Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (5): 100-108.doi: 10.19964/j.issn.1006-4990.2022-0397

• Environment·Health·Safety • Previous Articles Next Articles

Syudy on preparation of high-strength ceramsite from fluorite tailings and its properties

LI Yu( ), ZHAO Wei(

), ZHAO Wei( ), ZHANG Xinghua, WANG Rui, YAN Bingji, GUO Hongwei

), ZHANG Xinghua, WANG Rui, YAN Bingji, GUO Hongwei

- School of Iron and Steel,Soochow University,Suzhou 215006,China

-

Received:2022-06-30Online:2023-05-10Published:2023-05-15

CLC Number:

Cite this article

LI Yu, ZHAO Wei, ZHANG Xinghua, WANG Rui, YAN Bingji, GUO Hongwei. Syudy on preparation of high-strength ceramsite from fluorite tailings and its properties[J]. Inorganic Chemicals Industry, 2023, 55(5): 100-108.

share this article

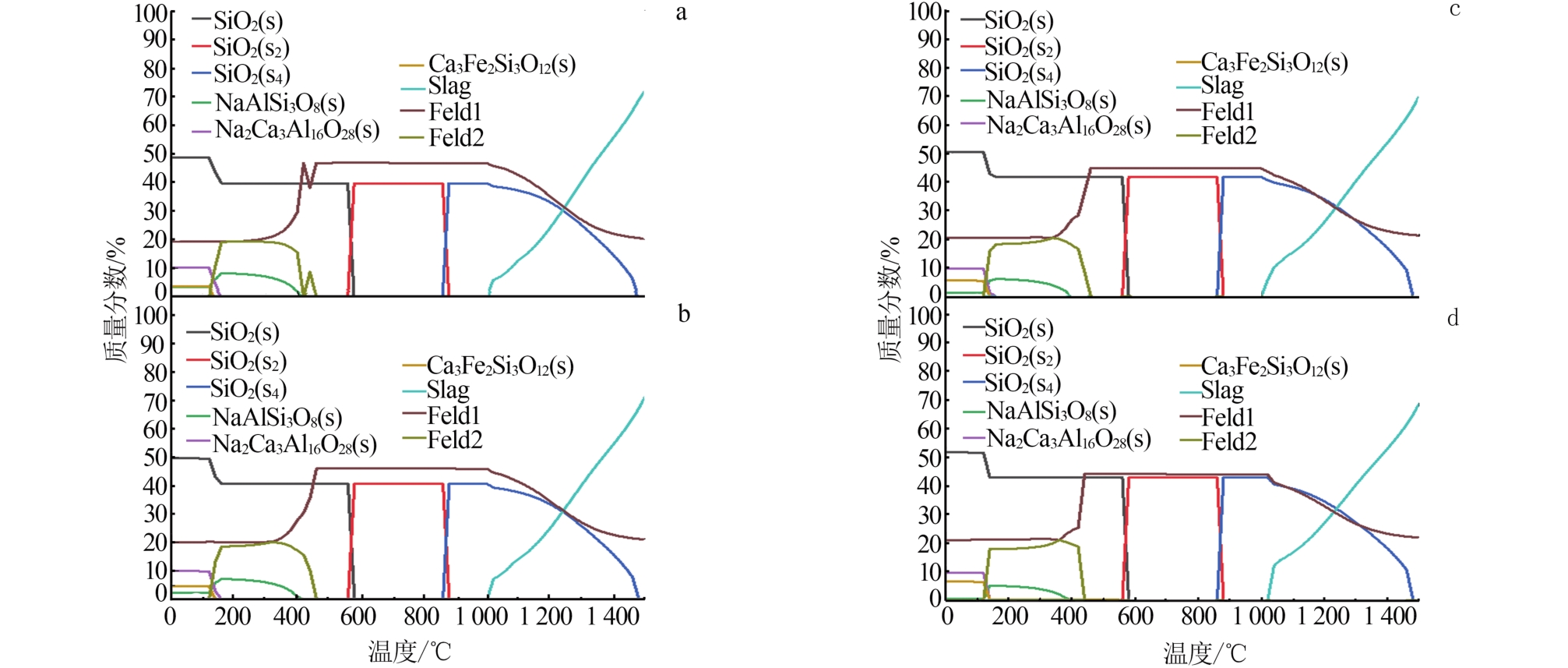

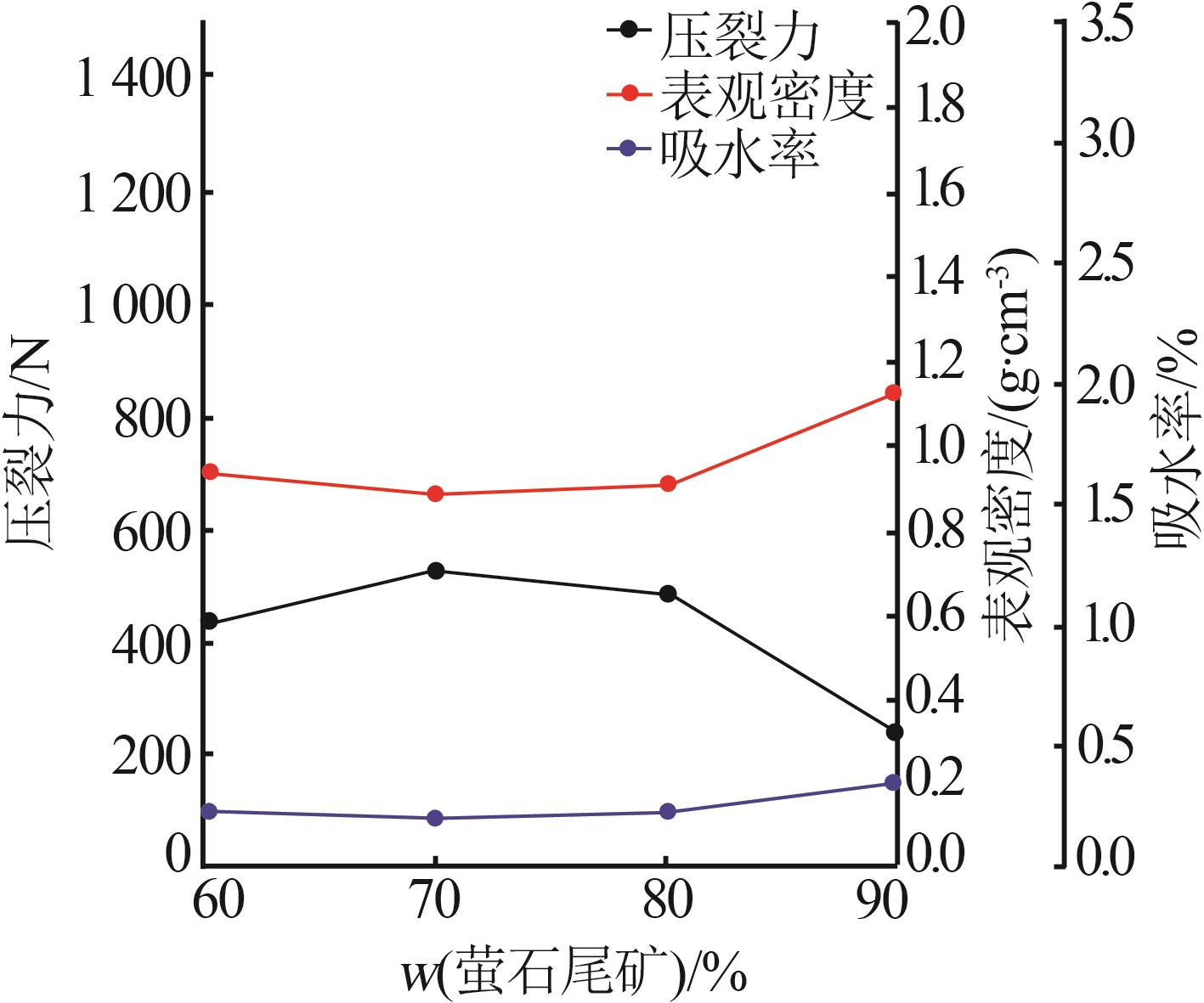

Table 4

Chemical compositions of ceramsite with different raw materials percentages"

m(萤石尾矿)∶ m(黏土) | w(SiO2)/ % | w(Al2O3)/ % | w(Fe2O3)/ % | w(CaO)/ % | w(MgO)/ % | w(Na2O)/ % | w(K2O)/ % | w(CaF2)/ % |

|---|---|---|---|---|---|---|---|---|

| 6∶4 | 68.098 | 12.152 | 3.310 | 4.354 | 1.068 | 0.996 | 3.262 | 2.464 |

| 7∶3 | 68.646 | 11.894 | 3.055 | 4.438 | 0.936 | 0.867 | 3.359 | 2.858 |

| 8∶2 | 69.194 | 11.636 | 2.800 | 4.522 | 0.804 | 0.738 | 3.456 | 3.252 |

| 9∶1 | 69.742 | 11.378 | 2.545 | 4.606 | 0.672 | 0.609 | 3.553 | 3.646 |

| 1 | 牛丽贤,张寿庭.中国萤石产业发展战略思考[J].中国矿业,2010,19(8):21-25. |

| NIU Lixian, ZHANG Shouting.Reviews on strategy of China fluorite industry development[J].China Mining Magazine,2010,19(8):21-25. | |

| 2 | 邹灏,张寿庭,方乙,等.中国萤石矿的研究现状及展望[J].国土资源科技管理,2012,29(5):35-42. |

| ZOU Hao, ZHANG Shouting, FANG Yi,et al.Current situation and prospect of fluorite deposit researches in China[J].Scientific and Technological Management of Land and Resources,2012,29(5):35-42. | |

| 3 | Survey U.S.Geological.Mineral Commodity Summaries 2020[R].Washington,2020,1-200. |

| 4 | 姚建云,高惠民,张孝平,等.低品位萤石尾矿回收萤石试验研究[J].化工矿物与加工,2016,45(1):15-18. |

| YAO Jianyun, GAO Huimin, ZHANG Xiaoping,et al.Experimental research on recovery of fluorite in low grade fluorite tailings[J].Industrial Minerals & Processing,2016,45(1):15-18. | |

| 5 | 陈剑啸.利用高炉渣和萤石尾矿制备矿渣微晶玻璃[D].苏州:苏州大学,2018. |

| CHEN Jianxiao.Preparation of slag glass-ceramics using blast furnace slag and fluorite tailings[D].Suzhou:Soochow University,2018. | |

| 6 | DJEBBI C, CHAABANI F, FONT O,et al.Atmospheric dust deposition on soils around an abandoned fluorite mine(Hammam Zriba,NE Tunisia)[J].Environmental Research,2017,158:153- 166. |

| 7 | 余昆,郑涛,熊龙,等.阳离子抗泥剂对含黏土水泥胶砂性能的影响及机理分析[J].新型建筑材料,2021,48(7):163-167. |

| YU Kun, ZHENG Tao, XIONG Long,et al.The influence of cationic anti-sludge agent on the properties of clay-bearing cement-based colloidal sand and its mechanism analysis[J].New Building Materials,2021,48(7):163-167. | |

| 8 | 汪灵,黄绩大,高欢,等.页岩陶粒轻骨料混凝土墙板的保温隔热与节能效应计算[J].混凝土,2021(12):120-123. |

| WANG Ling, HUANG Jida, GAO Huan,et al.Thermal insulation and energy-saving effect calculation of shale ceramsite lightweight aggregate concrete wallboard[J].Concrete,2021(12):120-123. | |

| 9 | HOU Lijun, LIU Taoyong, LU Anxian.Red mud and fly ash-based ceramic foams using starch and manganese dioxide as foaming agent[J].Transactions of Nonferrous Metals Society of China,2017,27(3):591-598. |

| 10 | 柴春镜,宋慧平,冯政君,等.粉煤灰陶粒的研究进展[J].洁净煤技术,2020,26(6):11-22. |

| CHAI Chunjing, SONG Huiping, FENG Zhengjun,et al.Research progress on the fly ash ceramsite[J].Clean Coal Technology,2020,26(6):11-22. | |

| 11 | 杨雪晴,宋杰光,钟璐,等.利用工业固废制备陶粒的研究及建筑工程领域应用现状[J].砖瓦,2021(8):51-54. |

| YANG Xueqing, SONG Jieguang, ZHONG Lu,et al.Research on prepared ceramsite using industrial solid waste and application status in construction engineering[J].Brick-Tile,2021(8):51- 54. | |

| 12 | 汪学彬,杨重卿,张祥伟,等.工业固体废弃物制备陶粒及其应用研究进展[J].中国粉体技术,2021,27(2):1-8. |

| WANG Xuebin, YANG Chongqing, ZHANG Xiangwei,et al.Preparation and application of ceramsite prepared from industrial solid waste:A review[J].China Powder Science and Technology,2021,27(2):1-8. | |

| 13 | 马明亮,孙晓南,权宗刚,等.中国工业固废制备陶粒资源化利用的研究进展[J].硅酸盐通报,2020,39(8):2492-2500. |

| MA Mingliang, SUN Xiaonan, QUAN Zonggang,et al.Research progress on resource utilization of ceramsite prepared from industrial solid waste in China[J].Bulletin of the Chinese Ceramic Society,2020,39(8):2492-2500. | |

| 14 | 范锦忠.实验室陶粒配方和焙烧试验方法的改进意见[J].砖瓦,2011(5):5-8. |

| FAN Jinzhong.Suggestions on the test firing ways and the laboratory ceramisite formula[J].Block-Brick-Tile,2011(5):5-8. | |

| 15 | ZHAO Hailong, LIU Fang, LIU Hanqiao,et al.Comparative life cycle assessment of two ceramsite production technologies for reusing municipal solid waste incinerator fly ash in China[J].Waste Management,2020,113:447-455. |

| 16 | MOLINEUX C J, NEWPORT D J, AYATI B,et al.Bauxite residue(red mud) as a pulverised fuel ash substitute in the manufacture of lightweight aggregate[J].Journal of Cleaner Production,2016,112:401-408. |

| 17 | CHEN H J, YANG M D, TANG C W,et al.Producing synthetic lightweight aggregates from reservoir sediments[J].Construction and Building Materials,2012,28(1):387-394. |

| 18 | CHANG F,LO S, LEE M,et al.Leachability of metals from sludge-based artificial lightweight aggregate[J].Journal of Hazardous Materials,2007,146(1/2):98-105. |

| 19 | ZHUANG Yizhou, CHEN Caiyi, JI Tao.Effect of shale ceramsite type on the tensile creep of lightweight aggregate concrete[J].Construction and Building Materials,2013,46:13-18. |

| 20 | 秦晋一,李涵,李晓光,等.高Fe2O3含量对铁尾矿陶粒物相和力学性能的影响[J].新型建筑材料,2019,46(7):83-88. |

| QIN Jinyi, LI Han, LI Xiaoguang,et al.Effect of high Fe2O3 content on phase and mechanical properties of iron tailings ceramsi- | |

| te[J].New Building Materials,2019,46(7):83-88. | |

| 21 | HWANG C, LE A, LIN K,et al.Manufacture and performance of lightweight aggregate from municipal solid waste incinerator fly ash and reservoir sediment for self-consolidating lightweight concrete[J].Cement and Concrete Composites,2012,34(10):1159-1166. |

| 22 | 杨丽艳,马鑫,梅锐锋,等.黄河流域沉沙池泥沙制备陶粒及其性能研究[J].无机盐工业,2022,54(5):109-115. |

| YANG Liyan, MA Xin, MEI Ruifeng,et al.Study on preparation and performance of ceramsite from sediment in Yellow River desilting basin[J].Inorganic Chemicals Industry,2022,54(5):109-115.Sediment in the Yellow River Basin[J].Inorganic Chemicals Industry,2022,54(05):109-115. | |

| 23 | 周鹏飞,罗立群,涂序.炼铜尾渣-湖泊底泥复合陶粒制备及其性能[J].中南大学学报:自然科学版,2021,52(12):4210-4218. |

| ZHOU Pengfei, LUO Liqun, TU Xu.Preparation and properties of copper slag tailing-lake sediment ceramsite[J].Journal of Central South University(Science and Technology),2021,52(12):4210-4218. | |

| 24 | 高鹏,徐悦清,曹云,等.淤泥基免烧陶粒的制备及性能影响因素[J].硅酸盐通报,2021,40(3):889-899. |

| GAO Peng, XU Yueqing, CAO Yun,et al.Preparation and performance influencing factors of silt-based non-sintered ceramsite[J].Bulletin of the Chinese Ceramic Society,2021,40(3):889-899. | |

| 25 | 童思意,刘长淼,刘玉林,等.中国固体废弃物制备陶粒的研究进展[J].矿产保护与利用,2019,39(3):140-150. |

| TONG Siyi, LIU Changmiao, LIU Yulin,et al.Research status of ceramsite prepared from solid waste in China[J].Conservation and Utilization of Mineral Resources,2019,39(3):140-150. | |

| 26 | 张晓亚,冯丽娟,王济,等.城市污泥/磷尾矿陶粒的烧结条件及性能研究[J].地球环境学报,2021,12(4):447-454. |

| ZHANG Xiaoya, FENG Lijuan, WANG Ji,et al.Research on sintering conditions and performance of municipal sludge/phosphate tailings ceramsite[J].Journal of Earth Environment,2021,12(4):447-454. | |

| 27 | 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 轻集料及其试验方法—第1部分:轻集料 [S].北京:中国标准出版社,2010. |

| General Administration of Quality Supervision,Inspection and Quarantine of the People′s Republic of China,Standardization Administration of China. Lightweight aggregates and its test methods—Part 1:Lightweight aggregates [S].Beijing:China Standard Press, 2010. | |

| 28 | 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 轻集料及其试验方法—第2部分:轻集料试验方法 [S].北京:中国标准出版社,2010. |

| General Administration of Quality Supervision,Inspection and Quarantine of the People′s Republic of China,Standardization Administration of China. Lightweight aggregates and its test methods—Part 2:Test methods for lightweight aggregates [S].Beijing: China Standard Press, 2010. |

| [1] | LIU Jintong, ZHANG Jie, ZHOU Junliang, WU Bingdang, HUANG Tianyin, YANG Jingjing. Summary of antimony residues and status in antimony recovery technology [J]. Inorganic Chemicals Industry, 2024, 56(9): 1-11. |

| [2] | ZHU Zongjiang, WANG Gang, WEI Yuanfeng, TANG Yanhong, KAKUTA Cheng, LIU Chengbin. Research progress and prospect of resourceful recycling technology of electrolyte from decommissioned lithium⁃ion battery [J]. Inorganic Chemicals Industry, 2024, 56(7): 11-17. |

| [3] | ZHANG Lijin, LÜ Qing, CHEN Xiaolang, LI Qingxin, SHI Hongyu, QIN Jun. Preparation of Ca-based LDO composite material and its adsorption performance for phosphate [J]. Inorganic Chemicals Industry, 2024, 56(7): 37-45. |

| [4] | CHEN Junhui, LIU Xiang, HU Qingxi, TIAN Bangxin, CHEN Jiale. Study on leaching extraction of high purity potassium chloride from sintering machine head ash [J]. Inorganic Chemicals Industry, 2024, 56(6): 102-108. |

| [5] | YE Fen, CHENG Hao, XIANG Yuan, LIU Song, SHI Wei. Preparation of ceramic aggregate from electrolytic manganese slag and its application in concrete [J]. Inorganic Chemicals Industry, 2024, 56(6): 127-132. |

| [6] | YAO Jiankang, HU Shuozhen, NIU Dongfang, WU Jianping, ZHANG Xinsheng. Study on electrochemical treatment of sodium chloride organic waste salt in spice industry [J]. Inorganic Chemicals Industry, 2024, 56(3): 105-115. |

| [7] | YANG Fengling, QIAO Guoxin, YANG Pu, REN Lei, WANG Qiong, WU Haibin, CHENG Fangqin. Research progress and application of α-hemihydrate gypsum preparation from desulfurization gypsum [J]. Inorganic Chemicals Industry, 2024, 56(2): 11-20. |

| [8] | LÜ Lingshuang, CAO Wenhao, YU Ruixian, WANG Shouzhi, WANG Guodong, ZHU Yajun, DU Jiachen, XU Xiangang, ZHANG Lei. Research on purification process of AlN source material by two-step sintering method [J]. Inorganic Chemicals Industry, 2024, 56(12): 51-55. |

| [9] | LI Lei, LI Yuelei, LIU Bangxian. Dielectric properties of fine-grained 0.8PMN-0.2PT ceramics prepared by spark plasma sintering [J]. Inorganic Chemicals Industry, 2024, 56(11): 139-144. |

| [10] | LIU Guanfa, ZENG Chaocong, WANG Zekai, ZENG Xiangrong, HUANG Wanfu. Study on preparation of high strength sintered ceramsite from tungsten smelting slag and its property [J]. Inorganic Chemicals Industry, 2023, 55(8): 132-139. |

| [11] | LI Tong, YIN Hongfeng. Study on controllable preparation of nickel phyllosilicate nanotubes catalysts and their catalytic performance [J]. Inorganic Chemicals Industry, 2023, 55(5): 128-136. |

| [12] | JIN Suna, LÜ Ruiliang. Research and application progress of wet flue gas desulfurization wastewater treatment technology [J]. Inorganic Chemicals Industry, 2023, 55(4): 27-37. |

| [13] | JI Hongfeng, LI Canhua, DU Gang, ZHANG Yongzhu, XU Wenzhen, LI Minghui. Research progress of preparation and sintering resistance of calcium-based CO2 trapping materials from solid waste sources [J]. Inorganic Chemicals Industry, 2023, 55(3): 28-35. |

| [14] | XU Wenzhen,LI Canhua,JI Hongfeng,LI Zimu,WU Zhaoyang,LI Minghui. Research progress of red mud in field of recycled metals and building materials [J]. Inorganic Chemicals Industry, 2023, 55(2): 10-18. |

| [15] | WANG Song, ZHANG Jianbin, SHEN Yüfang, QIN Shuhong, WANG Shengqiang, ZHANG Jingbing. Study on preparation process of high-purity zinc oxide by dechlorination of zinc oxide dust [J]. Inorganic Chemicals Industry, 2023, 55(11): 47-52. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||