Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (10): 103-109.doi: 10.19964/j.issn.1006-4990.2024-0119

• Environment·Health·Safety • Previous Articles Next Articles

Study on application of phosphogypsum oxalic acid pretreatment liquid in oriented silicon steel coatings

XIANG Linghui1( ), WU Lin1,2, LIU Ying2,3, HU Ya1,2(

), WU Lin1,2, LIU Ying2,3, HU Ya1,2( )

)

- 1.School of Chemistry and Chemical Engineering, Wuhan University of Science and Technology, Wuhan 430081, China

2.Academy of Green Manufacturing Engineering, Wuhan University of Science and Technology, Wuhan 430081, China

3.College of Resource and Environmental Engineering, Wuhan University of Science and Technology, Wuhan 430081, China

-

Received:2024-03-04Online:2024-10-10Published:2024-11-05 -

Contact:HU Ya E-mail:xianglinghui@wust.edu.cn;huya@wust.wust.edu.cn

CLC Number:

Cite this article

XIANG Linghui, WU Lin, LIU Ying, HU Ya. Study on application of phosphogypsum oxalic acid pretreatment liquid in oriented silicon steel coatings[J]. Inorganic Chemicals Industry, 2024, 56(10): 103-109.

share this article

| 1 | 匡国明.湿法磷酸工艺路线的探讨[J].无机盐工业,2013, 45(4):1-4. |

| KUANG Guoming.Discussion on process routes of wet⁃process phosphoric acid[J].Inorganic Chemicals Industry,2013,45(4):1-4. | |

| 2 | 贺雷,朱干宇,郑光明,等.湿法磷酸体系磷石膏结晶过程与机理研究[J].无机盐工业,2022,54(7):110-116. |

| HE Lei, ZHU Ganyu, ZHENG Guangming,et al.Study on crystallization process and mechanism of phosphogypsum in wet process phosphoric acid system[J].Inorganic Chemicals Industry,2022,54(7):110-116. | |

| 3 | 张峻,解维闵,董雄波,等.磷石膏材料化综合利用研究进展[J].材料导报,2023,37(16):163-174. |

| ZHANG Jun, XIE Weimin, DONG Xiongbo,et al.Research progress on comprehensive utilization of phosphogypsum for materials:A review[J].Materials Reports,2023,37(16):163-174. | |

| 4 | 李东旭,焦嘉伟,廖大龙.我国磷石膏在新型建筑材料行业的发展及思考[J].新型建筑材料,2021,48(11):1-4,11. |

| LI Dongxu, JIAO Jiawei, LIAO Dalong.The development and thinking of phosphogypsum used in new building materials in China[J].New Building Materials,2021,48(11):1-4,11. | |

| 5 | 姚炜栋,石林.低品位磷矿的资源化利用研究[J].矿业研究与开发,2022,42(10):63-68. |

| YAO Weidong, SHI Lin.Resource utilization of low⁃grade phosphate rock[J].Mining Research and Development,2022,42(10):63-68. | |

| 6 | 张利珍,张永兴,吴照洋,等.脱除磷石膏中水溶磷、水溶氟的实验研究[J].无机盐工业,2022,54(4):40-45. |

| ZHANG Lizhen, ZHANG Yongxing, WU Zhaoyang,et al.Experimental study on removal of water⁃soluble phosphorus and water⁃soluble fluorine from phosphogypsum[J].Inorganic Chemicals Industry,2022,54(4):40-45. | |

| 7 | 董泽,翟延波,任志威,等.磷石膏建材资源化利用研究进展[J].无机盐工业,2022,54(4):5-9. |

| DONG Ze, ZHAI Yanbo, REN Zhiwei,et al.Research progress on phosphogypsum utilization in building materials[J].Inorganic Chemicals Industry,2022,54(4):5-9. | |

| 8 | 王秀秀.磷石膏渗滤液除磷研究[D].重庆:重庆大学,2021. |

| WANG Xiuxiu.Study on phosphorus removal from phosphogypsum leachate[D].Chongqing:Chongqing University,2021. | |

| 9 | SONG Xiaoyan, PAN Yanqiu, WU Quyin,et al.Phosphate removal from aqueous solutions by adsorption using ferric sludge[J].Desalination,2011,280(1/2/3):384-390. |

| 10 | 杨浩,王成,肖小波,等.添加硼酸和钨酸铵对取向硅钢无铬绝缘涂层的影响[J].材料导报,2021,35(22):22141-22145. |

| YANG Hao, WANG Cheng, XIAO Xiaobo,et al.Effects of boric acid and ammonium tungstate additions on the chromium⁃free insulating coating of grain⁃oriented silicon steel[J].Materials Reports,2021,35(22):22141-22145. | |

| 11 | CHENG Ling, MENG Li, GUO Dawei,et al.Deterioration law and evaluation of insulation coating of grain⁃oriented silicon steel in service[J].Iron & Steel,2019,54(1):79-84. |

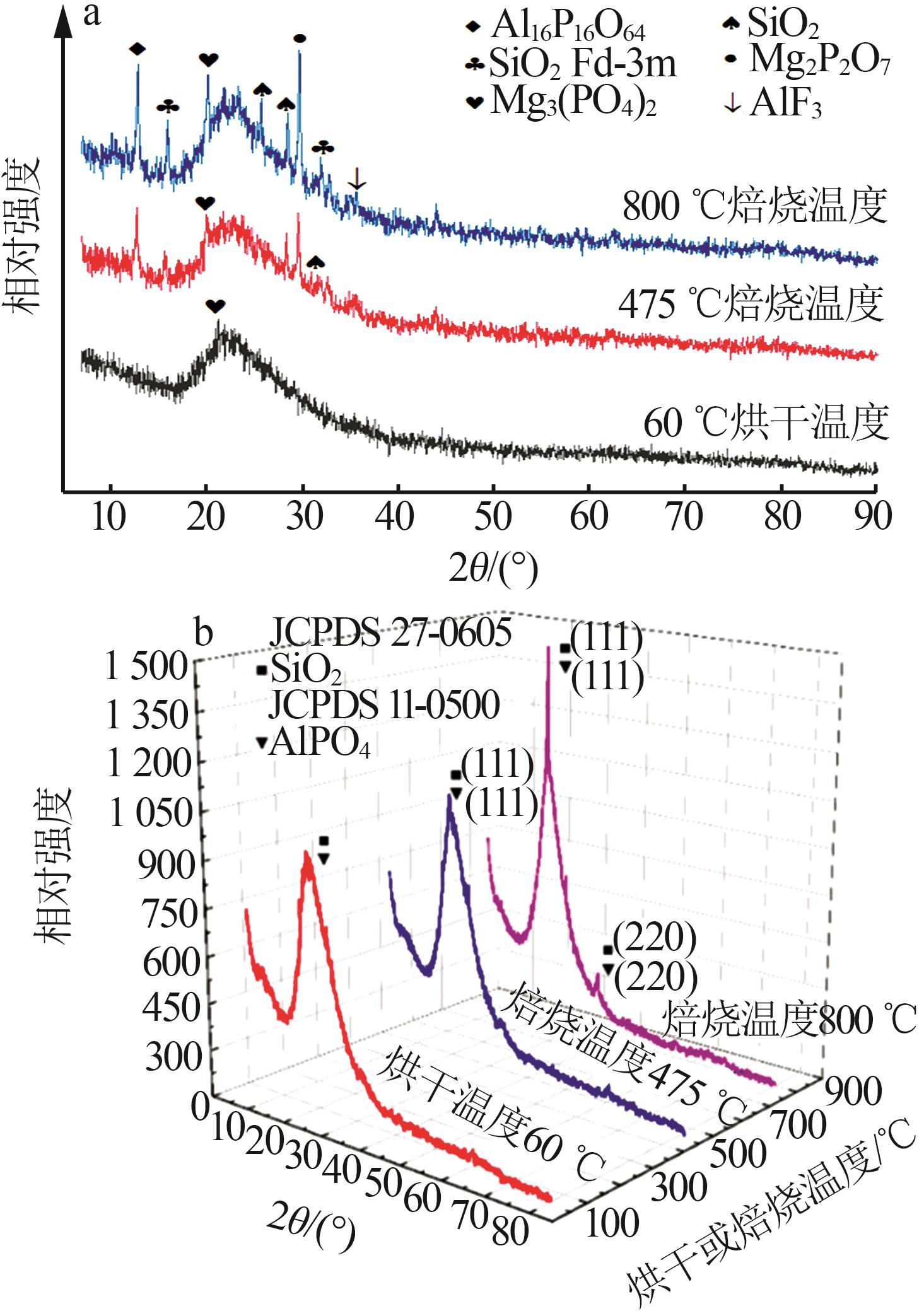

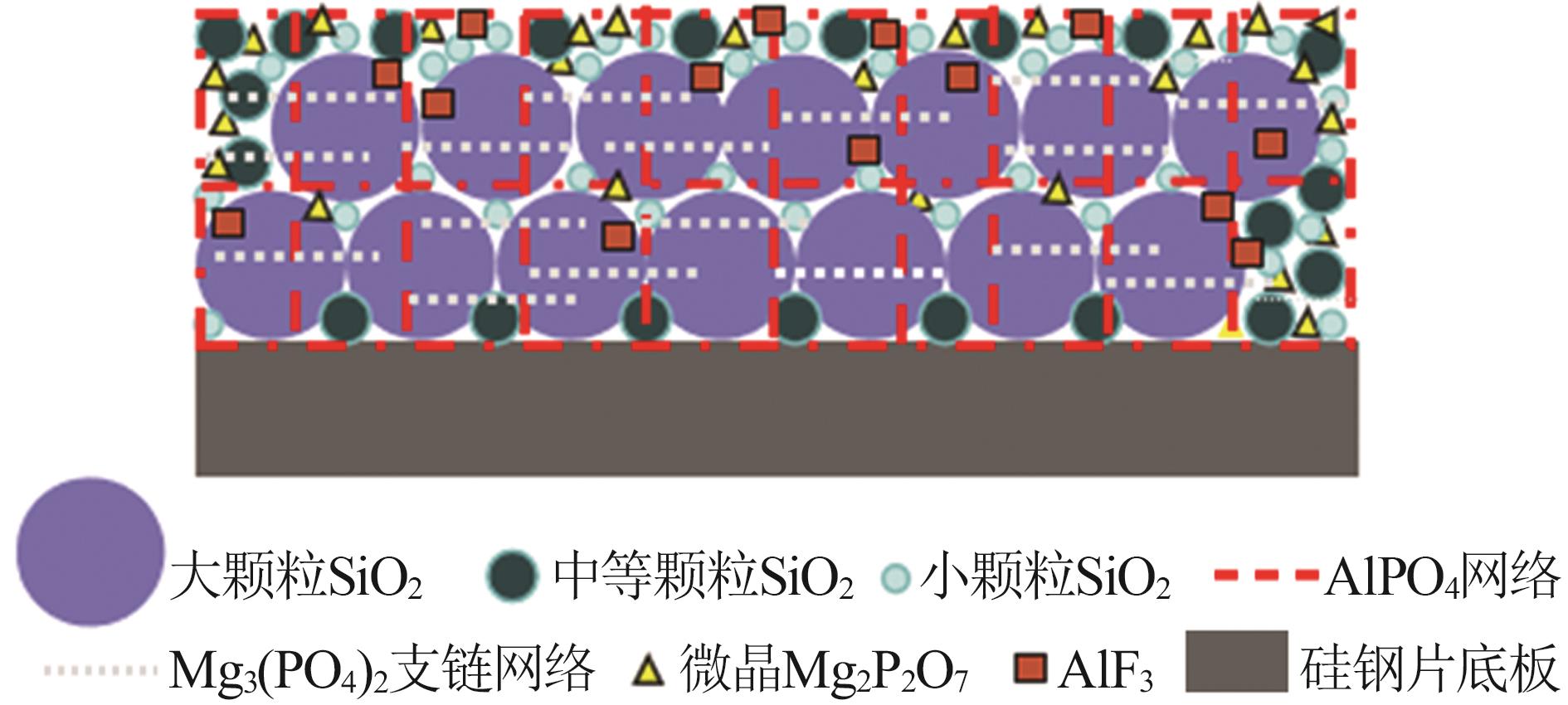

| 12 | LIU Ying, WU Lin, CHEN Ao,et al.Component design of environmentally friendly high⁃temperature resistance coating for oriented silicon steel and effects on anti⁃corrosion property[J].Coatings,2022,12(7):959. |

| 13 | CAI Qiang, JIANG Jun, MA Bing,et al.Efficient removal of phosphate impurities in waste phosphogypsum for the production of cement[J].Science of the Total Environment,2021,780:146600. |

| 14 | 曹京宜,熊金平,李水冰,等.利用EIS高频区参数评价两种环氧涂层的性能[J].化工学报,2008,59(11):2851-2856. |

| CAO Jingyi, XIONG Jinping, LI Shuibing,et al.Evaluation of protective performance of organic coatings by EIS parameters at high frequency zone[J].CIESC Journal,2008,59(11):2851-2856. | |

| 15 | 翁诗甫.傅里叶变换红外光谱分析[M].2版.北京:化学工业出版社,2010:348-352. |

| 16 | 史学海,陈志宇,周斌,等.无机磷酸盐耐高温涂料的防腐机理及研究进展[J].电镀与涂饰,2021,40(14):1110-1118. |

| SHI Xuehai, CHEN Zhiyu, ZHOU Bin,et al.Anticorrosion mechanism and research progress of high⁃temperature⁃resistant inorganic phosphate coatings[J].Electroplating & Finishing,2021,40(14):1110-1118. | |

| 17 | 陈洋,丁军,邓承继,等.室温固化磷酸二氢铝-硅溶胶复合高温黏结剂的制备及物理性能[J].硅酸盐学报,2018,46(12):1762-1770. |

| CHEN Yang, DING Jun, DENG Chengji,et al.Preparation and physical properties of room⁃temperature curing aluminum dihydrogen phosphate-silica sol composite high temperature adhesi⁃ve[J].Journal of the Chinese Ceramic Society,2018,46(12):1762-1770. | |

| 18 | 张全利,陈长林.偏磷酸镁修饰钨铝复合氧化物载铂催化剂的稳定性研究[J].南京工业大学学报(自然科学版),2022, 44(1):36-44. |

| ZHANG Quanli, CHEN Changlin.Study on stability of platinum supported on tungsten-aluminum composite oxide modified by magnesium metaphosphate[J].Journal of Nanjing Tech University(Natural Science Edition),2022,44(1):36-44. | |

| 19 | 杨淑莉,李富天,邓毅,等.酸性高氯介质中氟离子对Incoloy825合金腐蚀行为的影响[J].焊管,2023,46(10):8-13. |

| YANG Shuli, LI Futian, DENG Yi,et al.Effect of fluoride ions on corrosion behavior of Incoloy825 alloy in acidic high chloride solution[J].Welded Pipe and Tube,2023,46(10):8-13. | |

| 20 | XIAO Wei, WANG Ying.Corrosion resistance of aluminum fluoride modified 6061 aluminum alloy[J].Materials Letters,2021,298:129932. |

| 21 | WANG Zhijiang, WU Lina, CAI Wei,et al.Effects of fluoride on the structure and properties of microarc oxidation coating on aluminium alloy[J].Journal of Alloys and Compounds,2010,505(1):188-193. |

| [1] | LENG Manxi, ZHU Yu, YAN Jikang, XIE Ke, ZOU Yongjie. Study on crystallization characteristics and mineral flotation performance of industrial waste phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(3): 108-115. |

| [2] | TAN Shanyi, WEN Huizi, HE Shuyu, ZHANG Liwen, CHEN Shaohua, XI Benjun. Study on leaching behavior and kinetics of phosphorus from phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(2): 105-112. |

| [3] | ZHANG Jinjun, GUO Linlin, MIAO Chengpeng, LI Xingyu, PANG Yaheng, YANG Rongkai, YU Yasen. Study on preparation of spherical calcium carbonate for coating fillers based on carbide slag as raw materials [J]. Inorganic Chemicals Industry, 2025, 57(2): 113-119. |

| [4] | TANG Kaijing, LIU Chuanbei, LI Yingding, JIANG Yong, WU Junnan, ZHANG Tao. Research on preparation and mechanism of superhydrophobic phosphogypsum products [J]. Inorganic Chemicals Industry, 2025, 57(1): 97-102. |

| [5] | PANG Hongchang, LIU Shuai, TIAN Peng, NING Guiling. Study on application of modified halloysite nanotubes in polyurea⁃based fireproof coatings [J]. Inorganic Chemicals Industry, 2024, 56(8): 27-32. |

| [6] | TANG Xuemei, WANG Meibo, XU Li, ZHANG Xujie, TAI Shijun, YI Xianmei, LIU Hongjuan, PAN Linyi. Study on whitening of phosphogypsum by low⁃temperature calcination [J]. Inorganic Chemicals Industry, 2024, 56(8): 110-115. |

| [7] | SUN Lan, CHEN Shiying, YANG Liuxu, NIU Yiming, ZHAO Aonan. Basic study on fixing soluble phosphorus in phosphogypsum with magnesium slag [J]. Inorganic Chemicals Industry, 2024, 56(8): 92-98. |

| [8] | HU Cheng, LIU Meng, XIANG Weiheng, CHEN Ping, WANG Neng, LU Guanju, ZHOU Jinlan. Preparation of α-hemihydrous gypsum from CaCl2 and MgCl2 and their composite solution [J]. Inorganic Chemicals Industry, 2024, 56(7): 112-117. |

| [9] | HU Dian, GUO Ze, ZHANG Hanquan, LU Manman. Research on effects of roasting process and typical impurities on reduction and decomposition process of phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(7): 88-95. |

| [10] | LEI Xinyu, SUN Henghui, YUAN Xinqiang, ZHANG Wei, JIANG Peng, ZHANG Lizhai. Study on preparation of core-shell structure VO2(M)@SiO2 by silica sol-gel coating [J]. Inorganic Chemicals Industry, 2024, 56(6): 46-54. |

| [11] | HU Cheng, LIU Meng, XIANG Weiheng, DUAN Pengxuan, LI Shunkai, MING Yang, WANG Neng, LU Guanju. Effect of NaCl solution concentration on transcrystallization behavior of α-hemihydrate gypsum from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(6): 87-93. |

| [12] | TU Yanping, BAI Dengxian, CHENG Shukai, XIE Junjie, HUANG Zhiliang, CHEN Guofu. Effect of high temperature modification of mineral powder and quicklime on properties of phosphogypsum cement based materials [J]. Inorganic Chemicals Industry, 2024, 56(6): 94-101. |

| [13] | WANG Mingshun, AO Xianquan, YUAN Xing, DONG Wenyan, CHEN Qianlin. Study on effect of crystallizer on preparation of anhydrous calcium sulfate from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(5): 101-107. |

| [14] | WANG Luwei, WANG Jie, LI Keke, FENG Chunhua, ZHANG Wenyan, ZHU Jianping. Study on leaching treatment of titanium gypsum with oxalic acid [J]. Inorganic Chemicals Industry, 2024, 56(5): 108-114. |

| [15] | DENG Fuli, XIA Zhixiang, LONG Bingwen, ZHANG Yi, DAI Yafen, WANG Bin, DING Yigang. Study on purification process of phosphogypsum by reverse flotation [J]. Inorganic Chemicals Industry, 2024, 56(5): 115-120. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||