Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (5): 94-100.doi: 10.19964/j.issn.1006-4990.2023-0593

• Industrial Techniques • Previous Articles Next Articles

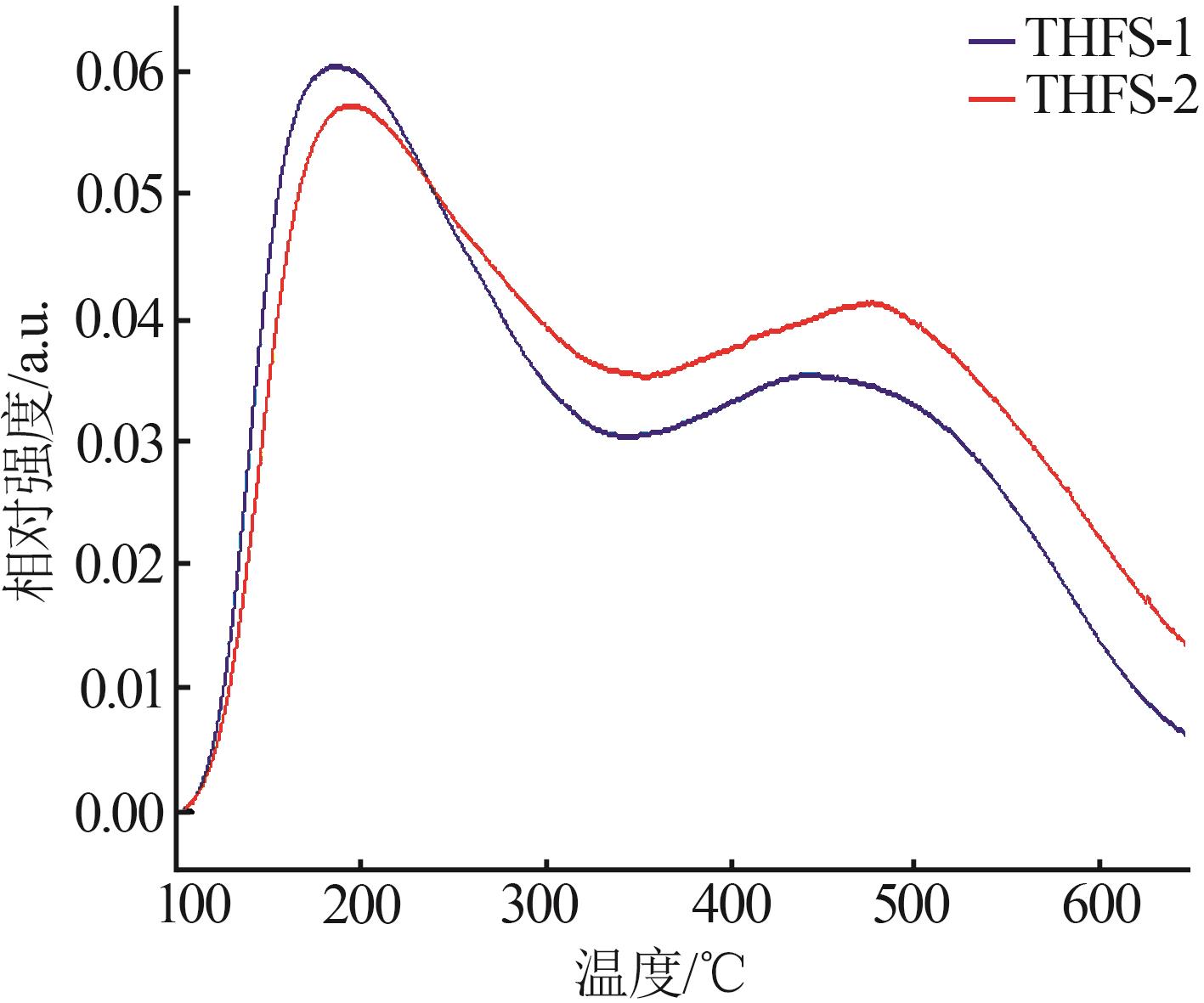

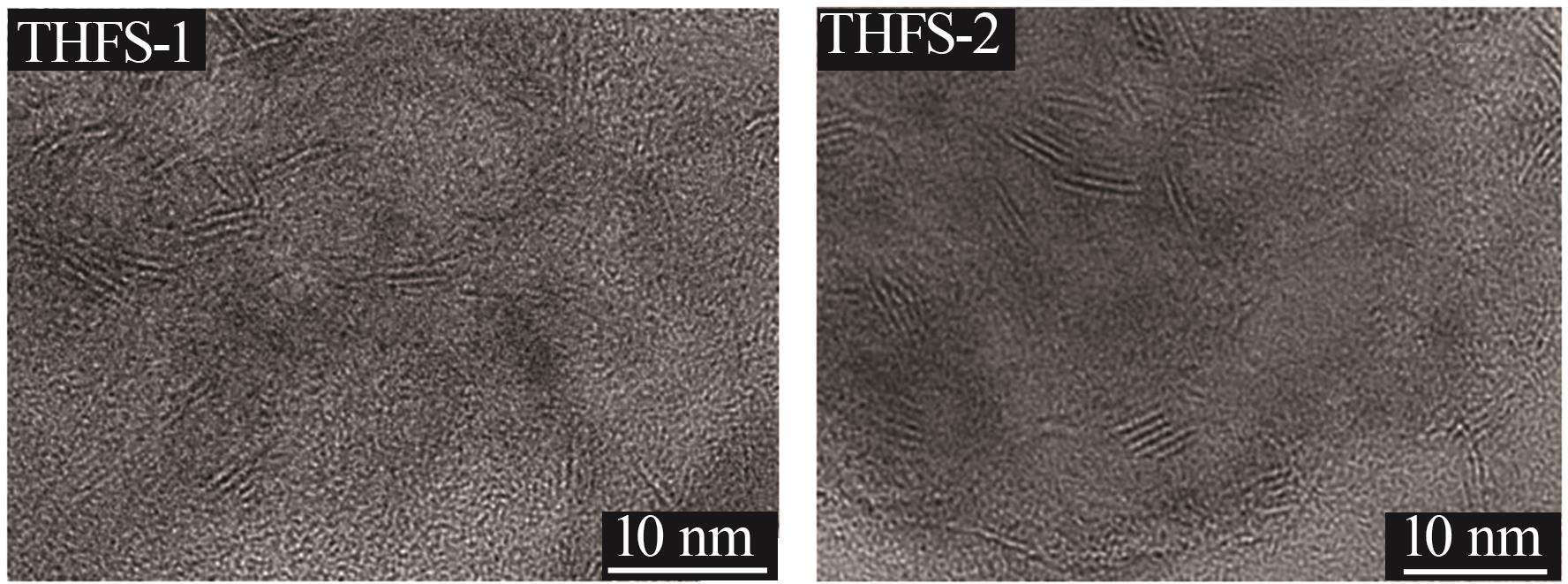

Industrial application of THFS-2 sulfurized reforming prehydrogenation catalysts

WANG Chao1( ), SONG Guoliang2, XIAO Han2(

), SONG Guoliang2, XIAO Han2( )

)

- 1.CNOOC Huizhou Petrochemical Company Limited, Huizhou 516086, China

2.CenterTech Tianjin Chemical Research and Design Institute Co. Ltd. , Tianjin 300131

-

Received:2023-12-08Online:2024-05-10Published:2024-05-15 -

Contact:XIAO Han E-mail:532978884@qq.com;xiaohancup@163.com

CLC Number:

Cite this article

WANG Chao, SONG Guoliang, XIAO Han. Industrial application of THFS-2 sulfurized reforming prehydrogenation catalysts[J]. Inorganic Chemicals Industry, 2024, 56(5): 94-100.

share this article

Table 5

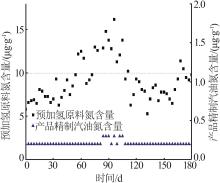

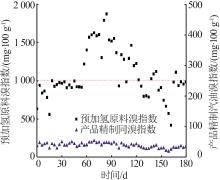

Nature of naphtha raw materials and hydrocharged naphtha in initial stage of construction"

| 项目 | 密度(20 ℃)/ (kg·m-3) | 硫含 量/ (μg·g-1) | 氮含 量/ (μg·g-1) | 砷含 量/(µg·kg-1) | 氯含 量/ (µg·g-1) | 溴指数/ (mg/ 100 g) | |

|---|---|---|---|---|---|---|---|

| 石脑油原料 | 技术 指标 | ≤740 | ≤800 | ≤10 | ≤50 | ≤5.0 | ≤1 000 |

| 实际值 | 725 | 210 | 8.5 | 31 | 3.2 | 990 | |

| 加氢石脑油 | 技术 指标 | ≤740 | ≤0.5 | ≤0.5 | ≤1.0 | ≤0.5 | ≤100 |

| 实际值 | 738.6 | 0.1 | 0.2 | <1.0 | <0.5 | 44.2 | |

| 1 | 慕彦君,宋倩倩,付凯妹,等.芳烃生产技术进展及产业发展建议[J].石化技术与应用,2021,39(5):371-377. |

| MU Yanjun, SONG Qianqian, FU Kaimei,et al.Progress and industrial development suggestion of aromatics production technology[J].Petrochemical Technology & Application,2021,39(5):371-377. | |

| 2 | 辛靖,高杨,侯章贵,等.以生产轻芳烃为目的的催化重整装置原料拓展研究进展[J].无机盐工业,2019,51(7):1-7. |

| XIN Jing, GAO Yang, HOU Zhanggui,et al.Research progress on expanding feedstocks for catalytic reforming units for the production of light aromatics[J].Inorganic Chemicals Industry,2019,51(7):1-7. | |

| 3 | ANCHEYTA-JUÁREZ J, VILLAFUERTE-MACÍAS E.Kinetic modeling of naphtha catalytic reforming reactions[J].Energy & Fuels,2000,14(5):1032-1037. |

| 4 | 李洪亮,冯连坤,陈晓华.催化重整联合装置减油增化措施[J].石化技术与应用,2023,41(4):315-319. |

| LI Hongliang, FENG Liankun, CHEN Xiaohua.Measures of reducing oil and increasing chemicals in catalytic reforming complex unit[J].Petrochemical Technology & Application,2023,41(4):315-319. | |

| 5 | 马致远,王辉,王文辰,等.催化裂化汽油馏分切割作连续重整原料生产芳烃[J].石化技术与应用,2023,41(6):456-460. |

| MA Zhiyuan, WANG Hui, WANG Wenchen,et al.Catalytic cracking gasoline fraction cutting as continuous reforming feedstock for producing aromatics[J].Petrochemical Technology & Application,2023,41(6):456-460. | |

| 6 | ZHANG Tiezhen, JIA Yungang, SUN Famin,et al.Preparation and performance evaluation of reforming prehydrogenation catalyst used for blending inferior coking gasoline[J].International Journal of Power and Energy Research,2020,4(3):27-33. |

| 7 | 王健,朱俊华,叶迎春,等.载体预处理对Mo/Al2O3催化剂催化裂解汽油加氢脱氮性能的影响[J].化学反应工程与工艺,2023,39(4):306-312. |

| WANG Jian, ZHU Junhua, YE Yingchun,et al.Effect of support treatment on hydrodenitrogenation performance for pyrolysis gasoline over Mo/Al2O3 catalysts[J].Chemical Reaction Engineering and Technology,2023,39(4):306-312. | |

| 8 | 刘帅,白鸿博.柴油加氢工艺及催化剂研究进展[J].当代化工,2023,52(9):2237-2242. |

| LIU Shuai, BAI Hongbo.Research progress of diesel hydrogenation reaction process and hydrogenation catalysts[J].Contemporary Chemical Industry,2023,52(9):2237-2242. | |

| 9 | RAHIMPOUR M R, JAFARI M, IRANSHAHI D.Progress in catalytic naphtha reforming process:A review[J].Applied Energy,2013,109:79-93. |

| 10 | 胡明涛,王德胜.浅谈芳烃联合装置原料变化对芳烃产品产率的影响[J].化工管理,2020(9):182-183. |

| HU Mingtao, WANG Desheng.Discussion on the influence of raw material change on aromatic hydrocarbon product yield in aromatic hydrocarbon combined plant[J].Chemical Enterprise Management,2020(9):182-183. | |

| 11 | 张春生.连续重整装置掺炼焦化石脑油可行性研究[J].炼油技术与工程,2023,53(4):5-8. |

| ZHANG Chunsheng.Feasibility study on blending coking naphtha in continuous catalytic reforming unit[J].Petroleum Refinery Engineering,2023,53(4):5-8. | |

| 12 | 王仲义,闫作杰,单敏,等.器外预硫化加氢裂化催化剂开工技术应用总结[J].炼油技术与工程,2021,51(1):10-12,32. |

| WANG Zhongyi, YAN Zuojie, SHAN Min,et al.Application summary of start-up technology of ex-situ presulfiding hydrocracking catalyst[J].Petroleum Refinery Engineering,2021,51(1):10-12,32. | |

| 13 | MANSUR D,AMINUDDIN.Chemical conversion of calophyllum inophyllum oil into bio-hydrocarbons fuel over presulfided NiMo/Al2O3 catalyst[J].International Journal of Energy Research,2020,44(9):7746-7760. |

| 14 | ZHOU Lin, LAWAL A.Evaluation of presulfided NiMo/γ-Al2O3 for hydrodeoxygenation of microalgae oil to produce green diesel[J].Energy & Fuels,2015,29(1):262-272. |

| 15 | 彭雪峰,于海斌,宋国良,等.器外预硫化型加氢催化剂的制备与性能研究[J].无机盐工业,2019,51(11):78-81. |

| PENG Xuefeng, YU Haibin, SONG Guoliang,et al.Preparation and properties of ex-situ presulfurization hydrogenation catalyst[J].Inorganic Chemicals Industry,2019,51(11):78-81. | |

| 16 | 李洪标,梁宇,吴显军,等.预硫化型石蜡加氢精制催化剂加氢技术研究[J].炼油与化工,2022,33(6):21-24. |

| LI Hongbiao, LIANG Yu, WU Xianjun,et al.Study on hydrogenation technology of prevulcanized paraffin hydrofining catalyst[J].Refining and Chemical Industry,2022,33(6):21-24. | |

| 17 | 罗树权,孙征,高雪.加氢催化剂器外预硫化技术现状[J].化工技术与开发,2014,43(8):34-37. |

| LUO Shuquan, SUN Zheng, GAO Xue.Current situation of ex-situ pre-sulfiding hydrotreatment catalyst[J].Technology & Development of Chemical Industry,2014,43(8):34-37. | |

| 18 | 彭雪峰,于海斌,张景成,等.THFS-I硫化型重整预加氢催化剂的首次工业应用[J].石油炼制与化工,2017,48(2):68- 71. |

| PENG Xuefeng, YU Haibin, ZHANG Jingcheng,et al.Industrial application of sulfide-type pre-hydrogenation catalyst THFS-I for reforming unit[J].Petroleum Processing and Petrochemicals,2017,48(2):68-71. | |

| 19 | 彭雪峰,于海斌,张景成,等.THFS-Ⅰ硫化型重整预加氢催化剂的开发与性能研究[J].无机盐工业,2017,49(2):82-86. |

| PENG Xuefeng, YU Haibin, ZHANG Jingcheng,et al.Preparation and properties of THFS-Ⅰ sulfide-type reforming pre-hydrogenation catalyst[J].Inorganic Chemicals Industry,2017,49(2):82-86. | |

| 20 | 彭雪峰,于海斌,孙彦民,等.THFS-I硫化型加氢催化剂在80万t·a-1重整预加氢装置上的工业运行情况[J].当代化工,2022,51(4):989-992. |

| PENG Xuefeng, YU Haibin, SUN Yanmin,et al.Industrial application of THFS-I sulfide-type hydrogenation catalyst in the 0.8 Mt·a-1 reforming pre-hydrogenation unit[J].Contemporary Chemical Industry,2022,51(4):989-992. | |

| 21 | 彭雪峰,于海斌,孙彦民,等.THFS-2硫化型加氢催化剂的工业应用[J].化学工程师,2022,36(5):75-78. |

| PENG Xuefeng, YU Haibin, SUN Yanmin,et al.Industrial application of THFS-2 sulfide-type hydrogenation catalyst[J].Chemical Engineer,2022,36(5):75-78. | |

| 22 | 王甫村,朱金玲,田然,等.用于FCC柴油加氢改质的选择性开环催化剂研究进展[J].化工进展,2011,30(9):1951-1955. |

| WANG Fucun, ZHU Jinling, TIAN Ran,et al.Advances in selective ring opening catalysts for FCC diesel hydro-upgrading[J].Chemical Industry and Engineering Progress,2011,30(9):1951-1955. | |

| 23 | 郭振雪,于海斌,张国辉,等.Si改性对NiMo/Al2O3催化剂加氢脱硫性能的影响[J].化工进展,2022,41(S1):210-220. |

| GUO Zhenxue, YU Haibin, ZHANG Guohui,et al.Effect of Si modification on hydrodesulfurization performance of NiMo/Al2O3 catalyst[J].Chemical Industry and Engineering Progress,2022,41(S1):210-220. | |

| 24 | 汪佩华,秦志峰,吴琼笑,等.磷添加方式对NiMo/Al2O3催化剂加氢脱硫性能的影响[J].化工进展,2021,40(2):890-900. |

| WANG Peihua, QIN Zhifeng, WU Qiongxiao,et al.Effect of phosphorus adding manners on the performance of NiMo/Al2O3 catalyst in hydrodesulfurization[J].Chemical Industry and Engineering Progress,2021,40(2):890-900. | |

| 25 | LIU Bin, LIU Lei, WANG Zhong,et al.Effect of hydrogen spillover in selective hydrodesulfurization of FCC gasoline over the CoMo catalyst[J].Catalysis Today,2017,282:214-221. |

| 26 | GUTIÉRREZ O Y, KLIMOVA T.Effect of the support on the high activity of the(Ni)Mo/ZrO2-SBA-15 catalyst in the simultaneous hydrodesulfurization of DBT and 4,6-DMDBT[J].Journal of Catalysis,2011,281(1):50-62. |

| [1] | SONG Guoliang, MU Zhanpeng, YANG Xiaxia, LI Zihan, ZHU Jinjian, ZHANG Jingcheng, YANG Wenru, MA Wenqi. Effect of magnesium modulation of Ni-Mo/Al2O3 on selectivity of catalyst hydrogenation [J]. Inorganic Chemicals Industry, 2024, 56(7): 150-156. |

| [2] | ZHANG Lijin, LÜ Qing, CHEN Xiaolang, LI Qingxin, SHI Hongyu, QIN Jun. Preparation of Ca-based LDO composite material and its adsorption performance for phosphate [J]. Inorganic Chemicals Industry, 2024, 56(7): 37-45. |

| [3] | WANG Peixiong, GONG Xiaomei, DING Jiaqi, CAO Hong. Effect of crystal modifier on preparation of α-hemihydrates gypsum from industrial gypsum [J]. Inorganic Chemicals Industry, 2024, 56(4): 112-117. |

| [4] | YANG Fengling, QIAO Guoxin, YANG Pu, REN Lei, WANG Qiong, WU Haibin, CHENG Fangqin. Research progress and application of α-hemihydrate gypsum preparation from desulfurization gypsum [J]. Inorganic Chemicals Industry, 2024, 56(2): 11-20. |

| [5] | WANG Yanyu, GU Shouyu, HOU Cuihong, JING Hongquan, GUAN Hongling, ZHANG Hui. Sulfur escape and slag physical phase analysis by carbon thermal reduction melting based on phosphogypsum ingredients [J]. Inorganic Chemicals Industry, 2024, 56(2): 86-94. |

| [6] | HOU Zhanggui, WU Chongchong, ZHANG Siran. Research progress of CO2 conversion via Reverse Water-Gas Shift reaction [J]. Inorganic Chemicals Industry, 2024, 56(11): 105-115. |

| [7] | JIN Shengshi, LIU Kaijie, LIU Qiuwen, ZHANG Yibo, YANG Xiangguang. Study on catalytic performance of phosphoric acid modified CeO2 nanorod supported Pt catalyst for propane combustion [J]. Inorganic Chemicals Industry, 2024, 56(1): 141-148. |

| [8] | CHEN Junxue, MO Jianxin, ZHOU Zhiyu, LI Zhonglin, WANG Ding, LI Yuping, HU Yongjun, JIANG Xuexian, LI Yibing. Study on synthesis of NaFe x Cr y (SO4)2(OH)6 and their electrochemical properties [J]. Inorganic Chemicals Industry, 2023, 55(8): 71-76. |

| [9] | WANG Yansu, LIU Guozhu, YU Haibin. Research progress of platinum-based propane dehydrogenation catalysts [J]. Inorganic Chemicals Industry, 2023, 55(7): 1-9. |

| [10] | LI Tong, YIN Hongfeng. Study on controllable preparation of nickel phyllosilicate nanotubes catalysts and their catalytic performance [J]. Inorganic Chemicals Industry, 2023, 55(5): 128-136. |

| [11] | FENG Xiaoqian, ZHAO Yilin, ZHAO Yonghua, ZHANG Qijian, WANG Huan, MENG Qingrun. Recent progress of modified montmorillonited-based catalysts [J]. Inorganic Chemicals Industry, 2023, 55(5): 24-30. |

| [12] | YANG Yue, ZHU Ganyu, ZHANG Jianbo, MENG Ziheng, LIU Xinhui, YANG Jing, YAN Kun, PENG Zonggui, WANG Qiujian, LI Huiquan. Study on preparation of desulfurizer and byproduct gypsum from calcium carbide slag by cyclone separation [J]. Inorganic Chemicals Industry, 2023, 55(5): 78-84. |

| [13] | JIN Suna, LÜ Ruiliang. Research and application progress of wet flue gas desulfurization wastewater treatment technology [J]. Inorganic Chemicals Industry, 2023, 55(4): 27-37. |

| [14] | YAO Yong, LI Shizhu, ZHENG Dongchen, ZENG Tinghua, WU Zhichao, YU Chi, LIU Faqian. Study on preparation,evaluation and application of new low-carbon emission nano calcium hydroxide desulfurizer [J]. Inorganic Chemicals Industry, 2023, 55(4): 38-44. |

| [15] | WEN Yuan, ZHOU Chenliang, ZHANG Qiang, YU Linfei, HE Wenxiu, LIU Quansheng. Research progress of electronic and structure promoters of iron-based catalysts for FTO reaction [J]. Inorganic Chemicals Industry, 2023, 55(3): 36-46. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||