Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (10): 64-69.doi: 10.19964/j.issn.1006-4990.2024-0031

• Research & Development • Previous Articles Next Articles

Study on influence mechanism of particle size composition of potassium mixed salt on its conversion flotation

ZHU Jian1( ), DONG Guangfeng1(

), DONG Guangfeng1( ), CHEN Peng1, JIA Feifei1, MA Songliang2, LIU Zhongjian2, XIANG Xiaocheng2

), CHEN Peng1, JIA Feifei1, MA Songliang2, LIU Zhongjian2, XIANG Xiaocheng2

- 1.Key Laboratory of Green Utilization of Critical Nonmetallic Mineral Resources,Ministry of Education,Wuhan University of Technology,Wuhan 430070,China

2.State Investment Xinjiang Lop Nur Potash Co. ,Ltd. ,Hami 839000,China

-

Received:2024-01-16Online:2024-10-10Published:2024-11-05 -

Contact:DONG Guangfeng E-mail:2797425800@qq.com;277036@whut.edu.cn

CLC Number:

Cite this article

ZHU Jian, DONG Guangfeng, CHEN Peng, JIA Feifei, MA Songliang, LIU Zhongjian, XIANG Xiaocheng. Study on influence mechanism of particle size composition of potassium mixed salt on its conversion flotation[J]. Inorganic Chemicals Industry, 2024, 56(10): 64-69.

share this article

Table 2

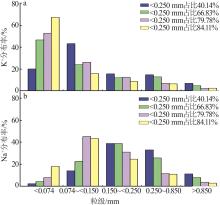

Particle size compositions and ion distribution of potassium mixed salt raw ore"

原矿筛析后 各粒级/mm | 分布占比/% | w(K+)/ % | w(Na+)/ % | K+分布率/% | Na+分布率/% |

|---|---|---|---|---|---|

| <0.074 | 12.26 | 19.55 | 0.32 | 13.23 | 0.68 |

| 0.074~<0.150 | 17.89 | 21.59 | 0.79 | 21.33 | 2.44 |

| 0.150~<0.250 | 9.99 | 27.98 | 1.83 | 15.45 | 3.16 |

| 0.250~0.850 | 13.89 | 26.64 | 9.45 | 20.43 | 22.68 |

| >0.850 | 45.97 | 11.64 | 8.94 | 29.56 | 71.04 |

Table 4

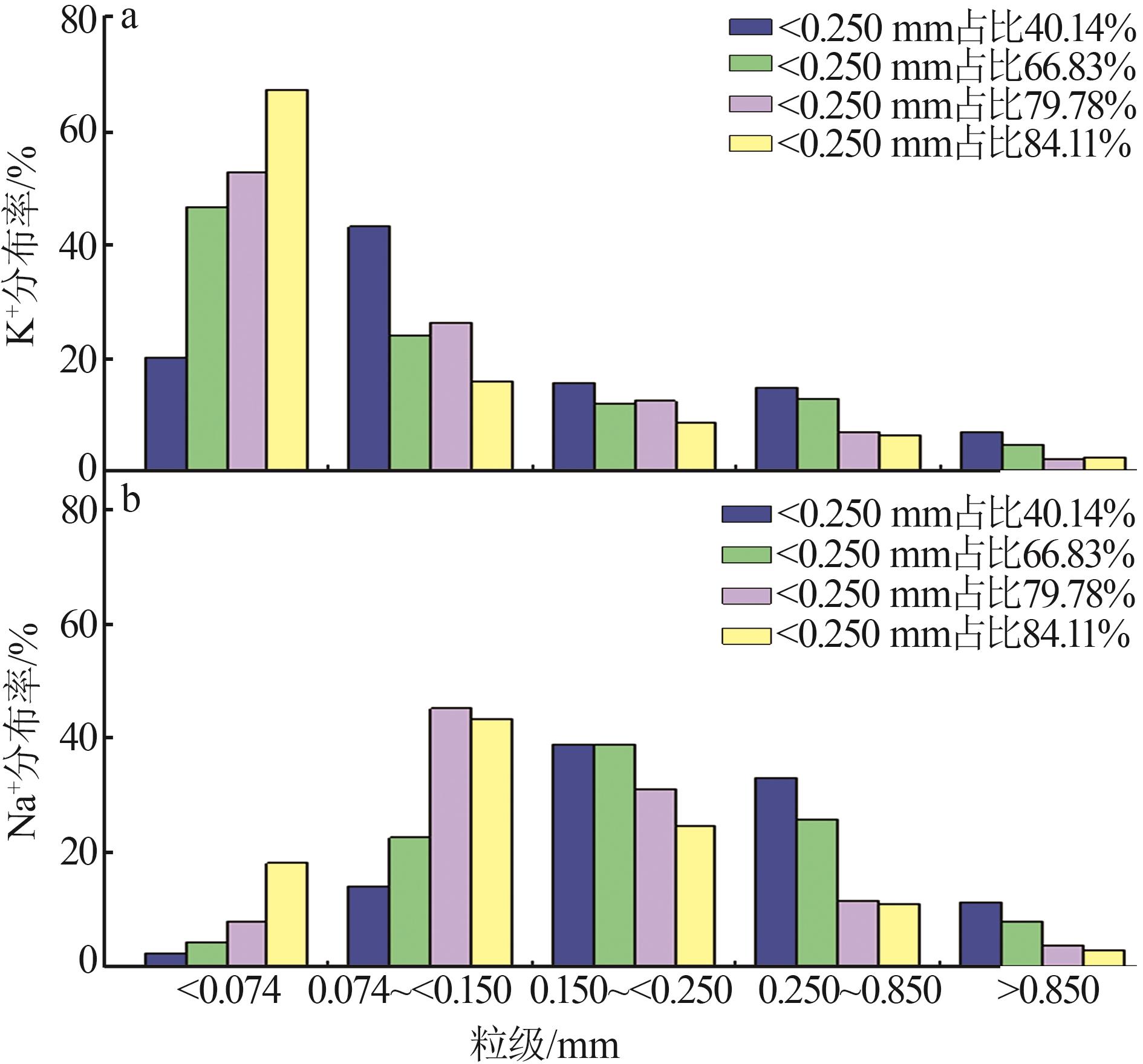

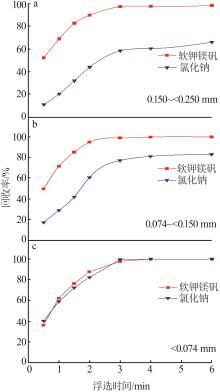

Fitting parameters of first⁃order rectangular distribution model for conversion products of different particle sizes"

| 不同粒级/mm | 浮选精矿产物 | ε∞/% | k/min-1 | R2 |

|---|---|---|---|---|

| <0.074 | 软钾镁矾 | 114.988 8 | 1.848 5 | 0.980 3 |

| 氯化钠 | 115.034 2 | 1.754 0 | 0.974 4 | |

| 0.074~<0.150 | 软钾镁矾 | 110.128 1 | 2.806 0 | 0.976 5 |

| 氯化钠 | 112.461 4 | 0.791 3 | 0.948 0 | |

| 0.150~<0.250 | 软钾镁矾 | 106.601 5 | 2.941 1 | 0.981 9 |

| 氯化钠 | 91.327 3 | 0.680 2 | 0.961 2 |

| 1 | 谭慧婷,孙伟,崔玉照,等.钾矿资源现状与杂卤石的开发应用分析[J].无机盐工业,2022,54(6):23-30. |

| TAN Huiting, SUN Wei, CUI Yuzhao,et al.Present situation of potash resources and analysis of development and application of polyhalite[J].Inorganic Chemicals Industry,2022,54(6):23-30. | |

| 2 | 张苏江,崔立伟,高鹏鑫,等.中国钾盐资源形势分析及管理对策建议[J].无机盐工业,2015,47(11):1-6. |

| ZHANG Sujiang, CUI Liwei, GAO Pengxin,et al.Analysis on development situation of potash ore resources and recommended management strategies in China[J].Inorganic Chemicals Industry,2015,47(11):1-6. | |

| 3 | DAI Jiapei.The core mechanism of natural selection:How the natural cycle of potassium resources affects the biological evolution and the change of human society[J].Natural Science,2022,14(10):434-440. |

| 4 | 李岩,马珍,宋兴福.青海氯化物型盐湖钾资源开发新进展与产业发展建议[J].无机盐工业,2023,55(8):84-90. |

| LI Yan, MA Zhen, SONG Xingfu.New development advance and industrial development proposals of chloride⁃type salt lake potassium resources in Qinghai[J].Inorganic Chemicals Industry,2023,55(8):84-90. | |

| 5 | 王振东,时贞,童海奎,等.青海柴达木盆地盐湖资源保障能力分析与对策研究[J].中国矿业,2023,32(2):38-42. |

| WANG Zhendong, SHI Zhen, TONG Haikui,et al.Analysis and countermeasures study of guarantee capability of salt lake resour⁃ces in Qinghai Qaidam Basin[J].China Mining Magazine,2023,32(2):38-42. | |

| 6 | 王露莎.钾资源开发利用技术及产业发展[J].世界有色金属,2021(21):1-2. |

| WANG Lusha.Development and utilization of potassium resources,technology and industrial development[J].World Nonferrous Metals,2021(21):1-2. | |

| 7 | 周园,李丽娟,吴志坚,等.青海盐湖资源开发及综合利用[J].化学进展,2013,25(10):1613-1624. |

| ZHOU Yuan, LI Lijuan, WU Zhijian,et al.Exploitation and comprehensive utilization for Qinghai salt lakes[J].Progress in Chemistry,2013,25(10):1613-1624. | |

| 8 | 李守江.罗布泊硫酸盐型盐湖钾盐浮选的理论与工艺研究[D].武汉:武汉理工大学,2019. |

| LI Shoujiang.Study on theory and technology of flotation of potassium salts in sulfate⁃type lake of Lop Nur[D].Wuhan:Wuhan University of Technology,2019. | |

| 9 | KANG X C, WANG D Y, ZHAO Bin,et al.Study on phase equilibri⁃um of the K+,Mg 2 +//Cl–,SO4 2–+H2O quaternary system at 353.15 K and its application[J].Journal of Chemical and Engineering Data,2020,65(8):3755-3769. |

| 10 | CHUKANOV N V, PEKOV I V, BELAKOVSKIY D I,et al.Katerinopoulosite,(NH4)2Zn(SO4)2·6H2O,a new mineral from the Esperanza Mine,Lavrion,Greece[J].European Journal of Mineralogy,2018,30(4):821-826. |

| 11 | 胡天琦,张志宏,王健康,等.软钾镁矾和氯化钾转化硫酸钾结晶粒度研究[J].无机盐工业,2017,49(3):14-18. |

| HU Tianqi, ZHANG Zhihong, WANG Jiankang,et al.Crystal size of K2SO4 crystallizing from K2SO4·MgSO4·6H2O and KCl[J].Inorganic Chemicals Industry,2017,49(3):14-18. | |

| 12 | 郭运鑫.基于高压辊磨机破碎粒度下的磨矿产品粒度优化研究[D].昆明:昆明理工大学,2019. |

| GUO Yunxin.Study on particle size optimization of ground mineral products based on crushing particle size of high pressure roller mill[D].Kunming:Kunming University of Science and Technology,2019. | |

| 13 | 应永朋,赵玉卿,熊艳,等.青海某伟晶岩型锂铍矿工艺矿物学研究[J].矿产综合利用,2023(5):75-79. |

| YING Yongpeng, ZHAO Yuqing, XIONG Yan,et al.Process mineralogy of a pegmatite lithium beryllium ore in Qinghai[J].Multipurpose Utilization of Mineral Resources,2023(5):75-79. | |

| 14 | 李青柯,巫焱明,顾帼华,等.硫化矿磨矿体系的物理和化学作用及其对浮选工艺的影响[J].金属矿山,2024(1):251- 260. |

| LI Qingke, WU Yanming, GU Guohua,et al.Physical and chemical effects of sulfide minerals grinding system and their influence on flotation process[J].Metal Mine,2024(1):251-260. | |

| 15 | 曹进成,韩跃新,刘磊,等.破碎方式对齐大山贫赤铁矿石磨矿性能的影响[J].矿产保护与利用,2023,43(3):105-111. |

| CAO Jincheng, HAN Yuexin, LIU Lei,et al.Effect of crushing modes on grinding performance of lean hematite iron ore from Qidashan[J].Conservation and Utilization of Mineral Resources,2023,43(3):105-111. | |

| 16 | 霍怡屹,祖伟,姜帆,等.速率常数在浮选过程中的变化机制研究进展[J].煤炭工程,2021,53(2):164-169. |

| HUO Yiyi, ZU Wei, JIANG Fan,et al.Progress of variation mechanism study on flotation rate constant[J].Coal Engineering,2021,53(2):164-169. | |

| 17 | 严文超,胡法林,曹沁波.高频超声波作用下黄铁矿的浮选性能及动力学研究[J].矿产保护与利用,2021,41(5):83- 88. |

| YAN Wenchao, HU Falin, CAO Qinbo.Flotation kinetics of pyrite under high⁃frequency ultrasonic treatment[J].Conservation and Utilization of Mineral Resources,2021,41(5):83-88. | |

| 18 | 马强,李育彪,李万青,等.矿物浮选动力学模型及影响因素研究进展[J].金属矿山,2021(11):74-80. |

| MA Qiang, LI Yubiao, LI Wanqing,et al.Research progress on mineral flotation kinetic model and influencing factors[J].Metal Mine,2021(11):74-80. | |

| 19 | 陈智杰,高惠民,任子杰,等.分子结构对石油磺酸钠浮选蓝晶石的影响研究[J].化工矿物与加工,2017,46(1):12- 15. |

| CHEN Zhijie, GAO Huimin, REN Zijie,et al.Influence of molecular structure of sodium petroleum sulfonate on flotation behavior of kyanite[J].Industrial Minerals & Processing,2017,46(1):12-15. | |

| 20 | BAHRAMI A, MIRMOHAMMADI M, GHORBANI Y,et al.Process mineralogy as a key factor affecting the flotation kinetics of copper sulfide minerals[J].International Journal of Minerals,Metallurgy,and Materials,2019,26(4):430-439. |

| [1] | LIU Xinlong, YANG Zhenyu, HAO He, LIU Shuxin, WU Chenyang, WANG Xingli, MA Qingqing. Study on shaped 4A zeolite synthesized with aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 78-85. |

| [2] | LENG Manxi, ZHU Yu, YAN Jikang, XIE Ke, ZOU Yongjie. Study on crystallization characteristics and mineral flotation performance of industrial waste phosphogypsum [J]. Inorganic Chemicals Industry, 2025, 57(3): 108-115. |

| [3] | ZHU Jicheng, YANG Qixin, LIANG Haoquan, WANG Zengkun, OUYANG Fugui, DI Jing, GAI Xikun. Effect of confined catalyst Ni@S2 on performance of methane dry reforming reaction [J]. Inorganic Chemicals Industry, 2025, 57(2): 138-146. |

| [4] | WANG Rui, ZHAO Hui, ZHAO Yuhang. Comparative study on decarbonization of aluminum extraction residue from fly ash by roasting and flotation [J]. Inorganic Chemicals Industry, 2024, 56(9): 136-141. |

| [5] | DENG Fuli, XIA Zhixiang, LONG Bingwen, ZHANG Yi, DAI Yafen, WANG Bin, DING Yigang. Study on purification process of phosphogypsum by reverse flotation [J]. Inorganic Chemicals Industry, 2024, 56(5): 115-120. |

| [6] | DING Xiaojiang, WU Yanni, LI Boyun, HUANG Youliang. Research on preparation of carnallite concentrate by pretreatment combined with reverse flotation [J]. Inorganic Chemicals Industry, 2024, 56(12): 113-119. |

| [7] | CHEN Xiaohong, YU Yi, ZHU Miao, YE Hengpeng, CHEN Shaohua, LI Yubiao. Study on co⁃reverse flotation process of phosphogypsum for impurity removal and whitening [J]. Inorganic Chemicals Industry, 2024, 56(10): 86-94. |

| [8] | DENG Yinxiang, CHEN Chaoyi, WANG Shiyu, GAO Yingxue, PENG Shuang. Effect of cell voltage on electrochemical conversion of CO2 to carbon materials in CaCl2 based molten salt [J]. Inorganic Chemicals Industry, 2024, 56(1): 40-46. |

| [9] | LI Yan, MA Zhen, SONG Xingfu. New development advance and industrial development proposals of chloride-type salt lake potassium resources in Qinghai [J]. Inorganic Chemicals Industry, 2023, 55(8): 84-90. |

| [10] | DONG Yizhuo, LI Hongru, SUN Ke, YIN Junlian, ZHOU Wentao, WANG Dezhong. Study on removal of metal ions from highly radioactive waste streams by micro/nano bubbles [J]. Inorganic Chemicals Industry, 2023, 55(7): 81-88. |

| [11] | WANG Linjian, CHANG Liming, CHEN Hang, SONG Xingfu. Effect of air flow and temperature on DPNB froth properties in KCl flotation [J]. Inorganic Chemicals Industry, 2023, 55(5): 39-44. |

| [12] | LIU Zihan, XI Guojun, LEI Guangping. Application of MOFs in adsorption refrigeration/heat pump [J]. Inorganic Chemicals Industry, 2023, 55(4): 20-26. |

| [13] | LIAO Shengde,YANG Yaofeng,LI Yaxin,WU Hao. Study on flotation experiment and mechanism of desulfurization by-product magnesium sulfite using dodecylamine [J]. Inorganic Chemicals Industry, 2023, 55(2): 113-118. |

| [14] | LIU Chao, FAN Chuigang, LIU Runguo, YU Dongxue, LI Songgeng. Preparation of α-hemihydrate gypsum from phosphogypsum by flotation and atmospheric trans-crystallization in solution [J]. Inorganic Chemicals Industry, 2023, 55(11): 107-114. |

| [15] | GUO Ze, ZHANG Pengfei, YANG Fan, ZHANG Hanquan, LU Manman. Preparation of β-hemihydrate gypsum by phosphogypsum roasting [J]. Inorganic Chemicals Industry, 2023, 55(10): 106-113. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||