| [1] |

LI G J, HUANG X X, GUO J K. Preparation and characteristics of nanocrystalline NiO by organic solvent method[J]. Materials Letters, 2001, 51(4):325-330.

doi: 10.1016/S0167-577X(01)00312-3

|

| [2] |

何焕华, 蔡乔方. 中国镍钴冶金[M].2版. 北京: 冶金工业出版社, 2009:641-642.

|

| [3] |

SATHISHA D, NAIK K G. Synjournal and characterization of nickel oxide nanostructures by hydrothermal method[J]. Advanced Science Letters, 2018, 24(8):5691-5694.

doi: 10.1166/asl.2018.12178

|

| [4] |

PRADEEP K V, MATHWE S, ANAND V R, et al. Defect level dependent visible emission of nickel oxide nanoparticles through controlled calcination temperature[J]. Optik, 2021, 231.Doi: 10.1016/j.ijleo.2021.166388.

doi: 10.1016/j.ijleo.2021.166388

|

| [5] |

GUPTA P, MAURYA S, PANDEY N K, et al. Structural,electrical and humidity sensing properties of nano-structured nickel oxide prepared by sol-gel method[J]. Journal of Materials Science:Materials in Electronics, 2021, 32(3):3529-3542.

doi: 10.1007/s10854-020-05099-4

|

| [6] |

SUNANDA K K, KARAN S, BHASKAR B. Electrodeposited MnO2NiO composites as a Pt free counter electrode for dye-sensitized solar cells[J]. Journal of Electronic Materials, 2020, 49(3):2197-2202.

doi: 10.1007/s11664-019-07925-w

|

| [7] |

KUMAR P R, PRASAD N, VEILLON F, et al. Raman spectroscopic and magnetic properties of europium doped nickel oxide nanoparticles prepared by microwave-assisted hydrothermal method[J]. Journal of Alloys and Compounds, 2021, 858.Doi: 10.1016/j.jallcom.2020.157639.

doi: 10.1016/j.jallcom.2020.157639

|

| [8] |

汪芳, 黄寅生, 赵宇. 固相法合成纳米MgO和NiO的实验探究[J]. 材料导报, 2013, 27(1):17-20.

|

| [9] |

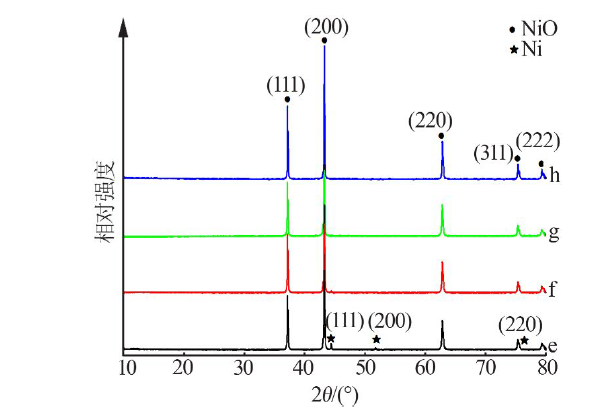

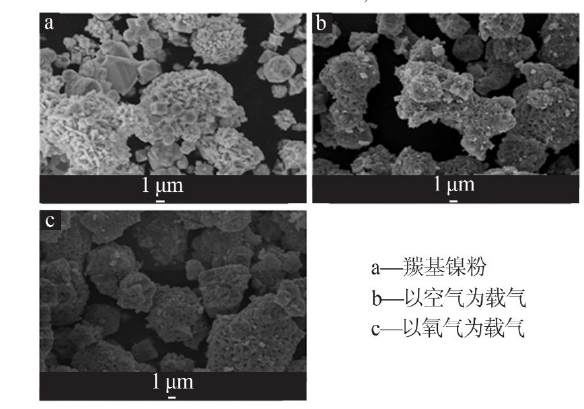

张新涛, 张科翠, 张娟, 等. 喷雾热解氧化亚镍制备微细镍粉工艺研究[J]. 有色金属:冶炼部分, 2019(3):64-67.

|

| [10] |

郭秋松, 郭学益, 田庆华. 溶液雾化焙烧法制备氧化亚镍超细粉体[J]. 材料科学与工艺, 2011, 19(2):47-51.

|

| [11] |

NOBUYUKI G, SHOHEI N, TSUYOSHI H, et al. Steam reforming of methane using double-walled reformer tubes containing hightemperature thermal storage Na2CO3/MgO composites for solar fuel production[J]. Energy, 2014, 68(4):773-782.

doi: 10.1016/j.energy.2014.01.107

|

| [12] |

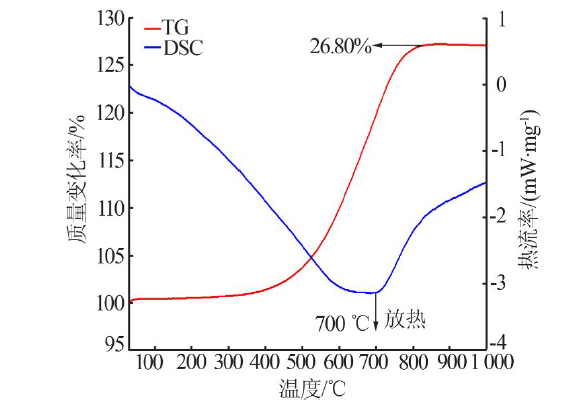

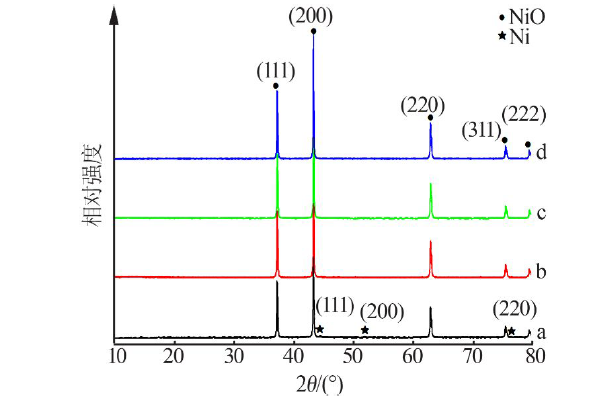

张荣良, 嵇立磊, 居殿春, 等. 碱式碳酸镍热解法制备氧化亚镍粉末的研究[J]. 无机盐工业, 2018, 50(5):33-35,39.

|

| [13] |

郭学益, 黄凯, 张多默, 等. 尿素均相沉淀法制备均分散氧化亚镍粉末(Ⅱ)——前驱体的热分解研究[J]. 中南工业大学学报, 1999, 30(4):378-381.

|

),FENG Xiaorui1,2(

),FENG Xiaorui1,2( ),LU Xiangjie1,2,GAO Xiaoqin1,2,FENG Yan1,2,HE Yan1,2

),LU Xiangjie1,2,GAO Xiaoqin1,2,FENG Yan1,2,HE Yan1,2