Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (12): 119-125.doi: 10.19964/j.issn.1006-4990.2022-0263

• Environment·Health·Safety • Previous Articles Next Articles

Study on high-value utilization of zinc oxide powder in rotary hearth furnace

YAO Haiwei( ),MAO Rui(

),MAO Rui( ),WANG Fei,ZHU Zuoqiao

),WANG Fei,ZHU Zuoqiao

- Shagang Iron & Steel Research Institute of Jiangsu Province,Zhangjiagang 215625,China

-

Received:2022-06-13Online:2022-12-10Published:2022-12-19 -

Contact:MAO Rui E-mail:iris@shasteel.cn;maorui-iris@shasteel.cn

CLC Number:

Cite this article

YAO Haiwei,MAO Rui,WANG Fei,ZHU Zuoqiao. Study on high-value utilization of zinc oxide powder in rotary hearth furnace[J]. Inorganic Chemicals Industry, 2022, 54(12): 119-125.

share this article

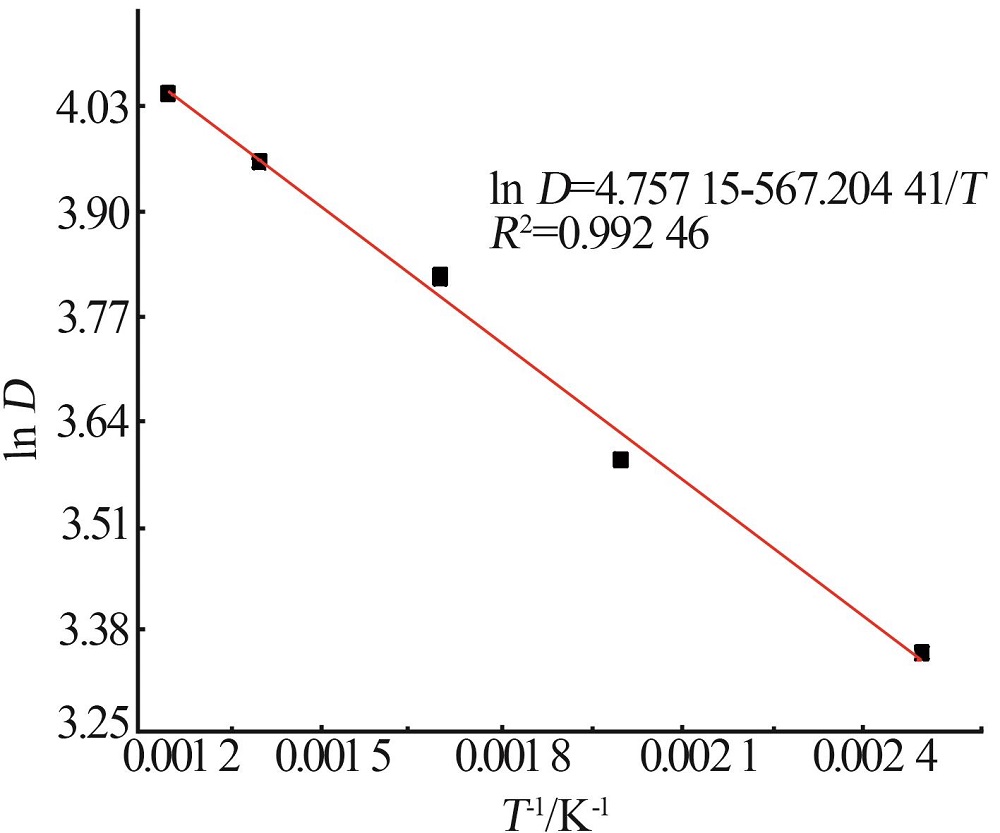

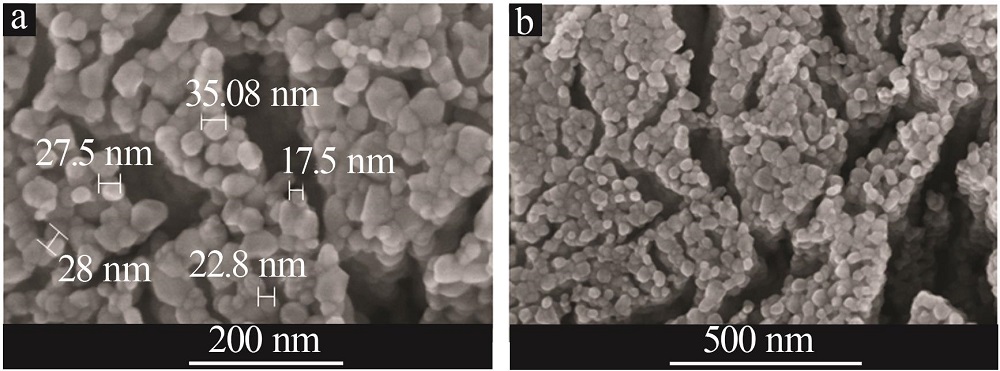

Table 2

Comparison of prepared nano zinc oxide with national standard"

| 项目 | w(ZnO)/ % | 电镜平均 粒径/nm | 比表面积/ (m2·g-1) | 团聚指数 | w(Pb)/ % | w(Mn)/ % | |

|---|---|---|---|---|---|---|---|

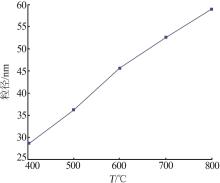

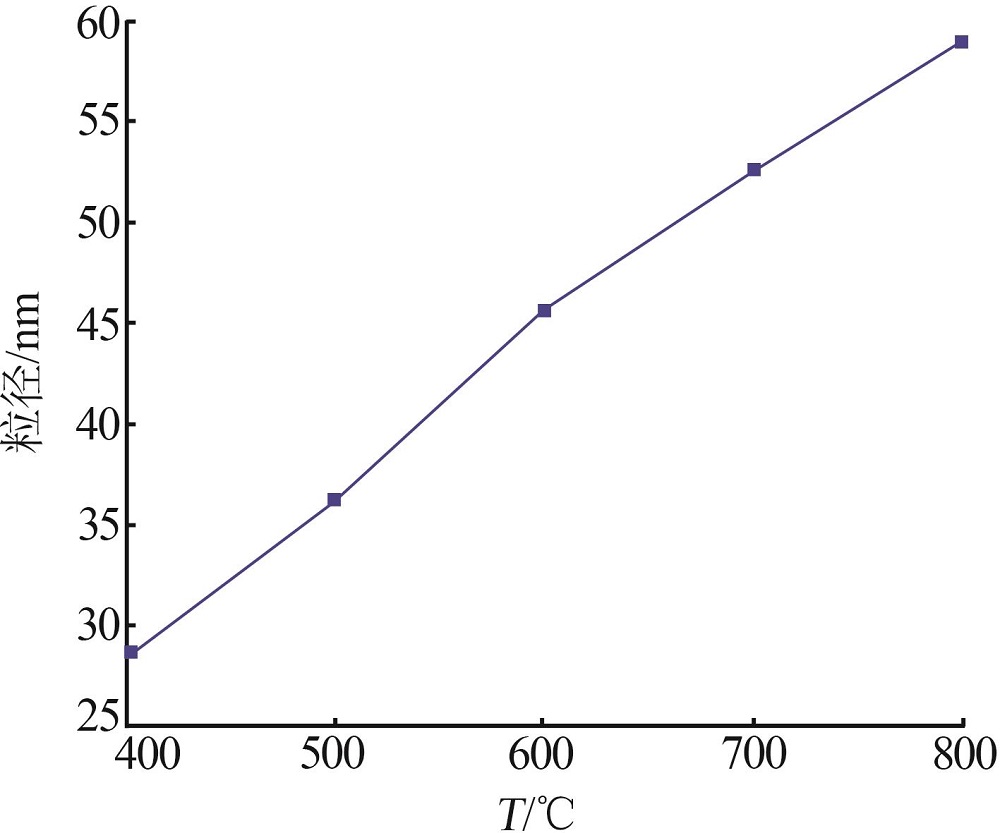

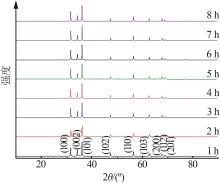

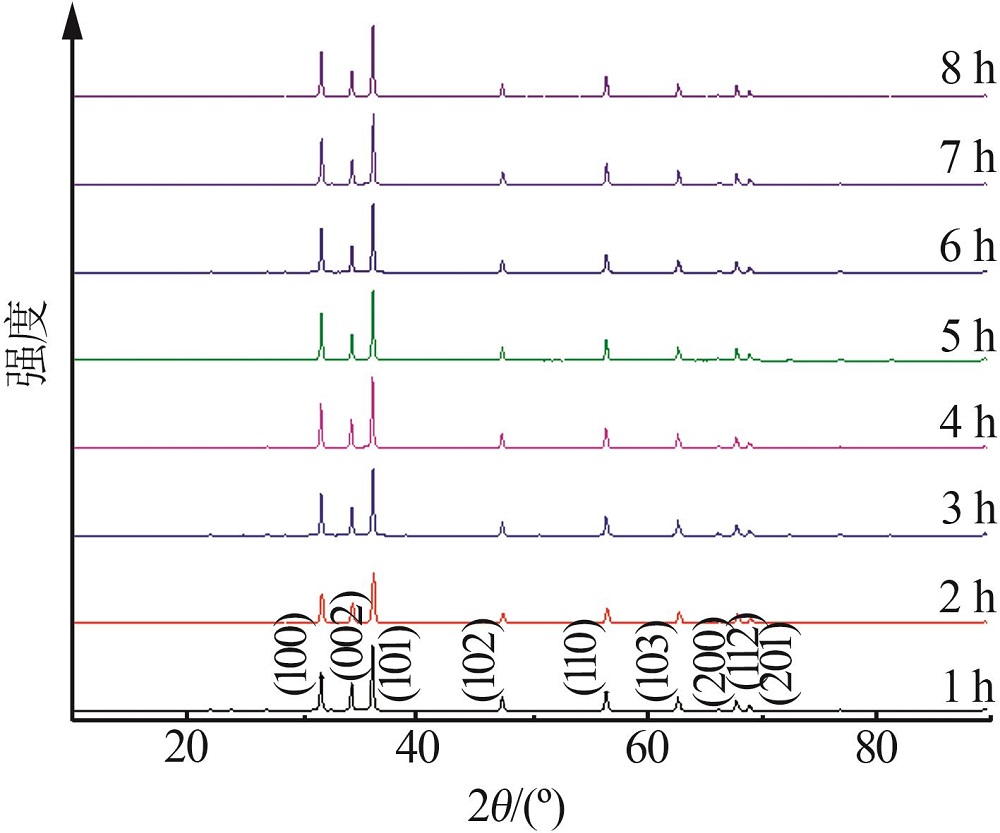

| CC-OA法 | 99.768 | 28.5 | 33.8 | — | 0 | — | |

| GB/T 19589—2004《纳米氧化锌》 | 1类 | ≥99.0 | ≤100 | ≥15 | ≤100 | ≤0.001 | ≤0.001 |

| 2类 | ≥97.0 | ≤100 | ≥15 | ≤100 | ≤0.001 | ≤0.01 | |

| 3类 | ≥95.0 | ≤100 | ≥15 | ≤100 | ≤0.03 | ≤0.005 | |

| 德国拜耳公司标准 | 93~96 | 50 | 45 | — | ≤0.04 | ≤0.002 | |

| 项目 | w(Cd)/ % | w(Hg)/ % | w(105 ℃挥 发物)/% | w(水溶物)/ % | w(盐酸不 溶物)/% | 灼烧失量/ % | |

| CC-OA法 | — | — | 0.32 | 0.048 | 0.011 | 1.28 | |

| GB/T 19589—2004《纳米氧化锌》 | 1类 | ≤0.001 5 | ≤0.000 1 | ≤0.5 | ≤0.1 | ≤0.02 | — |

| 2类 | ≤0.005 | — | ≤0.5 | ≤0.1 | ≤0.02 | ≤2 | |

| 3类 | — | — | ≤0.7 | ≤0.7 | ≤0.05 | ≤4 | |

| 德国拜耳公司标准 | — | — | — | 1.0 | — | 3~6 | |

| 1 | 张建良, 李洋, 袁骧, 等. 中国钢铁企业尘泥处理现状及展望[J]. 钢铁, 2018, 53(6):1-10. |

| ZHANG Jianliang, LI Yang, YUAN Xiang, et al. Present situation and prospect of dust treatment in Chinese iron and steel enterprises[J]. Iron & Steel, 2018, 53(6):1-10. | |

| 2 | 王飞, 毛瑞, 茅沈栋. 转底炉对转炉污泥的处理[J]. 钢铁, 2019, 54(12):111-116, 124. |

| WANG Fei, MAO Rui, MAO Shendong. Utilization of converter sludge by rotary hearth furnace[J]. Iron & Steel, 2019, 54(12):111-116, 124. | |

| 3 | 唐茜. 转底炉二次粉尘中有价元素提取工艺的实验研究[D].重庆:重庆大学, 2018. |

| TANG Qian. Experimental study on extraction process of valuable elements in RHF second dust[D].Chongqing:Chongqing University, 2018. | |

| 4 | 侯洪宇, 于淑娟, 钱峰, 等. 钢铁企业含锌尘泥利用[J]. 鞍钢技术, 2017(3):6-9. |

| HOU Hongyu, YU Shujuan, QIAN Feng, et al. Recycling of zinc-bearing dust and sludge generated by iron & steel enterprises[J]. Angang Technology, 2017(3):6-9 | |

| 5 | 李博, 毛艳丽, 王博蔚, 等. 转底炉技术及其在含铁尘泥处理中的应用[J]. 鞍钢技术, 2017(6):8-12. |

| LI Bo, MAO Yanli, WANG Bowei, et al. Treatment process by rotary hearth furnace and its application in treatment of iron-bearing sludge[J]. Angang Technology, 2017(6):8-12. | |

| 6 | 徐健祥, 齐凤升, 李宝宽, 等. 厚料层转底炉含铁尘泥直接还原模拟[J]. 中国冶金, 2021, 31(10):94-101. |

| XU Jianxiang, QI Fengsheng, LI Baokuan, et al. Direct reduction simulation of iron-bearing dust in thick-layer rotary hearth furnace[J]. China Metallurgy, 2021, 31(10):94-101. | |

| 7 | 曹刘奇, 王黎明, 徐丽慧, 等. 球形纳米氧化锌的制备及应用研究[J]. 化工新型材料, 2022, 50(4):47-51. |

| CAO Liuqi, WANG Liming, XU Lihui, et al. Preparation and application of spherical nano ZnO[J]. New Chemical Materials, 2022, 50(4):47-51. | |

| 8 | LYNN T H H, JITYEN A, TIVAKORNSASITHORN K, et al. Nano-flower structure of indium and gallium doped zinc oxide powder[J]. Materials Today:Proceedings, 2020, 23: 757-761. |

| 9 | 黄文艺, 王崇罡, 吕晓威, 等. 基于温度调控制备花状纳米氧化锌及其光催化性能[J]. 无机盐工业, 2018, 50(9):72-75. |

| HUANG Wenyi, WANG Chonggang, LV Xiaowei, et al. Preparation and photocatalytic properties of flower-shaped nano-zinc oxide based on temperature regulation[J]. Inorganic Chemicals Industry, 2018, 50(9):72-75. | |

| 10 |

YANG Ronggui, WANG Meiling, LIU Ting, et al. Room temperature solid state synthesis,characterization,and application of a zinc complex with pyromellitic acid[J]. Crystals, 2018, 8(2).Doi:10.3390/cryst8020056 .

doi: 10.3390/cryst8020056 |

| 11 | 胡鹏程, 江伟, 钟丽娟. 低共熔溶剂的应用研究进展[J]. 现代化工, 2018, 38(10):53-57. |

| HU Pengcheng, JIANG Wei, ZHONG Lijuan. Study on properties of deep eutectic solvents and their applications[J]. Modern Che-Industry mical, 2018, 38(10):53-57. | |

| 13 | 雷震, 徐存英, 华一新, 等. ChCl-urea-ZnO低共熔溶剂体系的电化学行为[J]. 化工学报, 2017, 68(8):3301-3309. |

| LEI Zhen, XU Cunying, HUA Yixin, et al. Eelectrochemical behaviors of ZnO in choline chloride-urea deep eutectic solvents[J]. CIESC Journal, 2017, 68(8):3301-3309. | |

| 14 | 王新玉, 吴春洋, 陈庆阳, 等. 绿色溶剂-离子液体的合成和性质[J]. 山东化工, 2019, 48(7):63-65. |

| WANG Xinyu, WU Chunyang, CHEN Qingyang, et al. Synthesis and properties of green solvents-ionic liquids[J]. Shandong Che-Industry mical, 2019, 48(7):63-65. | |

| 15 | 张盈盈, 吉晓燕, 陆小华. 氯化胆碱/尿素和氯化胆碱/甘油的性质与应用[J]. 中国科学:化学, 2014, 44(6):927-941. |

| ZHANG Yingying, JI Xiaoyan, LU Xiaohua. Properties and applications of choline chloride/urea and choline chloride/glycerol[J]. Scientia Sinica:Chimica, 2014, 44(6):927-941. | |

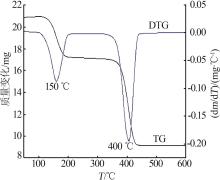

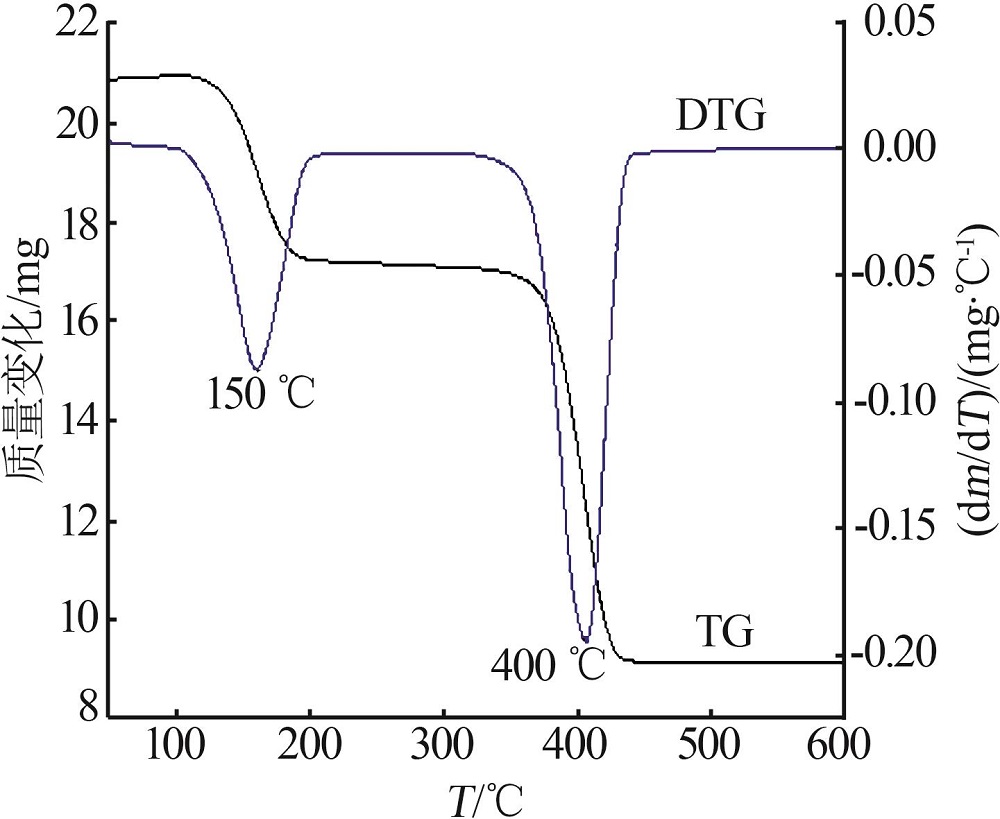

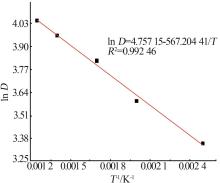

| 16 | 居殿春, 姚海威, 麻晗, 等. ChCl-urea-ZnO低共熔溶剂体系热稳定性[J]. 高校化学工程学报, 2020, 34(6):1393-1400. |

| JU Dianchun, YAO Haiwei, MA Han, et al. Thermal stability of ChCl-urea-ZnO eutectic solvent system[J]. Journal of Chemical Engineering of Chinese Universities, 2020, 34(6):1393-1400. | |

| 17 | ABBOTT A P, CAPPER G, DAVIES D L, et al. Solubility of metal oxides in deep eutectic solvents based on choline chloride[J]. Journal of Chemical & Engineering Data, 2006, 51(4):1280-1282. |

| 18 | 石升友, 李水娥, 刘祥伟. 低共熔溶剂的应用研究现状[J]. 化学通报, 2022, 85(5):583-589. |

| SHI Shengyou, LI Shuie, LIU Xiangwei. Application and research status of deep eutectic solvents[J]. Chemistry, 2022, 85(5):583- 589. | |

| 19 | 徐思语, 张俊, 李凡, 等. 低共熔溶剂电解沉积制备金属锌研究进展[J]. 有色金属工程, 2022, 12(3):76-85. |

| XU Siyu, ZHANG Jun, LI Fan, et al. Research progress of zinc electrodeposition from deep eutectic solvent[J]. Nonferrous Metals Engineering, 2022, 12(3):76-85. | |

| 20 | YAO Haiwei, MA Han, MAO Rui, et al. Preparation of ZnO nanoparticles from Zn-containing rotary hearth furnace dust[J]. Journal of Wuhan University of Technology-Mater.Sci.Ed., 2022, 37(1):32-37. |

| 21 | 刘成, 张连红. 低共熔溶剂及其应用的研究进展[J]. 现代化工, 2022, 42(4):43-47. |

| LIU Cheng, ZHANG Lianhong. Research progress in deep eutectic solvent and its application[J]. Modern Chemical Industry, 2022, 42(4):43-47. | |

| 22 | 曹雪辰, 周东杰, 姚海威, 等. 氯化胆碱-草酸低共熔溶剂处理含铁尘泥制备纳米氧化铁及动力学研究[J]. 无机盐工业, 2021, 53(11):100-106. |

| CAO Xuechen, ZHOU Dongjie, YAO Haiwei, et al. Study on preparation of nanometer iron oxide and its kinetics by CC-OA DES treatment of iron-containing dust[J]. Inorganic Chemicals Industry, 2021, 53(11):100-106. | |

| 23 |

JU Dianchun, YAO Haiwei, MA Han, et al. Removal process and mechanism of lead in Zn-containing rotary hearth furnace dust[J]. Inorganic Chemistry Communications, 2021, 127.Doi:10.1016/j.inoche.2021.108496 .

doi: 10.1016/j.inoche.2021.108496 |

| 24 | 张远, 李林菲, 李坚, 等. 氯化胆碱-水合草酸低共熔溶剂中ZnO的溶解行为[J]. 中南大学学报:自然科学版, 2016, 47(8):2591-2599. |

| ZHANG Yuan, LI Linfei, LI Jian, et al. Dissolution behavior of zinc oxide in choline chloride-oxalate hydrates deep eutectic solvents[J]. Journal of Central South University:Science and Technology, 2016, 47(8):2591-2599. | |

| 25 | 徐如人, 庞文琴. 无机合成与制备化学[M].北京:高等教育出版社, 2001. |

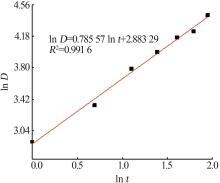

| 26 | 冯炜, 邹克华, 翟增秀. 微波辅助低温制备纳米TiO2晶体生长动力学研究[J]. 无机材料学报, 2010, 25(8):815-819. |

| FENG Wei, ZOU Kehua, ZHAI Zengxiu. Study on the crystal growth kinetics of nano TiO2 prepared with microwave aid at low temperature[J]. Journal of Inorganic Materials, 2010, 25(8):815-819. |

| [1] | FAN Fangfang, TONG Zhongkai, ZUO Weiyuan. Study on adsorption of tetracycline from wastewater by calcium modified peanut shell biochar [J]. Inorganic Chemicals Industry, 2023, 55(6): 109-115. |

| [2] | ZHOU Qiang, WU Bin, CHEN Kui, JI Lijun, WU Yanyang. Study on thermal decomposition kinetic mechanism and calcination process of phosphorus tailings [J]. Inorganic Chemicals Industry, 2023, 55(3): 47-54. |

| [3] | TIAN Xiaoli, LI Zhixun, FENG Runtang, ZHANG Jie, ZHENG Quanfu, SHI Xuwu, DU Yongbin. Study on thermal decomposition behavior of Tibetan Kamado microcrystalline magnesite [J]. Inorganic Chemicals Industry, 2023, 55(3): 60-65. |

| [4] | ZHANG Xing,XU Jie,WANG Zibing,HOU Peng,HE Long,LIU Huan. Effect of feedstock particle size on kinetics of limestone thermal decomposition reaction [J]. Inorganic Chemicals Industry, 2023, 55(2): 79-84. |

| [5] | DING Ning, ZHANG Jian, PING Qingwei, SHENG Xueru, LI Na. Study on adsorption and release properties of matrine by magnesium-modified diatomite [J]. Inorganic Chemicals Industry, 2023, 55(11): 37-46. |

| [6] | LI Xiyan, ZHANG Hong, LIU Xuejing, YANG Hao, XU Shuai, LI Jiaxin, XIE Jiaqi, XU Guangwen. Study on decomposition characteristic and kinetics of magnesite in inhibitory atmosphere [J]. Inorganic Chemicals Industry, 2023, 55(10): 50-55. |

| [7] | PENG Jiaoyu, TAN Yuqin, YANG Keli, DONG Yaping, ZHANG Bo, LI Wu. Study on crystallization mechanism and kinetics of macallisterite synthesized with bischofite from salt lake [J]. Inorganic Chemicals Industry, 2023, 55(10): 56-62. |

| [8] | WU Di, LI Laishi, WANG Junkai, WU Yusheng, WANG Yuzheng, LI Mingchun. Study on decomposition process and thermal decomposition kinetics of ammonium sulfate [J]. Inorganic Chemicals Industry, 2023, 55(10): 86-92. |

| [9] | ZHU Yue,QIU Shengbo,LIU Chenglin,YU Jianguo. Study on enhancement of spodumene phase reconstruction process by mechanical activation [J]. Inorganic Chemicals Industry, 2023, 55(1): 81-86. |

| [10] | ZHANG Shaokang,ZHAO Hua,LIU Runjing. Study on macro?kinetics of carbonization reaction of ammonia alkali salt sludge [J]. Inorganic Chemicals Industry, 2022, 54(6): 120-124. |

| [11] | ZHANG Shaokang,ZHAO Hua,LIU Runjing. Study on macro?kinetics of carbonization reaction of ammonia alkali salt sludge [J]. Inorganic Chemicals Industry, 2022, 54(6): 120-124. |

| [12] | ZHENG Hanxiao,LÜ Li,TANG Shengwei,HE Yanjun,ZHANG Tao. Leaching behavior of phosphate ore in phosphoric acid [J]. Inorganic Chemicals Industry, 2022, 54(10): 96-101. |

| [13] | ZHOU Jiaqi,CHEN Kui,WU Bin,JI Lijun,WU Yanyang. Study on kinetics of phosphate tailings calcination and acid leaching process [J]. Inorganic Chemicals Industry, 2022, 54(1): 77-82. |

| [14] | CAO Xuechen,ZHOU Dongjie,YAO Haiwei,JU Dianchun. Study on preparation of nanometer iron oxide and its kinetics by CC-OA DES treatment of iron-containing dust [J]. Inorganic Chemicals Industry, 2021, 53(11): 100-106. |

| [15] | Jiao Shuai,Yi Shouzhi,Zhang Hongling,Chen Huixia,Cheng Xichuan,Zhang Lichang,Xu Hongbin. Effect of reaction condition and aging process on the oxidation rate of chromium hydroxide [J]. Inorganic Chemicals Industry, 2021, 53(10): 59-63. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||