Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (2): 85-91.doi: 10.19964/j.issn.1006-4990.2022-0191

• Environment·Health·Safety • Previous Articles Next Articles

Study on preparation of metatitanic acid by hydrolysis of leaching solution of roasted mixture of red mud and ammonium sulfate

PAN Sicheng1,2,3( ),XU Hongbin2,3,4(

),XU Hongbin2,3,4( ),ZHANG Hongling2,3,4,DONG Yuming2,3,ZHANG Hongjun5,LOU Taiping1

),ZHANG Hongling2,3,4,DONG Yuming2,3,ZHANG Hongjun5,LOU Taiping1

- 1. Northeastern University,Shenyang 110819,China

2. CAS Key Laboratory of Green Process and Engineering,Institute of Process Engineering,Chinese Academy of Sciences,Beijing 100190,China

3. National Engineering Research Center of Green Recycling for Strategic Metal Resources,Institute of Process Engineering,Chinese Academy of Sciences,Beijing 100190,China

4. University of Chinese Academy of Sciences,Beijing 100049,China

5. Gansu Jinshi Chemical Industry Co.,Ltd.,Zhangye 734500,China

-

Received:2022-04-12Online:2023-02-10Published:2023-02-16

CLC Number:

Cite this article

PAN Sicheng,XU Hongbin,ZHANG Hongling,DONG Yuming,ZHANG Hongjun,LOU Taiping. Study on preparation of metatitanic acid by hydrolysis of leaching solution of roasted mixture of red mud and ammonium sulfate[J]. Inorganic Chemicals Industry, 2023, 55(2): 85-91.

share this article

| 1 | PIETRANTONIO M, PUCCIARMATI S, TORELLI G N,et al.Towards an integrated approach for red mud valorisation:A focus on titanium[J].International Journal of Environmental Science and Technology,2021,18(2):455-462. |

| 2 | 赵恒,李望,朱晓波,等.赤泥提钛研究现状与展望[J].河南化工,2018,35(6):3-7,12. |

| ZHAO Heng, LI Wang, ZHU Xiaobo,et al.Research status and prospect on extracting titanium from red mud[J].Henan Chemical Industry,2018,35(6):3-7,12. | |

| 3 | EVANS K.The history,challenges,and new developments in the management and use of bauxite residue[J].Journal of Sustainable Metallurgy,2016,2(4):316-331. |

| 4 | JONES B E H, HAYNES R J.Bauxite processing residue:A critical review of its formation,properties,storage,and revegetation[J].Critical Reviews in Environmental Science and Technology,2011,41(3):271-315. |

| 5 | 李博琦,谢贤,纪翠翠,等.赤泥提钛技术研究现状与展望[J].矿冶,2020,29(6):87-93. |

| LI Boqi, XIE Xian, JI Cuicui,et al.Research status and prospect of titanium extraction from red mud[J].Mining and Metallurgy,2020,29(6):87-93. | |

| 6 | PEPPER R A.Comprehensive examination of acid leaching behaviour of mineral phases from red mud:Recovery of Fe,Al,Ti,and Si[J].Minerals Engineering,2016,99:8-18. |

| 7 | 韩东战,尹中林.赤泥提钛的研究现状[J].矿产综合利用,2017(3):33-37. |

| HAN Dongzhan, YIN Zhonglin.Current research situation of recovering titanium from red mud[J].Multipurpose Utilization of Mineral Resources,2017(3):33-37. | |

| 8 | 王红伟,马科友,秦凤婷,等.烧结法赤泥中有价金属分离试验研究[J].湿法冶金,2014,33(3):192-195. |

| WANG Hongwei, MA Keyou, QIN Fengting,et al.Separation of valuable metals from red mud of sintering method[J].Hydrometallurgy of China,2014,33(3):192-195. | |

| 9 | 刘宏辉,潘思呈,雷炳宏,等.一种赤泥中有价组分综合回收的方法:中国,112795784B[P].2022-04-05. |

| 10 | 孙帅,孙宏骞,宋静,等.钪资源现状及溶剂萃取在钪提取过程中的应用研究进展[J].过程工程学报,2020,20(8):877-886. |

| SUN Shuai, SUN Gqiansun, SONG Jing,et al.Current status of scandium resources and application research progress of solvent extraction in the process of scandium extraction[J].The Chinese Journal of Process Engineering,2020,20(8):877-886. | |

| 11 | 王红伟,马科友,安松琦.拜耳法赤泥中主要组分分离研究[J].材料与冶金学报,2014,13(1):24-27,36. |

| WANG Hongwei, MA Keyou, AN Songqi.Research on separation of the main components in Bayer red mud[J].Journal of Materials and Metallurgy,2014,13(1):24-27,36. | |

| 12 | 龚家竹.中国钛白粉行业60年发展历程及未来发展趋势[J].无机盐工业,2020,52(10):55-63,83. |

| GONG Jiazhu.Future trend and development course of titanium dioxide pigment industry for sixty years in China[J].Inorganic Chemicals Industry,2020,52(10):55-63,83. | |

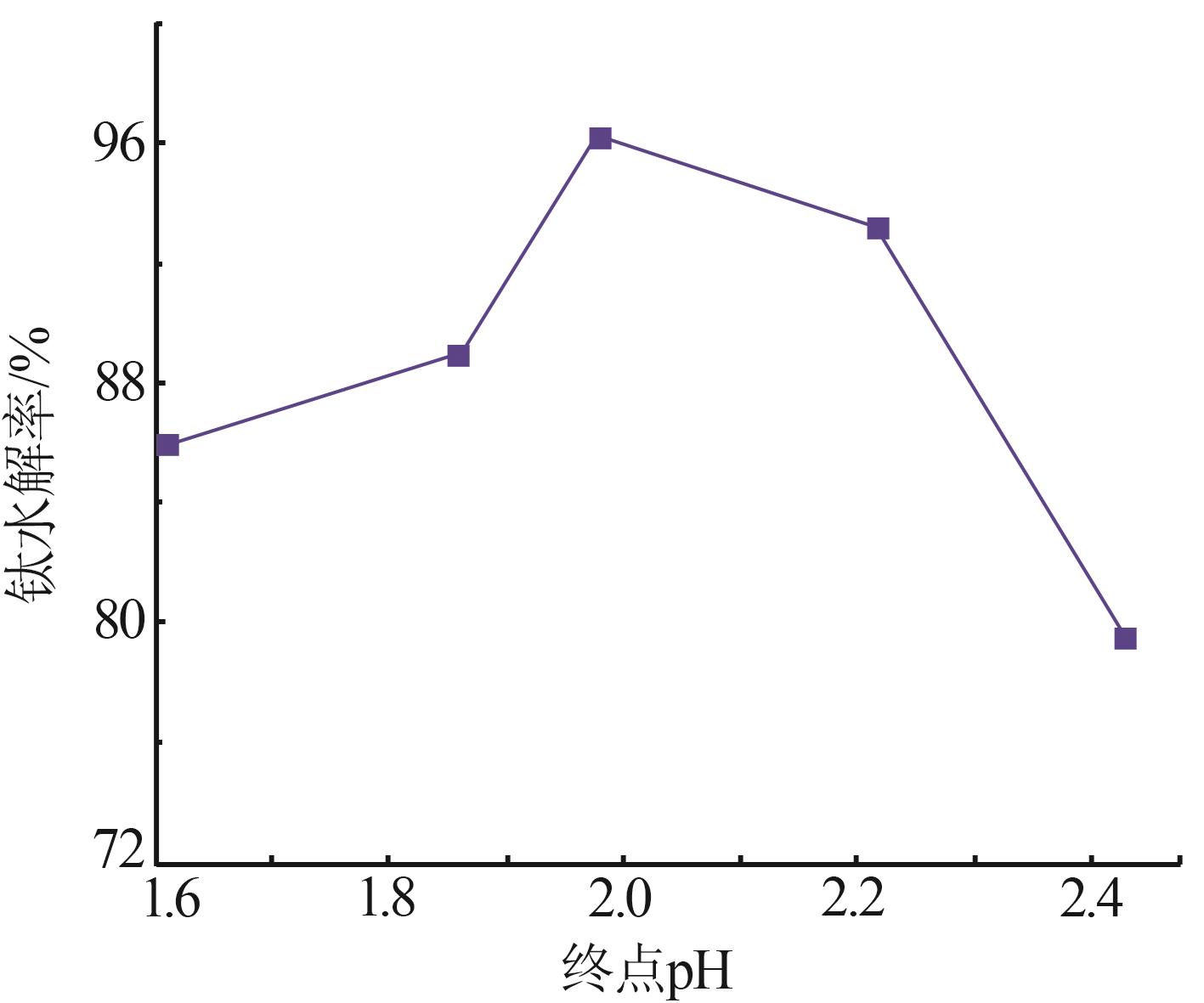

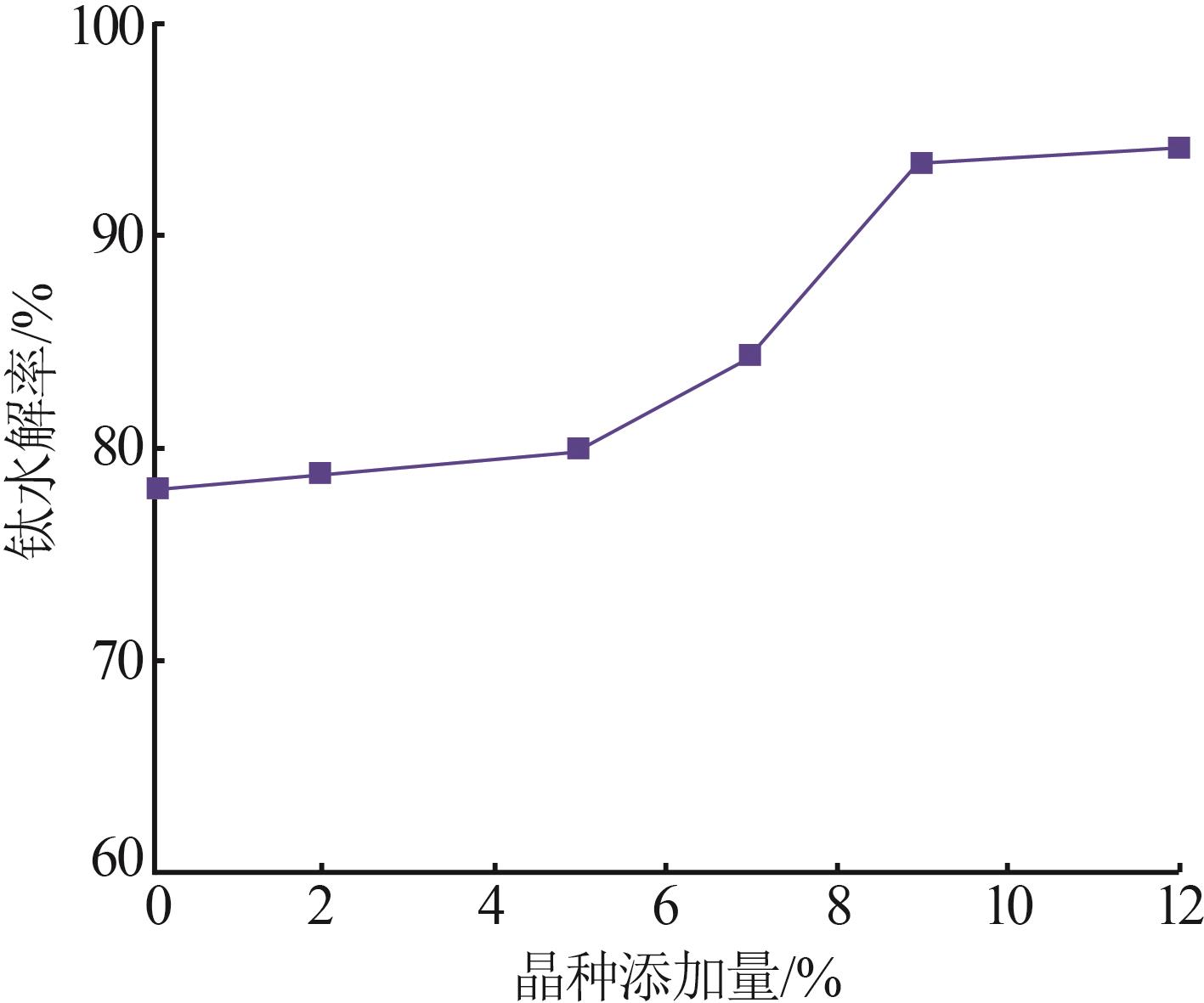

| 13 | 朱容梅,陈葵,朱家文,等.外加晶种对钛白粉水解过程及其亮度的影响[J].无机盐工业,2019,51(2):30-34. |

| ZHU Rongmei, CHEN Kui, ZHU Jiawen,et al.Influence of crystal seeds amount on hydrolysis process of rutile titanium dioxide and its brightness[J].Inorganic Chemicals Industry,2019,51(2):30-34. | |

| 14 | 王伟菁.熔盐法钛白清洁工艺中硫酸氧钛溶液的制备和水解机理的研究[D].北京:中国科学院大学.2014. |

| 15 | 吴鹏辉,贾定田,许文杰,等.钛白副产物硫酸亚铁制备氧化铁黄[J].过程工程学报,2016,16(2):310-316. |

| WU Penghui, JIA Dingtian, XU Wenjie,et al.Preparation of iron oxide yellow with iron sulfate heptahydrate by-product from production of titanium dioxide[J].The Chinese Journal of Process Engineering,2016,16(2):310-316. | |

| 16 | 张益都.硫酸法钛白粉生产技术创新[M].北京:化学工业出版社,2010. |

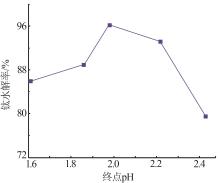

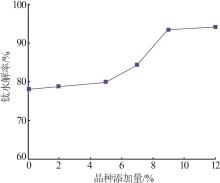

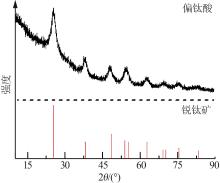

| 17 | 杨林,易德莲,汪成,等.硫酸钛液稳定性分析及偏钛酸粒度控制研究[J].无机盐工业,2015,47(4):26-29. |

| YANG Lin, YI Delian, WANG Cheng,et al.Analysis on stability of titanium sulfate solution and metatitanic acid size control[J].Inorganic Chemicals Industry,2015,47(4):26-29. | |

| 18 | 欧昌锐,刘联平,杨宛霖,等.硫酸钛水解法制备偏钛酸粉体[J].沈阳理工大学学报,2018,37(4):49-52,91. |

| Changrui OU, LIU Lianping, YANG Wanlin,et al.Preparation of titanic acid powders by hydrolysis of titanium sulfate[J].Journal of Shenyang Ligong University,2018,37(4):49-52,91. | |

| 19 | 唐玉梅,何思祺,黄晨,等.高钛高炉渣酸浸液沸腾水解制备偏钛酸的过程动力学研究[J].化工矿物与加工,2022,51(1):1-5. |

| TANG Yumei, HE Siqi, HUANG Chen,et al.Study on the process kinetics for producing metatitanic acid by boiling hydrolysis of acid leaching liquor from high-titanium blast furnace slag[J].Industrial Minerals & Processing,2022,51(1):1-5. | |

| 20 | 黄晨,何思祺,唐玉梅,等.高钛高炉渣硫酸酸浸液沸腾水解制备二氧化钛的研究[J].钢铁钒钛,2021,42(3):44-52,93. |

| HUANG Chen, HE Siqi, TANG Yumei,et al.Preparation of titanium dioxide from acid leaching solution of high titanium blast furnace slag by boiling hydrolysis[J].Iron Steel Vanadium Titanium,2021,42(3):44-52,93. | |

| 21 |

TIAN Congxue.A novel preparation of high purity TiO2 from industrial low concentration TiOSO4 solution via short sulfate process[J].Materials Science in Semiconductor Processing,2022,137.Doi:10.1016/j.mssp.2021.106166 .

doi: 10.1016/j.mssp.2021.106166 |

| 22 | 何思祺.攀枝花高钛高炉渣有价组分提取分离原理与化学动力学研究[D].绵阳:西南科技大学,2020. |

| 23 | 王明花,张华林,徐泗蛟,等.水在TiO2表面的吸附研究进展[J].化学世界,2010,51(10):635-638. |

| WANG Minghua, ZHANG Hualin, XU Sijiao,et al.Progress of research of the adsorption of water on TiO2 surface[J].Chemical World,2010,51(10):635-638. | |

| 24 | SATHYAMOORTHY S, MOGGRIDGE G D, HOUNSLOW M J.Particle formation during anatase precipitation of seeded titanyl sulfate solution[J].Crystal Growth & Design,2001,1(2):123-129. |

| 25 | 林华香,王绪绪,付贤智.TiO2表面羟基及其性质[J].化学进展,2007,19(5):665-670. |

| LIN Huaxiang, WANG Xuxu, FU Xianzhi.Properties and distribution of the surface hydroxyl groups of TiO2 [J].Progress in Che-mistry,2007,19(5):665-670. | |

| 26 | 王子楠,陈葵,朱家文,等.晶种和盐处理剂对煅烧过程中二氧化钛晶型转变的影响[J].无机盐工业,2020,52(3):45-50. |

| WANG Zinan, CHEN Kui, ZHU Jiawen,et al.Effects of crystal seeds and salt dopants on phase transformation of TiO2 in calcination process[J].Inorganic Chemicals Industry,2020,52(3):45-50. | |

| 27 | TSAKIRIDIS P E, OUSTADAKIS P, KATSIAPI A,et al.Synthesis of TiO2 nano-powders prepared from purified sulphate leach liquor of red mud[J].Journal of Hazardous Materials,2011,194:42-47. |

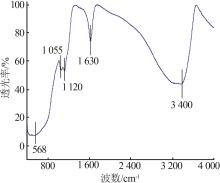

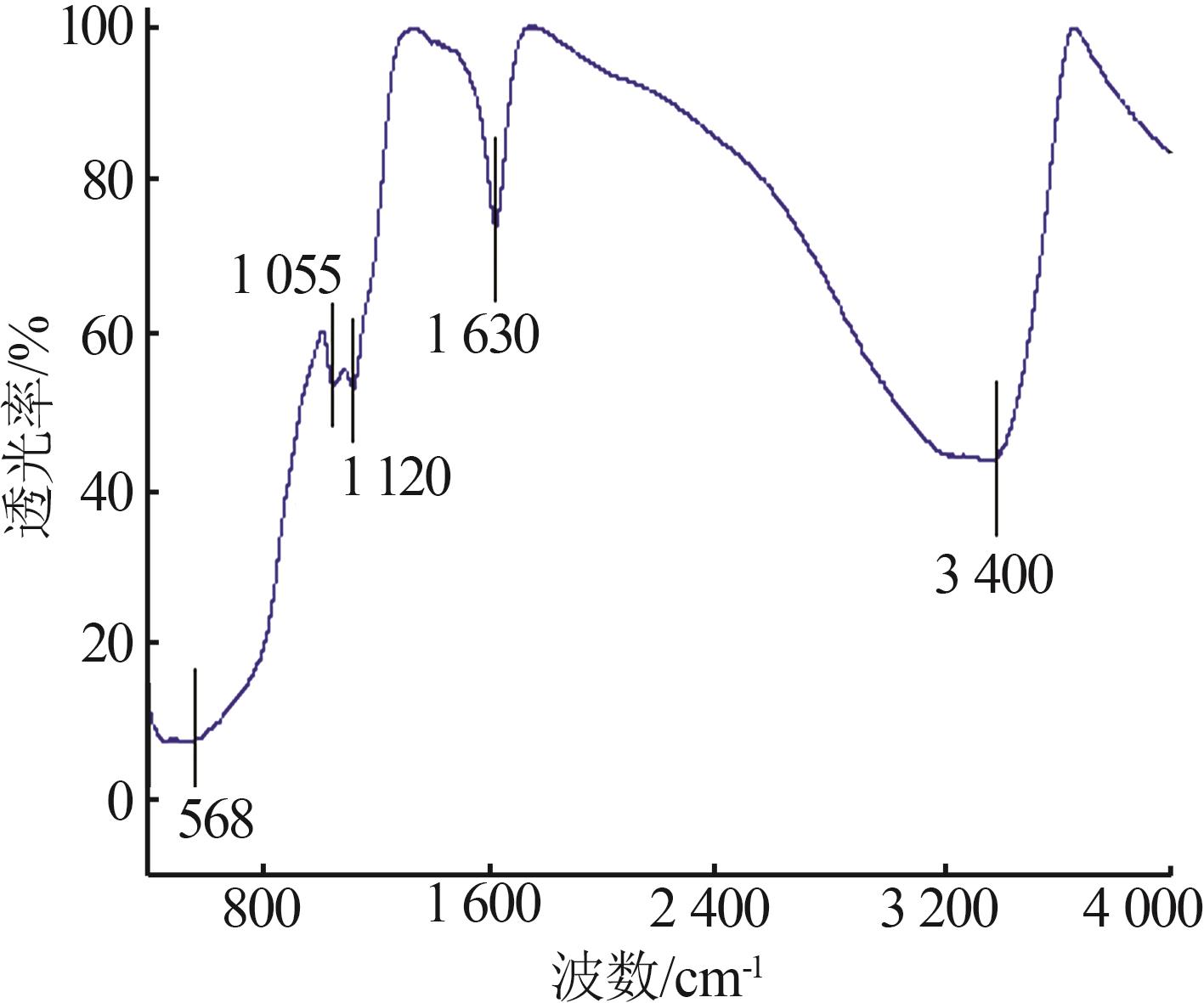

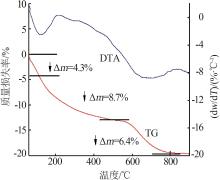

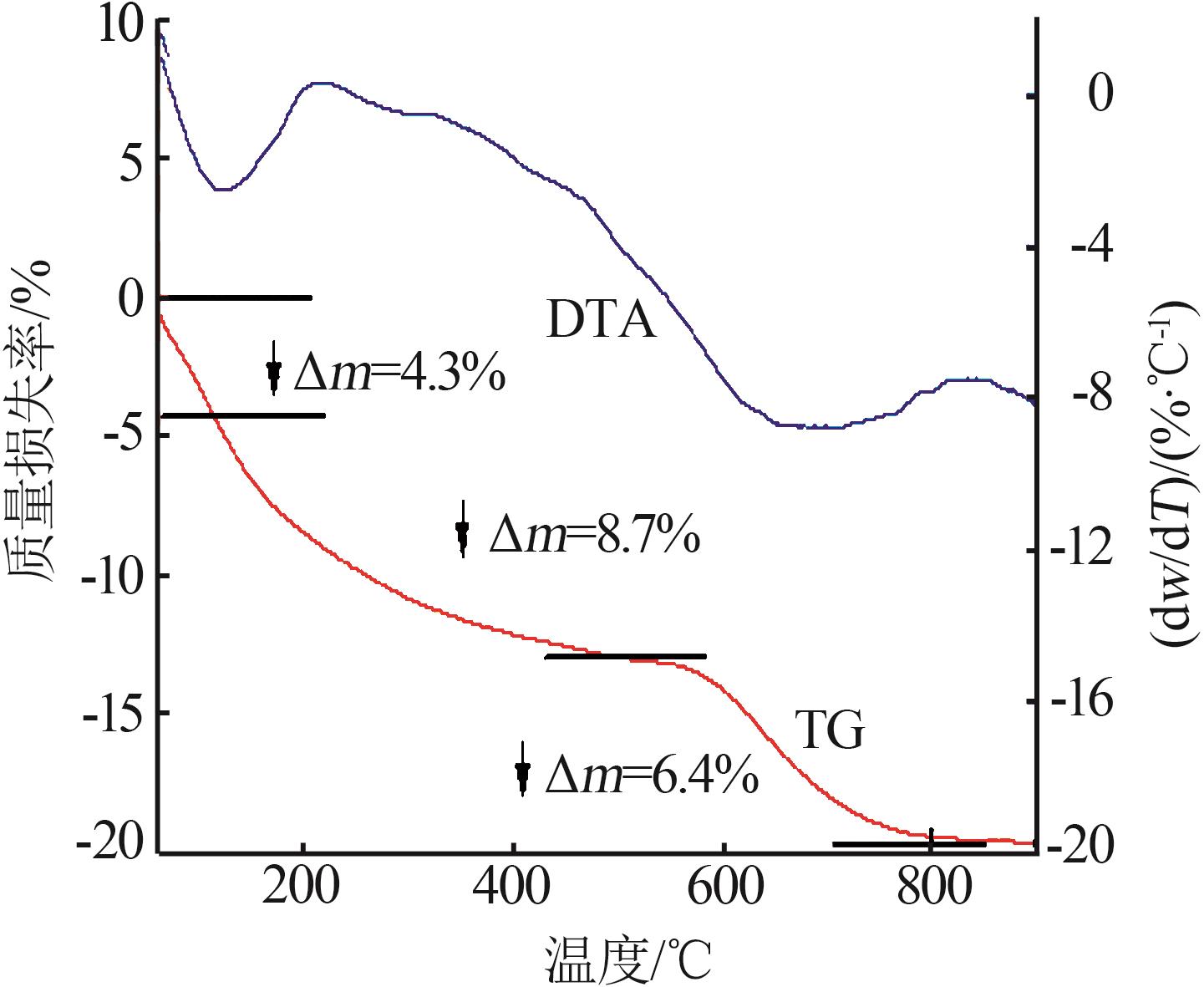

| 28 | 翟蔚然,徐宝强,陈思峰,等.不同气氛下偏钛酸脱水行为动力学研究[J].材料导报,2021,35(20):20016-20021. |

| ZHAI Weiran, XU Baoqiang, CHEN Sifeng,et al.Dehydration kinetics study on metatitanic acid in different atmosphere[J].Materials Reports,2021,35(20):20016-20021. |

| [1] | HUANG Tianyin, SUN Ling, ZHAO Qinzheng, CHEN Xin, SONG Xiaojie, WU Bingdang. Study on performance and mechanism of titanium salt coagulant for treatment of oily wastewater [J]. Inorganic Chemicals Industry, 2025, 57(2): 68-75. |

| [2] | LI Zhao, YIN Youyou, LIU Chenhui, WANG Fang, GAO Jiyun. Study on preparation of two⁃dimensional titanium carbide/zinc oxide nanoparticles and their ethanol gas sensitive properties [J]. Inorganic Chemicals Industry, 2024, 56(8): 33-39. |

| [3] | XIANG Quanjin, QUAN Xuejun, LI Li, WANG Haibo, CHEN Xinhong, LI Ping. Formation rules and emission reduction method of sublimed sulfur in acidolysis exhaust gas of titanium concentrate [J]. Inorganic Chemicals Industry, 2024, 56(7): 96-103. |

| [4] | WANG Luwei, WANG Jie, LI Keke, FENG Chunhua, ZHANG Wenyan, ZHU Jianping. Study on leaching treatment of titanium gypsum with oxalic acid [J]. Inorganic Chemicals Industry, 2024, 56(5): 108-114. |

| [5] | QUAN Yuanxia, QUAN Xuejun, KE Lianghui, LI Li. Study on surface characteristics and dispersion properties of titanium dioxide base particles by sulfate and chloride processes [J]. Inorganic Chemicals Industry, 2024, 56(11): 123-131. |

| [6] | LI Huaquan, QIU Guibao, LÜ Xuewei. Research progress of titanium dioxide preparation technology [J]. Inorganic Chemicals Industry, 2024, 56(10): 20-27. |

| [7] | WEI Tianshun, JI Lijun, SHENG Yong, CHEN Kui, WU Yanyang, WU Bin. Study on fractional crystallization process of ammonium sulfate and sodium sulfate in high salt wastewater [J]. Inorganic Chemicals Industry, 2024, 56(1): 102-106. |

| [8] | XIANG Mengqi, MENG Hua, WANG Ye, MENG Xianzhang, BAI Yuhang, WANG Yujunyao, ZHANG Yidan. Study on kinetic of iron leaching from titanium gypsum and its cyclic acid leaching process [J]. Inorganic Chemicals Industry, 2024, 56(1): 114-120. |

| [9] | WANG Song, WANG Jiawei, GOU Bibo, YANG Pan, HE Yue, YANG Chunyuan, WANG Haifeng. Study on distribution law of magnesium in leaching solution of rhodochrosite by complex salt crystallization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 65-71. |

| [10] | WANG Lijuan, YAN Kezhou, GUO Zhiqiang, ZHAO Zhonghe, GUO Yanxia, CHENG Fangqin. Preparation of poly-aluminum chloride from acid leaching liquor of red mud-coal gangue activated by sodium salt [J]. Inorganic Chemicals Industry, 2023, 55(4): 76-83. |

| [11] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [12] | PENG Shuang, CHEN Chaoyi, WANG Shiyu, BAI Yang, LI Tianpei, GU Wei. Study on preparation of titanium carbide derived carbon by electrolysis-etching in CaCl2 molten salt [J]. Inorganic Chemicals Industry, 2023, 55(3): 78-83. |

| [13] | XU Wenzhen,LI Canhua,JI Hongfeng,LI Zimu,WU Zhaoyang,LI Minghui. Research progress of red mud in field of recycled metals and building materials [J]. Inorganic Chemicals Industry, 2023, 55(2): 10-18. |

| [14] | LI Songhong,ZHOU Songhua,ZHAO Aiming,DONG Wenyan,JIANG Chunyan,CAO Yang,AO Xianquan. Study on catalytic gasification reaction of distillers′grains under H2O/CO2 atmosphere [J]. Inorganic Chemicals Industry, 2023, 55(2): 132-140. |

| [15] | LU Jingjing,XIE Yan,LI Chen,MENG Mei,FENG Lunwei. Study on treatment of phosphorus-containing wastewater by lanthanum-loaded magnetized red mud [J]. Inorganic Chemicals Industry, 2023, 55(2): 99-105. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||