| 1 |

杜小旺,仲剑初,王孝天.高硅水镁石钠化焙烧法除硅工艺研究[J].无机盐工业,2020,52(10):92-95.

|

|

DU Xiaowang, ZHONG Jianchu, WANG Xiaotian.Study on removal of silicon from high-silicon brucite by sodium roasting method[J].Inorganic Chemicals Industry,2020,52(10):92-95.

|

| 2 |

李兵,李杰,张遵乾.高炉渣热资源回收及利用展望[J].科技风,2022(4):87-91.

|

|

LI Bing, LI Jie, ZHANG Zunqian.Blast furnace slag heat resource recovery and prospect of utilization[J].Technology Wind,2022(4):87-91.

|

| 3 |

李晨.空冷高钛型高炉渣中主要组分的分离提取研究[D].成都:成都理工大学,2012.

|

|

LI Chen.Study on the separation and extraction of the main components from air-cooled high Ti-bearing blast furnace slag[D].Chen-gdu:Chengdu University of Technology,2012.

|

| 4 |

HUANG Yukun, GENG Yangbo, HAN Guihong, et al.A perspective of stepwise utilization of hazardous zinc plant purification residue based on selective alkaline leaching of zinc[J].Journal of Hazardous Materials,2020,389.Doi:10.1016/j.jhazmat.2020.122090.

doi: 10.1016/j.jhazmat.2020.122090

|

| 5 |

WANG Lingyun, LEE M S.Separation of zirconium and hafnium from nitric acid solutions with LIX 63,PC 88A and their mixture by solvent extraction[J].Hydrometallurgy,2014,150: 153-160.

|

| 6 |

连水瑕.高炉渣中二氧化硅选择性提取及应用研究[D].太原:太原理工大学,2021.

|

|

LIAN Shuixia.Study on selective extraction and application of silicon oxide from blast furnace slag[D].Taiyuan:Taiyuan University of Technology,2021.

|

| 7 |

杜阳.富钨渣中回收钨的研究[D].西安:西安建筑科技大学,2014.

|

|

DU Yang.Research on recovery of tungsten from enriched tungsten residue[D].Xi'an:Xi'an University of Architecture and Technology,2014.

|

| 8 |

韩东,张强,张敏.含碱硅酸钠溶液的回收和利用工艺研究[J].无机盐工业,2022,54(2):106-110.

|

|

HAN Dong, ZHANG Qiang, ZHANG Min.Study on recovery and utilization process of alkali containing sodium silicate solution[J].Inorganic Chemicals Industry,2022,54(2):106-110.

|

| 9 |

孙双双,仲剑初,王洪志.铜冶炼废渣脱硅工艺研究[J].无机盐工业,2021,53(9):83-87.

|

|

SUN Shuangshuang, ZHONG Jianchu, WANG Hongzhi.Study on desiliconization process of copper smelting slag[J].Inorganic Che-Industry micals,2021,53(9):83-87.

|

| 10 |

张向超.水溶液中硅、铁、铜杂质的脱除研究[D].天津:河北工业大学,2017.

|

|

ZHANG Xiangchao.Removal of silicon,iron and copper impurities in aqueous solution[D].Tianjin:Hebei University of Technology,2017.

|

| 11 |

袁杰,和晓才,宋宁,等.铝酸钠溶液氧化钙深度脱硅研究[J].矿冶,2015,24(1):57-60.

|

|

YUAN Jie, HE Xiaocai, SONG Ning, et al.Deep desiliconization of sodium aluminate solution with CaO[J].Mining and Metallurgy,2015,24(1):57-60.

|

| 12 |

吴江,王雨,薛天艳,等.氧氯化锆生产中转型料酸解与絮凝脱硅过程[J].过程工程学报,2013,13(6):986-991.

|

|

WU Jiang, WANG Yu, XUE Tianyan, et al.Acid decomposition and desilication by flocculation of transformation mass in production of zirconium oxychloride[J].The Chinese Journal of Process Engineering,2013,13(6):986-991.

|

| 13 |

杨丽静,田辉平,龙军,等.碱性硅溶胶稳定性的研究[J].石油炼制与化工,2010,41(6):12-16.

|

|

YANG Lijing, TIAN Huiping, LONG Jun, et al.Study on the stability of alkaline silica sol[J].Petroleum Processing and Petrochemicals,2010,41(6):12-16.

|

| 14 |

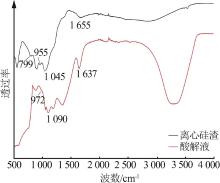

陈和生,孙振亚,邵景昌.八种不同来源二氧化硅的红外光谱特征研究[J].硅酸盐通报,2011,30(4):934-937.

|

|

CHEN Hesheng, SUN Zhenya, SHAO Jingchang.Investigation on FT-IR spectroscopy for eight different sources of SiO2 [J].Bulletin of the Chinese Ceramic Society,2011,30(4):934-937.

|

| 15 |

朱振峰,李晖,朱敏.微乳液法制备无定形纳米二氧化硅[J].无机盐工业,2006,38(6):14-16.

|

|

ZHU Zhenfeng, LI Hui, ZHU Min.The preparation of amorphous silica nanoparticls by microemulsion method[J].Inorganic Che-Industry micals,2006,38(6):14-16.

|

),TANG Jianwei2,3,LIU Yong1,3,LIU Pengfei2,HUA Quanxian1,WANG Baoming2,3(

),TANG Jianwei2,3,LIU Yong1,3,LIU Pengfei2,HUA Quanxian1,WANG Baoming2,3( )

)