Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (12): 113-119.doi: 10.19964/j.issn.1006-4990.2024-0097

• Research & Development • Previous Articles Next Articles

Research on preparation of carnallite concentrate by pretreatment combined with reverse flotation

DING Xiaojiang( ), WU Yanni(

), WU Yanni( ), LI Boyun, HUANG Youliang

), LI Boyun, HUANG Youliang

- Geology Institute of China Chemical Geology and Mine Bureau,Beijing 100101,China

-

Received:2024-02-23Online:2024-12-10Published:2024-04-09 -

Contact:WU Yanni E-mail:53049846@qq.com;16499335@qq.com

CLC Number:

Cite this article

DING Xiaojiang, WU Yanni, LI Boyun, HUANG Youliang. Research on preparation of carnallite concentrate by pretreatment combined with reverse flotation[J]. Inorganic Chemicals Industry, 2024, 56(12): 113-119.

share this article

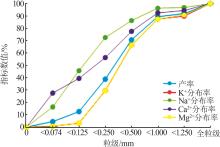

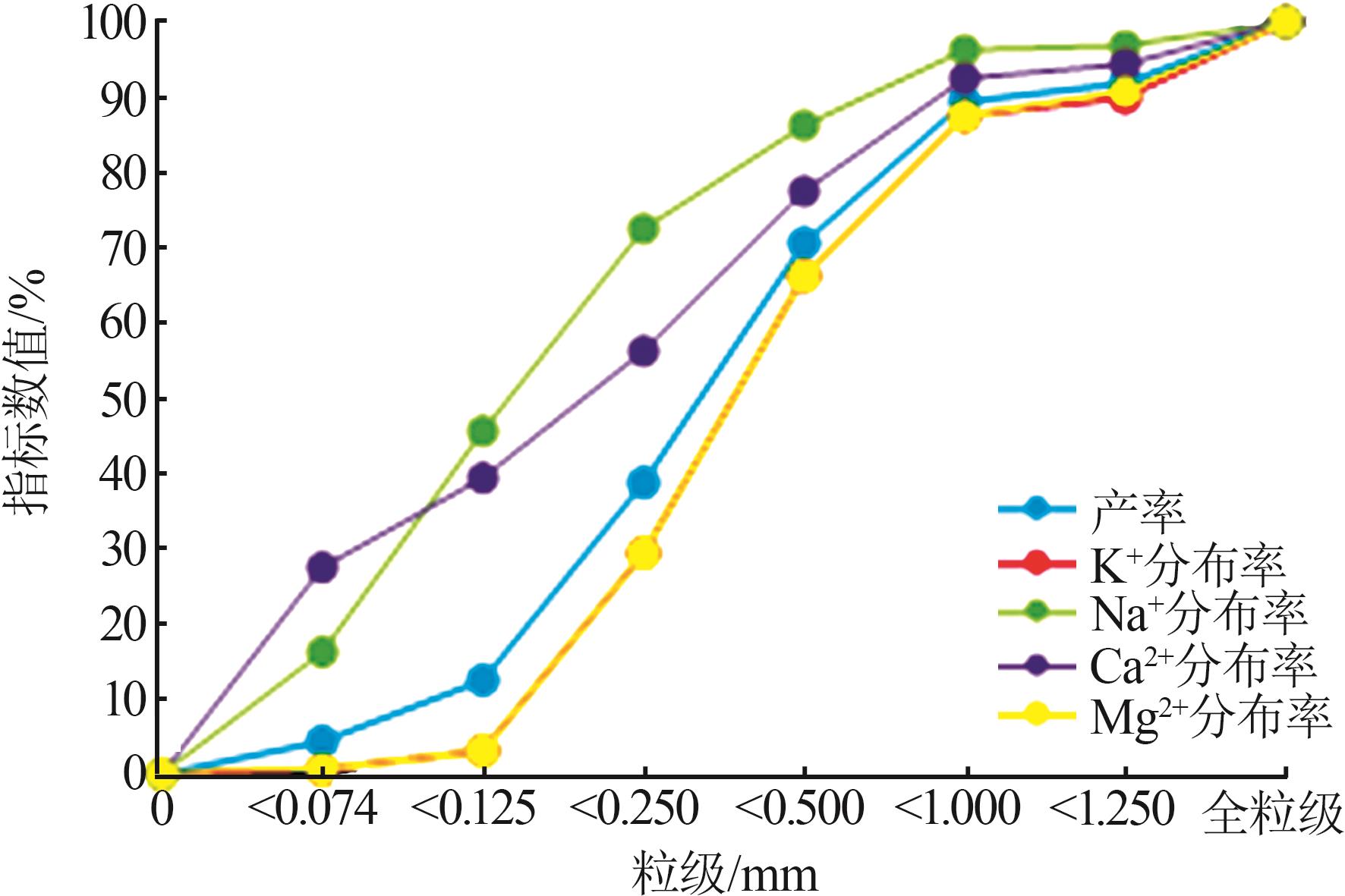

Table 3

Screening test results of raw ore"

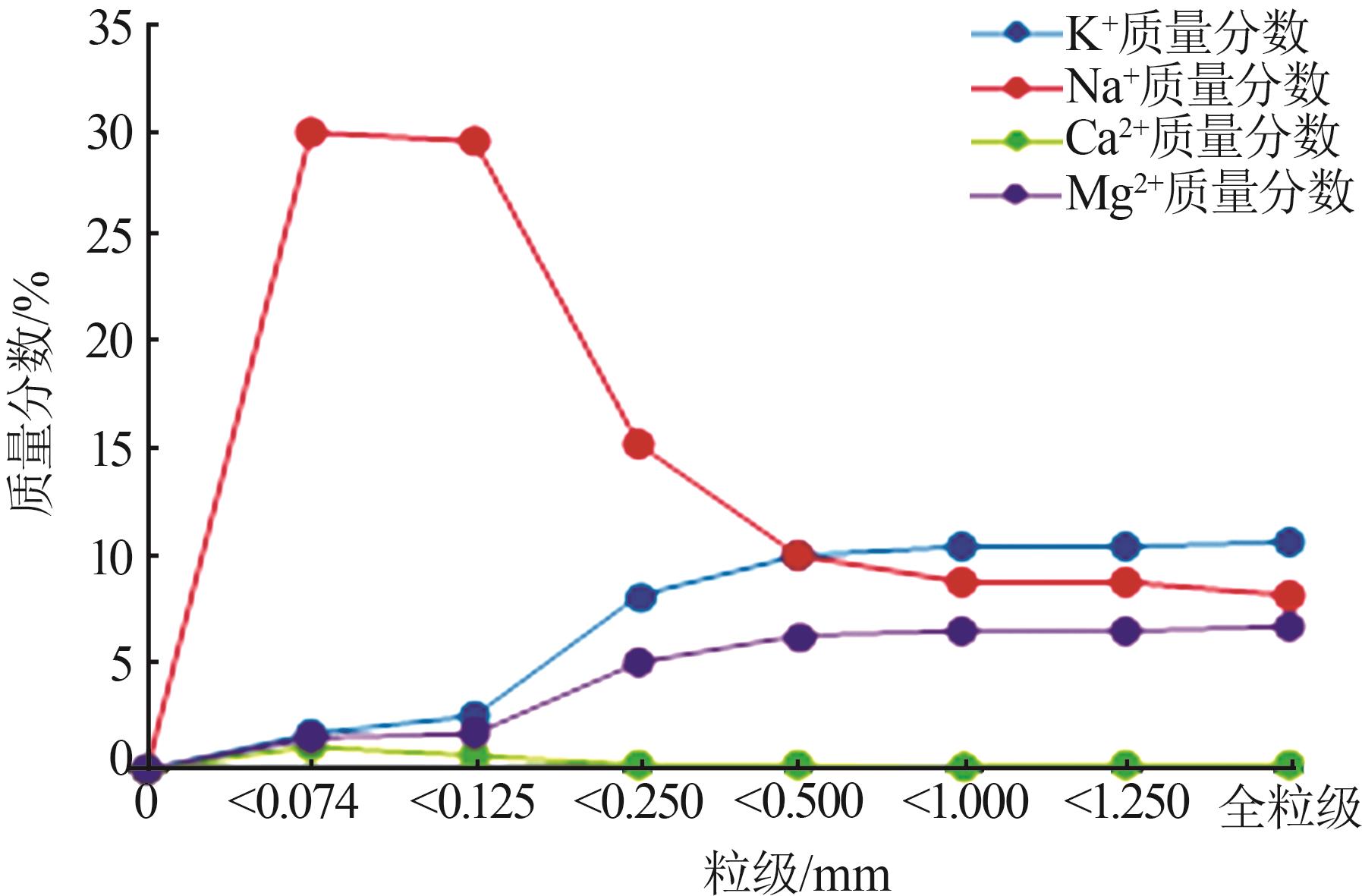

| 粒级/mm | 产率/% | 质量分数/% | 分布率/% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K+ | Na+ | Ca2+ | Mg2+ | K+ | Na+ | Ca2+ | Mg2+ | |||

| 合计 | 100.00 | 10.57 | 8.18 | 0.172 | 6.65 | 100.00 | 100.00 | 100.00 | 100.00 | |

| ≥1.25 | 8.58 | 12.30 | 2.90 | 0.116 | 7.60 | 9.98 | 3.04 | 5.78 | 9.81 | |

| 1.0~<1.25 | 2.42 | 11.66 | 3.82 | 0.122 | 7.62 | 2.67 | 1.13 | 1.71 | 2.76 | |

| 0.5~<1.0 | 18.58 | 11.91 | 4.24 | 0.141 | 7.56 | 20.93 | 9.63 | 15.20 | 21.12 | |

| 0.25~<0.5 | 31.75 | 12.31 | 3.60 | 0.114 | 7.70 | 36.96 | 13.97 | 20.99 | 36.76 | |

| 0.125~<0.25 | 26.00 | 10.74 | 8.31 | 0.114 | 6.72 | 26.41 | 26.41 | 17.19 | 26.27 | |

| 0.074~<0.125 | 8.25 | 2.98 | 29.42 | 0.245 | 1.91 | 2.33 | 29.67 | 11.72 | 2.37 | |

| <0.074 | 4.42 | 1.72 | 29.90 | 1.070 | 1.37 | 0.72 | 16.15 | 27.41 | 0.91 | |

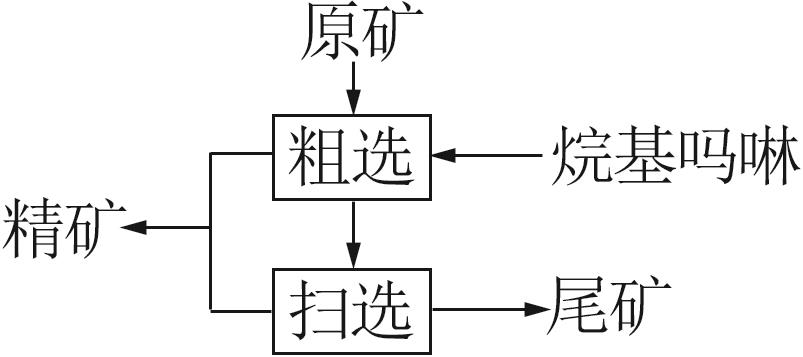

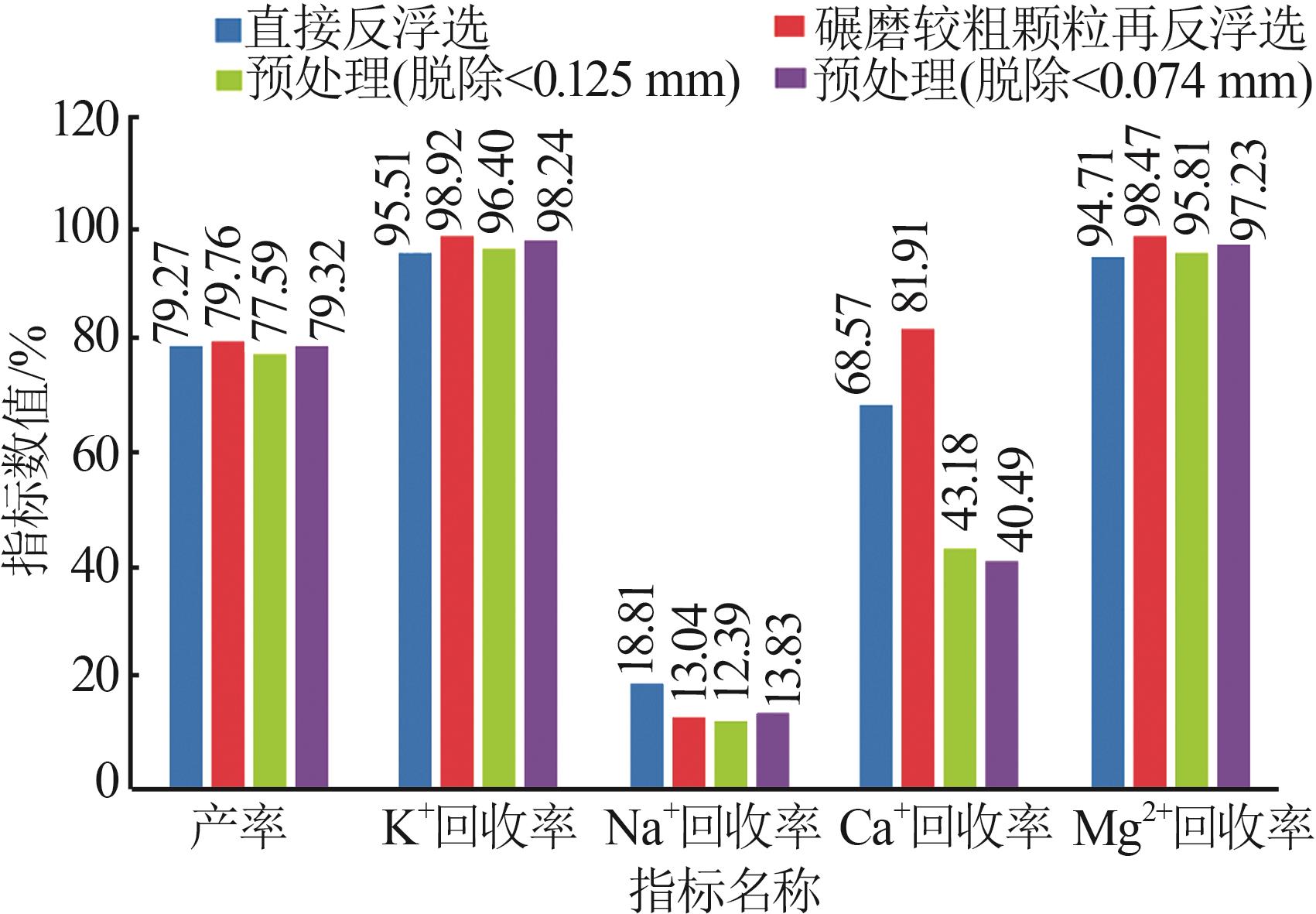

Table 6

Test results of pretreatment combine with reverse flotation"

产品 名称 | 产率/ % | 品位/% | 回收率/% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K+ | Na+ | Ca2+ | Mg2+ | K+ | Na+ | Ca2+ | Mg2+ | |||

| 精矿 | 77.59 | 13.22 | 1.37 | 0.094 | 8.78 | 96.40 | 12.39 | 43.18 | 95.81 | |

| 尾矿 | 12.05 | 1.74 | 34.38 | 0.126 | 1.24 | 1.97 | 48.32 | 8.99 | 2.10 | |

| <0.125 mm | 10.36 | 1.67 | 32.53 | 0.780 | 1.43 | 1.63 | 39.29 | 47.83 | 2.09 | |

| 原矿 | 100.00 | 10.64 | 8.58 | 0.169 | 7.11 | 100.00 | 100.00 | 100.00 | 100.00 | |

| 精矿 | 79.32 | 13.01 | 1.45 | 0.092 | 8.66 | 98.24 | 13.83 | 40.49 | 97.23 | |

| 尾矿 | 16.73 | 0.84 | 35.70 | 0.119 | 0.89 | 1.34 | 71.80 | 11.05 | 2.11 | |

| <0.074 mm | 3.95 | 1.11 | 30.25 | 2.210 | 1.18 | 0.42 | 14.37 | 48.46 | 0.66 | |

| 原矿 | 100.00 | 10.50 | 8.32 | 0.180 | 7.06 | 100.00 | 100.00 | 100.00 | 100.00 | |

| [1] | 熊增华,王石军.中国钾资源开发利用技术及产业发展综述[J].矿产保护与利用,2020,40(6):1-7. |

| XIONG Zenghua, WANG Shijun.Overview of potassium resources exploitation & utilization technology and potash industry development[J].Conservation and Utilization of Mineral Resources,2020,40(6):1-7. | |

| [2] | 王石军.全球钾肥产业发展现状与展望[J].磷肥与复肥,2019,34(10):9-13. |

| WANG Shijun.Development status and prospect of potash fertilizer industry in the world[J].Phosphate & Compound Fertilizer,2019,34(10):9-13. | |

| [3] | 张苏江,张琳,姜爱玲,等.中国盐湖资源开发利用现状与发展建议[J].无机盐工业,2022,54(10):13-21. |

| ZHANG Sujiang, ZHANG Lin, JIANG Ailing,et al.Current situation and development suggestions of development and utilization of salt lake resources in China[J].Inorganic Chemicals Industry,2022,54(10):13-21. | |

| [4] | ZHANG Shichun, YU Xueshan, TANG Haiying,et al.Effects of fine-NaCl on decomposition-crystallization process of carnallite with high content of fine-NaCl[J].Journal of Salt Lake Research,2023,31(4) :93-100. |

| [5] | 张生太,孟浩,屈小荣,等.“反浮选-冷结晶” 氯化钾生产中粗钾筛上物回收技术的研究与探讨[J].当代化工研究,2020(6):38-39. |

| ZHANG Shengtai, MENG Hao, QU Xiaorong,et al.Research and discussion on recovery technology of coarse potassium sieve in the production of “reverse flotation-cold crystallization” potassium chloride[J].Modern Chemical Research,2020(6):38-39. | |

| [6] | 切知加,马生奎,杜景灵,等.响应面法优化提高低钠光卤石制备KCl收率研究[J].盐科学与化工,2022,51(3):25-30. |

| Zhijia QIE, MA Shengkui, DU Jingling,et al.Optimization of KCl yield from low sodium carnallite by response surface methodology[J].Journal of Salt Science and Chemical Industry,2022,51(3):25-30. | |

| [7] | CHENG Chen, HUANG Zhiqiang, ZHANG Ruirui,et al.Synthesis of an emerging morpholine-typed Gemini surfactant and its application in reverse flotation carnallite ore for production of potash fertilizer at low temperature[J].Journal of Cleaner Production,2020,261:121121. |

| [8] | 杜景灵,董伟兵,切知加,等.柠檬酸三钠对低钠光卤石分解制备氯化钾晶体粒度影响研究[J].无机盐工业,2022,54(4):112-118. |

| DU Jingling, DONG Weibing, Zhijia QIE,et al.Study on effect of trisodium citrate on particle size of potassium chloride crystal prepared by decomposition of low sodium carnallite[J].Inorganic Chemicals Industry,2022,54(4):112-118. | |

| [9] | 齐美玲,王刚,张莉媛,等.光卤石中氯化钾溶解度、介穏区、诱导期测定[J].无机盐工业,2020,52(5):45-49. |

| QI Meiling, WANG Gang, ZHANG Liyuan,et al.Determination of KCl solubility,interfacial region and induction period in carnallite[J].Inorganic Chemicals Industry,2020,52(5):45-49. | |

| [10] | 李小松,陈艳,罗妍,等.光卤石反浮选-冷结晶法生产氯化钾过程的结晶热力学[J].华东理工大学学报(自然科学版),2009,35(4):506-510. |

| LI Xiaosong, CHEN Yan, LUO Yan,et al.Crystallization thermodynamics of reverse-flotation and cold-crystallization process for producing potassium chloride from KCl·MgCl2·H2O[J].Journal of East China University of Science and Technology(Natural Science Edition),2009,35(4):506-510. | |

| [11] | 惠庆华,权朝明,张慧芳,等.我国盐湖浮选提钾技术及机理[J].应用化工,2021,50(12):3414-3419. |

| HUI Qinghua, QUAN Chaoming, ZHANG Huifang,et al.Flotation potassium technology and mechanism from salt lake in China[J].Applied Chemical Industry,2021,50(12):3414-3419. | |

| [12] | 切知加,董伟兵,杜景灵,等.低钠光卤石冷结晶法制备氯化钾的收率研究[J].无机盐工业,2022,54(5):72-78. |

| Zhijia QIE, DONG Weibing, DU Jingling,et al.Study on yield of KCl prepared by cold crystallization of low-sodium carnallite[J].Inorganic Chemicals Industry,2022,54(5):72-78. | |

| [13] | 尹明,李家熙,何红蓼,等.岩石矿物分析[M].北京:地质出版社,2011. |

| [1] | LENG Manxi, ZHU Yu, YAN Jikang, XIE Ke, ZOU Yongjie. Study on crystallization characteristics and mineral flotation performance of industrial waste phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(3): 108-115. |

| [2] | SONG Jiaxi, JI Renfei, CHEN Jun, LIN Sen, YU Jianguo. Research on characteristics analysis and pretreatment on deeply deactivated power battery ternary cathode materials [J]. Inorganic Chemicals Industry, 2025, 57(2): 44-49. |

| [3] | WANG Rui, ZHAO Hui, ZHAO Yuhang. Comparative study on decarbonization of aluminum extraction residue from fly ash by roasting and flotation [J]. Inorganic Chemicals Industry, 2024, 56(9): 136-141. |

| [4] | GUO Kaihua, FAN Yuxin, YANG Jing, ZHAO Wenli, JIA Yuanyuan, WANG Yanfei. Analysis of effect of carnallite raw ore grade on its cold decomposition and crystallization of potassium chloride [J]. Inorganic Chemicals Industry, 2024, 56(8): 9-18. |

| [5] | CHEN Junhui, LIU Xiang, HU Qingxi, TIAN Bangxin, CHEN Jiale. Study on leaching extraction of high purity potassium chloride from sintering machine head ash [J]. Inorganic Chemicals Industry, 2024, 56(6): 102-108. |

| [6] | CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, LIU Xuejing. Study on dissolution crystallization for extraction of potassium and separation of magnesium and lithium from salt lake brine [J]. Inorganic Chemicals Industry, 2024, 56(6): 34-39. |

| [7] | DENG Fuli, XIA Zhixiang, LONG Bingwen, ZHANG Yi, DAI Yafen, WANG Bin, DING Yigang. Study on purification process of phosphogypsum by reverse flotation [J]. Inorganic Chemicals Industry, 2024, 56(5): 115-120. |

| [8] | YAO Jiankang, HU Shuozhen, NIU Dongfang, WU Jianping, ZHANG Xinsheng. Study on electrochemical treatment of sodium chloride organic waste salt in spice industry [J]. Inorganic Chemicals Industry, 2024, 56(3): 105-115. |

| [9] | LI Yaguang, HAN Dongzhan, QI Lijuan. Recent research on pretreatment of waste lithium-ion batteries and electrolyte recovery technology [J]. Inorganic Chemicals Industry, 2024, 56(2): 1-10. |

| [10] | YANG Bo, MA Zhen, ZENG Ying, YAN Xiongzhong, LI Qi, HOU Yuansheng, YU Xudong. Study on solid-liquid phase equilibria in ternary system of Li+(K+),Rb+//Cl--H2O at 288.2 K [J]. Inorganic Chemicals Industry, 2024, 56(11): 116-122. |

| [11] | CHEN Xiaohong, YU Yi, ZHU Miao, YE Hengpeng, CHEN Shaohua, LI Yubiao. Study on co⁃reverse flotation process of phosphogypsum for impurity removal and whitening [J]. Inorganic Chemicals Industry, 2024, 56(10): 86-94. |

| [12] | ZHU Jian, DONG Guangfeng, CHEN Peng, JIA Feifei, MA Songliang, LIU Zhongjian, XIANG Xiaocheng. Study on influence mechanism of particle size composition of potassium mixed salt on its conversion flotation [J]. Inorganic Chemicals Industry, 2024, 56(10): 64-69. |

| [13] | LI Hongyuan, ZHANG Jianhua. Study on removal process of total organic carbon from industrial waste salts by pyrolysis [J]. Inorganic Chemicals Industry, 2024, 56(10): 95-102. |

| [14] | WANG Yanfei, YANG Chaofan, CAO Di, XU Shijie. Study on solid-liquid phase equilibrium of ternary system of Li+, Na+∥Cl--H2O at different temperatures [J]. Inorganic Chemicals Industry, 2024, 56(1): 33-39. |

| [15] | GAN Shunpeng, DING Ding, SUN Chenggao, JIANG Shipeng, GUAN Junfang. Study on cold decomposition crystallization process of underground primary high-sodium carnallite ore [J]. Inorganic Chemicals Industry, 2024, 56(1): 67-72. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||