Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (10): 47-54.doi: 10.19964/j.issn.1006-4990.2023-0599

• Research & Development • Previous Articles Next Articles

Study on agglomeration phenomenon and regulation method of lithium carbonate crystal prepared from potassium carbonate

CHENG Chunchun1( ), LI Yulong2,3,4(

), LI Yulong2,3,4( ), ZHANG Zhiqiang1, ZUO Shuo1, QIN Donglan1, ZHOU Na1, WANG Jiaqin1

), ZHANG Zhiqiang1, ZUO Shuo1, QIN Donglan1, ZHOU Na1, WANG Jiaqin1

- 1.College of Chemical engineering,Qinghai University,Xining 810016,China

2.Qinghai Geological Survey Institute,Xining 810012,China

3.Key Laboratory of the Northern QinghaiTibet Plateau Geological Processes and;Mineral Resources,Xining 810012,China

4.Engineering and Technology Center of Remote;Sensing Big Data in Qinghai Province,Xining 810012,China

-

Received:2023-12-13Online:2024-10-10Published:2024-11-05 -

Contact:LI Yulong E-mail:alenlover@sina.com;lilong3849446@163.com

CLC Number:

Cite this article

CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, ZUO Shuo, QIN Donglan, ZHOU Na, WANG Jiaqin. Study on agglomeration phenomenon and regulation method of lithium carbonate crystal prepared from potassium carbonate[J]. Inorganic Chemicals Industry, 2024, 56(10): 47-54.

share this article

| 1 | GAO Tianming, FAN Na, CHEN Wu,et al.Lithium extraction from hard rock lithium ores(spodumene,lepidolite,zinnwaldite,petalite):Technology,resources,environment and cost[J].China Geology,2023(1):137-153. |

| 2 | 邢凯,朱清,任军平,等.全球锂资源特征及市场发展态势分析[J].地质通报,2023,42(8):1402-1421. |

| XING Kai, ZHU Qing, REN Junping,et al.Research on the characteristics and market development trend of global lithium resourc⁃es[J].Geological Bulletin of China,2023,42(8):1402-1421. | |

| 3 | SHANG Xiaohong, LIU Jianyun, HU Bin,et al.CNT-strung LiMn2O4 for lithium extraction with high selectivity and stabili⁃ ty[J].Small Methods,2022,6(7):2200508. |

| 4 | HU Bin, SHANG Xiaohong, NIE Pengfei,et al.Lithium ion sieve modified three⁃dimensional graphene electrode for selective extraction of lithium by capacitive deionization[J].Journal of Colloid and Interface Science,2022,612:392-400. |

| 5 | 乜贞,伍倩,丁涛,等.中国盐湖卤水提锂产业化技术研究进展[J].无机盐工业,2022,54(10):1-12. |

| NIE Zhen, WU Qian, DING Tao,et al.Research progress on industrialization technology of lithium extraction from salt lake brine in China[J].Inorganic Chemicals Industry,2022,54(10):1-12. | |

| 6 | ZHANG Ye, SUN Wei, XU Rui,et al.Lithium extraction from water lithium resources through green electrochemical⁃battery approaches:A comprehensive review[J].Journal of Cleaner Production,2021,285:124905. |

| 7 | ZHANG Ye, HU Yuehua, WANG Li,et al.Systematic review of lithium extraction from salt⁃lake brines via precipitation approach⁃ es[J].Minerals Engineering,2019,139:105868. |

| 8 | NGUYEN T, LEE M.A review on the separation of lithium ion from leach liquors of primary and secondary resources by solvent extraction with commercial extractants[J].Processes,2018,6(5): 55. |

| 9 | QIAO Linju, CHEN Hang, YU Jianguo.Recovery of lithium from salt⁃lake brine by liquid⁃liquid extraction using TBP-FeCl3 based mixture solvent[J].The Canadian Journal of Chemical Engineering,2023,101(4):2139-2147. |

| 10 | GUO Youhong,BAE J, FANG Zhiwei,et al.Hydrogels and hydrogel⁃derived materials for energy and water sustainability[J].Chemical Reviews,2020,120(15):7642-7707. |

| 11 | SHANG Xiaohong, HU Bin, NIE Pengfei,et al.LiNi0.5Mn1.5O4-based hybrid capacitive deionization for highly selective adsorption of lithium from brine[J].Separation and Purification Technology,2021,258:118009. |

| 12 | WU Qian, YU Jiangjiang, BU Lingzhong,et al.The application of an enhanced salinity⁃gradient solar pond with nucleation matrix in lithium extraction from Zabuye salt lake in Tibet[J].Solar Energy,2022,244:104-114. |

| 13 | MULLIN J W.Crystallisation[M].4th ed.London:Elsevier Science,2001. |

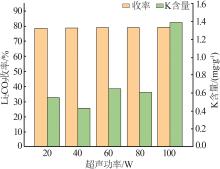

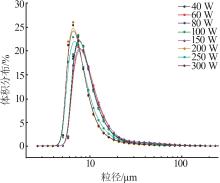

| 14 | 刘玉强,张志强,毕秋艳,等.超声波对碳酸锂反应结晶过程的影响[J].无机盐工业,2019,51(4):42-47. |

| LIU Yuqiang, ZHANG Zhiqiang, BI Qiuyan,et al.Influence of ultrasonic on reaction crystallization process of lithium carbon⁃ate[J].Inorganic Chemicals Industry,2019,51(4):42-47. | |

| 15 | TABORGA P, BRITO I, GRABER T A.Effect of additives on size and shape of lithium carbonate crystals[J].Journal of Crystal Gro⁃ wth,2017,460:5-12. |

| 16 | 王彦飞,王磊鑫,邢红,等.反应结晶制备碳酸锂的粒度及形貌控制[J].无机盐工业,2016,48(9):13-17. |

| WANG Yanfei, WANG Leixin, XING Hong,et al.Size and morphology controlling of lithium carbonate in reactive crystallization process[J].Inorganic Chemicals Industry,2016,48(9):13-17. | |

| 17 | 殷海青,马祎明,万旭兴,等.碳酸锂气液固三相反应结晶过程研究[J].化工学报,2022,73(3):1207-1220. |

| YIN Haiqing, MA Yiming, WAN Xuxing,et al.Research of lithium carbonate three⁃phase reactive crystallization process[J].CIESC Journal,2022,73(3):1207-1220. | |

| 18 | 曾雄,易丹青,王斌,等.超声对碳酸锂溶液反应结晶成核过程的影响[J].有色金属文摘,2015,30(3):111-113. |

| ZENG Xiong, YI Danqing, WANG Bin,et al.The effects of ultrasound on the process of lithium carbonate solution reaction crystal nucleation[J].Nonferrous Metals Abstract,2015, 30(3): 111-113. | |

| 19 | LI Hong, LI Hairong, GUO Zhichao,et al.The application of power ultrasound to reaction crystallization[J].Ultrasonics Sonochemistry,2006,13(4):359-363. |

| 20 | LI Hong, WANG Jingkang, BAO Ying,et al.Rapid sonocrystallization in the salting⁃out process[J].Journal of Crystal Growth,2003,247(1/2):192-198. |

| 21 | GAHN C, MERSMANN A.Brittle fracture in crystallization processes Part B.Growth of fragments and scale⁃up of suspension crystallizers[J].Chemical Engineering Science,1999,54(9):1283-1292. |

| 22 | HOUNSLOW M J, RYALL R L, MARSHALL V R.A discretized population balance for nucleation,growth,and aggregation[J].AIChE Journal,1988,34(11):1821-1832. |

| [1] | WANG You, LIAO Lianzhen, CHEN Zheng, GAO Youjun. Effect of surfactants on electrocrystallization of Ni(OH)2 [J]. Inorganic Chemicals Industry, 2025, 57(3): 58-63. |

| [2] | GUO Yingjun, WU Songsong, DING Chunyan, ZHAO Shikai, SONG Tao, WEN Guangwu. Preparation of SSZ-13 zeolite membrane from glass-ceramics-strontium feldspar by crystal transformation method [J]. Inorganic Chemicals Industry, 2025, 57(2): 76-82. |

| [3] | ZHU Jicheng, YANG Qixin, LIANG Haoquan, WANG Zengkun, OUYANG Fugui, DI Jing, GAI Xikun. Effect of confined catalyst Ni@S2 on performance of methane dry reforming reaction [J]. Inorganic Chemicals Industry, 2025, 57(2): 138-146. |

| [4] | ZHANG Jianle, CAO Yapeng, ZU Minghua, ZHANG Zhikun, LIU Yumin, HAN Jilong. Study on morphology of calcium carbonate controlled by sodium dodecyl sulfate and amino acid double template [J]. Inorganic Chemicals Industry, 2025, 57(1): 58-63. |

| [5] | ZOU Yang, LU Zhiyan, HU Zhilin, SUN Ze. Study on metastable zone width and primary nucleation kinetics for cooling crystallization of KNO3 [J]. Inorganic Chemicals Industry, 2024, 56(9): 67-74. |

| [6] | LI Shuai, LI Tianxiang, ZHU Jing, LIU Songlin. Study on purification process of sodium fluoride [J]. Inorganic Chemicals Industry, 2024, 56(9): 90-97. |

| [7] | WANG Jianjie, SHU Xiaolong, XIAO Xia, WANG Peng, FAN Xiaoqiang, KONG Lian, XIE Zean, ZHAO Zhen. Study on synthesis of hierarchical flower⁃like ZSM-5 zeolite and its catalytic performance for n-octane cracking [J]. Inorganic Chemicals Industry, 2024, 56(8): 139-146. |

| [8] | SU Hang, SONG Jitian, HUANG Zhiqiang, DONG Qing, ZHANG Yaxiong. Study on crystallization kinetics of manganese sulfate monohydrate in H2SO4-H2O binary system [J]. Inorganic Chemicals Industry, 2024, 56(8): 40-46. |

| [9] | GUO Kaihua, FAN Yuxin, YANG Jing, ZHAO Wenli, JIA Yuanyuan, WANG Yanfei. Analysis of effect of carnallite raw ore grade on its cold decomposition and crystallization of potassium chloride [J]. Inorganic Chemicals Industry, 2024, 56(8): 9-18. |

| [10] | CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, LIU Xuejing. Study on dissolution crystallization for extraction of potassium and separation of magnesium and lithium from salt lake brine [J]. Inorganic Chemicals Industry, 2024, 56(6): 34-39. |

| [11] | HU Cheng, LIU Meng, XIANG Weiheng, DUAN Pengxuan, LI Shunkai, MING Yang, WANG Neng, LU Guanju. Effect of NaCl solution concentration on transcrystallization behavior of α-hemihydrate gypsum from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(6): 87-93. |

| [12] | LI Yuxing, ZHANG Jincai, CHENG Fangqin. Research progress of preparation and growth mechanism of various crystalline nano-calcium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(5): 1-10. |

| [13] | WANG Mingshun, AO Xianquan, YUAN Xing, DONG Wenyan, CHEN Qianlin. Study on effect of crystallizer on preparation of anhydrous calcium sulfate from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(5): 101-107. |

| [14] | LI Yongheng, MI Xiaotong, ZHANG Peipei. Synthesis of holycrystalline nano-ZSM-5 aggregate and its application in methylation of toluene [J]. Inorganic Chemicals Industry, 2024, 56(5): 135-140. |

| [15] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||