Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (2): 132-140.doi: 10.19964/j.issn.1006-4990.2022-0243

• Catalytic Materials • Previous Articles Next Articles

Study on catalytic gasification reaction of distillers′grains under H2O/CO2 atmosphere

LI Songhong1( ),ZHOU Songhua2,ZHAO Aiming1,DONG Wenyan1,JIANG Chunyan1,CAO Yang1,AO Xianquan1(

),ZHOU Songhua2,ZHAO Aiming1,DONG Wenyan1,JIANG Chunyan1,CAO Yang1,AO Xianquan1( )

)

- 1. Guizhou University, School of Chemistry and Chemical Engineering, Guiyang 550025, China

2. Guizhou Tianfu Chemical Co. , Ltd. , Fuquan 550501, China

-

Received:2022-04-28Online:2023-02-10Published:2023-02-16 -

Contact:AO Xianquan E-mail:1131289687@qq.com;aoxianquan@163.com

CLC Number:

Cite this article

LI Songhong,ZHOU Songhua,ZHAO Aiming,DONG Wenyan,JIANG Chunyan,CAO Yang,AO Xianquan. Study on catalytic gasification reaction of distillers′grains under H2O/CO2 atmosphere[J]. Inorganic Chemicals Industry, 2023, 55(2): 132-140.

share this article

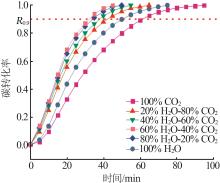

Table 3

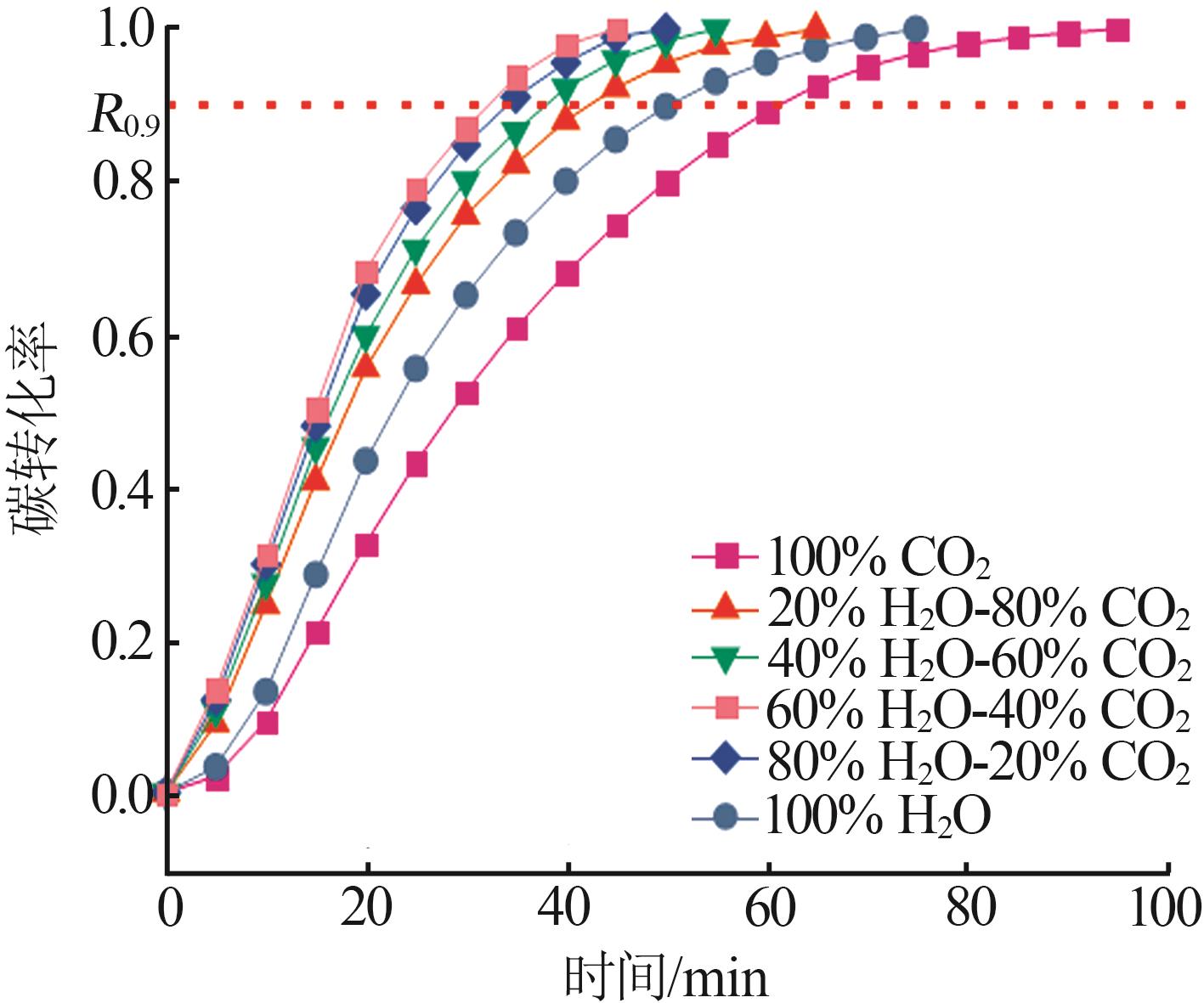

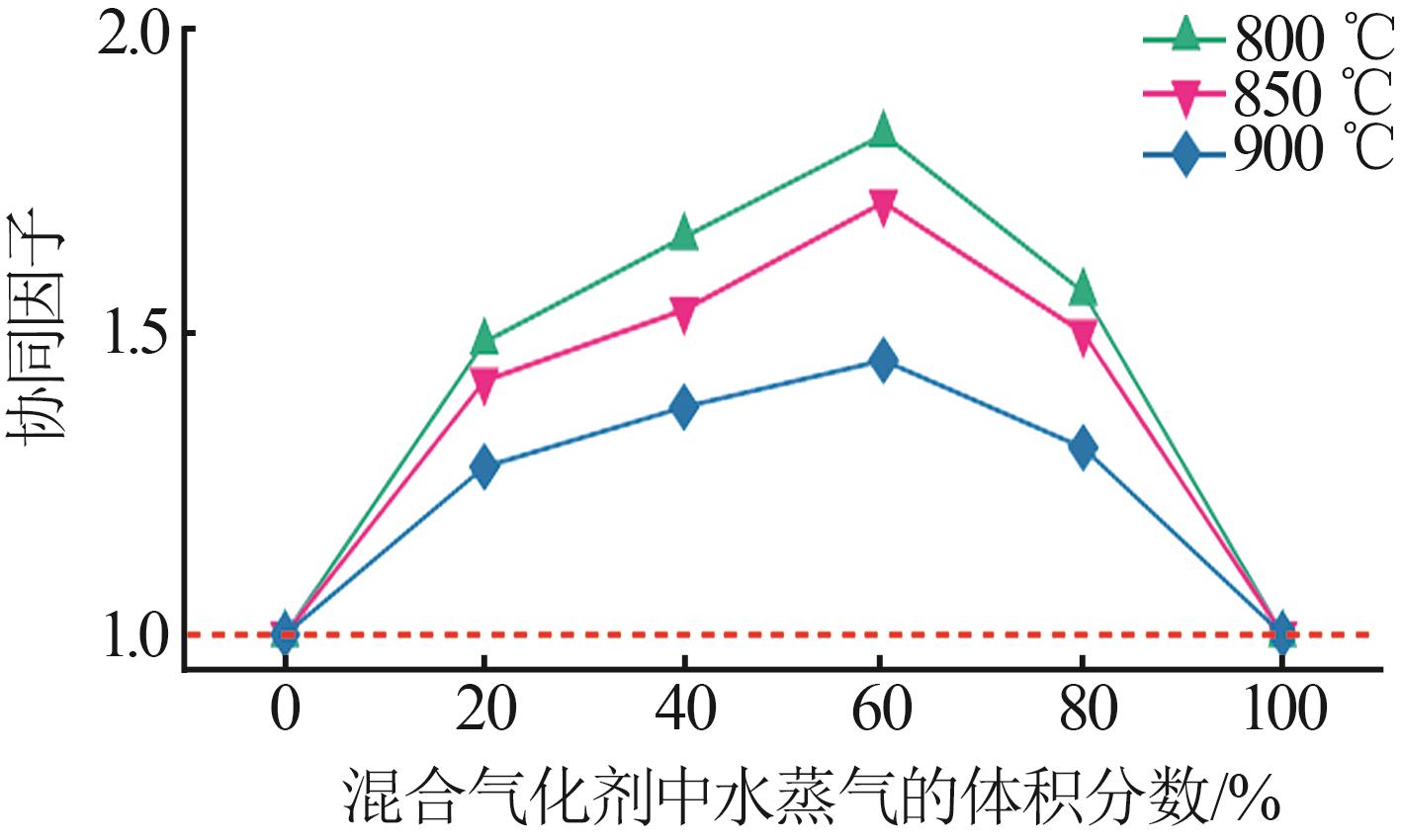

R0.9,cal,R0.9,exp and synergetic factor of samplesunder different atmospheres"

| 不同气氛下的样品 | 理论反应性指数 | 实际反应性指数 | 协同因子 |

|---|---|---|---|

| 100%CO2 | 0.014 6 | 0.014 6 | 1.000 |

| 20%H2O-80%CO2 | 0.015 1 | 0.021 4 | 1.418 |

| 40%H2O-60%CO2 | 0.015 8 | 0.024 2 | 1.535 |

| 60%H2O-40%CO2 | 0.016 4 | 0.028 1 | 1.712 |

| 80%H2O-20%CO2 | 0.016 9 | 0.026 4 | 1.562 |

| 100%H2O | 0.017 5 | 0.017 5 | 1.000 |

| 1 | 中华人民共和国国家统计局.中国统计年鉴[M].北京:中国统计出版社,2020. |

| National Bureau of Statistics of the People's Republic of China.China Statistical Yearbook[M].Beijing:China Statistics Press,2020. | |

| 2 | 王兆夺,祝超伟,于东生.全球气候变化背景下对“温室效应”的思考[J].辽宁师范大学学报:自然科学版,2017,40(3):407-414. |

| WANG Zhaoduo, ZHU Chaowei, YU Dongsheng.On“Greenhouse Effect”under the background of global climate change[J].Journal of Liaoning Normal University:Natural Science Edition,2017,40(3):407-414. | |

| 3 |

IRFAN M, ELAVARASAN R M, AHMAD M,et al.Prioritizing and overcoming biomass energy barriers:Application of AHP and G-TOPSIS approaches[J].Technological Forecasting and Social Change,2022,177.Doi:10.1016/j.techfore.2022.121524 .

doi: 10.1016/j.techfore.2022.121524 |

| 4 | 聂永增.对于酒糟综合利用现状及创新应用的思考[J].轻工科技,2021,37(9):11-12. |

| NIE Yongzeng.Thoughts on the comprehensive utilization of distiller's grains and its innovative application[J].Light Industry Science and Technology,2021,37(9):11-12. | |

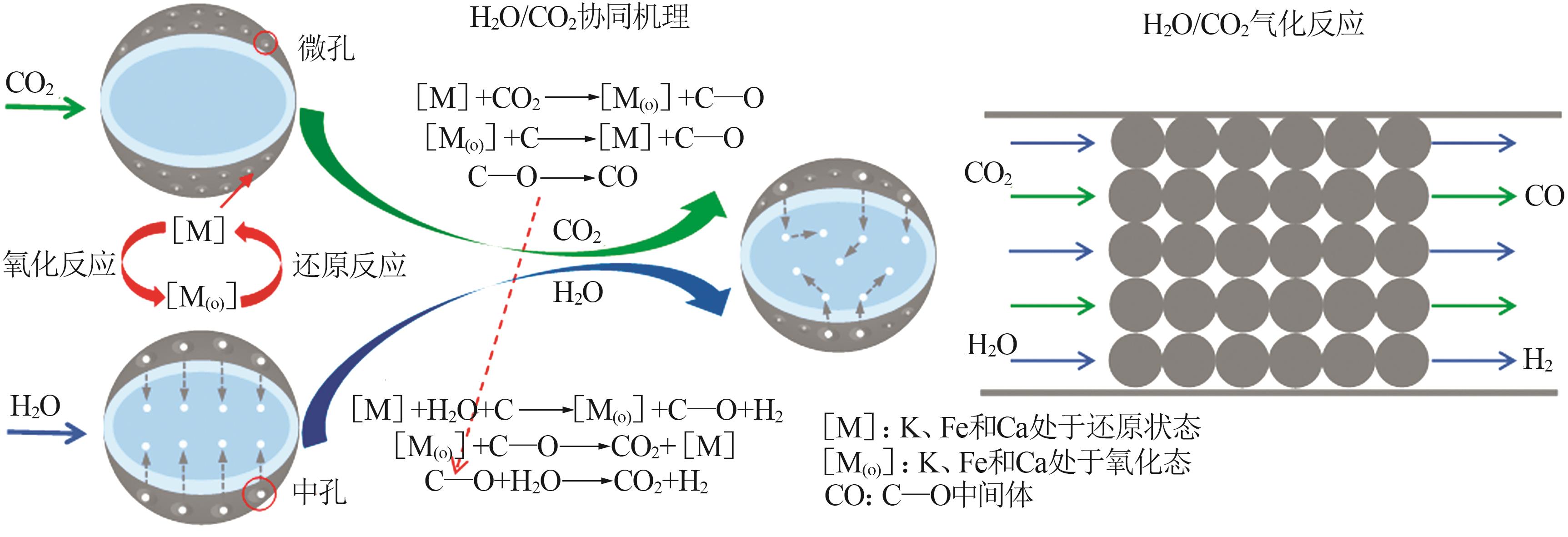

| 5 | 张德成,敖先权,陈前林,等.酒糟与煤焦在CO2气氛下的共气化活性[J].过程工程学报,2016,16(4):629-633. |

| ZHANG Decheng, AO Xianquan, CHEN Qianlin,et al.Co-gasification characteristics of distillery residue with coal char in CO2 atmosphere[J].The Chinese Journal of Process Engineering,2016,16(4):629-633. | |

| 6 |

WANG Jiaxing, ZHANG Shuping, XU Dan,et al.Catalytic activity evaluation and deactivation progress of red mud/carbonaceous catalyst for efficient biomass gasification tar cracking[J].Fuel,2022,323.Doi:10.1016/j.fuel.2022.124278 .

doi: 10.1016/j.fuel.2022.124278 |

| 7 | LV Jiwei, AO Aianquan, LI Qian,et al.Steam co-gasification of different ratios of spirit-based distillers′grains and anthracite coal to produce hydrogen-rich gas[J].Bioresource Technology,2019,283:59-66. |

| 8 | ZHAO Aiming, LV Jiwei, CHEN Qianlin,et al.Spirit-based distillers’grains and red mud synergistically catalyse the steam gasification of anthracite to produce hydrogen-rich synthesis gas[J].International Journal of Hydrogen Energy,2021,46(1):314-323. |

| 9 |

PHOUNGLAMCHEIK A, BACKEBO M, ROBINSON R,et al.The significance of intraparticle and interparticle diffusion during CO2 gasification of biomass char in a packed bed[J].Fuel,2022,3.Doi:1010.1016/j.fuel.2021.122302 .

doi: 1010.1016/j.fuel.2021.122302 |

| 10 |

CAI Jianjun, ZHANG Wenheng, LUO Ming,et al.Evaluation of the CO2 gasification of residual char under a regeneration atmosphere via calcium-based chemical looping gasification[J].Chemical Engineering and Processing-Process Intensification,2021,168.Doi:10.1016/j.cep.2021.108564 .

doi: 10.1016/j.cep.2021.108564 |

| 11 | NILSSON S, GOMEZ-BAREA A, OLLEROll P.Gasification of char from dried sewage sludge in fluidized bed:Reaction rate in mixtures of CO2 and H2O[J].Fuel,2013,105:764-768. |

| 12 | CHANG Guozhang, YAN Ximin, QI Pengyu,et al.Characteristics of reactivity and structures of palm kernel shell(PKS) biochar during CO2/H2O mixture gasification[J].Chinese Journal of Chemical Engineering,2018,26(10):2153-2161. |

| 13 | 关昱,张彦迪,刘银河.CO2/H2O气氛下红沙泉煤中碱(土)金属的分布及其气化反应特性[J].燃料化学学报,2022,50(6):674-682. |

| GUAN Yu, ZHANG Yandi, LIU Yinhe.Distribution of alkaline(earth) metals and gasification reaction characteristics of HSQ coal under CO2/H2O atmosphere[J].Journal of Fuel Chemistry and Technology,2022,50(6):674-682. | |

| 14 | HOWANIEC N.Temperature induced development of porous structure of bituminous coal chars at high pressure[J].Journal of Sustainable Mining,2016,15(3):120-124. |

| 15 | GLENK G, REICHELSTEIN S.Economics of converting renewable power to hydrogen[J].Nature Energy,2019,4(3):216-222. |

| 16 | GUIZANI C, ESCUDERO-SANZ F J, SALVADOR S.The gasification reactivity of high-heating-rate chars in single and mixed atmospheres of H2O and CO2 [J].Fuel,2013,108:812-823. |

| 17 | MASSOUDI-FARID M, HWANG J.Competition between H2O and CO2 for active sites during co-gasification of bituminous coal and pineapple sawdust in an atmosphere containing H2O,CO2,H2,and CO[J].Fuel,2017,207:198-203. |

| 18 | ROBERTS D G, HARRIS D J.Char gasification kinetics in mixtures of CO2 and H2O:The role of partial pressure in determining the extent of competitive inhibition[J].Energy & Fuels,2014,28(12):7643-7648. |

| 19 | UMEMOTO S, KAJITANI S, HARA S.Modeling of coal char gasification in coexistence of CO2 and H2O considering sharing of active sites[J].Fuel,2013,103:14-21. |

| 20 | BAI Yonghui, LV Peng, YANG Xuhao,et al.Gasification of coal char in H2O/CO2 atmospheres:Evolution of surface morphology and pore structure[J].Fuel,2018,218:236-246. |

| 21 | GAO Meiqi, LV Peng, YANG Zhirong,et al.Effects of Ca/Na compounds on coal gasification reactivity and char characteristics in H2O/CO2 mixtures[J].Fuel,2017,206:107-116. |

| 22 |

LIU Rui, ZHANG Yan, ZHENG Ling,et al.Some new insights into the synergy occurring during char gasification in CO2/H2O mixtures[J].Fuel,2020,268.Doi:10.1016/j.fuel.2020.117307 .

doi: 10.1016/j.fuel.2020.117307 |

| 23 | GIL M V, RIAZA J, ÁLVAREZ L,et al.Biomass devolatilization at high temperature under N2 and CO2:Char morphology and reactivity[J].Energy,2015,91:655-662. |

| 24 | WEI Juntao, GUO Qinghua, HE Qing,et al.Co-gasification of bituminous coal and hydrochar derived from municipal solid waste:Reactivity and synergy[J].Bioresource Technology,2017,239:482-489. |

| 25 | KORUS A, RAVENNI G, LOSKA K,et al.The importance of inherent inorganics and the surface area of wood char for its gasification reactivity and catalytic activity towards toluene conversi- on[J].Renewable Energy,2021,173:479-497. |

| 26 | MASSOUDI FARID M, JEONG H J, HWANG J.Kinetic study on coal-biomass mixed char co-gasification with H2O in the presence of H2 [J].Fuel,2016,181:1066-1073. |

| 27 | PARTHASARATHY P, K.S NARAYANAN.Hydrogen production from steam gasification of biomass:Influence of process parameters on hydrogen yield-A review[J].Renewable Energy,2014,66:570-579. |

| 28 | ELLIS N, MASNADI M S, ROBERTS D G.Mineral matter interactions during co-pyrolysis of coal and biomass and their impact on intrinsic char co-gasification reactivity[J].Chemical Engineering Journal,2015,279:402-408. |

| 29 | XU Deliang, YANG Liu, DING Kuan,et al.Mini-review on char catalysts for tar reforming during biomass gasification:The importance of char structure[J].Energy & Fuels,2020,34(2):1219-1229. |

| 30 | JAYARAMAN K, GOKALP I, JEYAKUMAR S.Estimation of synergetic effects of CO2 in high ash coal-char steam gasificati-on[J].Applied Thermal Engineering,2017,110:991-998. |

| 31 | 黄艳琴,苏德仁,阴秀丽,等.木粉焦CO2和H2O气化过程孔结构及反应性的变化[J].燃料化学学报,2011,39(6):432- 437. |

| HUANG Yanqin, SU Deren, YIN Xiuli,et al.Changes of pore structure and reactivity during CO2 and H2O gasification of fir char[J].Journal of Fuel Chemistry and Technology,2011,39(6):432-437. | |

| 32 | SHENG Changdong.Char structure characterised by Raman spectroscopy and its correlations with combustion reactivity[J].Fuel,2007,86(15):2316-2324. |

| 33 | LI Xiao, CHANG Guozhang, YANG Laishun,et al.Enhancement of coke gasification by lignite and a low-cost Fe/red mud catalyst to produce syngas[J].Journal of the Energy Institute,2021,98:116-123. |

| 34 | FENG Dongdong, ZHAO Yijun, ZHANG Yu,et al.Catalytic mechanism of ion-exchanging alkali and alkaline earth metallic species on biochar reactivity during CO2/H2O gasification[J].Fuel,2018,212:523-532. |

| [1] | HU Mingliang, ZHOU Wei, LI Bin, LAI Xiaoling. Research progress of synergistic effect catalytic reforming of methane and carbon dioxide [J]. Inorganic Chemicals Industry, 2024, 56(1): 23-32. |

| [2] | MI Xiaotong, LI Xiaoguo, CHANG Yang, ZHANG Yongkun, LI Yongheng, CAO Hui, HOU Zhanggui. Collaborative construction of nanoscale ZSM-5 aggregates by crystal seeds and templates [J]. Inorganic Chemicals Industry, 2023, 55(6): 130-135. |

| [3] | WU Taolong, ZHANG Shengjiang, LIU Jinyang, HONG Xiaobo, LI Limin, QIN Xiaoyu, TAN Xiaoying, ZHOU Yan. Research progress of bimetallic-organic frameworks materials [J]. Inorganic Chemicals Industry, 2023, 55(6): 8-17. |

| [4] | WANG Lijuan, YAN Kezhou, GUO Zhiqiang, ZHAO Zhonghe, GUO Yanxia, CHENG Fangqin. Preparation of poly-aluminum chloride from acid leaching liquor of red mud-coal gangue activated by sodium salt [J]. Inorganic Chemicals Industry, 2023, 55(4): 76-83. |

| [5] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [6] | XU Wenzhen,LI Canhua,JI Hongfeng,LI Zimu,WU Zhaoyang,LI Minghui. Research progress of red mud in field of recycled metals and building materials [J]. Inorganic Chemicals Industry, 2023, 55(2): 10-18. |

| [7] | PAN Sicheng,XU Hongbin,ZHANG Hongling,DONG Yuming,ZHANG Hongjun,LOU Taiping. Study on preparation of metatitanic acid by hydrolysis of leaching solution of roasted mixture of red mud and ammonium sulfate [J]. Inorganic Chemicals Industry, 2023, 55(2): 85-91. |

| [8] | LU Jingjing,XIE Yan,LI Chen,MENG Mei,FENG Lunwei. Study on treatment of phosphorus-containing wastewater by lanthanum-loaded magnetized red mud [J]. Inorganic Chemicals Industry, 2023, 55(2): 99-105. |

| [9] | YUE Yuansui, CHENG Guanwen, XU Min, XU Xiaoyu, ZHANG Zhenlin, NONG Guowu. Function and effect of ferric chloride solution in alkaline regulation of red mud [J]. Inorganic Chemicals Industry, 2023, 55(11): 121-129. |

| [10] | LI Xiangyang,LIU Ziwei,LI Keyan,GUO Xinwen. Study on preparation and performance of FeMn-MOF/CN heterojunction photo-Fenton catalyst [J]. Inorganic Chemicals Industry, 2022, 54(12): 126-132. |

| [11] | PAN Zude,LIU Qi,CAO Yang,CHEN Qianlin,YANG Min,XIE Yan. Study on preparation and properties of phosphogypsum based mine filling materials [J]. Inorganic Chemicals Industry, 2022, 54(11): 90-95. |

| [12] | HUANG Zhiwei,SU Xiangdong,ZHANG Jiangang,LUO Diyuan,CHEN Ye,LI Haijia. Study on leaching of heavy metals from red mud-phosphogypsum composite materials [J]. Inorganic Chemicals Industry, 2022, 54(10): 133-140. |

| [13] | Liu Junxia,Yang Yanmeng,Wang Shuaiqi,Liu Pan,Zhang Maoliang,Hai Ran. Effect of chemical activator on mechanical property of red mud geopolymer mortar [J]. Inorganic Chemicals Industry, 2020, 52(6): 72-75. |

| [14] | Li Xiaoguo,Mi Xiaotong,Hou Zhanggui. Synthesis of aggregated nano-sized ZSM-5 zeolite with ternary pore structure [J]. Inorganic Chemicals Industry, 2020, 52(12): 104-108. |

| [15] | Hai Ran,Wang Shuaiqi,Liu Pan,Liu Junxia. Effect of thermal activated temperature on activation and mechanism of red mud from alumina production [J]. Inorganic Chemicals Industry, 2019, 51(9): 72-75. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||