| 1 |

董泽,翟延波,任志威,等.磷石膏建材资源化利用研究进展[J].无机盐工业,2022,54(4):5-9.

|

|

DONG Ze, ZHAI Yanbo, REN Zhiwei,et al.Research progress on phosphogypsum utilization in building materials[J].Inorganic Che-Industry micals,2022,54(4):5-9.

|

| 2 |

吴浩,韩超南,汤昱.我国磷石膏资源化利用研究进展[J].现代化工,2023,43(3):18-21.

|

|

WU Hao, HAN Chaonan, TANG Yu.Research progress on reutilization of phosphogypsum in China[J].Modern Chemical Industry,2023,43(3):18-21.

|

| 3 |

ROSALES J, PÉREZ S M, CABRERA M,et al.Treated phosphogypsum as an alternative set regulator and mineral addition in cement production[J].Journal of Cleaner Production,2020,244:118752.

|

| 4 |

周诗彤.磷对磷石膏胶结充填体材料性能和环境行为影响研究[D].长沙:中南大学,2022.

|

|

ZHOU Shitong.Effect of phosphorus on the material properties and environmental behavior of phosphogypsum-based cemented backfill[D].Changsha:Central South University,2022.

|

| 5 |

杜明霞,王进明,董发勤,等.磷石膏资源化利用研究进展[J].矿产保护与利用,2020,40(3):121-126.

|

|

DU Mingxia, WANG Jinming, DONG Faqin,et al.Research progress on resource utilization of phosphogypsum[J].Conservation and Utilization of Mineral Resources,2020,40(3):121-126.

|

| 6 |

赵静,段晓牧,刘佳佳,等.磷石膏复合胶凝材料配比优化及浸出机制[J].矿业研究与开发,2023,43(4):30-36.

|

|

ZHAO Jing, DUAN Xiaomu, LIU Jiajia,et al.Ratio optimization and leaching mechanism of phosphogypsum composite cementitious material[J].Mining Research and Development,2023,43(4):30-36.

|

| 7 |

张太玥,谢凡,郭君渊.磷石膏基复合胶凝材料的性能优化及机理研究[J].无机盐工业,2022,54(9):136-142.

|

|

ZHANG Taiyue, XIE Fan, GUO Junyuan.Study on performance optimization and mechanism of phosphogypsum based composite cementitious materials[J].Inorganic Chemicals Industry,2022,54(9):136-142.

|

| 8 |

何芋崎,李显波,杜亚文,等.粉磨细度对磷石膏物相转变速率和力学强度的影响研究[J].矿产综合利用,2022(6):36-41.

|

|

HE Yuqi, LI Xianbo, DU Yawen,et al.Study on effect of grinding fineness on phase transformation rate and mechanical strength of phosphogypsum[J].Multipurpose Utilization of Mineral Resour-ces,2022(6):36-41.

|

| 9 |

JIANG Guanzhao, WU Aixiang, WANG Yiming,et al.Low cost and high efficiency utilization of hemihydrate phosphogypsum:Used as binder to prepare filling material[J].Construction and Building Materials,2018,167:263-270.

|

| 10 |

杨林,曹建新,刘亚明.半水磷石膏的矿物学特征[J].岩石矿物学杂志,2015,34(6):827-834.

|

|

YANG Lin, CAO Jianxin, LIU Yaming.Mineralogical characteristics of hemi-hydrate phosphogypsum[J].Acta Petrologica et Mineralogica,2015,34(6):827-834.

|

| 11 |

LIU Shuhua, FANG Peipei, REN Jun,et al.Application of lime neutralised phosphogypsum in supersulfated cement[J].Journal of Cleaner Production,2020,272:122660.

|

| 12 |

程想,陈思翰,胡群,等.高温改性磷石膏基水泥砂浆强度性能研究[J].非金属矿,2022,45(1):37-40,45.

|

|

CHENG Xiang, CHEN Sihan, HU Qun,et al.Study on the strength performance of modified phosphogypsum-based cement mortar[J].Non-Metallic Mines,2022,45(1):37-40,45.

|

| 13 |

余洋,沈承金,孙恕,等.矿粉水泥砂浆抗硫酸盐腐蚀行为研究[J].腐蚀科学与防护技术,2014,26(4):355-359.

|

|

YU Yang, SHEN Chengjin, SUN Shu,et al.Sulfate corrosion behavior of slag cement mortar[J].Corrosion Science and Protection Technology,2014,26(4):355-359.

|

| 14 |

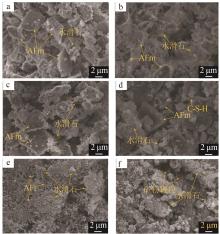

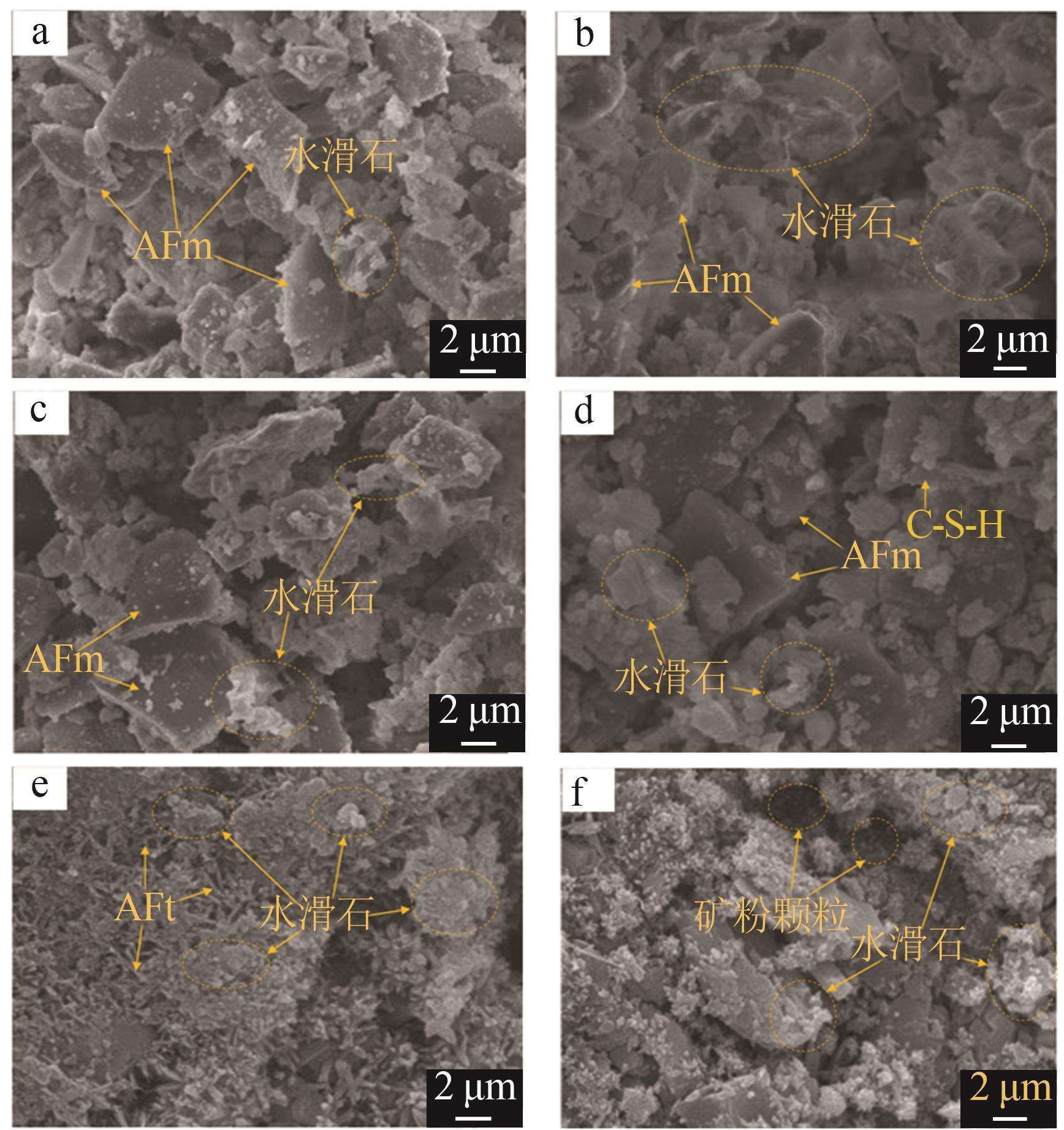

杨荣辉,水中和.磷石膏-矿渣体系水化过程与水化产物研究[J].建材世界,2016,37(1):33-36,41.

|

|

YANG Ronghui, SHUI Zhonghe.Hydration process and hydrates of phosphgypsum-blastfurnace slag-cement blends[J].The World of Building Materials,2016,37(1):33-36,41.

|

| 15 |

厉超.矿渣、高/低钙粉煤灰玻璃体及其水化特性研究[D].北京:清华大学,2011.

|

|

LI Chao.Research on the glass phase of slag,high calcium fly ash and low calcium fly ash and their hydration mechanism[D].Beijing:Tsinghua University,2011.

|

| 16 |

李宇,孙恒虎,赵永宏,等.水淬渣的胶凝活性及其形成机理[J].过程工程学报,2007,7(1):79-84.

|

|

LI Yu, SUN Henghu, ZHAO Yonghong,et al.Research of formation mechanism on cementitious reactivity of water-cooled slag[J].The Chinese Journal of Process Engineering,2007,7(1):79-84.

|

| 17 |

汤玉娟,左晓宝,何绍丽,等.矿渣掺量和水胶比对水泥浆体溶蚀特性的影响[J].硅酸盐学报,2016,44(11):1579-1587.

|

|

TANG Yujuan, ZUO Xiaobao, HE Shaoli,et al.Influences of slag content and water-binder ratio on leaching behavior of cement paste[J].Journal of the Chinese Ceramic Society,2016,44(11):1579-1587.

|

), BAI Dengxian1,2, CHENG Shukai1,2, XIE Junjie1,2, HUANG Zhiliang3, CHEN Guofu4(

), BAI Dengxian1,2, CHENG Shukai1,2, XIE Junjie1,2, HUANG Zhiliang3, CHEN Guofu4( )

)