Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (2): 11-20.doi: 10.19964/j.issn.1006-4990.2023-0242

• Reviews and Special Topics • Previous Articles Next Articles

Research progress and application of α-hemihydrate gypsum preparation from desulfurization gypsum

YANG Fengling1,2( ), QIAO Guoxin1, YANG Pu2, REN Lei1, WANG Qiong3, WU Haibin1,2, CHENG Fangqin1,2

), QIAO Guoxin1, YANG Pu2, REN Lei1, WANG Qiong3, WU Haibin1,2, CHENG Fangqin1,2

- 1.Shanxi University,Taiyuan 030006,China

2.Yellow River Laboratory,Shanxi University,Taiyuan 030006,China

3.Shanxi Dachen New Material Technology Co. ,Ltd. ,Jinzhong 031300,China

-

Received:2023-04-26Online:2024-02-10Published:2024-02-06

CLC Number:

Cite this article

YANG Fengling, QIAO Guoxin, YANG Pu, REN Lei, WANG Qiong, WU Haibin, CHENG Fangqin. Research progress and application of α-hemihydrate gypsum preparation from desulfurization gypsum[J]. Inorganic Chemicals Industry, 2024, 56(2): 11-20.

share this article

Table 1

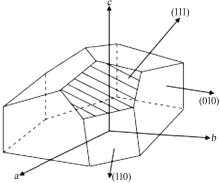

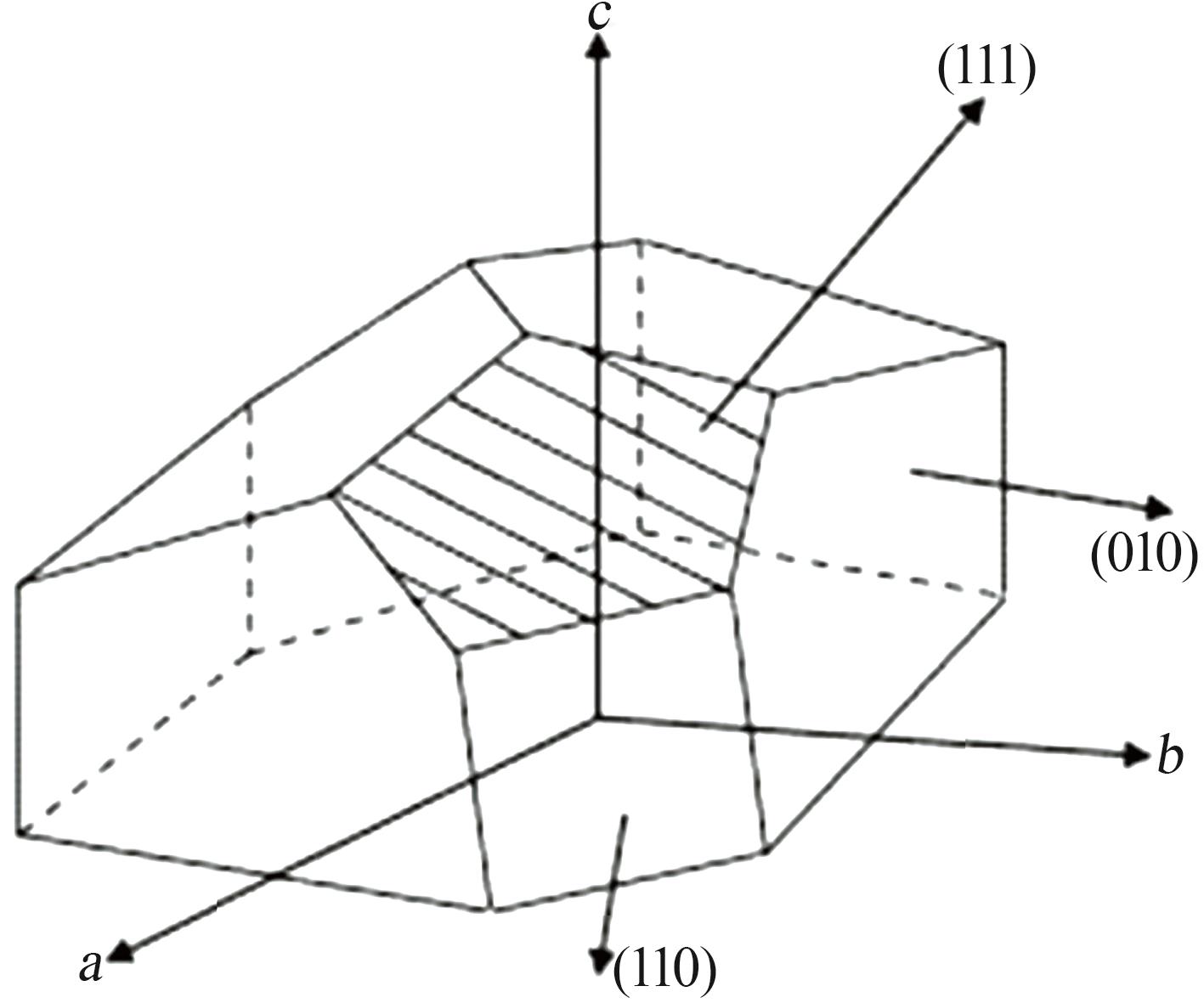

Single cell parameters of α-HH structure"

| 化学式 | a/Å | b/Å | c/Å | 晶系, 空间组 |

|---|---|---|---|---|

| CaSO4·0.5H2O[ | 12.028 0 | 6.932 0 | 12.691 0 | 单斜,I2 |

| CaSO4·0.5H2O[ | 17.518 0(8) | 6.929 1(1) | 12.034 4(2) | 单斜,C2 |

| CaSO4·0.5H2O[ | 12.031 7(4) | 6.927 2(2) | 12.671 1 | 单斜,I12 |

| CaSO4·0.5H2O[ | 12.035 0(5) | 6.929 4(3) | 12.670 5(4) | 单斜,I12 |

| CaSO4·0.5H2O[ | 12.031 7(4) | 6.926 9(2) | 12.671 2(3) | 单斜,I121 |

Table 2

Comparison of α-hemihydrate gypsum preparation methods"

| 制备方法 | 优缺点 | |

|---|---|---|

化学 转化法 | 亚硫酸钙强制氧化法 | 成本较高,需在高温下强制通入空气或氧气来进行氧化 |

固相 转化法 | 陈化法 | 制得的产品不均一,强度一般也比较低 |

| 折衷法 | 简单易操作,但制备过程中易残留羧酸盐,不利于产品的凝结硬化 | |

| 干闷法 | 能耗较低,但所需设备和生产成本较高且所得产物不纯 | |

| 蒸压法 | 能耗高,但反应时间短、产率高,易于工业化生产 | |

液相 转化法 | 加压水溶液法 | 生产工艺较复杂且效率较低,能耗成本较高,但产品强度等级很高 |

| 常压盐溶液法 | 节能、常压、温度低,但此工艺较为复杂 | |

| 常压醇水法 | 反应条件温和,对设备无腐蚀 | |

| 反相微乳液法 | 反应条件温和,易于操作 | |

微波 加热法 | 微波脱水法 | 物料整体受热均匀,反应时间短且效率高 |

Table 3

Comparison of influencing generation factors of α-hemihydrate gypsum"

| 影响因素 | 制备方法 | 研究结果 | 总结 |

|---|---|---|---|

| 反应温度 | 蒸压法[ | 生成半水石膏时存在一个相变温度,当温度超过此值时会发生反应进行脱水 | 随着温度的升高,反应时间缩短,生成晶体的速率加快 |

| 常压盐溶液法[ | 反应温度对产品的晶形有很大的影响 | ||

| 常压醇水法[ | 随着温度的升高,反应速率加快,反应时间缩短,转化率升高 | ||

| 盐溶液浓度 | 常压盐溶液法[ | NaCl溶液浓度对反应的影响较大 | 可通过改变溶液浓度调控晶体生长速率 |

| 常压盐溶液法[ | 当醇质量分数为50%时,二水石膏能较快转化生成半水石膏晶体 | ||

| 常压盐溶液法[48] | 通过比较Ca2+、Mg2+、K+、Na+的氯盐溶液发现,NaCl最有利于半水石膏的生成 | ||

| 常压盐溶液法[ | 盐溶液浓度是该方法制备半水石膏的关键因素 | ||

| 反应时间 | 常压盐溶液法[ | 当反应时间较短时,反应进行较慢,转化率较低,随着反应时间的延长,产物晶形逐渐变为棒状甚至是短柱状 | 主要决定了石膏脱水生成产物的程度,以及生成产物中石膏相态的组成状况 |

| 常压醇水法[ | 随着时间的延长,生成的α-半水石膏比例增大 | ||

| 常压盐溶液法[ | 随着丁二酸掺量的增加,样品脱水速率减缓,脱水时间延长 | ||

| pH | 常压盐溶液法[ | 随着pH升高,样品脱水速率先快后慢 | 能改变石膏相的溶解度,同时还会影响溶液中的离子电离平衡 |

| 常压醇水法[ | 随着pH升高,样品脱水速率先快后慢 | ||

| 常压盐溶液法[ | 通过调控pH来影响丁二酸的电离程度进而影响半水石膏的晶体形貌 | ||

| 常压盐溶液法[ | 随着pH升高,长棒状α-HH晶体逐渐减少 | ||

| 转晶剂 | 常压盐溶液法[ | 随着丁二酸掺量的增加,α-半水石膏的长径比降低 | 通过影响晶体的成核、生长情况来调控α-半水石膏的晶体形貌 |

| 微波加热法[ | 随着Na2SO4掺量的增加,所得晶体长径比先增大后减小 | ||

| 常压盐溶液法[ | 通过添加不同转晶剂发现,掺加质量分数为0.06%的柠檬酸制得的α-HH强度较高 | ||

| 加压水溶液法[ | 随着硫酸铝掺量(质量分数为1%~5%)的增加,α-HH晶体长径比减小,反应时间变长 |

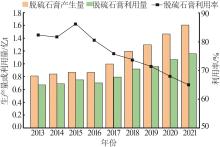

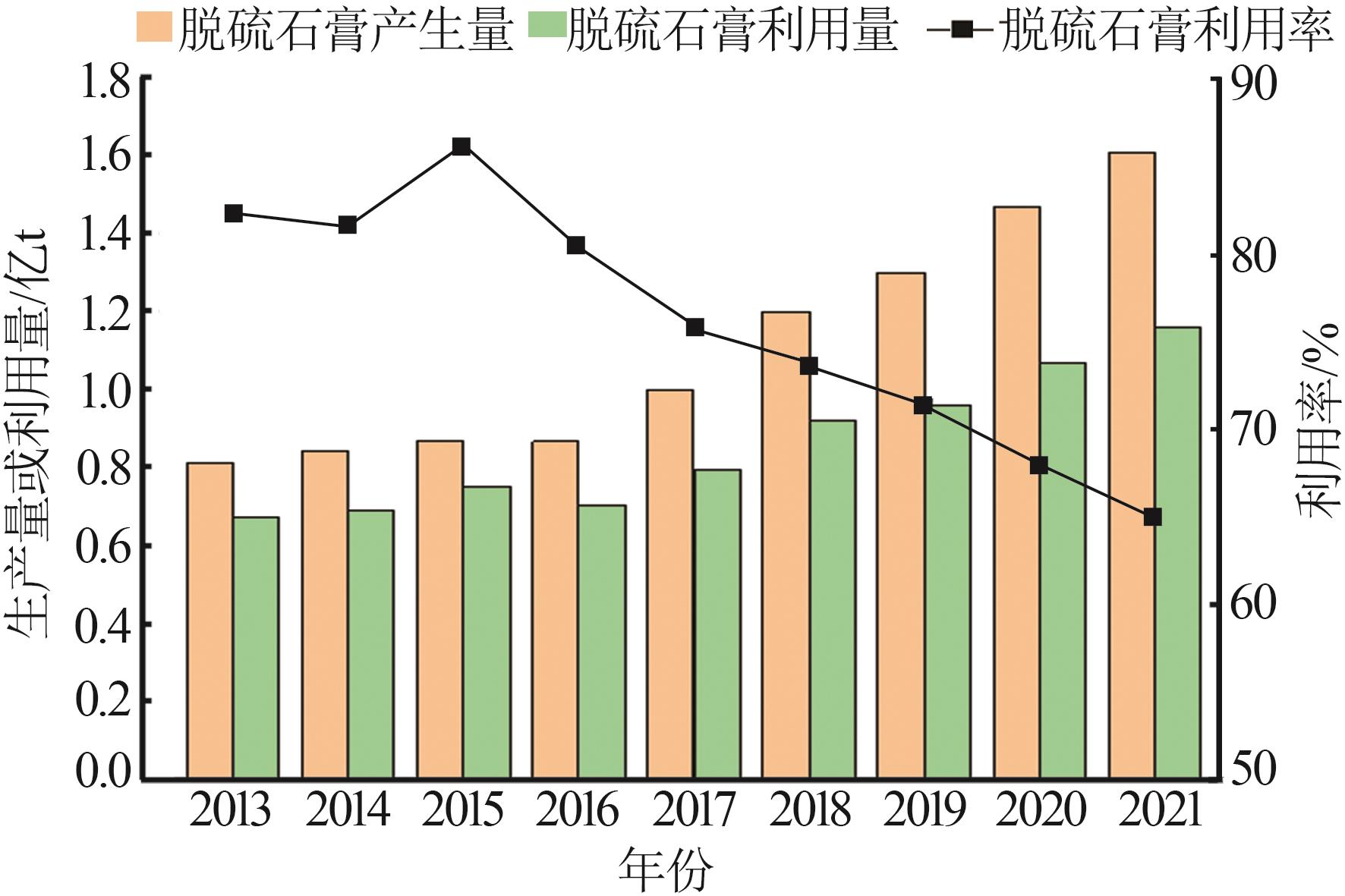

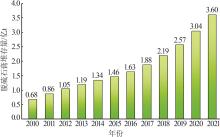

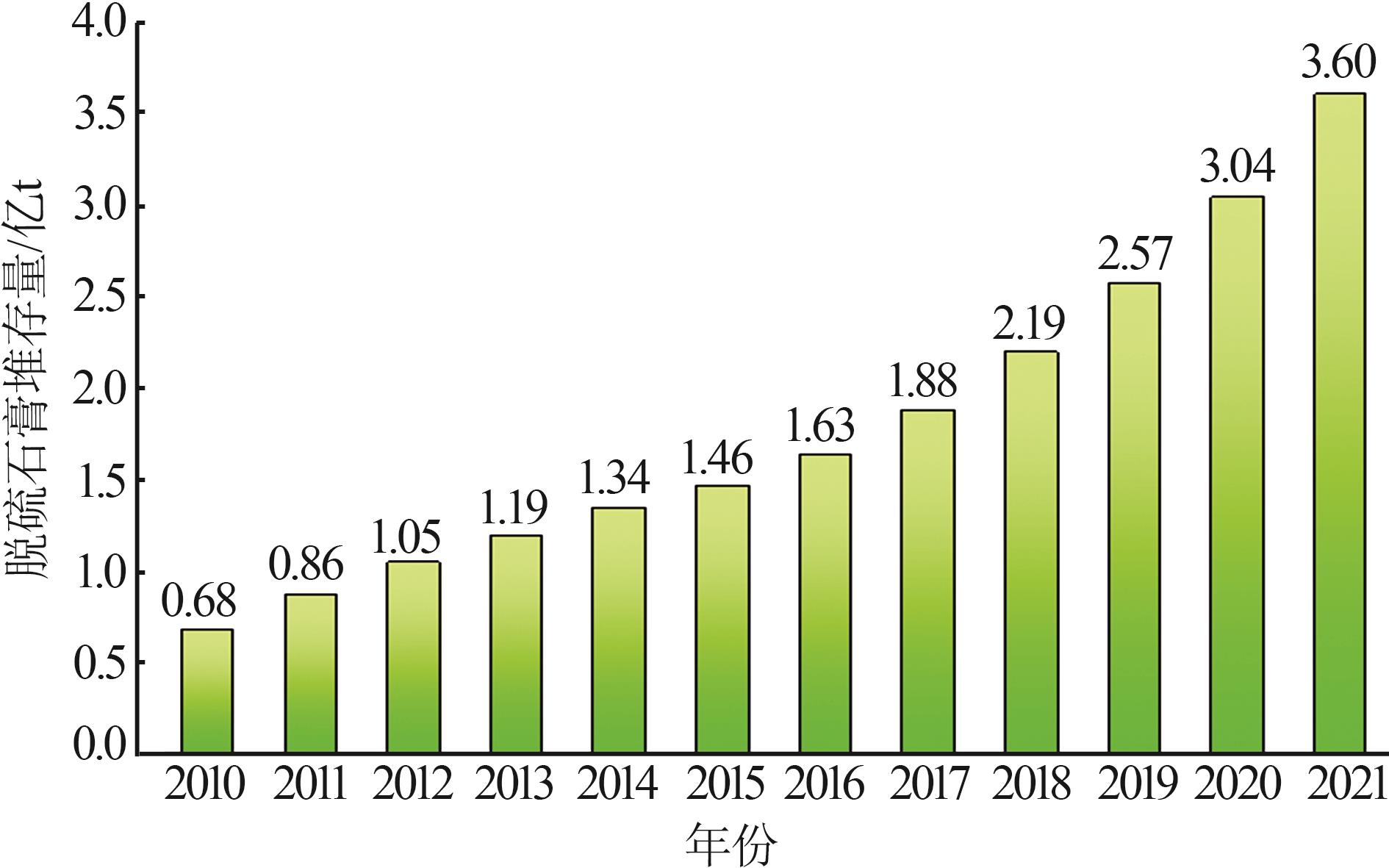

| 1 | 中华人民共和国生态环境部.2014—2020年全国大中城市固体废物污染环境防治年报[EB/OL].[2020-12-28].https://www.mee.gov.cn/hjzl/sthjzk/gtfwwrfz/. |

| 2 | 中商产业研究院.2021年中国新型建材产业链上中下游市场剖析[EB/OL].[2021-9-26].https://www.askci.com/news/chanye/20210926/1500221603972_5.shtml. |

| 3 | 高子栋,展琳琳.浅谈我国脱硫石膏环保资源化综合利用现状[J].砖瓦,2022(6):44-46,49. |

| GAO Zidong, ZHAN Linlin.Current situation of comprehensive utilization of desulfurization gypsum environmental protection resources[J].Brick-Tile,2022(6):44-46,49. | |

| 4 | 张志明,桂联政,廖达琛,等.燃煤电厂粉煤灰高值化利用研究进展[J].能源环境保护,2023,37(4):1-11. |

| ZHANG Zhiming, GUI Lianzheng, LIAO Dachen,et al.Advances in high-value utilization of fly ash from coal-fired power plants[J].Energy Environmental Protection,2023,37(4):1-11. | |

| 5 | 赵龙广,艾勇.火电厂脱硫石膏的产生与利用现状[J].科技视界,2017(7):209-210. |

| ZHAO Longguang, AI Yong.Research progress for comprehensive utilization of FGD gypsum[J].Science & Technology Vision, 2017(7):209-210. | |

| 6 | GUAN Qingjun, SUI Ying, ZHANG Fang,et al.Preparation of α-calcium sulfate hemihydrate from industrial by-product gypsum:A review[J].Physicochemical Problems of Mineral Processing,2020,57(1):168-181. |

| 7 | 胡宏,何兵兵,薛绍秀. α-半水石膏的制备与应用研究进展[J].新型建筑材料,2015,42(4):44-48. |

| HU Hong, HE Bingbing, XUE Shaoxiu.Research progress on pre-paration and application of α-calcium sulfate hemihydrate[J].New Building Materials,2015,42(4):44-48. | |

| 8 | ZHANG Xiaofei, WANG Jinshu, WU Junshu,et al.Phase-and morphology-controlled crystallization of gypsum by using flue-gas-desulfurization gypsum solid waste[J].Journal of Alloys and Compounds,2016,674:200-206. |

| 9 | SCHMIDT H, PASCHKE I, FREYER D,et al.Water channel structure of bassanite at high air humidity:Crystal structure of CaSO4·0.625H2O[J].Acta Crystallographica Section B Structural Science,2011,67(6):467-475. |

| 10 | JACQUES S D M, GONZÁLEZ-SABORIDO A, LEYNAUD O,et al.Structural evolution during the dehydration of gypsum materials[J].Mineralogical Magazine,2009,73(3):421-432. |

| 11 | BALLIRANO P, MARAS A, MELONI S,et al.The monoclinic I2 structure of bassanite,calcium sulphate hemihydrate(CaSO4·0.5H2O)[J].European Journal of Mineralogy,2001,13(5):985-993. |

| 12 | BEZOU C, NONAT A, MUTIN J C,et al.Investigation of the crystal structure of γ-CaSO4,CaSO4·0.5H2O,and CaSO4·0.6H2O by powder diffraction methods[J].Journal of Solid State Chemistry,1995,117(1):165-176. |

| 13 | 郭会宾.脱硫石膏制备α-半水石膏工艺研究[D].西宁:青海大学,2013. |

| GUO Huibin.Research of process conditions on the preparation of hemi hydrate gypsum from desulfurization gypsum[D].Xining:Qinghai University,2013. | |

| 14 | 董一苇,徐祖顺,杨婷婷,等.化学石膏制备α-半水石膏的研究进展[J].材料导报,2021,35(S2):241-247. |

| DONG Yiwei, XU Zushun, YANG Tingting,et al.Research progress on the preparation of α-calcium sulfate hemihydrate from chemical gypsum[J].Materials Reports,2021,35(S2):241- 247. | |

| 15 | YANG Baojun, DONG Yinzhe, WANG Bainian,et al.A mild alcohol-salt route to synthesize α-hemihydrate gypsum microrods from flue gas desulfurization gypsum in large scale[J].Materials Research Express,2019,6(4):045507. |

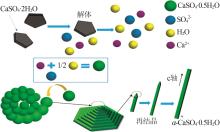

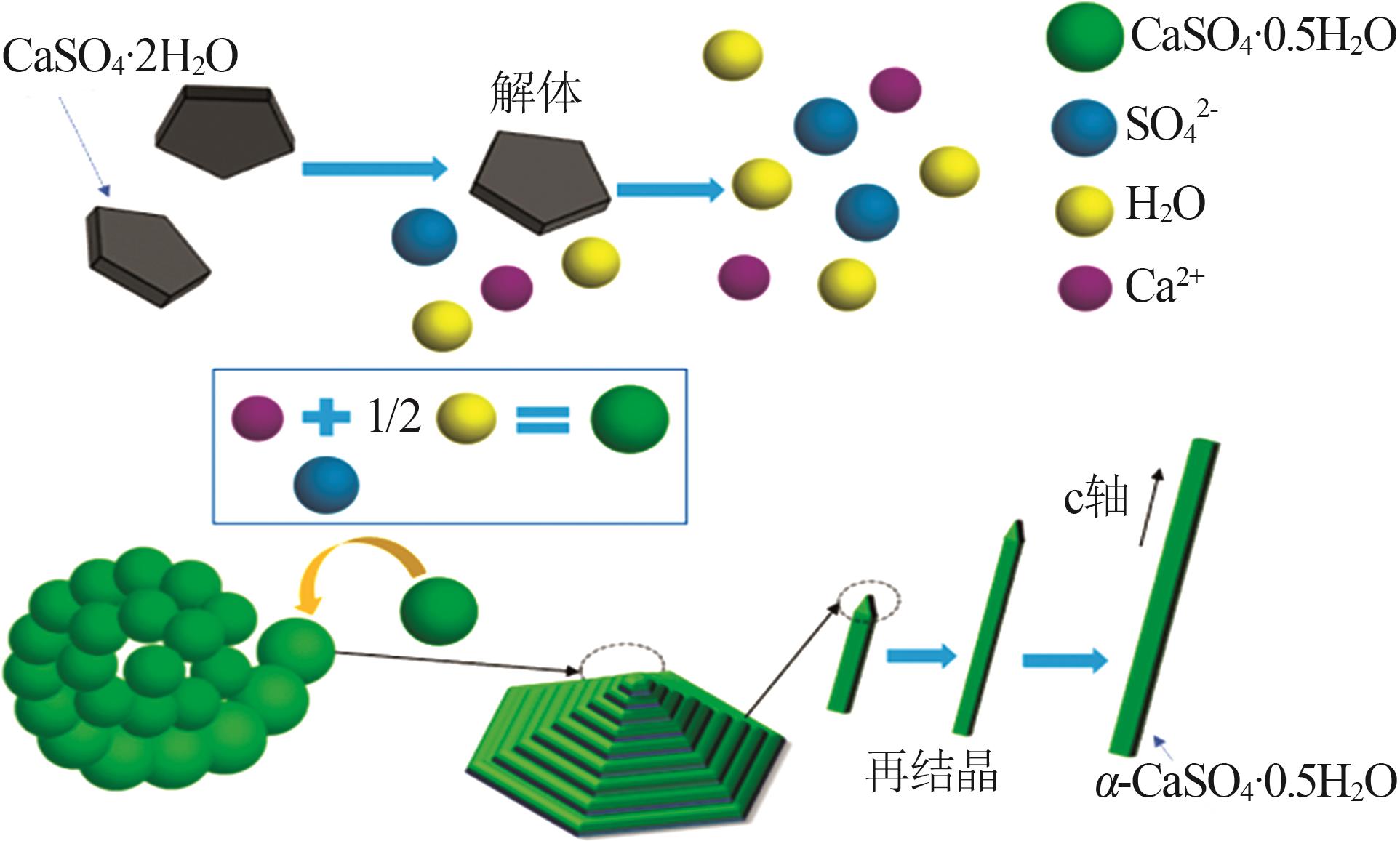

| 16 | 龚小梅,宾晓蓓,杨少博,等.脱硫石膏转化为半水石膏的过程及机理[J].硅酸盐通报,2015,34(9):2491-2495. |

| GONG Xiaomei, Xiaobei BIN, YANG Shaobo,et al.Preparation and mechanism of hemihydrate gypsum with FGD gypsum[J].Bulletin of the Chinese Ceramic Society,2015,34(9):2491-2495. | |

| 17 | 吴晓琴,杨有余,裘建军.常压盐溶液法转化脱硫石膏制备α-半水石膏的相变机理[J].武汉科技大学学报,2011,34(1):37-41. |

| WU Xiaoqin, YANG Youyu, QIU Jianjun.Mechanism of α-calcium sulfate hemihydrate produced from FGD gypsum in thermal solution[J].Journal of Wuhan University of Science and Technology,2011,34(1):37-41. | |

| 18 | 邵朵朵.脱硫石膏制备大颗粒α-半水石膏及其增白工艺的研究[D].天津:河北工业大学,2018. |

| SHAO Duoduo.Study on the preparation of large-grained α-calcium sulfate hemihydrate and the whitening process of flue gas desulfurization gypsum[D].Tianjin:Hebei University of Technology,2018. | |

| 19 | 董胤喆.常压醇盐体系由脱硫石膏制备α-半水石膏的工艺条件研究[D].合肥:合肥工业大学,2019. |

| DONG Yinzhe.Study on the prepartion conditions of α-hemihydrate gypsum from flue gas desulfurization gypsum in alcohol-salt system under normal pressure[D].Hefei:Hefei University of Technology,2019. | |

| 20 | SAKAKIBARA S.Method of producing a gypsum plaster board:US,4392896[P].1983-07-12. |

| 21 | 赵辉. α半水石膏的制备及其改性[D].武汉:湖北大学,2015. |

| ZHAO Hui.Preparation and modification of α hemihydrate gypsum[D].Wuhan:Hubei University,2015. | |

| 22 | 吴传龙.常压醇水法α-半水石膏的形貌调控及性能研究[D].绵阳:西南科技大学,2016. |

| WU Chuanlong.Study on morphology control and performance of α-hemihydrate gypsum by the glycerol water method at atmospheric pressure[D].Mianyang:Southwest University of Science and Technology,2016. | |

| 23 | 陈金文,易芸,张慧,等.蒸压参数与杂质对磷石膏制备α-半水石膏的影响[J].无机盐工业,2022,54(3):91-96. |

| CHEN Jinwen, YI Yun, ZHANG Hui,et al.Effect of autoclave parameters and impurities on preparation of α-hemihydrate gypsum from phosphogypsum[J].Inorganic Chemicals Industry,2022,54(3):91-96. | |

| 24 | 黎明川,韦家崭,陈平,等.转晶剂与蒸压参数对磷石膏制备α半水石膏的影响[J].无机盐工业,2022,54(8):132-137. |

| LI Mingchuan, WEI Jiazhan, CHEN Ping,et al.Effect of crystal modifier and autoclave parameters on preparation of α-hemihydrate gypsum from phosphogypsum[J].Inorganic Chemicals Industry,2022,54(8):132-137. | |

| 25 | KAMAROU M, KOROB N, KWAPINSKI W,et al.High-quality gypsum binders based on synthetic calcium sulfate dihydrate produced from industrial waste[J].Journal of Industrial and Engineering Chemistry,2021,100:324-332. |

| 26 | 陈勇,张毅,李东旭.利用脱硫石膏制备α-半水石膏的蒸压制度研究[J].硅酸盐通报,2015,34(5):1241-1245. |

| CHEN Yong, ZHANG Yi, LI Dongxu.Autoclaved system research of calcium sulfate prepared with desulfurization gypsum[J].Bulletin of the Chinese Ceramic Society,2015,34(5):1241-1245. | |

| 27 | 徐成.石膏固废制备α-半水石膏工艺及性能研究[D].常州:常州大学,2022. |

| XU Cheng.Study on the technology and performance of α-hemihydrate gypsum prepared from gypsum solid waste[D].Changzhou:Changzhou University,2022. | |

| 28 | 韩康,管学茂,王燕峰,等.加压水溶液法制备工艺对α型高强石膏性能的影响[J].硅酸盐通报,2021,40(5):1620-1630,1645. |

| HAN Kang, GUAN Xuemao, WANG Yanfeng,et al.Effect of preparation process of pressurized aqueous solution method on properties of α-high strength gypsum[J].Bulletin of the Chinese Ceramic Society,2021,40(5):1620-1630,1645. | |

| 29 | 岳文海,王志. α半水石膏晶形转化剂作用机理的探讨[J].武汉工业大学学报,1996,18(2):1-4. |

| YUE Wenhai, WANG Zhi.Investigation on the mechanism of crystal shape modifying agent of α-hemihydrate[J].Journal of Wuhan University of Technology,1996,18(2):1-4. | |

| 30 | 胡俊要,李军,金央,等.盐种类对常压盐溶液法制备半水石膏的影响[J].无机盐工业,2018,50(6):47-50. |

| HU Junyao, LI Jun, JIN Yang,et al.Effect of salt species on preparation of hemihydrate gypsum by atmospheric salt solution method[J].Inorganic Chemicals Industry,2018,50(6):47-50. | |

| 31 | 丁峰,窦焰,郑之银,等.常压盐溶液-丁二酸转晶体系中pH对α-CaSO4·0.5H2O的影响[J].无机盐工业,2020,52(1):82-86,98. |

| DING Feng, DOU Yan, ZHENG Zhiyin,et al.Effect of pH on α-CaSO4·0.5H2O in salt solution at atmospheric pressure-succinic acid crystal transfer system[J].Inorganic Chemicals Industry,2020,52(1):82-86,98. | |

| 32 | 胡成,向玮衡,陈平,等.丁二酸对水热合成α-半水脱硫石膏微晶形貌及力学强度的影响[J].无机盐工业,2021,53(4):76-80. |

| HU Cheng, XIANG Weiheng, CHEN Ping,et al.Effects of succinic acid on crystallite morphology and mechanical strength of α-hemihydrate desulfurized gypsum synthesized by hydrothermal method[J].Inorganic Chemicals Industry,2021,53(4):76-80. | |

| 33 | MA Baoguo, LU Wenda, SU Ying,et al.Synthesis of α-hemihydrate gypsum from cleaner phosphogypsum[J].Journal of Cleaner Production,2018,195:396-405. |

| 34 | 杨后文,刘丰,江郡,等.常压水热法制备半水脱硫石膏的工艺因素研究[J].矿产综合利用,2021(1):140-143,198. |

| YANG Houwen, LIU Feng, JIANG Jun,et al.Research on process condition on the preparation of hemihydrate desulfurization gypsum with hydrothermal method under atmospheric pressure[J].Multipurpose Utilization of Mineral Resources,2021(1):140-143,198. | |

| 35 | 吴传龙,董发勤,陈德玉,等.常压醇水法制备α-高强石膏的工艺条件研究[J].西南科技大学学报,2016,31(4):33- 37. |

| WU Chuanlong, DONG Faqin, CHEN Deyu,et al.Study on process conditions for preparation of α-high strength gypsum by the glycerol water method under atmospheric pressure[J].Journal of Southwest University of Science and Technology,2016,31(4):33-37. | |

| 36 | 李德星,郭荣鑫,林志伟,等.常压微波醇水法制备α半水硫酸钙晶须的研究[J].非金属矿,2022,45(1):46-50,55. |

| LI Dexing, GUO Rongxin, LIN Zhiwei,et al.Study on preparation of α-calcium sulfate hemihydrate whiskers by atmospheric microwave glycerol water method[J].Non-Metallic Mines,2022,45(1):46-50,55. | |

| 37 | 杨月静.丙烯酰胺在离子液体1-丁基-3-甲基四氟硼酸盐中的分散聚合研究[D].青岛:青岛科技大学,2014. |

| YANG Yuejing.Study on dispersion polymerization of acrylamide in ionic liquids[D].Qingdao:Qingdao University of Science & Technology,2014. | |

| 38 | 孔宝.反相微乳液法合成α-半水石膏及其形貌控制[D].杭州:浙江大学,2012. |

| KONG Bao.Synthesis and morphology control of α-calcium sulfate hemihydrate in a reverse microemulsion[D].Hangzhou:Zhejiang University,2012. | |

| 39 | 郭荣鑫,林志伟,杨洋,等.一种反相微乳液体系中磷石膏制备纳米级α型半水硫酸钙晶须的方法:中国,110835780B[P]. 2021-11-09. |

| 40 | 卢佳艳.微波辅助微乳液法制备脱水相硫酸钙[D].湘潭:湘潭大学,2021. |

| LU Jiayan.Preparation of dehydrated calcium sulfate by micro-wave-assisted microemulsion method[D].Xiangtan:Xiangtan University,2021. | |

| 41 | 陈星宇,林志伟,郭荣鑫,等.以磷石膏为原料在反相微乳液体系中制备α型半水石膏及晶体调控[J].硅酸盐通报,2020,39(11):3542-3548. |

| CHEN Xingyu, LIN Zhiwei, GUO Rongxin,et al.Preparation of α-hemihydrate gypsum and crystal regulation with phosphogypsum as raw material in reverse microemulsion system[J].Bulletin of the Chinese Ceramic Society,2020,39(11):3542-3548. | |

| 42 | 郭宇.脱硫石膏含水量对微波加热特性的影响[D].太原:太原理工大学,2016. |

| GUO Yu.Effect of water content in FGD gypsum on microwave heating characteristics[D].Taiyuan:Taiyuan University of Technology,2016. | |

| 43 | 张绍奇,郭荣鑫,林志伟,等.微波醇水体系下制备α-半水石膏晶须的研究[J].非金属矿,2020,43(2):84-87. |

| ZHANG Shaoqi, GUO Rongxin, LIN Zhiwei,et al.Study on preparation of α-calcium sulfate hemihydrate whiskers under microwave alcohol-water system[J].Non-Metallic Mines,2020,43(2):84-87. | |

| 44 | 冯焱,张绍奇,林志伟,等.微波辐照下丁二酸对磷石膏制备半水石膏的影响[J].硅酸盐通报,2020,39(11):3535-3541,3556. |

| FENG Yan, ZHANG Shaoqi, LIN Zhiwei,et al.Effect of succinic acid on preparation of hemihydrate gypsum from phosphogypsum under microwave irradiation[J].Bulletin of the Chinese Ceramic Society,2020,39(11):3535-3541,3556. | |

| 45 | SHAO Duoduo, ZHAO Bin, GAO Lili,et al.Preparation of whitening dihydrate gypsum and short columnar α-hemihydrate gypsum with FGD gypsum[J].Crystal Research and Technology,2017,52(9):1700166. |

| 46 | 汪潇,曹博伦,金彪,等.添加剂调控半水石膏晶体生长研究进展[J].硅酸盐学报,2020,48(1):94-103. |

| WANG Xiao, CAO Bolun, JIN Biao,et al.Using additives to control crystal growth of hemihydrate gypsum:A short review[J].Journal of the Chinese Ceramic Society,2020,48(1):94-103. | |

| 47 | 尹诗诗.石膏二水相-半水相转化过程调控研究[D].湘潭:湘潭大学,2020. |

| YIN Shishi.Study on contronlling the transformation process from dihydrate to hemihydrate gypsum[D].Xiangtan:Xiangtan University,2020. | |

| 48 | 陈平,田宇,胡成.盐溶液种类和浓度对α-半水脱硫石膏合成的影响[J].无机盐工业,2020,52(10):130-134. |

| CHEN Ping, TIAN Yu, HU Cheng.Effect of type and concentration of salt solution on synthesis of α-semi-water desulfurization gypsum[J].Inorganic Chemicals Industry,2020,52(10):130- 134. | |

| 49 | 韩康.加压水热法制备高强石膏[D].焦作:河南理工大学,2021. |

| HAN Kang.Preparation of high strength gypsum by pressurized hydrothermal method[D].Jiaozuo:Henan Polytechnic University,2021. | |

| 50 | 赵云龙.建筑石膏生产与应用技术[M].北京:中国建材工业出版社,2019:258-279. |

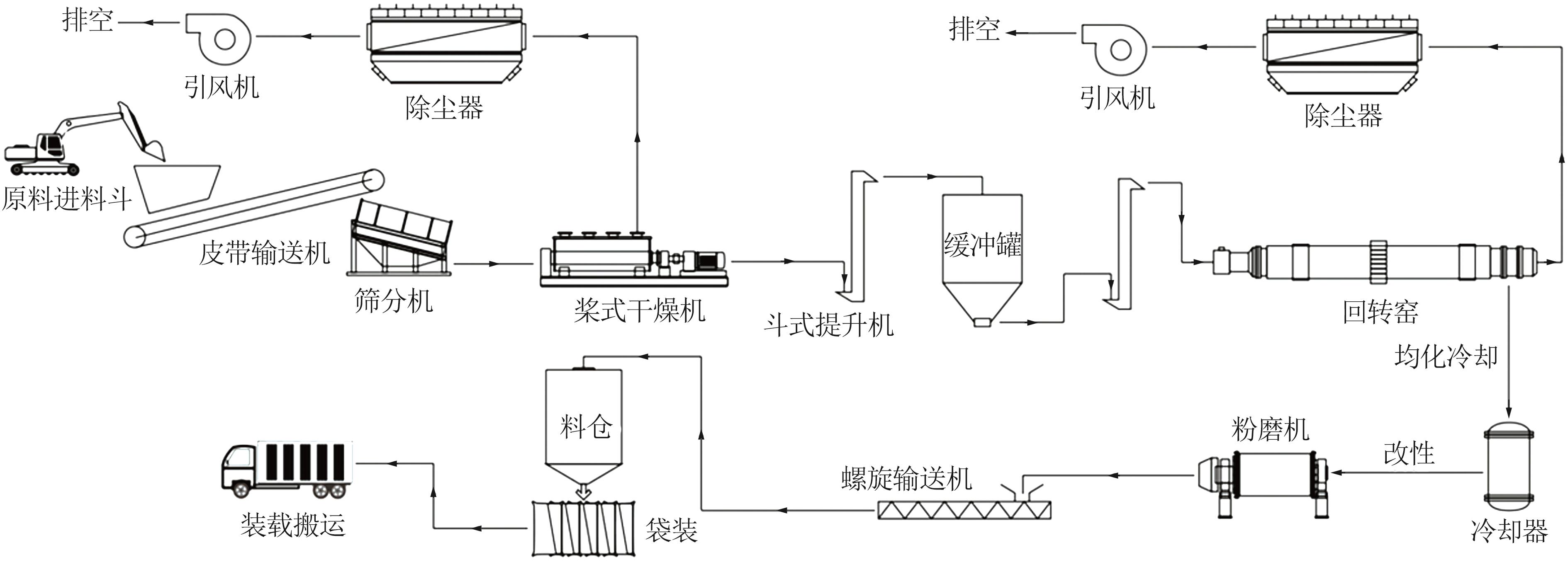

| 51 | 雷中明,苏根华,郭栋,等.石膏煅烧回转窑生产线系统:中国,114893960A[P].2022-08-12. |

| 52 | 蔡彦煌.脱硫石膏蒸汽二步法生产建筑石膏粉工艺简介[J].福建建材,2019(4):102-103,84. |

| CAI Yanhuang.Brief introduction to the process of producing building gypsum powder by steam two-step method of desulfurization gypsum[J].Fujian Building Materials,2019(4):102-103,84. | |

| 53 | 陈燕,岳文海,董若兰.石膏建筑材料[M].2版.北京:中国建材工业出版社,2012:380-393. |

| 54 | 中华人民共和国工业和信息化部. α型高强石膏:JC/T 2038—2010[S].北京:中国建材工业出版社,2011. |

| 55 | 中华人民共和国工业和信息化部. 石膏型熔模铸造用铸型粉:JB/T 11734—2013[S].北京:机械工业出版社,2014. |

| 56 | 中华人民共和国工业和信息化部. 陶瓷模用石膏粉:QB/T 1639—2014[S].北京:中国轻工业出版社,2014. |

| [1] | LIU Jintong, ZHANG Jie, ZHOU Junliang, WU Bingdang, HUANG Tianyin, YANG Jingjing. Summary of antimony residues and status in antimony recovery technology [J]. Inorganic Chemicals Industry, 2024, 56(9): 1-11. |

| [2] | ZHU Zongjiang, WANG Gang, WEI Yuanfeng, TANG Yanhong, KAKUTA Cheng, LIU Chengbin. Research progress and prospect of resourceful recycling technology of electrolyte from decommissioned lithium⁃ion battery [J]. Inorganic Chemicals Industry, 2024, 56(7): 11-17. |

| [3] | HU Cheng, LIU Meng, XIANG Weiheng, CHEN Ping, WANG Neng, LU Guanju, ZHOU Jinlan. Preparation of α-hemihydrous gypsum from CaCl2 and MgCl2 and their composite solution [J]. Inorganic Chemicals Industry, 2024, 56(7): 112-117. |

| [4] | ZHANG Lijin, LÜ Qing, CHEN Xiaolang, LI Qingxin, SHI Hongyu, QIN Jun. Preparation of Ca-based LDO composite material and its adsorption performance for phosphate [J]. Inorganic Chemicals Industry, 2024, 56(7): 37-45. |

| [5] | YE Fen, CHENG Hao, XIANG Yuan, LIU Song, SHI Wei. Preparation of ceramic aggregate from electrolytic manganese slag and its application in concrete [J]. Inorganic Chemicals Industry, 2024, 56(6): 127-132. |

| [6] | HU Cheng, LIU Meng, XIANG Weiheng, DUAN Pengxuan, LI Shunkai, MING Yang, WANG Neng, LU Guanju. Effect of NaCl solution concentration on transcrystallization behavior of α-hemihydrate gypsum from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(6): 87-93. |

| [7] | WANG Peixiong, GONG Xiaomei, DING Jiaqi, CAO Hong. Effect of crystal modifier on preparation of α-hemihydrates gypsum from industrial gypsum [J]. Inorganic Chemicals Industry, 2024, 56(4): 112-117. |

| [8] | YAO Jiankang, HU Shuozhen, NIU Dongfang, WU Jianping, ZHANG Xinsheng. Study on electrochemical treatment of sodium chloride organic waste salt in spice industry [J]. Inorganic Chemicals Industry, 2024, 56(3): 105-115. |

| [9] | LI Yu, ZHAO Wei, ZHANG Xinghua, WANG Rui, YAN Bingji, GUO Hongwei. Syudy on preparation of high-strength ceramsite from fluorite tailings and its properties [J]. Inorganic Chemicals Industry, 2023, 55(5): 100-108. |

| [10] | YANG Yue, ZHU Ganyu, ZHANG Jianbo, MENG Ziheng, LIU Xinhui, YANG Jing, YAN Kun, PENG Zonggui, WANG Qiujian, LI Huiquan. Study on preparation of desulfurizer and byproduct gypsum from calcium carbide slag by cyclone separation [J]. Inorganic Chemicals Industry, 2023, 55(5): 78-84. |

| [11] | JIN Suna, LÜ Ruiliang. Research and application progress of wet flue gas desulfurization wastewater treatment technology [J]. Inorganic Chemicals Industry, 2023, 55(4): 27-37. |

| [12] | LI Peng, WANG Likun, MENG Qiuyan. Study on effect of α-hemihydrate gypsum on performance of cement mortar and its hydration mechanism [J]. Inorganic Chemicals Industry, 2023, 55(3): 98-103. |

| [13] | XU Wenzhen,LI Canhua,JI Hongfeng,LI Zimu,WU Zhaoyang,LI Minghui. Research progress of red mud in field of recycled metals and building materials [J]. Inorganic Chemicals Industry, 2023, 55(2): 10-18. |

| [14] | LI Yunfei, LIU Shuqing, TANG Shengwei, ZHANG Tao. Preparation of α-hemihydrate gypsum in Mg-Na mixed salt solution system under atmospheric pressure [J]. Inorganic Chemicals Industry, 2023, 55(11): 100-106. |

| [15] | LIU Chao, FAN Chuigang, LIU Runguo, YU Dongxue, LI Songgeng. Preparation of α-hemihydrate gypsum from phosphogypsum by flotation and atmospheric trans-crystallization in solution [J]. Inorganic Chemicals Industry, 2023, 55(11): 107-114. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||