Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (1): 36-41.doi: 10.19964/j.issn.1006-4990.2024-0116

• Reviews and Special Topics • Previous Articles Next Articles

Research progress of quality improvement plans for industrial hydrogen peroxide

- Shandong Xinlong Technology Co.,Ltd.,Shouguang 262700,China

-

Received:2024-03-04Online:2025-01-10Published:2025-01-24

CLC Number:

Cite this article

QI Guoqing, LI Tong. Research progress of quality improvement plans for industrial hydrogen peroxide[J]. Inorganic Chemicals Industry, 2025, 57(1): 36-41.

share this article

Table 1

Technical requirements for industrial hydrogen peroxide %"

| 项目 | w (H2O2) | w[游离酸 (以H2SO4计)] | w (不挥 发物) | 稳定 度/% | w[总碳(以C计)] | w[硝酸盐(以NO3计)] | |

|---|---|---|---|---|---|---|---|

| 27.5% | 优等品 | ≥27.5 | ≤0.040 | ≤0.06 | ≥97.0 | ≤0.030 | ≤0.020 |

| 合格品 | ≥27.5 | ≤0.050 | ≤0.10 | ≥90.0 | ≤0.040 | ≤0.020 | |

| 35% | ≥35.0 | ≤0.040 | ≤0.08 | ≥97.0 | ≤0.025 | ≤0.020 | |

| 50% | ≥50.0 | ≤0.040 | ≤0.08 | ≥97.0 | ≤0.035 | ≤0.025 | |

| 60% | ≥60.0 | ≤0.040 | ≤0.06 | ≥97.0 | ≤0.045 | ≤0.028 | |

| 70% | ≥70.0 | ≤0.050 | ≤0.06 | ≥97.0 | ≤0.050 | ≤0.030 | |

Table 2

Physicochemical properties of food grade hydrogen peroxide"

| 项目 | w(H2O2)/ % | w[酸度(以 H2SO4计)]/% | 不挥发物含量/(mg·kg-1) | 稳定度/ % | 总有机碳(TOC) 含量(以C计)/ (mg·kg-1) | 磷酸盐含量 (以PO4计)/ (mg·kg-1) | Fe含量/(mg·kg-1) | Sn含量/(mg·kg-1) | Pb含量/(mg·kg-1) | As含量/(mg·kg-1) |

|---|---|---|---|---|---|---|---|---|---|---|

| 35% | ≥35.0 | ≤0.02 | ≤60 | ≥98.0 | ≤80 | ≤50 | ≤0.5 | ≤10 | ≤2 | ≤1 |

| 50% | ≥50.0 | ≤0.02 | ≤60 | ≥98.0 | ≤100 | ≤50 | ≤0.5 | ≤10 | ≤2 | ≤1 |

| 1 | 潘智勇,邢定峰.过氧化氢市场现状和技术发展趋势[J].现代化工,2021,41(4):11-16. |

| PAN Zhiyong, XING Dingfeng.Market status and technology development trend of hydrogen peroxide[J].Modern Chemical Industry,2021,41(4):11-16. | |

| 2 | 王犇,陈萌萌,张帆.过氧化氢提纯净化技术研究进展[J].无机盐工业,2019,51(6):1-4,10. |

| WANG Ben, CHEN Mengmeng, ZHANG Fan.Research progress on purification technology of hydrogen peroxide[J].Inorganic Che-Industry micals,2019,51(6):1-4,10. | |

| 3 | VASCONCELOS H, MATIAS A, MENDES J,et al.Compact biosensor system for the quantification of hydrogen peroxide in milk[J].Talanta,2023,253:124062. |

| 4 | 申桂英.索尔维镇江电子级过氧化氢工厂正式投产[J].精细与专用化学品,2018,26(11):15. |

| SHEN Guiying.Solvay zhenjiang electronic grade hydrogen peroxide factory is officially put into operation[J].Fine and Specialty Chemicals,2018,26(11):15. | |

| 5 | TAVASOL F, TABATABAIE T, RAMAVANDI B,et al.Photocatalyst production from wasted sediment and quality improvement with titanium dioxide to remove cephalexin in the presence of hydrogen peroxide and ultrasonic waves:A cost-effective technique[J].Chemosphere,2021,284:131337. |

| 6 | SATO N, XIE Rongjing, YONEDA T,et al.Water quality improvement by combined UF,RO,and ozone/hydrogen peroxide system(HiPOx) in the water reclamation process[J].Ozone:Science & Engineering,2014,36(2):153-165. |

| 7 | ISMAIL S Z, KHANDAKER M M,MAT N,et al.Effects of hydrogen peroxide on growth,development and quality of fruits:A review[J].Journal of Agronomy,2015,14(4):331-336. |

| 8 | ARVIN E, PEDERSEN L F.Hydrogen peroxide decomposition kinetics in aquaculture water[J].Aquacultural Engineering,2015,64:1-7. |

| 9 | PETTERSSON S J, LINDHOLM-LEHTO P C, PULKKINEN J T,et al.Effect of ozone and hydrogen peroxide on off-flavor compounds and water quality in a recirculating aquaculture system[J].Aquacultural Engineering,2022,98:102277. |

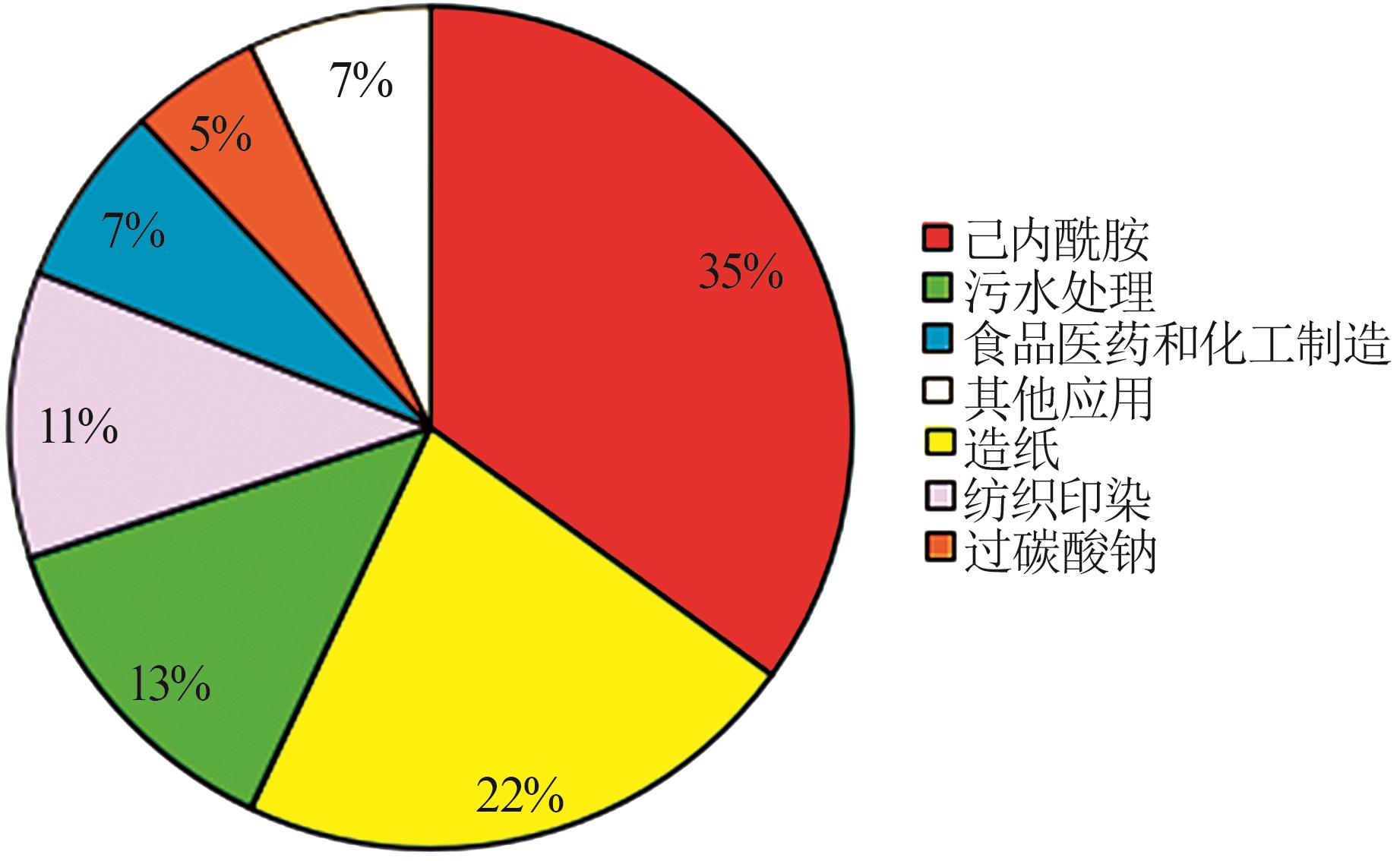

| 10 | 中商情报网.2024年中国双氧水产能及下游应用情况预测分析[EB/OL].(2023-10-26).. |

| 11 | CINDY O, LEE R, LORETTA W,et al.Quality control is indispensable for automated dilution systems with accelerated hydrogen peroxide[J].The Canadian journal of infection control,2009,24(4):226-228. |

| 12 | 佘林源,杨鉴,张焱焱,等.双氧水浓缩技术研究[J].化工设计通讯,2021,47(1):76-77. |

| SHE Linyuan, YANG Jian, ZHANG Yanyan,et al.Study on concentration technology of hydrogen peroxide[J].Chemical Engineering Design Communications,2021,47(1):76-77. | |

| 13 | 周伦,霍磊,胡宪正,等.双氧水生产装置设计探讨[J].化工设计,2023,33(1):13-15,20. |

| ZHOU Lun, HUO Lei, HU Xianzheng,et al.Discussion on the design of hydrogen peroxide production equipment[J].Chemical Engineering Design,2023,33(1):13-15,20. | |

| 14 | 于剑昆.电子工业用超高纯过氧化氢的制备工艺[J].化学推进剂与高分子材料,2014,12(2):1-24. |

| YU Jiankun.Preparation process of ultra high purity hydrogen peroxide for electronic industry[J].Chemical Propellants & Polymeric Materials,2014,12(2):1-24. | |

| 15 | 沈佐朝.电子级双氧水常见污染原因分析[J].化工设计通讯,2022,48(11):34-36. |

| SHEN Zuochao.Analysis on common contamination in electronic grade hydrogen peroxide unit[J].Chemical Engineering Design Communications,2022,48(11):34-36. | |

| 16 | 韩林,王翔,杜玮辰,等.LSA-5B树脂对工业双氧水溶液中有机杂质的吸附[J].南京工业大学学报(自然科学版),2023,45(1):45-51,59. |

| HAN Lin, WANG Xiang, DU Weichen,et al.Adsorption of organic impurities in industrial hydrogen peroxide solution by LSA-5B resin[J].Journal of Nanjing Tech University(Natural Science Edition),2023,45(1):45-51,59. | |

| 17 | 刘文宗.吸附树脂再生前后对双氧水稳定性的影响探讨[J].合成纤维工业,2021,44(5):86-90. |

| LIU Wenzong.Effect of adsorptive resin on stability of hydrogen peroxide before and after regeneration[J].China Synthetic Fiber Industry,2021,44(5):86-90. | |

| 18 | 武金锋.双氧水纯化工艺比较及选择[J].化工生产与技术,2020,26(1):33-35,9. |

| WU Jinfeng.Comparison and selection of hydrogen peroxide purification processes[J].Chemical Production and Technology,2020,26(1):33-35,9. | |

| 19 | 赵磊,姜杰,石宁,等.双氧水的热危险性及铁离子掺杂对其热稳定性的影响研究[J].山东化工,2014,43(11):31-34,38. |

| ZHAO Lei, JIANG Jie, SHI Ning,et al.Evaluation of the thermal hazard of hydrogen peroxide and study on its thermostability influenced by the addition of ferric ion[J].Shandong Chemical Industry,2014,43(11):31-34,38. | |

| 20 | 宋建华,刘娜,袁从明,等.双氧水钝化工艺条件的研究及应用[J].宁夏电力,2017(6):58-61. |

| SONG Jianhua, LIU Na, YUAN Congming,et al.Research and application of the passivation technique conditions for hydrogen peroxide[J].Ningxia Electric Power,2017(6):58-61. | |

| 21 | 宋望一,赵新访,刘伟,等.阀门硬化处理工艺对蒽醌法生产双氧水的影响[J].化工进展,2022,41(S1):54-59. |

| SONG Wangyi, ZHAO Xinfang, LIU Wei,et al.The influence of valve hardening treatment process on the production of hydrogen peroxide by anthraquinone method[J].Chemical Industry and Engineering Progress,2022,41(S1):54-59. | |

| 22 | 于子勋,刘畅,邓业煜,等.利用离子液体界面工程实现非均相分子催化剂高效生产双氧水(英文)[J].Chinese Journal of Catalysis,2022,43(5):1238-1246. |

| YU Zixun, LIU Chang, DENG Yeyu,et al.Efficient production of hydrogen peroxide using heterogeneous molecular catalysts using ionic liquid interface engineering[J].Chinese Journal of Catalysis,2022,43(5):1238-1246. | |

| 23 | 刘昭维.蒽醌法双氧水生产工艺改进及35%双氧水生产技术研究[D].上海:华东理工大学,2012. |

| LIU Zhaowei.Improvement of anthraquinone method hydrogen peroxide production process and research on 35% hydrogen peroxide production technology[D].Shanghai:East China University of Science and Technology,2012. | |

| 24 | 宋望一,薛玲,张燕丽,等.双氧水生产中碱液再生造成工作液流失的研究[J].化工设计通讯,2022,48(10):168-170. |

| SONG Wangyi, XUE Ling, ZHANG Yanli,et al.Research on the loss of working fluid caused by alkaline regeneration in hydrogen peroxide production[J].Chemical Engineering Design Communications,2022,48(10):168-170. | |

| 25 | 程文明.双氧水生产系统工作液性质影响因素的探讨[J].中国氯碱,2022(10):39-42. |

| CHENG Wenming.Exploration of factors influencing the properties of working fluid in hydrogen peroxide production system[J].China Chlor-Alkali,2022(10):39-42. | |

| 26 | 庞飞,许颖睿,柴春玲,等.蒽醌法过氧化氢生产工艺中废弃活性氧化铝的回收利用研究概况[J].无机盐工业,2023,55(6):1-7,49. |

| PANG Fei, XU Yingrui, CHAI Chunling,et al.Overview on recycling of waste activated alumina in production of hydrogen peroxide by anthraquinone process[J].Inorganic Chemicals Industry,2023,55(6):1-7,49. | |

| 27 | 李娜.双氧水装置工作液质量管控及氧化铝性能研究[J].氮肥与合成气,2023,51(1):1-2. |

| LI Na.Quality control of working fluid in hydrogen peroxide plant and research on alumina performance[J].Nitrogenous Fertilizer & Syngas,2023,51(1):1-2. | |

| 28 | 朱希增,朱顺兵,刘新华.有机磷酸稳定剂对双氧水绝热分解特性的影响[J].化工进展,2014,33(12):3197-3202. |

| ZHU Xizeng, ZHU Shunbing, LIU Xinhua.The effect of organic phosphate stabilizers on the adiabatic decomposition characteristics of hydrogen peroxide[J].Chemical Industry and Engineering Progress,2014,33(12):3197-3202. | |

| 29 | 谭建忠.工业过氧化氢溶液稳定性的研究[J].合成纤维工业,2020,43(1):46-49. |

| TAN Jianzhong.Study on stability of industrial hydrogen peroxide solution[J].China Synthetic Fiber Industry,2020,43(1):46-49. | |

| 30 | 张帆,信云霞,贾学五.大孔树脂对过氧化氢热稳定性的影响[J].无机盐工业,2017,49(8):73-76. |

| ZHANG Fan, XIN Yunxia, JIA Xuewu.Effect of macroporous resin on thermal stability of hydrogen peroxide[J].Inorganic Chemicals Industry,2017,49(8):73-76. | |

| 31 | 徐守兵.用箭推法书写有关过氧化氢的反应机理[J].化学教育(中英文),2023,44(11):112-116. |

| XU Shoubing.Writing reactions mechanisms related to hydrogen peroxide by arrow-pushing method[J].Chinese Journal of Chemical Education,2023,44(11):112-116. | |

| 32 | 孙健鹏.过氧化氢非硅稳定剂的合成及应用[D].西安:陕西科技大学,2020. |

| SUN Jianpeng.Synthesis and application of hydrogen peroxide non-silicon stabilizer[D].Xi′an:Shaanxi University of Science & Technology,2020. | |

| 33 | 吴梦玲,吴格辉,孙第,等.镁离子稳定双氧水分解的机理[J].印染助剂,2023,40(7):20-23. |

| WU Mengling, WU Gehui, SUN Di,et al.Mechanism of stable decomposition of hydrogen peroxide by magnesium ions[J].Textile Auxiliaries,2023,40(7):20-23. | |

| 34 | 孙峰,谢传欣,张帆,等.pH值对双氧水绝热分解特性的影响[J].化学工程,2012,40(2):42-45. |

| SUN Feng, XIE Chuanxin, ZHANG Fan,et al.Effect of pH value on adiabatic decomposition characteristics of hydrogen peroxi-de[J].Chemical Engineering,2012,40(2):42-45. | |

| 35 | 马原,张辉,李效军.溴素/双氧水溴化双酚A过程中酸的催化作用[J].精细石油化工,2016,33(6):17-20. |

| MA Yuan, ZHANG Hui, LI Xiaojun.The catalytic effect of acid in the bromination of bisphenol A with bromine/hydrogen peroxide[J].Speciality Petrochemicals,2016,33(6):17-20. | |

| 36 | 段志清.二氧化硫脲的制备[J].煤炭与化工,2017,40(4):144-147. |

| DUAN Zhiqing.Preparation of thiourea dioxide[J].Coal and Chemical Industry,2017,40(4):144-147. | |

| 37 | 乔迎超,万双华.蒽醌法生产双氧水的传统工艺和全酸性工艺对比[J].当代化工,2016,45(1):185-188. |

| QIAO Yingchao, WAN Shuanghua.Comparison of traditional processe and all-acidic processeof hydrogen peroxide production by anthraquinone method[J].Contemporary Chemical Industry,2016,45(1):185-188. |

| [1] | YU Xudong, LI Jing, REN Siying, LUO Jun, ZENG Ying. Study on solid-liquid phase equilibrium of Li+,K+,Ca2+//Cl--H2O quaternary system at 298.2 K [J]. Inorganic Chemicals Industry, 2025, 57(3): 30-35. |

| [2] | SHI Yunpeng, GUO Ze, ZHANG Hanquan, LU Manman. Study on treatment of ammonia nitrogen wastewater by roasted phosphorus tailings [J]. Inorganic Chemicals Industry, 2025, 57(3): 94-100. |

| [3] | SHI Wangfang, ZHANG Yongsheng. Study on NO x degradation performance of concrete-based non-metallic boron doped nitrogen-rich carbon nitride [J]. Inorganic Chemicals Industry, 2025, 57(3): 116-123. |

| [4] | LI Yongxiang, LIU Chenxi, LI Yundong, MA Hang, MEI Lianping, DANG Hui, SUN Zhi, WAN Banglong. Research progress of preparation technology of black phosphorus [J]. Inorganic Chemicals Industry, 2025, 57(3): 18-29. |

| [5] | LENG Manxi, ZHU Yu, YAN Jikang, XIE Ke, ZOU Yongjie. Study on crystallization characteristics and mineral flotation performance of industrial waste phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(3): 108-115. |

| [6] | LI Zihan, ZHANG Jiaqi, LI Shizhuo, LI Xinyu, LIU Shaozhuo, WANG Yihao, HAO Yucui, LIU Jian, LI Yanhua. Study on synthesis and catalytic mechanism of CdS/g-C3N4 composite photocatalyst [J]. Inorganic Chemicals Industry, 2025, 57(3): 124-132. |

| [7] | MA Mingyang, CHEN Minyi, SUN Tao, XUE Bin. Study on preparation and oil/water separation performance of silica-mediated superhydrophobic/superoleophilic hybrid sponge [J]. Inorganic Chemicals Industry, 2025, 57(3): 64-70. |

| [8] | TAN Shanyi, WEN Huizi, HE Shuyu, ZHANG Liwen, CHEN Shaohua, XI Benjun. Study on leaching behavior and kinetics of phosphorus from phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(2): 105-112. |

| [9] | MA Jun, JIN Yang, LI Jun, CHEN Ming, WANG Yubin. Study on photochemical synthesis of H2O2 in coiled flow inverter microreactor [J]. Inorganic Chemicals Industry, 2025, 57(2): 50-56. |

| [10] | ZHANG Jinjun, GUO Linlin, MIAO Chengpeng, LI Xingyu, PANG Yaheng, YANG Rongkai, YU Yasen. Study on preparation of spherical calcium carbonate for coating fillers based on carbide slag as raw materials [J]. Inorganic Chemicals Industry, 2025, 57(2): 113-119. |

| [11] | DONG Nan, WANG Nan, JI Lijun, SHENG Yong. Determination of potassium salt solubility at low temperature and study of liquid fertilizer formula [J]. Inorganic Chemicals Industry, 2025, 57(2): 92-97. |

| [12] | CHENG Xiaoqiang, MA Jun, FENG Bin, BAI Liguang, ZHAO Xiaodong. Discussion on application of post-treatment process in fixed bed hydrogen peroxide production process [J]. Inorganic Chemicals Industry, 2025, 57(2): 98-104. |

| [13] | WU Wei, XU Cuiping, ZHAO Qinzheng, YANG Jingjing, XU Xiaoyi, HUANG Tianyin, WU Bingdang. Study on coagulation performance and residual aluminum forms of aluminum salt coagulants for surface water [J]. Inorganic Chemicals Industry, 2025, 57(1): 42-50. |

| [14] | SUN Qinghao, LI Keyan, GUO Xinwen. Study on photocatalytic benzyl alcohol oxidation coupled with hydrogen production over Pd/ZnIn2S4 nanosheets [J]. Inorganic Chemicals Industry, 2025, 57(1): 113-119. |

| [15] | TANG Kaijing, LIU Chuanbei, LI Yingding, JIANG Yong, WU Junnan, ZHANG Tao. Research on preparation and mechanism of superhydrophobic phosphogypsum products [J]. Inorganic Chemicals Industry, 2025, 57(1): 97-102. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||