinetic modeling[J].Acta Scientiae Circumstantiae,2024,44(3):61-70. | |

| 20 | 关鹤达,杨博暄,温沁雪,等.高铁酸钾强化磁絮凝去除污水厂二级出水有机物[J].中国给水排水,2023,39(21):73-77. |

| GUAN Heda, YANG Boxuan, WEN Qinxue,et al.Potassium ferrate enhanced magnetic flocculation for the removal of organic matters in effluent from secondary treatment process[J].China Water & Wastewater,2023,39(21):73-77. | |

| 21 | 朱斯超,蒋若兰,王军,等.电芬顿-膜蒸馏复合工艺同步脱盐及去除水中有机物研究[J].能源环境保护,2023,37(4):20-29. |

| ZHU Sichao, JIANG Ruolan, WANG Jun,et al.Study on simultaneous desalination and removal of organic matter from water by electro⁃Fenton membrane distillation composite process[J].Energy Environmental Protection,2023,37(4):20-29. | |

| 22 | LI Weishi, HUANG Zechun, LIU Yuqiang,et al.Evaluation of low⁃medium temperature pretreatment on the removal efficiency of organic toxic pollutants from pesticide waste salts:Characteristics,regularity,and key factors[J].Journal of Cleaner Production,2021,316:128118. |

| 23 | 张森,王军,陈天虎,等.农药行业NaCl-KCl型废盐热处理研究[J].无机盐工业,2023,55(2):106-112. |

| ZHANG Sen, WANG Jun, CHEN Tianhu,et al.Research on heat treatment of NaCl-KCl waste salt in pesticide industry[J].Inorganic Chemicals Industry,2023,55(2):106-112. | |

| 24 | LIU Xueming, GUO Yi, ZHANG Genggeng,et al.Understanding and controlling the key crystal phase transformation for recovery of sodium chloride from organic waste salt[J].Surfaces and Interfaces,2021,27:101499. |

| [1] | WANG You, LIAO Lianzhen, CHEN Zheng, GAO Youjun. Effect of surfactants on electrocrystallization of Ni(OH)2 [J]. Inorganic Chemicals Industry, 2025, 57(3): 58-63. |

| [2] | ZHU Jicheng, YANG Qixin, LIANG Haoquan, WANG Zengkun, OUYANG Fugui, DI Jing, GAI Xikun. Effect of confined catalyst Ni@S2 on performance of methane dry reforming reaction [J]. Inorganic Chemicals Industry, 2025, 57(2): 138-146. |

| [3] | ZOU Yang, LU Zhiyan, HU Zhilin, SUN Ze. Study on metastable zone width and primary nucleation kinetics for cooling crystallization of KNO3 [J]. Inorganic Chemicals Industry, 2024, 56(9): 67-74. |

| [4] | LI Shuai, LI Tianxiang, ZHU Jing, LIU Songlin. Study on purification process of sodium fluoride [J]. Inorganic Chemicals Industry, 2024, 56(9): 90-97. |

| [5] | WANG Jianjie, SHU Xiaolong, XIAO Xia, WANG Peng, FAN Xiaoqiang, KONG Lian, XIE Zean, ZHAO Zhen. Study on synthesis of hierarchical flower⁃like ZSM-5 zeolite and its catalytic performance for n-octane cracking [J]. Inorganic Chemicals Industry, 2024, 56(8): 139-146. |

| [6] | GUO Kaihua, FAN Yuxin, YANG Jing, ZHAO Wenli, JIA Yuanyuan, WANG Yanfei. Analysis of effect of carnallite raw ore grade on its cold decomposition and crystallization of potassium chloride [J]. Inorganic Chemicals Industry, 2024, 56(8): 9-18. |

| [7] | ZHANG Bangcheng, WANG Li. Preparation and adsorption properties of waste polyester⁃based activated carbon activated by ZnCl2 [J]. Inorganic Chemicals Industry, 2024, 56(7): 126-134. |

| [8] | CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, LIU Xuejing. Study on dissolution crystallization for extraction of potassium and separation of magnesium and lithium from salt lake brine [J]. Inorganic Chemicals Industry, 2024, 56(6): 34-39. |

| [9] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [10] | LIN Weizhi, FU Chengbing, HU Ping, YANG Kaixu, CAO Jianxin. Study on mineralogical characteristics and occurrence state of elements of rhodochrosite in Tongren area [J]. Inorganic Chemicals Industry, 2024, 56(6): 73-79. |

| [11] | HU Cheng, LIU Meng, XIANG Weiheng, DUAN Pengxuan, LI Shunkai, MING Yang, WANG Neng, LU Guanju. Effect of NaCl solution concentration on transcrystallization behavior of α-hemihydrate gypsum from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(6): 87-93. |

| [12] | LI Yuxing, ZHANG Jincai, CHENG Fangqin. Research progress of preparation and growth mechanism of various crystalline nano-calcium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(5): 1-10. |

| [13] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [14] | YAO Jiankang, HU Shuozhen, NIU Dongfang, WU Jianping, ZHANG Xinsheng. Study on electrochemical treatment of sodium chloride organic waste salt in spice industry [J]. Inorganic Chemicals Industry, 2024, 56(3): 105-115. |

| [15] | LUO Ya, ZHOU Rong, LÜ Li, YANG Jie, TANG Shengwei, ZHANG Tao. Study on crystallization and filtration properties of calcium sulfate for treating industrial waste sulfuric acid with calcium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(12): 127-133. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||