| 1 |

李莹,段鹏选,倪文,等.基于生命周期的工业副产石膏制备胶凝材料碳足迹评价[J].硅酸盐通报,2023,42(6):1921-1930.

|

|

LI Ying, DUAN Pengxuan, NI Wen,et al.Carbon footprint assessment of cementitious materials prepared from industrial by-product gypsum based on life cycle[J].Bulletin of the Chinese Ceramic Society,2023,42(6):1921-1930.

|

| 2 |

郝建英,胡涛,程冠吉,等.脱硫石膏掺杂氧化锌转晶制备高性能建筑石膏[J].无机盐工业,2022,54(6):96-101.

|

|

HAO Jianying, HU Tao, CHENG Guanji,et al.Preparation of high-performance building gypsum by desulfurization gypsum doped with ZnO crystal transformation[J].Inorganic Chemicals Industry,2022,54(6):96-101.

|

| 3 |

谢浪,罗双,付汝宾,等.纤维-建筑石膏基复合材料力学及耐水性能研究进展[J].新型建筑材料,2021,48(6):34-39.

|

|

XIE Lang, LUO Shuang, FU Rubin,et al.Review of research progress on mechanical properties and water resistance of fiber-building gypsum based composites[J].New Building Materials,2021,48(6):34-39.

|

| 4 |

赵敏,张明涛,彭家惠,等.硫铝酸盐水泥增强建筑石膏的力学性能与耐水性能机理[J].材料导报,2021,35(12):12099-12102.

|

|

ZHAO Min, ZHANG Mingtao, PENG Jiahui,et al.Mechanisms for the improvement of mechanical properties and water resistance of building gypsum by sulphoaluminate cement[J].Materials Reports,2021,35(12):12099-12102.

|

| 5 |

郭会师,王庆佩,张果,等.普通硅酸盐水泥改性脱硫建筑石膏耐水性能[J].硅酸盐通报,2021,40(7):2288-2295.

|

|

GUO Huishi, WANG Qingpei, ZHANG Guo,et al.Water resistance of flue gas desulfurization building gypsum modified by ordinary Portland cement[J].Bulletin of the Chinese Ceramic Society,2021,40(7):2288-2295.

|

| 6 |

张峻,解维闵,董雄波,等.磷石膏材料化综合利用研究进展[J].材料导报,2023,37(16):167-178.

|

|

ZHANG Jun, XIE Weimin, DONG Xiongbo,et al.Research progress on comprehensive utilization of phosphogypsum for materials:A review[J].Materials Reports,2023,37(16):167-178.

|

| 7 |

周祥,李亮,张晓敏,等.硅酸盐水泥熟料和硅灰对磷建筑石膏耐水性和水化行为的影响[J].新型建筑材料,2023,50(9):77-81.

|

|

ZHOU Xiang, LI Liang, ZHANG Xiaomin,et al.Effect of silicate clinker and silica fume on water resistance and hydration behavior of phosphogypsum[J].New Building Materials,2023,50(9):77-81.

|

| 8 |

李桦军,刘东辉,王平艳,等.石膏防水剂的研究进展[J].硅酸盐通报,2014,33(4):831-835.

|

|

LI Huajun, LIU Donghui, WANG Pingyan,et al.Research progress on gypsum waterproofing agent[J].Bulletin of the Chinese Ceramic Society,2014,33(4):831-835.

|

| 9 |

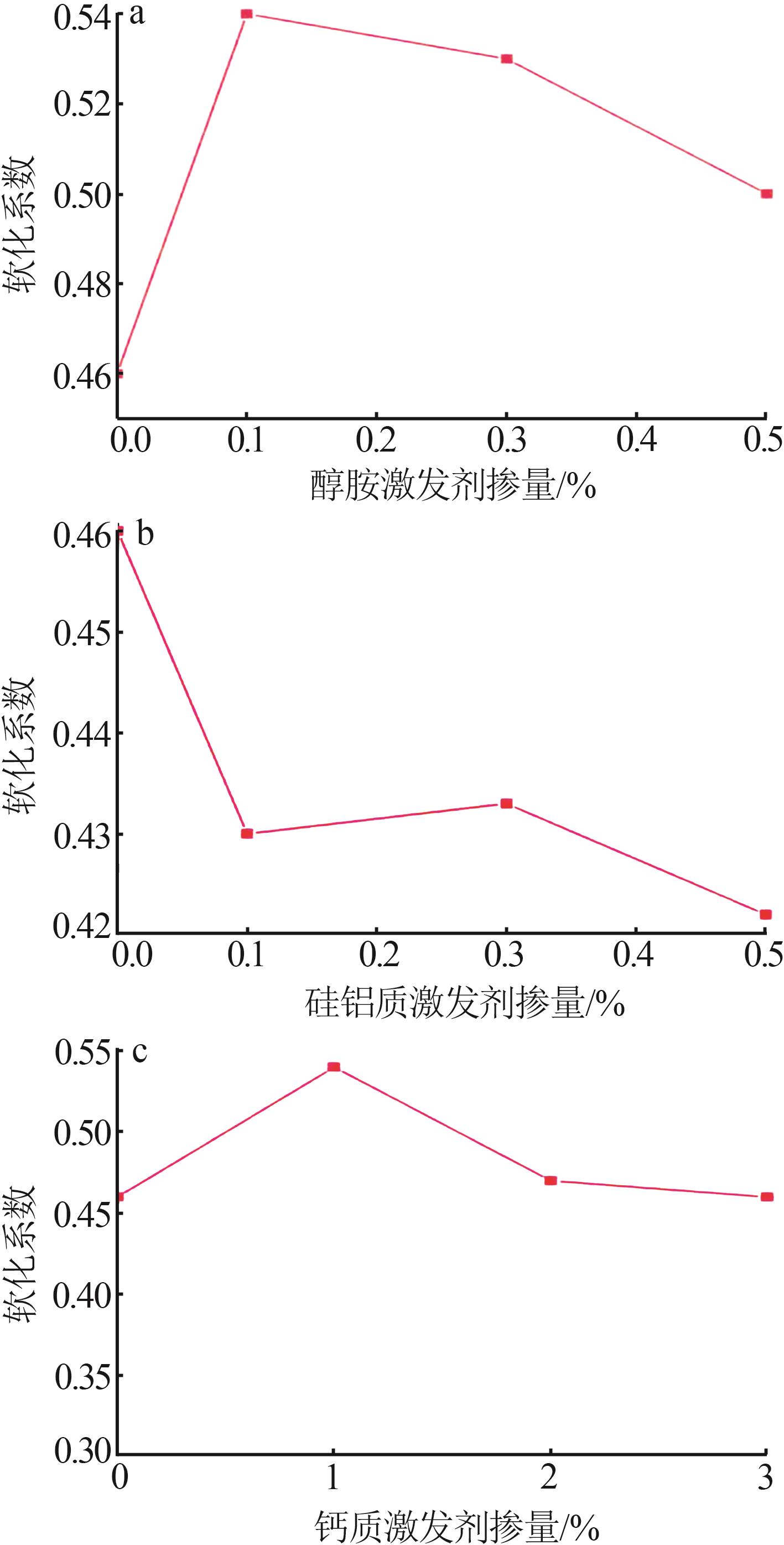

齐艳涛,刘芳,张奔,等.激发剂对掺有机硅磷石膏制品耐水性的影响[J].材料导报,2015,29(S2):450-452,467.

|

|

QI Yantao, LIU Fang, ZHANG Ben,et al.Effects of activator on water resistance of phosphogypsum mixed with silicone[J].Materials Reports,2015,29(S2):450-452,467.

|

| 10 |

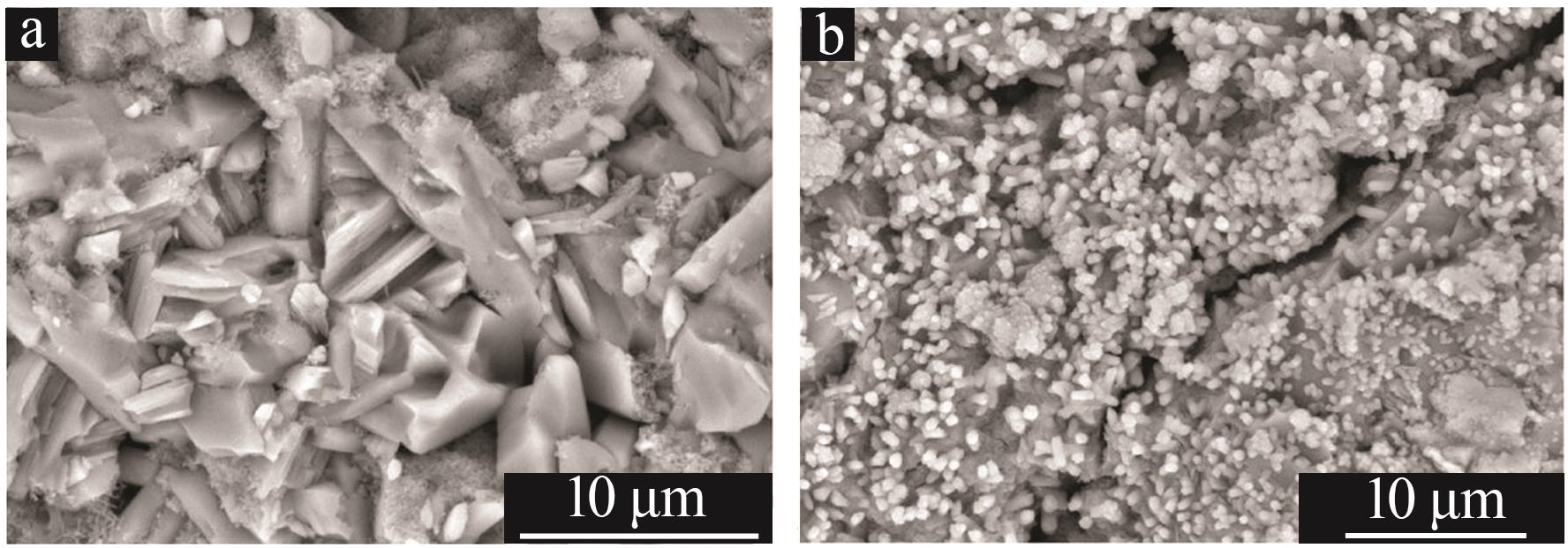

马红恩,吴其胜,钱旭阳,等.硅烷改性苯丙乳液对脱硫石膏防水性能的影响[J].材料科学与工程学报,2020,38(2):269-273,307.

|

|

MA Hongen, WU Qisheng, QIAN Xuyang,et al.Effect of silane modified styrene-acrylic emulsion on waterproof properties of desulfurized gypsum[J].Journal of Materials Science and Engineering,2020,38(2):269-273,307.

|

| 11 |

陈畅,邓逸豪,王绪富,等.含氢硅油乳液对脱硫石膏砌块耐水性能影响[J].非金属矿,2021,44(5):15-18.

|

|

CHEN Chang, DENG Yihao, WANG Xufu,et al.Effect of polymethylhydrosiloxane emulsion on hydrolytic resistance of FGD gypsum blocks[J].Non-Metallic Mines,2021,44(5):15-18.

|

| 12 |

延海龙.利用磷石膏制备建筑砌块的防水性能研究[D].济南:济南大学,2020.

|

|

YAN Hailong.Study on waterproof performance of building blocks made of phosphogypsum[D].Jinan:University of Jinan,2020.

|

| 13 |

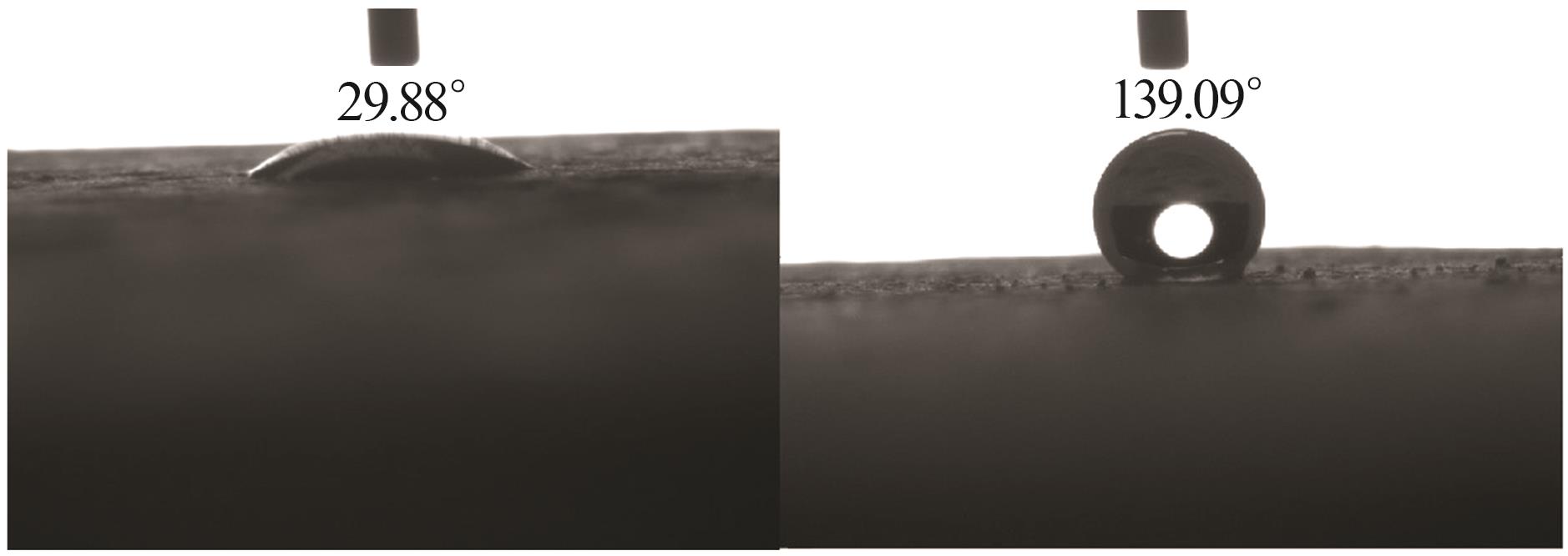

FERNANDEZ-TOLEDANO J C, BLAKE T D, LAMBERT P,et al.On the cohesion of fluids and their adhesion to solids:Young′s equation at the atomic scale[J].Advances in Colloid and Interface Science,2017,245:102-107.

|

| 14 |

刘子涵.地质聚合物基硅酮纳米纤维超疏水复合涂层的制备与性能研究[D].南宁:广西大学,2019.

|

|

LIU Zihan.Preparation and properties of geopolymer-based silicone nanofilaments superhydrophobic composite coatings[D].Nanning:Guangxi University,2019.

|

| 15 |

NEINHUIS C, BARTHLOTT W.Characterization and distribution of water-repellent,self-cleaning plant surfaces[J].Annals of Botany,1997,79(6):667-677.

|

| 16 |

BARTHLOTT W, NEINHUIS C.Purity of the sacred lotus,or escape from contamination in biological surfaces[J].Planta,1997,202(1):1-8.

|

), LIU Chuanbei2, LI Yingding3, JIANG Yong1, WU Junnan1, ZHANG Tao4

), LIU Chuanbei2, LI Yingding3, JIANG Yong1, WU Junnan1, ZHANG Tao4