Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (8): 101-105.doi: 10.19964/j.issn.1006-4990.2020-0531

• Environment·Health·Safety • Previous Articles Next Articles

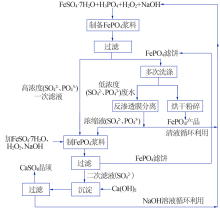

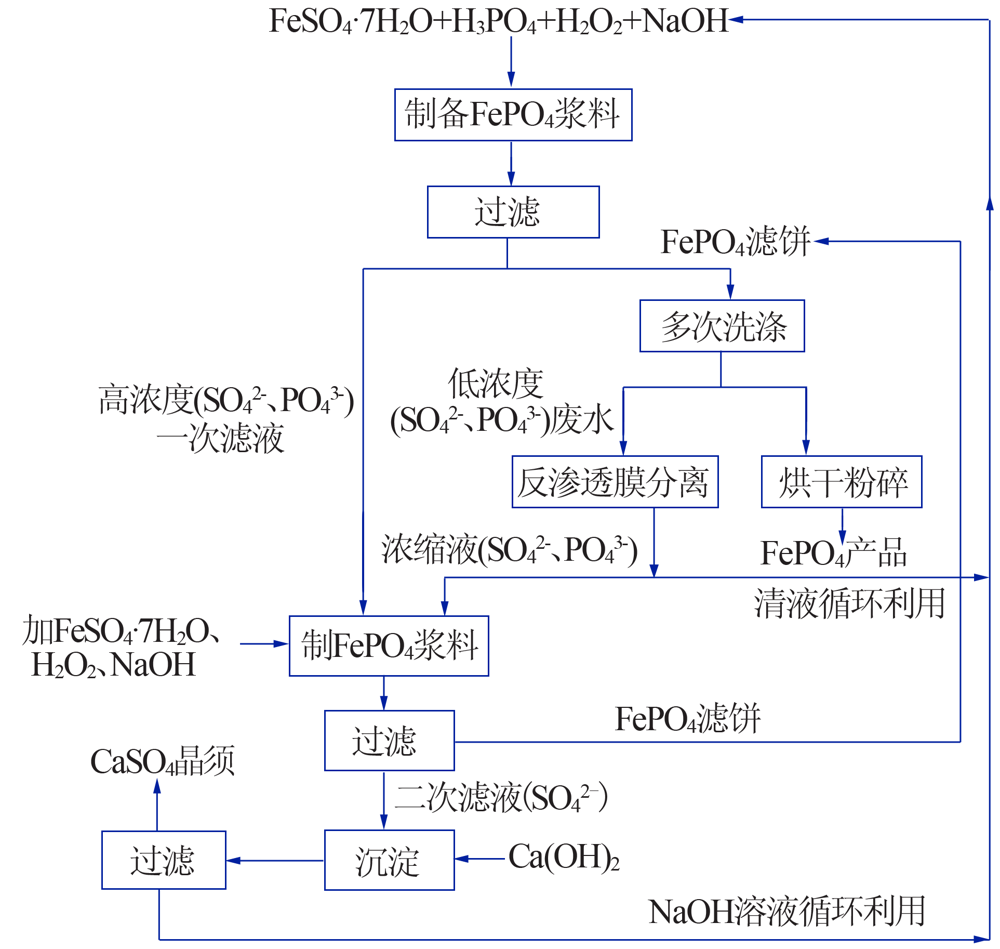

Study on reverse osmosis membrane process with zero-discharge for treating of wastewater from iron phosphate production

Liu maoju( ),Gong Fuzhong(

),Gong Fuzhong( ),Tie Yunfei,Li Yanlin

),Tie Yunfei,Li Yanlin

- College of chemistry and chemical engineering,Guangxi university,Nanning,530004,China