| [1] |

XIANG Mengqi, MENG Hua, WANG Ye, MENG Xianzhang, BAI Yuhang, WANG Yujunyao, ZHANG Yidan.

Study on kinetic of iron leaching from titanium gypsum and its cyclic acid leaching process

[J]. Inorganic Chemicals Industry, 2024, 56(1): 114-120.

|

| [2] |

CHEN Yanmeng, MO Huiling, ZHONG Jiamei, YANG Pengfei, LAN Junfeng.

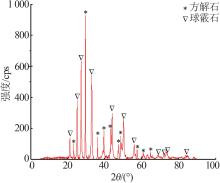

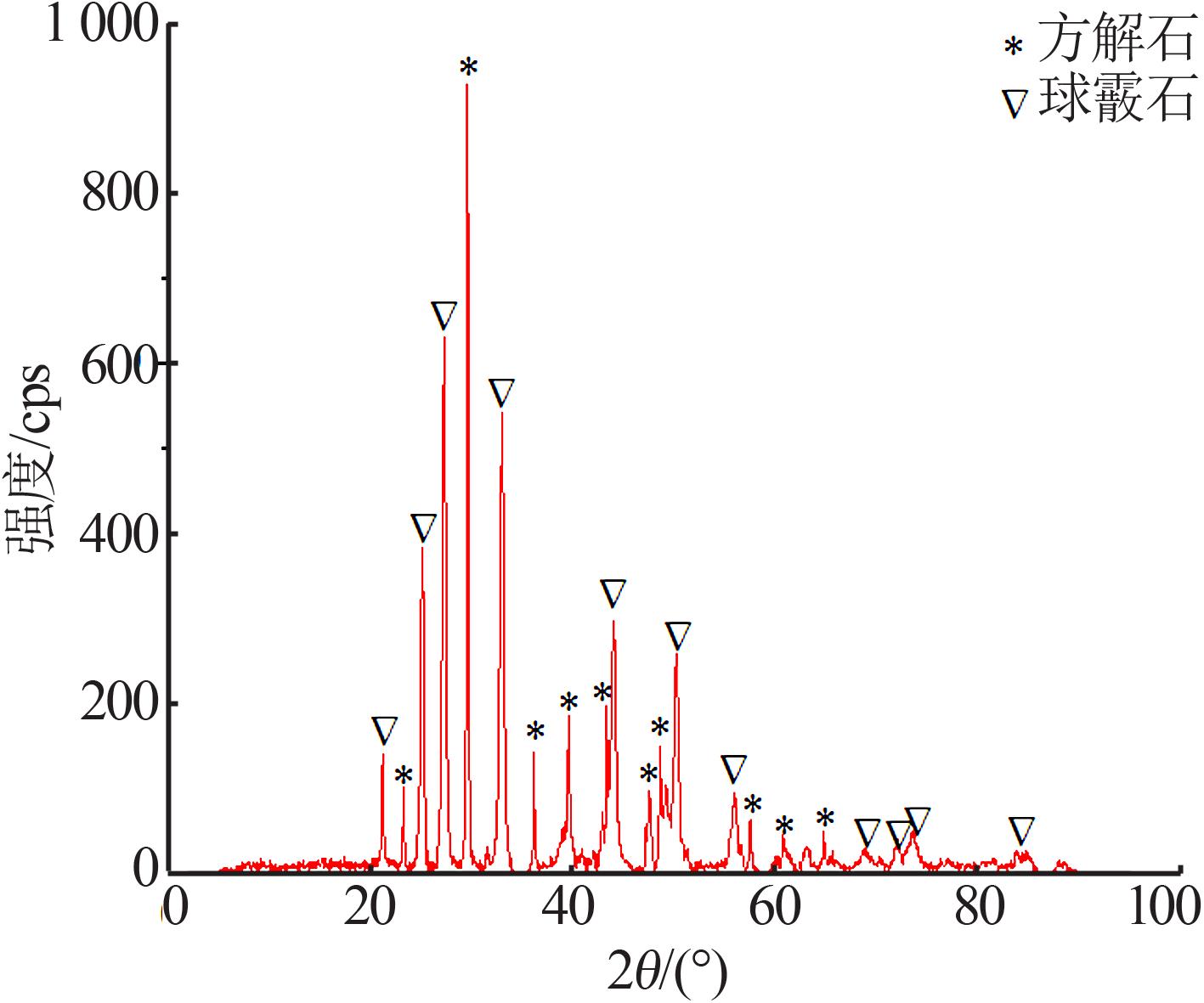

Study on preparation process of porous calcium carbonate by carbonization

[J]. Inorganic Chemicals Industry, 2023, 55(8): 102-108.

|

| [3] |

ZHANG Jinjun, GUO Linlin, LIU Bojing, FENG Shuang, SHI Qi.

Study on preparation of needle-like shaped CaCO3 from calcium carbide slag

[J]. Inorganic Chemicals Industry, 2023, 55(7): 103-108.

|

| [4] |

HE Yanfang, ZHAO Lüxuan, FENG Yuan, WU Kaiqing, LIU Bingyan, HUANG Junkai.

Countermeasures and suggestions for high-quality development of calcium carbonate industry and ecological environment protection in Guangxi

[J]. Inorganic Chemicals Industry, 2023, 55(7): 25-31.

|

| [5] |

QU Xiaoyuan, ZHENG Qiang, FAN Yuanyang, LIU Haili, DENG Xiaoyang, LI Xue.

Study on preparation of large cube calcium carbonate by secondary carbonization of dolomite

[J]. Inorganic Chemicals Industry, 2023, 55(7): 58-64.

|

| [6] |

MA Xue, ZHOU Yuan, HUANG Chao, ZHU Xiaping.

Study on preparation process of high purity calcium citrate from Zigong underground yellow brine

[J]. Inorganic Chemicals Industry, 2023, 55(4): 60-64.

|

| [7] |

DENG Weilin,HUANG Wenke,HUANG Chongqiu,ZENG Xingbin.

Regulatory preparation of porous calcium carbonate by polyacrylic acid and polystyrene sulfonate

[J]. Inorganic Chemicals Industry, 2023, 55(2): 67-72.

|

| [8] |

WEI Kang, ZHANG Hao, GAN Shunpeng.

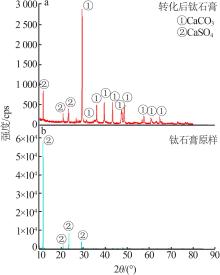

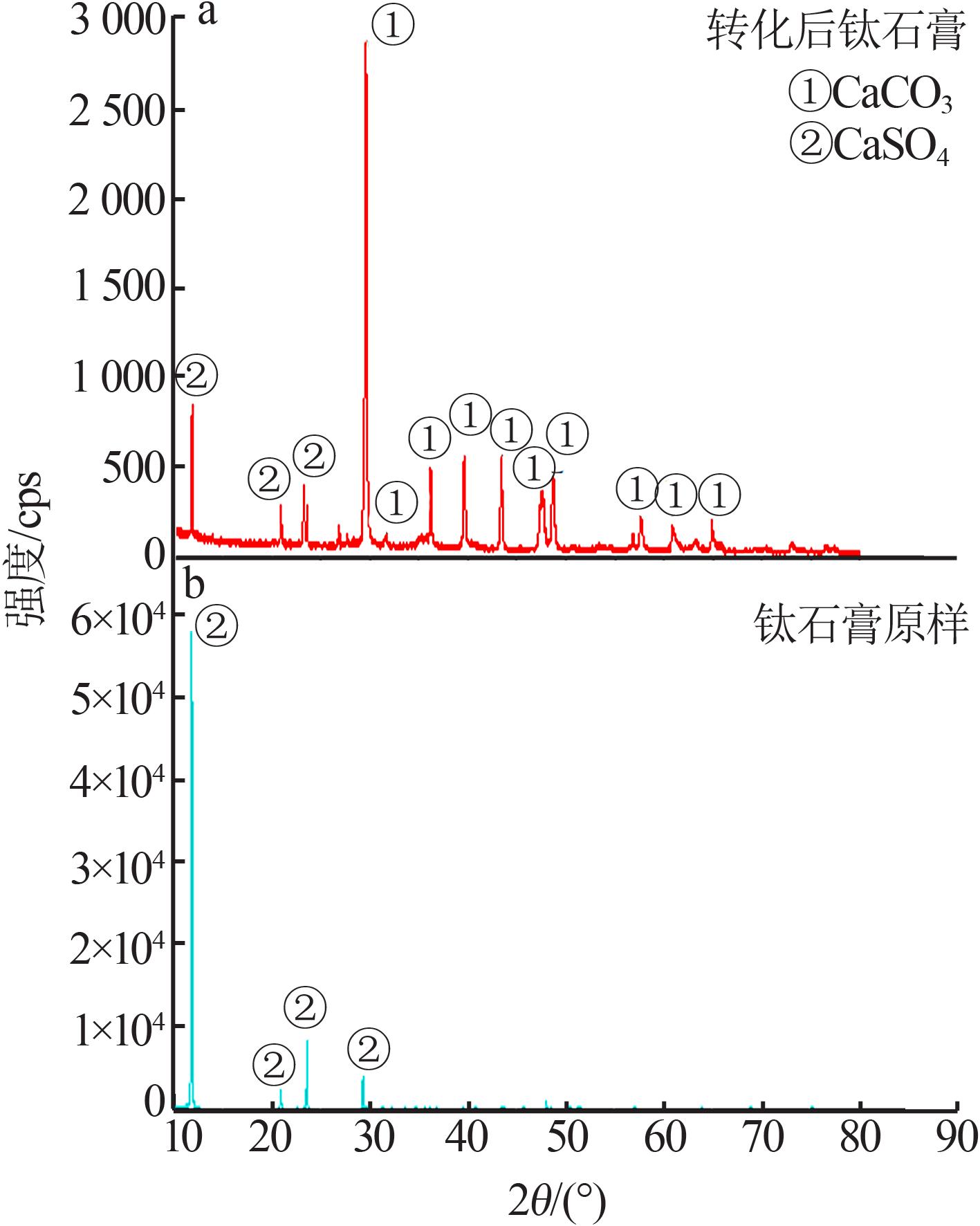

Research on mechanical drive enhancement crystallization process for titanium gypsum

[J]. Inorganic Chemicals Industry, 2023, 55(11): 78-85.

|

| [9] |

HU Luoxing,HUANG Qimao,QU Hongyou.

Preparation of Fe3O4 from FeCl2 by-product of new process of titanium dioxide by hydrochloric acid

[J]. Inorganic Chemicals Industry, 2023, 55(1): 118-123.

|

| [10] |

ZHU Wanye,TANG Ding,CHI Heting,LIAO Xianghui,ZHUANG Rongchuan,WANG Qiankun,SHEN Qingfeng.

Study on impurity removal rule of ferrous sulfate from by-product of titanium dioxide by crystallization purification

[J]. Inorganic Chemicals Industry, 2022, 54(7): 105-109.

|

| [11] |

HE Lei,ZHU Ganyu,ZHENG Guangming,WU Wenfen,ZhANG Jianbo,LI Fang,LI Huiquan,CHEN Wen.

Study on crystallization process and mechanism of phosphogypsum in wet process phosphoric acid system

[J]. Inorganic Chemicals Industry, 2022, 54(7): 110-116.

|

| [12] |

TANG Shuyang,GUO Yufeng,ZHENG Fuqiang,CHEN Feng,WANG Shuai,YANG Lingzhi.

Present situation and prospects of preparation methods of titanium dioxide

[J]. Inorganic Chemicals Industry, 2022, 54(7): 27-34.

|

| [13] |

LIANG Chao,LI Chunquan,SUN Zhiming,ZHENG Shuilin.

Surface modification effect and mechanism of new organic modifiers on ground calcium carbonate

[J]. Inorganic Chemicals Industry, 2022, 54(7): 70-77.

|

| [14] |

LIU Yaxiong.

Preparation and application of submicron cubic calcium carbonate

[J]. Inorganic Chemicals Industry, 2022, 54(7): 98-104.

|

| [15] |

WANG Youyou,YUAN Hao,HAN Qingqing,CHEN Shiying.

Activation of activator on fly ash?titanium gypsum?calcium carbide slag system and its hydration mechanism

[J]. Inorganic Chemicals Industry, 2022, 54(6): 115-119.

|

),YANG Yujun1,LUO Hui1,PAN Chunying1,WANG Guo1

),YANG Yujun1,LUO Hui1,PAN Chunying1,WANG Guo1