| 1 |

PANG Zhongya, LI Guangshi, XIONG Xiaolu,et al.Molten salt synthesis of porous carbon and its application in supercapacitors:A review[J].Journal of Energy Chemistry,2021,61:622-640.

|

| 2 |

唐金琼,孔勇,沈晓冬.碳化物衍生碳的制备及其应用研究进展[J].化工进展,2022,41(2):791-802.

|

|

TANG Jinqiong, KONG Yong, SHEN Xiaodong.Advances in the synthesis and application of the carbide-derived carbons[J].Chemical Industry and Engineering Progress,2022,41(2):791-802.

|

| 3 |

王红妍,王宝冬,李俊华,等.碳化物衍生碳及其在吸附领域中的应用研究进展[J].化工进展,2018,37(2):637-643.

|

|

WANG Hongyan, WANG Baodong, LI Junhua,et al.Research progress of carbide-derived carbon and its application in adsorption[J].Chemical Industry and Engineering Progress,2018,37(2):637-643.

|

| 4 |

DASH R, CHMIOLA J, YUSHIN G,et al.Titanium carbide derived nanoporous carbon for energy-related applications[J].Carbon,2006,44(12):2489-2497.

|

| 5 |

NAHEED L, KOPPEL M, PAALO M,et al.Hydrogen adsorption properties of carbide-derived carbons at ambient temperature and high pressure[J].International Journal of Hydrogen Energy,2021,46(29):15761-15772.

|

| 6 |

罗清威.不同热处理气氛下制备CDC涂层[J].云南大学学报:自然科学版,2020,42(5):936-940.

|

|

LUO Qingwei.Preparation of CDC coatingsunder different heat treatment atmospheres[J].Journal of Yunnan University:Natural Sciences Edition,2020,42(5):936-940.

|

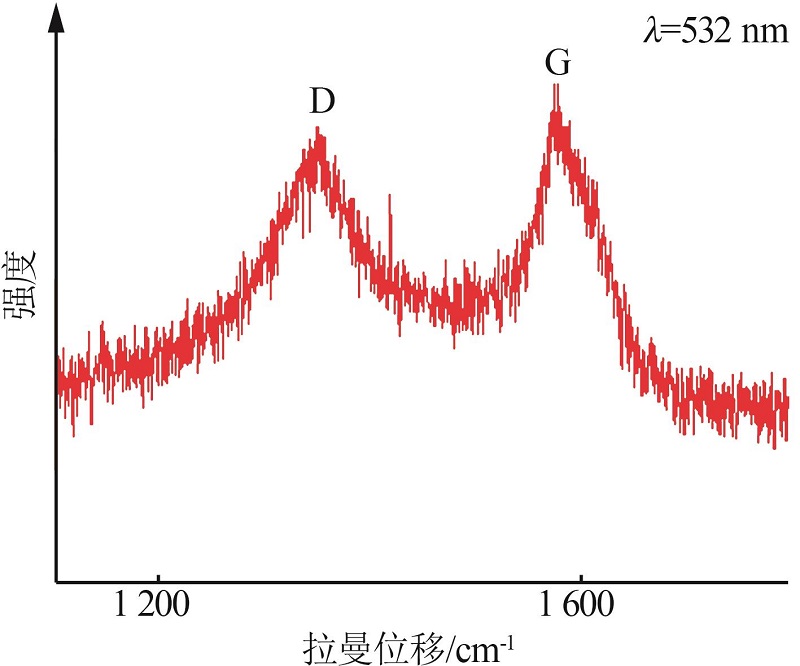

| 7 |

LILLOJA J, KIBENA-PÕLDSEPP E, SARAPUU A,et al.Transition metal and nitrogen-doped carbide-derived carbon/carbon nanotube composites as cathode catalysts for anion-exchange mem-cells[J].ACS catalysis,2021,11(4):1920-1931.

|

| 8 |

PANG Zhongya, LI Guangshi, ZOU Xingli,et al.An integrated strategy towards the facile synthesis of core-shell SiC-derived carbon@N-doped carbon for high-performance supercapacitors[J].Journal of Energy Chemistry,2021,56:512-521.

|

| 9 |

MALMBERG S, ARULEPP M, SAVEST N,et al.Directly electrospun electrodes for electrical double-layer capacitors from carbide-derived carbon[J].Journal of Electrostatics,2020,103.Doi:10.1016/j.elstat.2019.103396.

|

| 10 |

LI Tao, BAI Xue, GULZAR U,et al.Facile synthesis of highly graphitized carbon via reaction of CaC2 with sulfur and its application for lithium/sodium-ion batteries[J].ACS Omega,2019,4(5):8312-8317.

|

| 11 |

BADAMI D V.X-Ray studies of graphite formed by decomposing silicon carbide[J].Carbon,1965,3(1):53-57.

|

| 12 |

张静.HCl辅助Cl2刻蚀SiC和WC制备碳化物衍生碳的工艺及机理[D].南昌:南昌大学,2016.

|

|

ZHANG Jing.Preparation technology and mechanism of carbide-derived carbon by HCl-assisted Cl2 etching SiC and WC[D].Nanchang:Nanchang University,2016.

|

| 13 |

SCHWANDT C.Molten salts chemistry and technology.herausgegeben von marcelle gaune-escard und Geir Martin haarberg[J].Angewandte Chemie,2015,127(1):36.

|

| 14 |

LIU Wei, LIU Guolong, KOU Qian,et al.Novel process for producing hierarchical carbide derived carbon monolith and low carbon ferromanganese from high carbon ferromanganese[J].RSC Advances,2017,7(54):33875-33882.

|

| 15 |

PANG Zhongya, ZOU Xingli, TANG Wei,et al.Electrosynthesis of Ti3AlC2-derived porous carbon in molten salt[J].JOM,2020,72(11):3887-3894.

|

| 16 |

LIU Wei, LIU Guolong, KOU Qian,et al.A simple method for preparing 3D hierarchical carbide derived carbon by single step molten salts electrolysis[J].Fullerenes,Nanotubes and Carbon Nanostructures,2018,26(6):325-329.

|

| 17 |

PANG Zhongya, ZOU Xingli, ZHENG Kai,et al.Sustainable synthesis of Cr7C3,Cr2AlC,and their derived porous carbons in molten salts[J].ACS Sustainable Chemistry & Engineering,2018,6(12):16607-16615.

|

| 18 |

ZHENG Kai, ZOU Xingli, XIE Xueliang,et al.Electrosynthesis of SiC derived porous carbon nanospheres for supercapacitors[J].Materials Letters,2018,216:265-268.

|

| 19 |

CHEN Yunfei, WANG Mingyong, LV Aijing,et al.Green preparation of vanadium carbide through one-step molten salt electrolys-is[J].Ceramics International,2021,47(20):28203-28209.

|

| 20 |

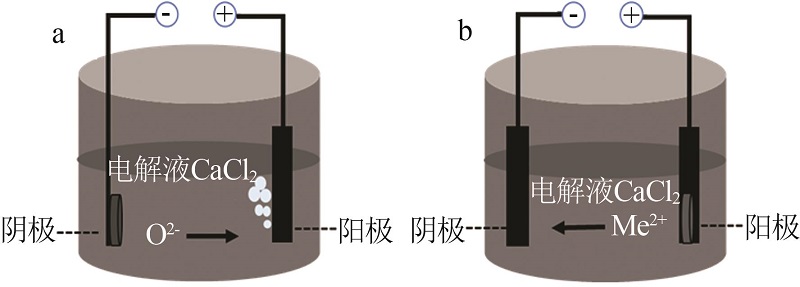

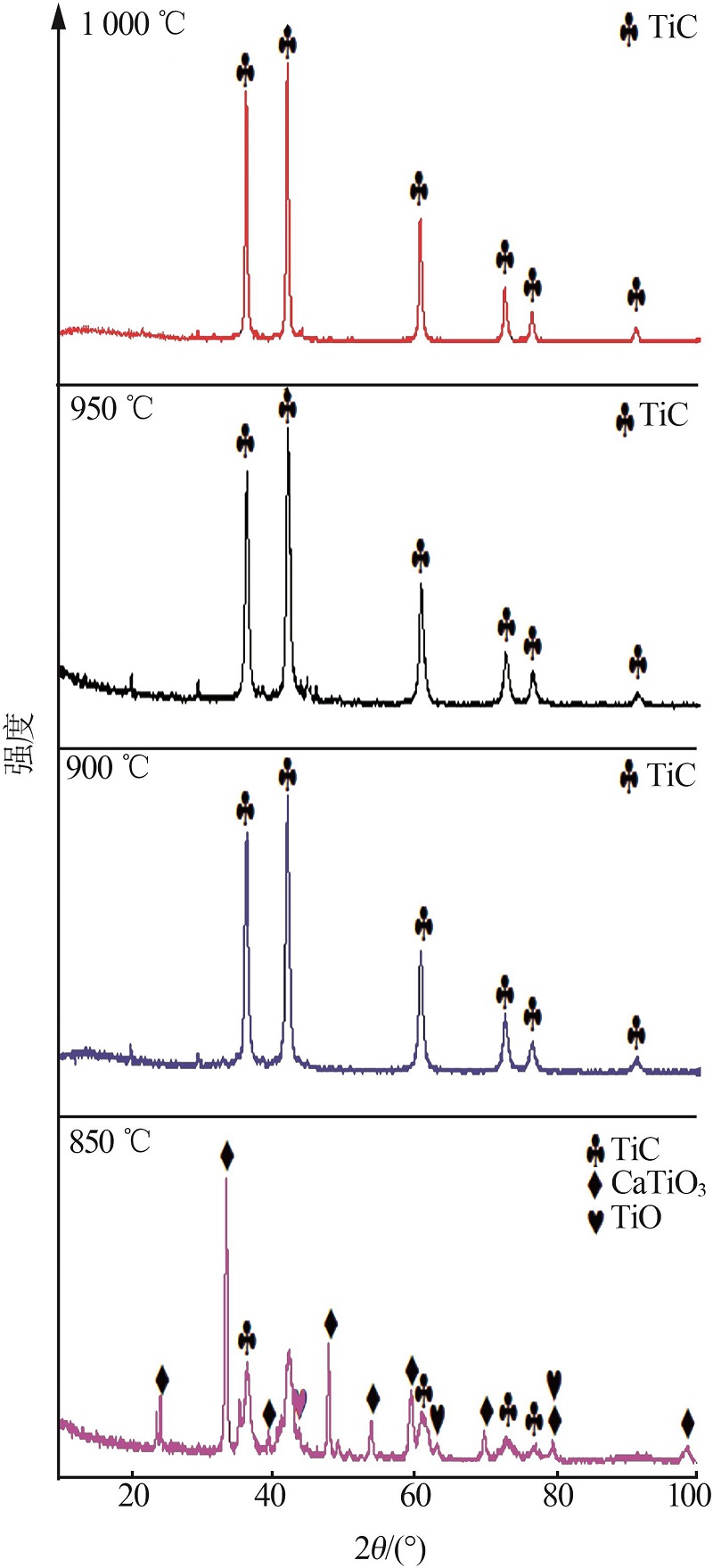

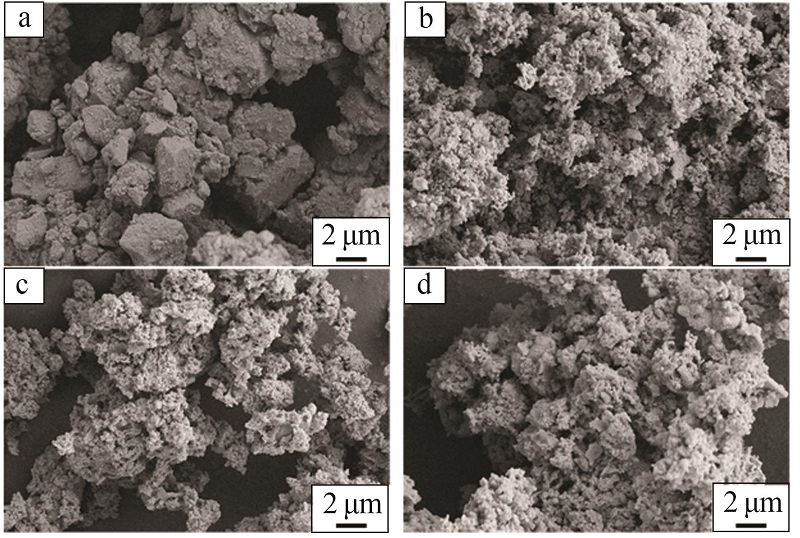

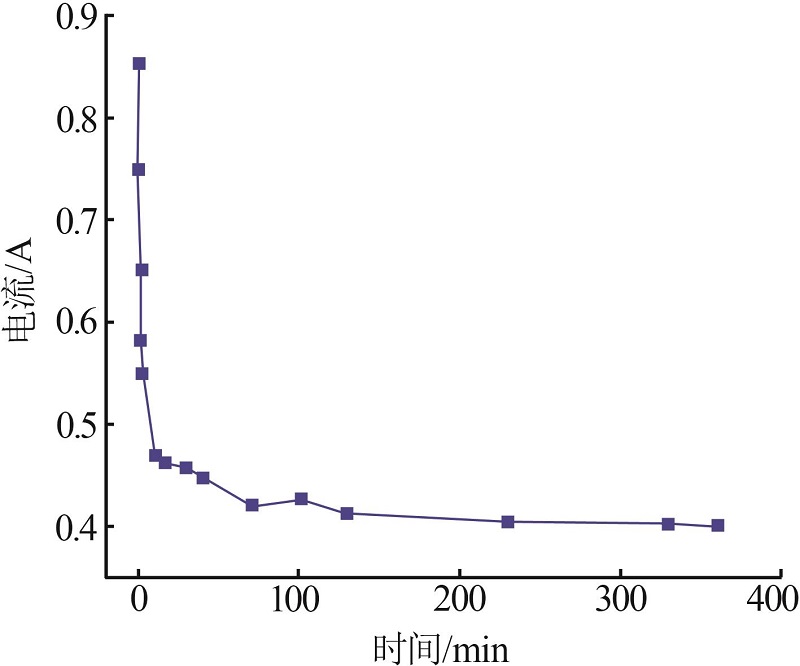

郎晓川,谢宏伟,翟玉春,等.熔盐电解法制备TiC粉末的研究[J].稀有金属与硬质合金,2013,41(5):1-4,24.

|

|

LANG Xiaochuan, XIE Hongwei, ZHAI Yuchun,et al.Research on preparation of TiC powders by molten salt electrolysis[J].Rare Metals and Cemented Carbides,2013,41(5):1-4,24.

|

| 21 |

WAN Chaopin.Molten salt electrolytic fabrication of TiC-CDC and its applications for supercapacitor[J].Journal of Materials Science & Technology,2017,33(8):788-792.

|

| 22 |

XU Jiang, ZHANG Ruijun, CHEN Peng.Mechanism of formation and electrochemical performance of carbide-derived carbons obtained from different carbides[J].Carbon,2013,64:444-455.

|

| 23 |

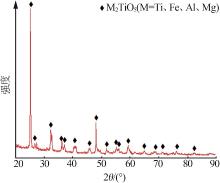

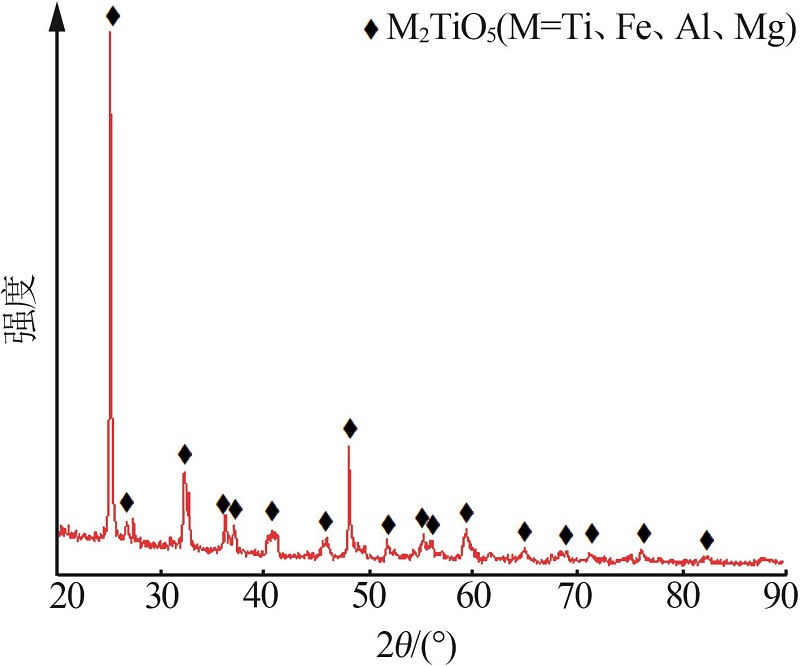

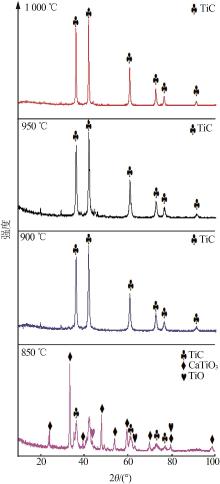

盖家萱,陈朝轶,李军旗,等.熔盐电脱氧含钛废渣制备金属钛[J].中南大学学报:自然科学版,2021,52(4):1076-1082.

|

|

GAI Jiaxuan, CHEN Chaoyi, LI Junqi,et al.Preparation metal titanium from molten salt electrodeoxidized titanium-containing waste residue[J].Journal of Central South University:Science and Technology,2021,52(4):1076-1082.

|

| 24 |

WANG Bo, CHEN Chaoyi, LI Junqi,et al.Production of Fe–Ti alloys from mixed slag containing titanium and Fe2O3 via direct electrochemical reduction in molten calcium chloride[J].Metals,2020,10(12) .Doi:10.3390/met10121611.

|

| 25 |

GORDO E, CHEN G Z, FRAY D J.Toward optimisation of electrolytic reduction of solid chromium oxide to chromium powder in molten chloride salts[J].Electrochimica Acta,2004,49(13):2195-2208.

|

| 26 |

陈朝轶,鲁雄刚,李重和,等.三相界面反应机制在SOM法制备金属钽中的应用[J].中国有色金属学报,2009,19(3):583-588.

|

|

CHEN Chaoyi, LU Xionggang, LI Chonghe,et al.Application of three-phase interline reaction mechanism on preparation of Ta metal using SOM process[J].The Chinese Journal of Nonferrous Metals,2009,19(3):583-588.

|

| 27 |

FERRARI A C, ROBERTSON J.Interpretation of Raman spectra of disordered and amorphous carbon[J].Physical Review B,2000,61(20):14095-14107.

|

| 28 |

ROBERTSON J.Amorphous carbon[J].Advances in Physics,1986,35(4):317-374.

|

| 29 |

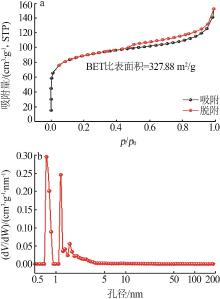

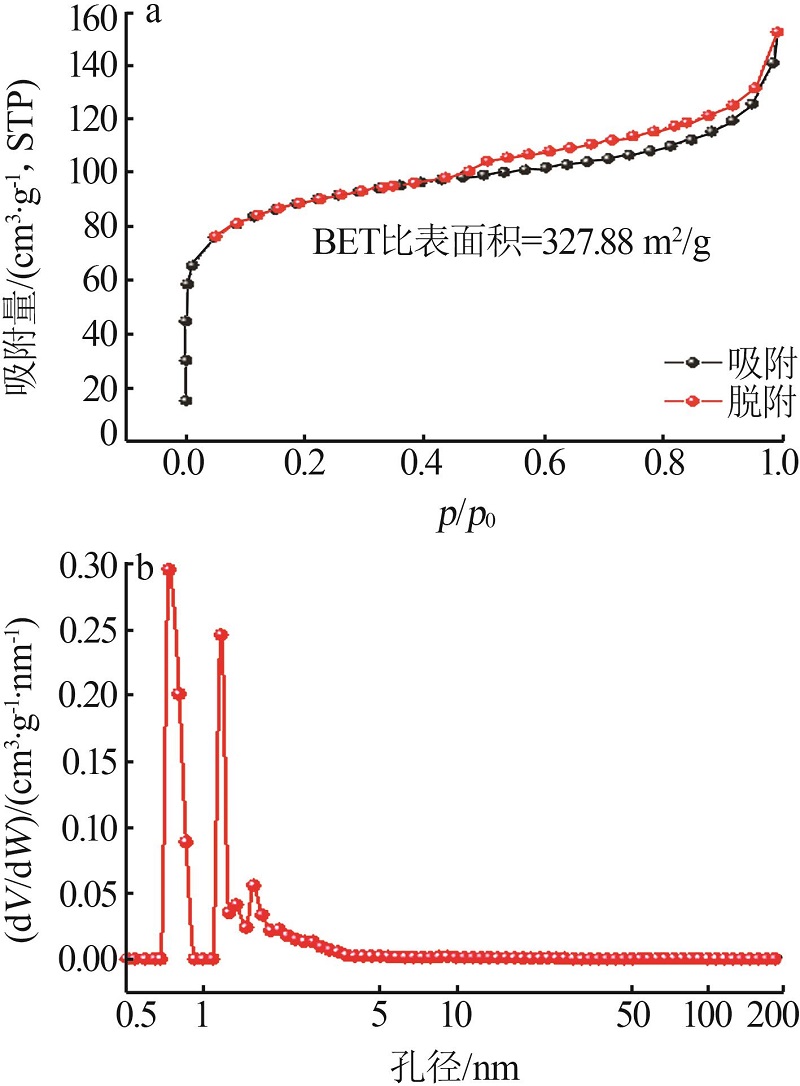

ROUQUEROL J, AVNIR D, FAIRBRIDGE C W,et al.Recommendations for the characterization of porous solids (technical report)[J].Pure and Applied Chemistry,1994,66(8):1739-1758.

|

), CHEN Chaoyi1,2(

), CHEN Chaoyi1,2( ), WANG Shiyu1,2, BAI Yang1,2, LI Tianpei1,2, GU Wei1,2

), WANG Shiyu1,2, BAI Yang1,2, LI Tianpei1,2, GU Wei1,2