Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (11): 130-138.doi: 10.19964/j.issn.1006-4990.2023-0072

• Environment·Health·Safety • Previous Articles Next Articles

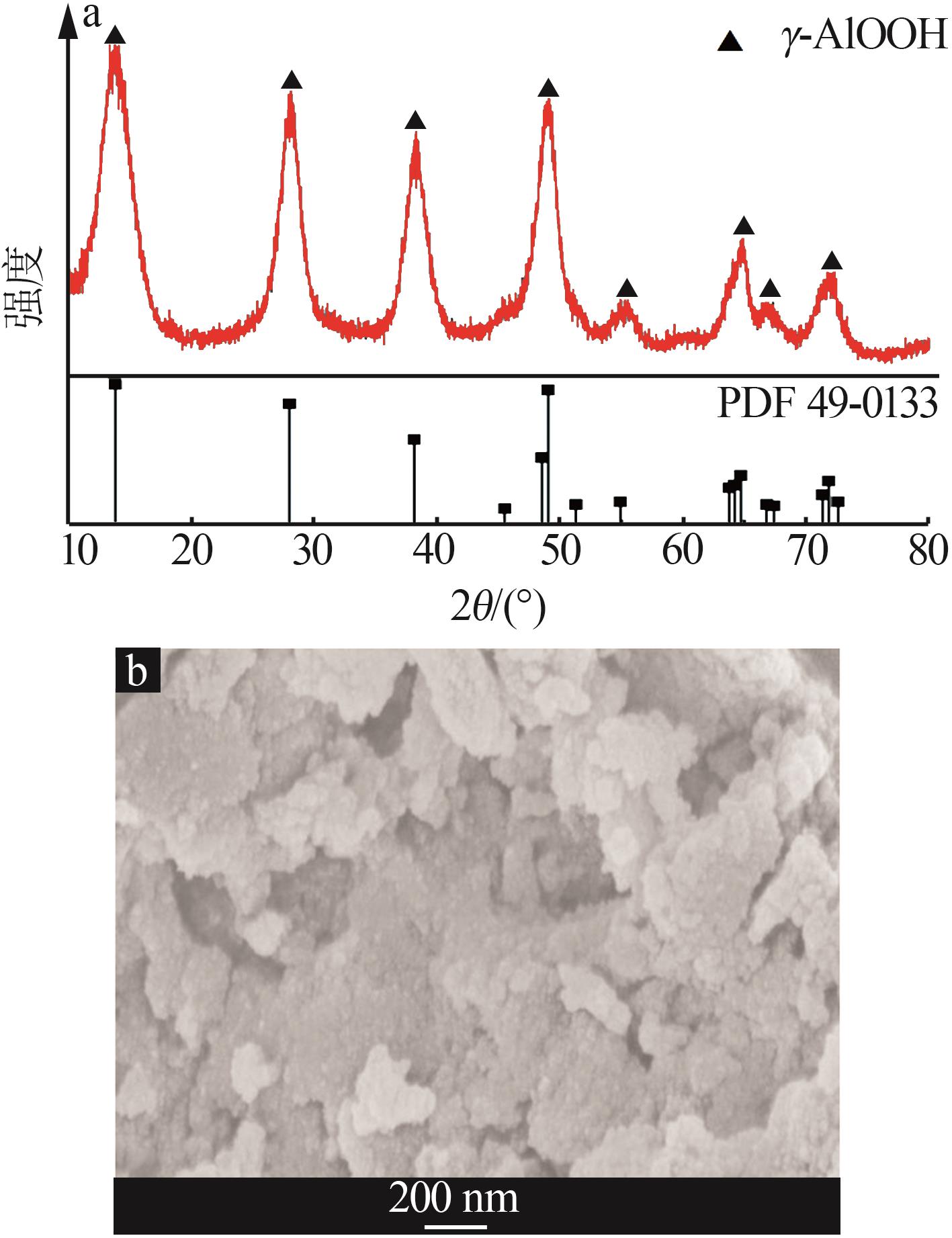

Study on preparation of pseudo-boehmite from aluminum dross resource treatment

TENG Jiayang1( ), FENG Qingge1,2(

), FENG Qingge1,2( ), ZHANG Xuan1, QIN Fanghong1, FENG Jinghang1, HU Jiawen3, CHEN Chaohong3

), ZHANG Xuan1, QIN Fanghong1, FENG Jinghang1, HU Jiawen3, CHEN Chaohong3

- 1.School of Resources,Environment and Materials,Guangxi University,Nanning 530004,China

2.Key Laboratory of Environmental Protection(Guangxi University),Education Department of Guangxi Zhuang Autonomous Region,Nanning 530004,China

3.Taiwan Cement(Guigang) Corporation,Guigang 537100,China

-

Received:2023-02-14Online:2023-11-10Published:2023-11-16 -

Contact:FENG Qingge E-mail:964270321@qq.com;fengqg@gxu.edu.cn

CLC Number:

Cite this article

TENG Jiayang, FENG Qingge, ZHANG Xuan, QIN Fanghong, FENG Jinghang, HU Jiawen, CHEN Chaohong. Study on preparation of pseudo-boehmite from aluminum dross resource treatment[J]. Inorganic Chemicals Industry, 2023, 55(11): 130-138.

share this article

Table 4

Response surface analysis of variance"

| 方差来源 | 平方和 | 自由度 | 均方 | F值 | P值 | 显著性 |

|---|---|---|---|---|---|---|

| 模型 | 85.77 | 9 | 9.53 | 19.42 | 0.000 4 | ** |

| A | 3.52 | 1 | 3.52 | 7.18 | 0.031 5 | * |

| B | 14.39 | 1 | 14.39 | 29.33 | 0.001 0 | ** |

| C | 1.62 | 1 | 1.62 | 3.30 | 0.112 0 | 不显著 |

| AB | 3.69 | 1 | 3.69 | 7.51 | 0.028 9 | * |

| AC | 1.78 | 1 | 1.78 | 3.63 | 0.098 3 | 不显著 |

| BC | 1.53 | 1 | 1.53 | 3.11 | 0.121 2 | 不显著 |

| A2 | 32.75 | 1 | 32.75 | 66.76 | <0.000 1 | ** |

| B2 | 11.52 | 1 | 11.52 | 23.48 | 0.001 9 | ** |

| C2 | 9.37 | 1 | 9.37 | 19.09 | 0.003 3 | ** |

| 残差 | 3.43 | 7 | 0.490 6 | |||

| 失拟项 | 1.62 | 3 | 0.539 0 | 1.19 | 0.420 5 | 不显著 |

| 纯误差 | 1.82 | 4 | 0.454 3 | |||

| 总离差 | 89.21 | 16 | ||||

| R2=0.961 5 |

| 1 | 石志平,姜澜,杨洪亮,等.铝灰的回收处理及资源化利用研究现状[J].无机盐工业,2020,52(9):21-25. |

| SHI Zhiping, JIANG Lan, YANG Hongliang,et al.Research status of recycling and resource utilization of aluminum dross[J].Inorganic Chemicals Industry,2020,52(9):21-25. | |

| 2 | MESHRAM A, SINGH K K.Recovery of valuable products from hazardous aluminum dross:A review[J].Resources,Conservation and Recycling,2018,130:95-108. |

| 3 | SHEN Hanlin, LIU Bo, EKBERG C,et al.Harmless disposal and resource utilization for secondary aluminum dross:A review[J].Science of the Total Environment,2021,760:143968. |

| 4 | EWAIS E M M, BESISA N H A.Tailoring of magnesium aluminum titanate based ceramics from aluminum dross[J].Materials & Design,2018,141:110-119. |

| 5 | ZHU Weijun, WU Kangkai, ZHANG Senjing,et al.Zero-waste progress for the synthesis of high-purity β-sialon ceramics from secondary aluminum dross[J].Advanced Engineering Materials,2021,23(4):2001298. |

| 6 | HONG Jianping, WANG Jun, CHEN Haiyan,et al.Process of aluminum dross recycling and life cycle assessment for Al-Si alloys and brown fused alumina[J].Transactions of Nonferrous Metals Society of China,2010,20(11):2155-2161. |

| 7 | 胡保国,蒋晨,赵海侠,等.铝灰酸溶法制备聚合氯化铝[J].化工环保,2013,33(4):325-329. |

| HU Baoguo, JIANG Chen, ZHAO Haixia,et al.Preparation of polyaluminium chloride from alumina ash by acid dissolution method[J].Environmental Protection of Chemical Industry,2013,33(4):325-329. | |

| 8 | ADEOSUN S O, AKPAN E I, DADA M O.Refractory characteristics of aluminum dross-kaolin composite[J].JOM,2014,66(11):2253-2261. |

| 9 | BENKHELIF A, KOLLI M.Synthesis of pure magnesium aluminate spinel(MgAl2O4) from waste aluminum dross[J].Waste and Biomass Valorization,2022,13(5):2637-2649. |

| 10 | ELSEKNIDY M H, SALMIATON A, SHAFIZAH I NOR,et al.A study on mechanical properties of concrete incorporating aluminum dross,fly ash,and quarry dust[J].Sustainability,2020,12(21):9230. |

| 11 | ZHANG Yu, NI Hongjun, LV Shuaishuai,et al.Preparation of sintered brick with aluminum dross and optimization of process parameters[J].Coatings,2021,11(9):1039. |

| 12 | GUO Hongwei, WANG Jun, ZHANG Xiuxia,et al.Study on the extraction of aluminum from aluminum dross using alkali roasting and subsequent synthesis of mesoporous γ-alumina[J].Metallurgical and Materials Transactions B,2018,49(5):2906-2916. |

| 13 | LV Han, XIE Mingzhuang, SHI Litao,et al.A novel green process for the synthesis of high-whiteness and ultrafine aluminum hydroxide powder from secondary aluminum dross[J].Ceramics International,2022,48(1):953-962. |

| 14 | LEVIN I, GEMMING T, BRANDON D G.Some metastable polymorphs and transient stages of transformation in alumina[J].Phy- sica Status Solidi (a),1998,166(1):197-218. |

| 15 | CAI Yuhang, ZHAO Mengmeng, WANG Henti,et al.Synthesis and properties of flame-retardant poly(vinyl alcohol)/pseudo-boehmite nanocomposites with high transparency and enhanced refractive index[J].Polymer Degradation and Stability,2014,99:53-60. |

| 16 | VAN GARDEREN N, CLEMENS F J, ANEZIRIS C G,et al.Improved γ-alumina support based pseudo-boehmite shaped by micro-extrusion process for oxygen carrier support application[J].Ceramics International,2012,38(7):5481-5492. |

| 17 | LI Jie, QIAN Linping, HU Liya,et al.Low-temperature hydrogenation of maleic anhydride to succinic anhydride and γ-butyrolactone over pseudo-boehmite derived alumina supported metal (metal=Cu,Co and Ni) catalysts[J].Chinese Chemical Letters,2016,27(7):1004-1008. |

| 18 | XU Xinhai, ZHANG Shuyang, LI Peiwen,et al.Adsorptive desulfurization of liquid Jet-A fuel at ambient conditions with an improved adsorbent for on-board fuel treatment for SOFC applications[J].Fuel Processing Technology,2014,124:140-146. |

| 19 | 李凡,杨雨哲,田朋,等.仲丁醇铝水解制备高纯拟薄水铝石[J].无机盐工业,2022,54(7):78-84,104. |

| LI Fan, YANG Yuzhe, TIAN Peng,et al.Preparation of high purity pseudo-boehmite by hydrolysis of aluminium sec-butoxide[J].Inorganic Chemicals Industry,2022,54(7):78-84,104. | |

| 20 | 田朋,李伟,杨雨哲,等.异丙醇铝水解制高纯拟薄水铝石[J].无机盐工业,2022,54(2):54-59. |

| TIAN Peng, LI Wei, YANG Yuzhe,et al.Preparation of high purity pseudo-boehmite by hydrolysis of aluminium isopropanol[J].Inorganic Chemicals Industry,2022,54(2):54-59. | |

| 21 | CAI Weiquan, LI Huiquan, ZHANG Yi.Influences of processing techniques of the H2O2-precipitated pseudoboehmite on the struc-tural and textural properties of γ-Al2O3[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2007,295(1/2/3):185-192. |

| 22 | YANG Yang, XU Yanyan, HAN Baozhai,et al.Effects of synthetic conditions on the textural structure of pseudo-boehmite[J].Journal of Colloid and Interface Science,2016,469:1-7. |

| 23 | REN Xiaojing, LIU Youzhi, MIAO Longxin.Continuous carbonation for synthesis of pseudo-boehmite by using cross-flow rotating packed bed through the reaction of NaAlO2 solution with CO2 gas[J].Nanomaterials,2020,10(2):263. |

| 24 | 陈建章.基于拟薄水铝石氧化铝气凝胶制备工艺研究[D].湘潭:湖南科技大学,2018. |

| CHEN Jianzhang.Study on the preparation process of alumina aerogel based on pseudo-boehmite[D].Xiangtan:Hunan University of Science and Technology,2018. | |

| 25 | 刘袁李.异丙醇铝水解制备催化用拟薄水铝石和氧化铝[D].大连:大连理工大学,2020. |

| LIU Yuanli.Synthesis of catalysis pseudobohmite and alumina from aluminium isopropoxide[D].Dalian:Dalian University of Technology,2020. | |

| 26 | 罗铃,李平,黄凯,等.NaAlO2硫酸法合成高质量拟薄水铝石[J].过程工程学报,2022,22(12):1710-1718. |

| LUO Ling, LI Ping, HUANG Kai,et al.Synthesis of high-qualified pseudo-boehmite by NaAlO2 sulfuric acid method[J].The Chinese Journal of Process Engineering,2022,22(12):1710-1718. | |

| 27 | 轩晓蝶,刘锰钰,郭静静,等.拟薄水铝石合成及其性能研究进展[J].工业催化,2022,30(6):21-30. |

| XUAN Xiaodie, LIU Mengyu, GUO Jingjing,et al.Progresson synthesis and properties of pseudo-boehmite[J].Industrial Catalysis,2022,30(6):21-30. | |

| 28 | 左少卿,熊晓云,许勐,等.拟薄水铝石胶溶性影响因素的研究进展[J].应用化工,2018,47(6):1250-1253. |

| ZUO Shaoqing, XIONG Xiaoyun, XU Meng,et al.Research progress of the factors to impact the dispersion of pseudo-boehmite[J].Applied Chemical Industry,2018,47(6):1250-1253. | |

| 29 | TRIPATHY A K, MAHALIK S, SARANGI C K,et al.A pyro-hydrometallurgical process for the recovery of alumina from waste aluminium dross[J].Minerals Engineering,2019,137:181-186. |

| 30 | 朱江凯.兰州铝业回收大修渣减量化及无害化工艺研究[D].兰州:兰州理工大学,2020. |

| ZHU Jiangkai.The reduction and harmless process research of recycled SPL of LANZHOU ALUMINUM CO.,LTD[D].Lanzhou:Lanzhou University of Technology,2020. | |

| 31 | MÄKELÄ M.Experimental design and response surface methodology in energy applications:A tutorial review[J].Energy Conversion and Management,2017,151:630-640. |

| 32 | MOHAMMED B S, KHED V C, NURUDDIN M F.Rubbercrete mixture optimization using response surface methodology[J].Journal of Cleaner Production,2018,171:1605-1621. |

| 33 | 刘袁李,沈善文,杨雨哲,等.异丙醇铝控制水解制备高纯拟薄水铝石和多孔氧化铝[J].工业催化,2020,28(1):24-31. |

| LIU Yuanli, SHEN Shanwen, YANG Yuzhe,et al.Synthesis of high-purity pseudoboehmite and porous alumina from aluminum isopropoxide[J].Industrial Catalysis,2020,28(1):24-31. | |

| 34 | WANG Zheming, WALTER E D, SASSI M,et al.The role of surface hydroxyls on the radiolysis of gibbsite and boehmite nanoplatelets[J].Journal of Hazardous Materials,2020,398:122853. |

| 35 | 高建峰,徐春彦,王建中,等.用偏铝酸钠直接制取高纯拟薄水铝石[J].催化学报,2003,24(7):505-508. |

| GAO Jianfeng, XU Chunyan, WANG Jianzhong,et al.Preparation of ultra-pure pseudo-boehmite from sodium meta-aluminate[J].Chinese Journal of Catalysis,2003,24(7):505-508. | |

| 36 | 曾丰,杨清河,曾双亲.采用NaAlO2-CO2连续中和法制备拟薄水铝石[J].石油学报(石油加工),2015,31(5):1069-1074. |

| ZENG Feng, YANG Qinghe, ZENG Shuangqin.Preparation of pseudo-boehmite by continuous neutralization of NaAlO2-CO2 method[J].Acta Petrolei Sinica(Petroleum Processing Section),2015,31(5):1069-1074. | |

| 37 | 伍艳辉,钱君律,方学兵,等.硝酸法制备拟薄水铝石研究:成胶条件的影响[J].同济大学学报(自然科学版),2003,31(7):878-882. |

| WU Yanhui, QIAN Junlü, FANG Xuebing,et al.Preparation of pseudo-boehmite with nitric acid and sodium aluminate:Influences of precipitation conditions[J].Journal of Tongji University,2003,31(7):878-882. | |

| 38 | 李涛.工业铝醇化—水解制备高纯Al2O3的研究[D].贵阳:贵州大学,2019. |

| LI Tao.Preparation of high purity Al2O3 by alcoholization-hydrolysis of industrial aluminum[D].Guiyang:Guizhou University,2019. | |

| 39 | 赵历,卓民权,龚福忠,等.碳化法制备球霰石碳酸钙微球及形成机理[J].无机盐工业,2021,53(3):38-43. |

| ZHAO Li, ZHUO Minquan, GONG Fuzhong,et al.Synthesis of vaterite CaCO3 microspheres by carbonization method and its formation mechanism[J].Inorganic Chemicals Industry,2021,53(3):38-43. | |

| 40 | TOLEDO-CHÁVEZ G, PANIAGUA-RODRÍGUEZ J C,ZÁRATE-MEDINA J,et al.Reactions analysis during the synthesis of pseudo-boehmite as precursor of gamma-alumina[J].Catalysis Today,2016,271:207-212. |

| 41 | 张欣,陈建章,唐安山,等.拟薄水铝石胶溶过程研究[J].人工晶体学报,2018,47(11):2393-2397. |

| ZHANG Xin, CHEN Jianzhang, TANG Anshan,et al.Research on peptizing process of pseudo-boehmite[J].Journal of Synthetic Crystals,2018,47(11):2393-2397. | |

| 42 | 李波,邵玲玲.氧化铝、氢氧化铝的XRD鉴定[J].无机盐工业,2008,40(2):54-57. |

| LI Bo, SHAO Lingling.Appraisal of alumina and aluminium hydroxide by XRD[J].Inorganic Chemicals Industry,2008,40(2):54-57. | |

| 43 | 刘滨,杨清河,胡大为,等.高孔体积、大孔径渣油加氢催化材料的开发[J].石油炼制与化工,2021,52(6):6-10. |

| LIU Bin, YANG Qinghe, HU Dawei,et al.Preparation of catalytic material with high pore volume and large pore for residue hydrotreating[J].Petroleum Processing and Petrochemicals,2021,52(6):6-10. |

| [1] | LIU Xinlong, YANG Zhenyu, HAO He, LIU Shuxin, WU Chenyang, WANG Xingli, MA Qingqing. Study on shaped 4A zeolite synthesized with aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 78-85. |

| [2] | ZOU Liao, MA Xiaolin, LI Xiaobao, YE Judi. Study on preparation of Lignin/LDH and improvement of mechanical properties of polyurethane [J]. Inorganic Chemicals Industry, 2025, 57(1): 64-70. |

| [3] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [4] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [5] | ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM [J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113. |

| [6] | WANG Yingnan, SHENG Linlin, HUANG Juan, HUANG Zhanbin. Study on adsorption performance of lead from water by coal-fired slag [J]. Inorganic Chemicals Industry, 2023, 55(8): 109-115. |

| [7] | DONG Xiongwei, HAN Fenglan, HUA Wei, LI Maohui, AN Changcong, HUANG Yucai. Synthesis and characterization of silico-manganese slag zeolite [J]. Inorganic Chemicals Industry, 2023, 55(12): 128-132. |

| [8] | ZHANG Zhiqiang, CUI Kangping, CHEN Xing, LI Haiyang. Optimization of preparation of ultrafine chromium oxide by carbothermal reduction of sodium dichromate by response surface methodology [J]. Inorganic Chemicals Industry, 2023, 55(10): 136-144. |

| [9] | FANG Weicheng,CHENG Xingxing,SUN Changrong. Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology [J]. Inorganic Chemicals Industry, 2022, 54(9): 119-125. |

| [10] | FU Ziqi, ZHANG Cheng, SHENG Yong, JI Lijun. Study on preparation of phosphoric acid by leaching fluoride residue from wet-process phosphoric acid with organic solvents [J]. Inorganic Chemicals Industry, 2022, 54(7): 129-134. |

| [11] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| [12] | TIAN Peng,LI Wei,YANG Yuzhe,LIU Kunji,XU Qianjin,NING Guiling. Preparation of high purity pseudo-boehmite by hydrolysis of aluminium isopropanol [J]. Inorganic Chemicals Industry, 2022, 54(2): 54-59. |

| [13] | SHI Kai,ZHAO Xu,ZHANG Hongzhi,REN Yixuan,LI Xiaofeng. Study on synthesis of SAPO-34 molecular sieve by silicon-modified pseudo-boehmite [J]. Inorganic Chemicals Industry, 2022, 54(10): 149-154. |

| [14] | Shi Zhiping, Jiang Lan, Yang Hongliang, Zhang Jingzhou, Fu Gaofeng. Research status of recycling and resource utilization of aluminum dross [J]. Inorganic Chemicals Industry, 2020, 52(9): 21-25. |

| [15] | Xiong Xiaoyun,Hu Qingxun,Zhao Hongjuan,Gao Xionghou. Impact of alumina matrix on cracking performance of heavy oil molecule of FCC catalyst [J]. Inorganic Chemicals Industry, 2019, 51(8): 83-87. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||