| [1] |

LENG Manxi, ZHU Yu, YAN Jikang, XIE Ke, ZOU Yongjie.

Study on crystallization characteristics and mineral flotation performance of industrial waste phosphogypsum

[J]. Inorganic Chemicals Industry, 2025, 57(3): 108-115.

|

| [2] |

TAN Shanyi, WEN Huizi, HE Shuyu, ZHANG Liwen, CHEN Shaohua, XI Benjun.

Study on leaching behavior and kinetics of phosphorus from phosphogypsum

[J]. Inorganic Chemicals Industry, 2025, 57(2): 105-112.

|

| [3] |

SONG Jiaxi, JI Renfei, CHEN Jun, LIN Sen, YU Jianguo.

Research on characteristics analysis and pretreatment on deeply deactivated power battery ternary cathode materials

[J]. Inorganic Chemicals Industry, 2025, 57(2): 44-49.

|

| [4] |

TANG Kaijing, LIU Chuanbei, LI Yingding, JIANG Yong, WU Junnan, ZHANG Tao.

Research on preparation and mechanism of superhydrophobic phosphogypsum products

[J]. Inorganic Chemicals Industry, 2025, 57(1): 97-102.

|

| [5] |

TANG Dongwu, YE Changwen, DENG Jie, AO Fang.

Study on leaching rate of calcium and magnesium from phosphorus tailings based on thermodynamic analysis and response surface method

[J]. Inorganic Chemicals Industry, 2024, 56(9): 98-106.

|

| [6] |

SUN Lan, CHEN Shiying, YANG Liuxu, NIU Yiming, ZHAO Aonan.

Basic study on fixing soluble phosphorus in phosphogypsum with magnesium slag

[J]. Inorganic Chemicals Industry, 2024, 56(8): 92-98.

|

| [7] |

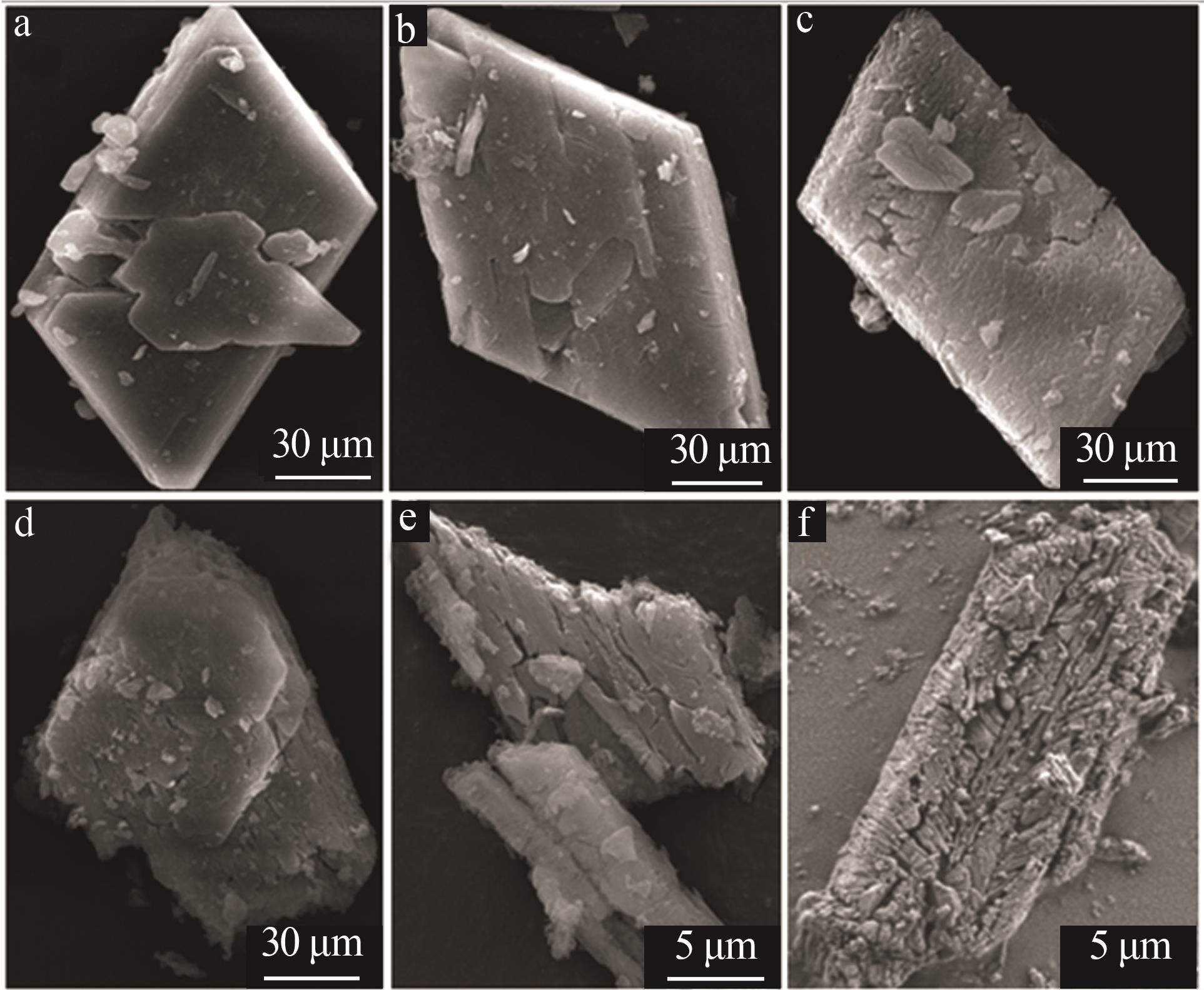

HU Cheng, LIU Meng, XIANG Weiheng, CHEN Ping, WANG Neng, LU Guanju, ZHOU Jinlan.

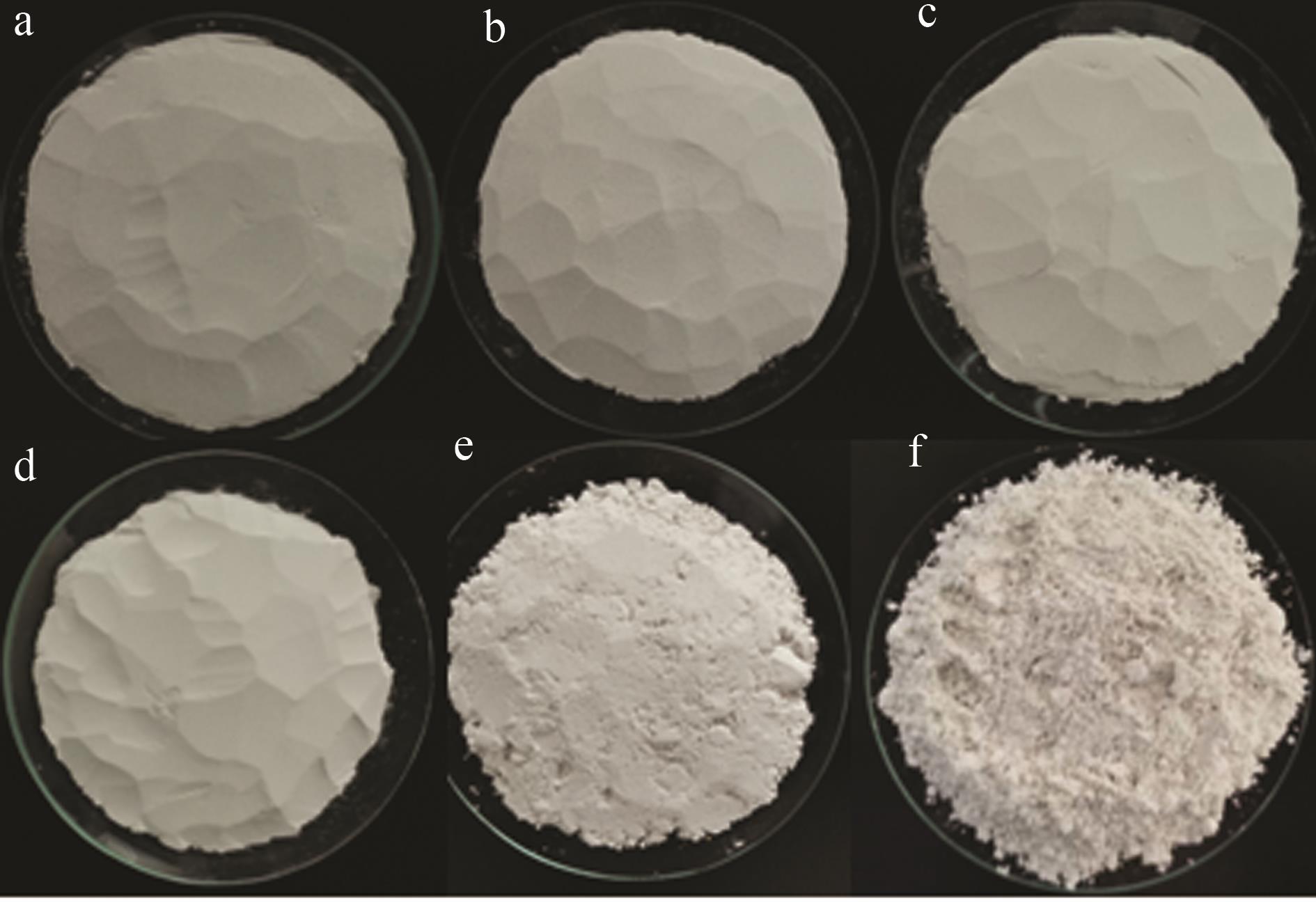

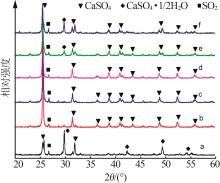

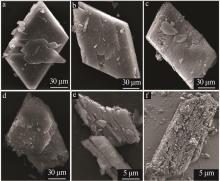

Preparation of α-hemihydrous gypsum from CaCl2 and MgCl2 and their composite solution

[J]. Inorganic Chemicals Industry, 2024, 56(7): 112-117.

|

| [8] |

HU Dian, GUO Ze, ZHANG Hanquan, LU Manman.

Research on effects of roasting process and typical impurities on reduction and decomposition process of phosphogypsum

[J]. Inorganic Chemicals Industry, 2024, 56(7): 88-95.

|

| [9] |

LIU Hui, WANG Hongliang, YU Kun, GAO Shengnan.

Effect of calcination on porous structure and electrochemical properties of air electrode

[J]. Inorganic Chemicals Industry, 2024, 56(6): 80-86.

|

| [10] |

HU Cheng, LIU Meng, XIANG Weiheng, DUAN Pengxuan, LI Shunkai, MING Yang, WANG Neng, LU Guanju.

Effect of NaCl solution concentration on transcrystallization behavior of α-hemihydrate gypsum from phosphogypsum

[J]. Inorganic Chemicals Industry, 2024, 56(6): 87-93.

|

| [11] |

TU Yanping, BAI Dengxian, CHENG Shukai, XIE Junjie, HUANG Zhiliang, CHEN Guofu.

Effect of high temperature modification of mineral powder and quicklime on properties of phosphogypsum cement based materials

[J]. Inorganic Chemicals Industry, 2024, 56(6): 94-101.

|

| [12] |

WANG Mingshun, AO Xianquan, YUAN Xing, DONG Wenyan, CHEN Qianlin.

Study on effect of crystallizer on preparation of anhydrous calcium sulfate from phosphogypsum

[J]. Inorganic Chemicals Industry, 2024, 56(5): 101-107.

|

| [13] |

DENG Fuli, XIA Zhixiang, LONG Bingwen, ZHANG Yi, DAI Yafen, WANG Bin, DING Yigang.

Study on purification process of phosphogypsum by reverse flotation

[J]. Inorganic Chemicals Industry, 2024, 56(5): 115-120.

|

| [14] |

FANG Xiaoning, KUANG Fei, LIU Chenglin.

Study on extraction of potassium from K-feldspar by roasting-leaching of mixed salts

[J]. Inorganic Chemicals Industry, 2024, 56(5): 53-57.

|

| [15] |

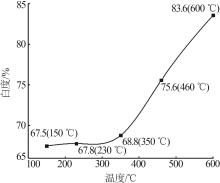

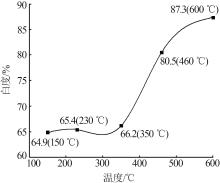

WANG Shengchang, HAO Jianying, CHEN Jianing, TIAN Bo.

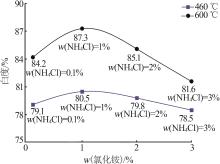

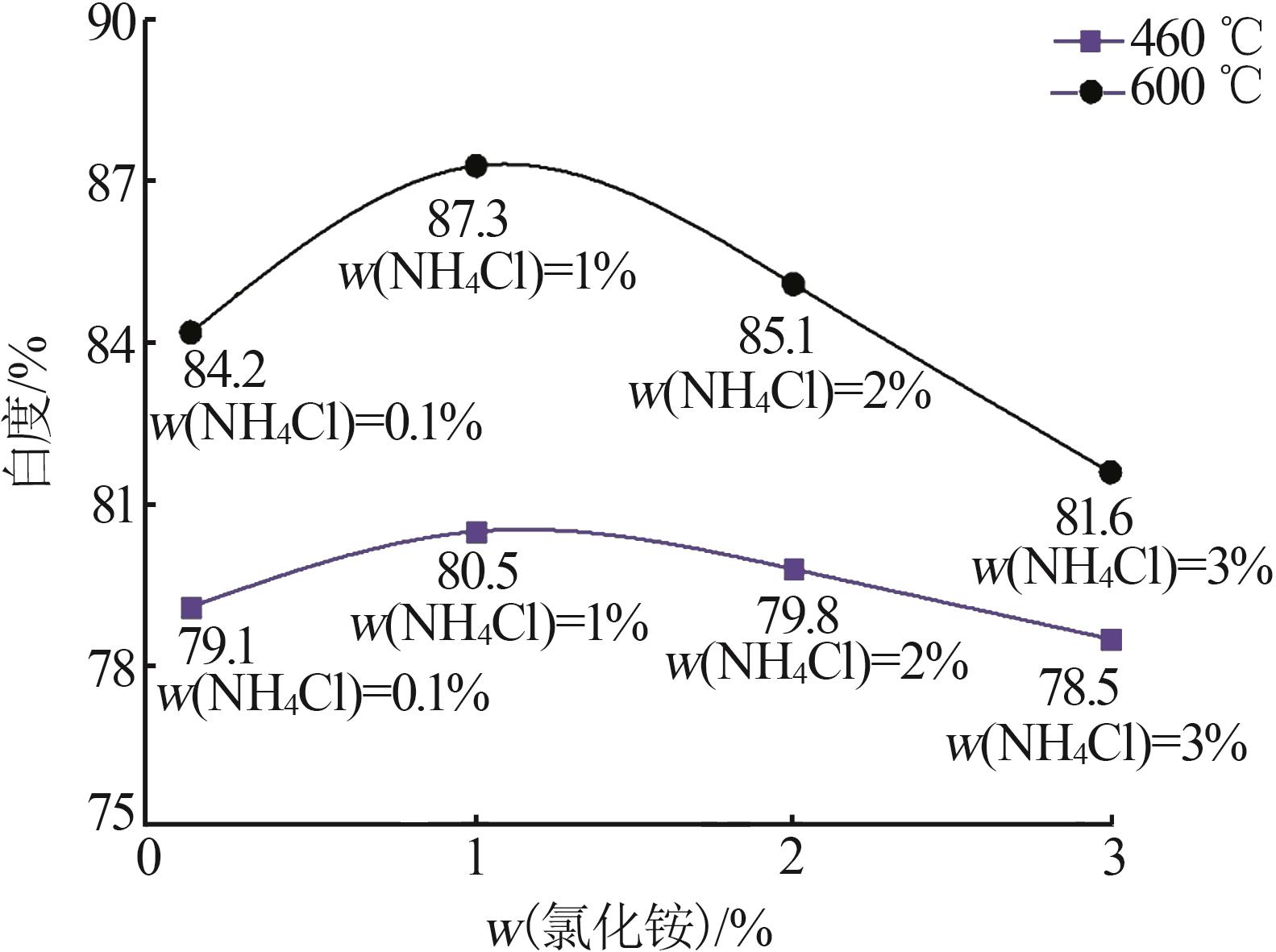

Effect of calcination on properties of calcined gypsum prepared from desulphurization gypsum with potassium aluminum sulfate

[J]. Inorganic Chemicals Industry, 2024, 56(4): 105-111.

|

), WANG Meibo, XU Li, ZHANG Xujie, TAI Shijun, YI Xianmei, LIU Hongjuan, PAN Linyi

), WANG Meibo, XU Li, ZHANG Xujie, TAI Shijun, YI Xianmei, LIU Hongjuan, PAN Linyi