Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (4): 31-36.doi: 10.19964/j.issn.1006-4990.2024-0259

• Research & Development • Previous Articles Next Articles

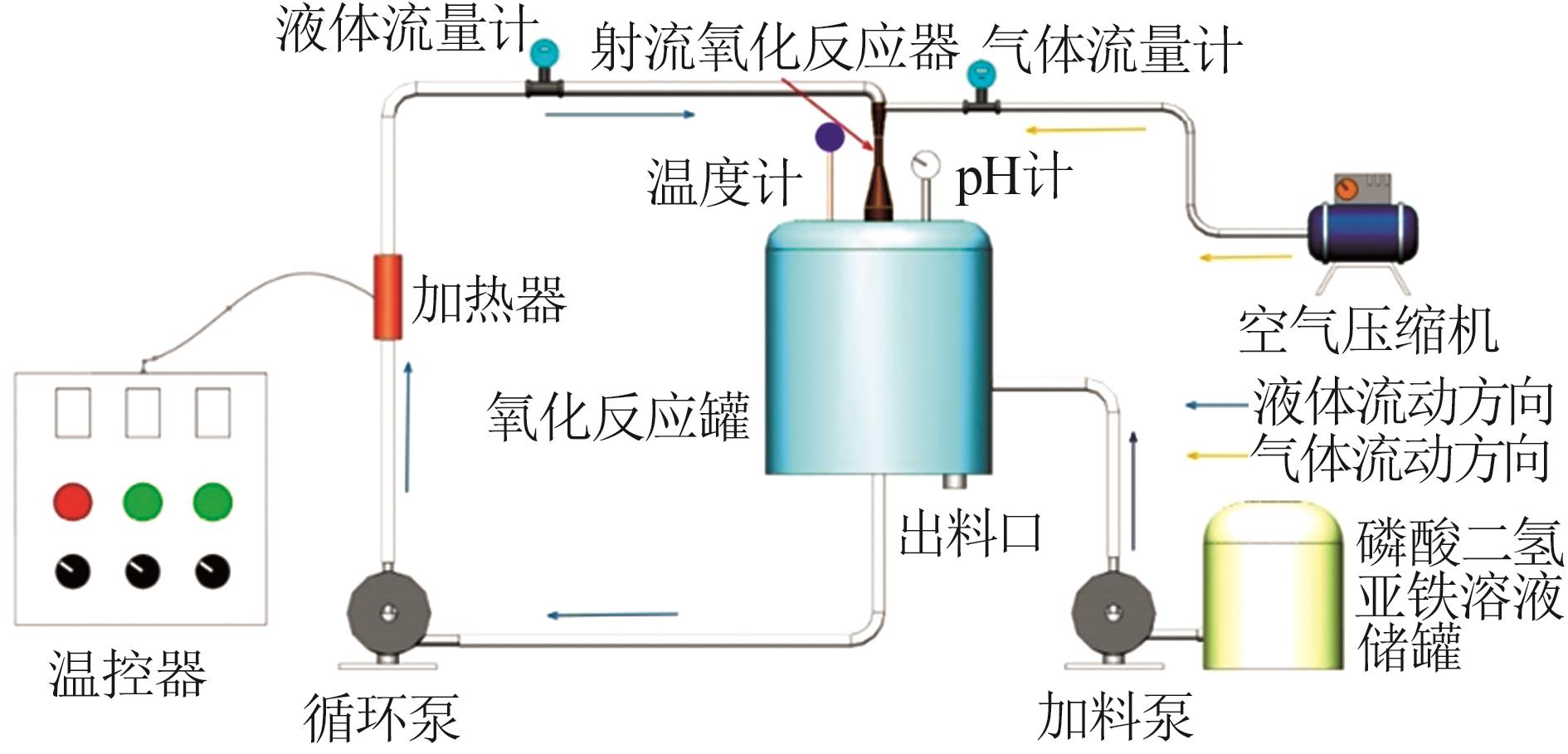

Preparation of battery-grade iron phosphate by jet-enhanced air oxidation method

YU Hesong( ), WANG Dexi, YU Honglei(

), WANG Dexi, YU Honglei( ), ZUO Maosheng, LI Jiazhi

), ZUO Maosheng, LI Jiazhi

- School of Mechanical Engineering,Shenyang University of Technology,Shenyang 110870,China

-

Received:2024-05-09Online:2025-04-10Published:2024-06-11 -

Contact:YU Honglei E-mail:yu1820767418@163.com;braveyhl@163.com

CLC Number:

Cite this article

YU Hesong, WANG Dexi, YU Honglei, ZUO Maosheng, LI Jiazhi. Preparation of battery-grade iron phosphate by jet-enhanced air oxidation method[J]. Inorganic Chemicals Industry, 2025, 57(4): 31-36.

share this article

Table 3

Carbonization orthogonal test results"

| 序号 | A | B | C | D | E | D50/μm | Φ/% |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 8.85 | 60.18 |

| 2 | 1 | 2 | 2 | 2 | 2 | 9.27 | 72.57 |

| 3 | 1 | 3 | 3 | 3 | 3 | 9.98 | 84.85 |

| 4 | 1 | 4 | 4 | 4 | 4 | 8.35 | 89.51 |

| 5 | 1 | 5 | 5 | 5 | 5 | 10.06 | 83.21 |

| 6 | 2 | 1 | 2 | 3 | 4 | 6.62 | 74.23 |

| 7 | 2 | 2 | 3 | 4 | 5 | 6.07 | 86.29 |

| 8 | 2 | 3 | 4 | 5 | 1 | 9.89 | 86.25 |

| 9 | 2 | 4 | 5 | 1 | 2 | 7.57 | 81.19 |

| 10 | 2 | 5 | 1 | 2 | 3 | 10.17 | 78.18 |

| 11 | 3 | 1 | 3 | 5 | 2 | 6.24 | 84.25 |

| 12 | 3 | 2 | 4 | 1 | 3 | 3.35 | 85.34 |

| 13 | 3 | 3 | 5 | 2 | 4 | 5.01 | 89.93 |

| 14 | 3 | 4 | 1 | 3 | 5 | 8.43 | 79.26 |

| 15 | 3 | 5 | 2 | 4 | 1 | 11.76 | 82.41 |

| 16 | 4 | 1 | 4 | 2 | 5 | 2.64 | 81.28 |

| 17 | 4 | 2 | 5 | 3 | 1 | 5.47 | 84.84 |

| 18 | 4 | 3 | 1 | 4 | 2 | 8.77 | 84.37 |

| 19 | 4 | 4 | 2 | 5 | 3 | 8.43 | 90.85 |

| 20 | 4 | 5 | 3 | 1 | 4 | 4.58 | 87.61 |

| 21 | 5 | 1 | 5 | 4 | 3 | 4.53 | 91.37 |

| 22 | 5 | 2 | 1 | 5 | 4 | 8.31 | 83.73 |

| 23 | 5 | 3 | 2 | 1 | 5 | 4.61 | 76.55 |

| 24 | 5 | 4 | 3 | 2 | 1 | 7.52 | 83.56 |

| 25 | 5 | 5 | 4 | 3 | 2 | 6.15 | 92.04 |

| k1(D50) | 9.302 | 5.776 | 8.906 | 5.792 | 8.698 | ||

| k2(D50) | 8.064 | 6.494 | 8.138 | 6.922 | 7.600 | ||

| k3(D50) | 6.958 | 7.652 | 6.878 | 7.330 | 7.292 | ||

| k4(D50) | 5.978 | 8.060 | 6.076 | 7.896 | 6.574 | ||

| k5(D50) | 6.224 | 8.544 | 6.528 | 8.586 | 6.362 | ||

| R(D50) | 3.324 | 2.768 | 2.830 | 2.794 | 2.336 | ||

| k1(Φ) | 78.064 | 78.262 | 77.144 | 78.174 | 79.448 | ||

| k2(Φ) | 81.228 | 82.554 | 79.322 | 81.104 | 82.884 | ||

| k3(Φ) | 84.238 | 84.390 | 85.312 | 83.044 | 86.118 | ||

| k4(Φ) | 85.790 | 84.874 | 86.884 | 86.790 | 85.002 | ||

| k5(Φ) | 85.450 | 84.690 | 86.108 | 85.658 | 81.318 | ||

| R(Φ) | 7.726 | 6.612 | 9.740 | 8.616 | 6.670 |

| [1] | WANG Yuesheng, YANG Shize, YOU Ya,et al.High-capacity and long-cycle life aqueous rechargeable lithium-ion battery with the FePO4 anode[J].ACS Applied Materials & Interfaces,2018,10(8):7061-7068. |

| [2] | 张婷,林森,于建国.磷酸铁锂正极材料的制备及性能强化研究进展[J].无机盐工业,2021,53(6):31-40. |

| ZHANG Ting, LIN Sen, YU Jianguo.Research progress in synthesis and performance enhancement of LiFePO4 cathode materials[J].Inorganic Chemicals Industry,2021,53(6):31-40. | |

| [3] | WANG Xiaoyan, WEN Lizhi, ZHENG Yi,et al.Effect of FeSO4 purity on low temperature performance of LiFePO4/C[J].Ionics,2020,26(9):4433-4442. |

| [4] | 吴康,李军,陈明.乙醇-水体系3D纳/微米球形磷酸铁的制备与表征[J].无机盐工业,2020,52(6):41-45. |

| WU Kang, LI Jun, CHEN Ming.Synthesis and characterization of 3D nano/micro spherical iron phosphate in ethanol-water sys-tem[J].Inorganic Chemicals Industry,2020,52(6):41-45. | |

| [5] | DENG Yuanfu, YANG Chunxiang, ZOU Kaixiang,et al.Recent advances of Mn‐rich LiFe1‐ y Mn y PO4(0.5≤y<1.0) cathode materials for high energy density lithium ion batteries[J].Advanced Energy Materials,2017,7(13):1601958. |

| [6] | 袁文龙,王碧侠,赵瑛,等.用钛白副产硫酸亚铁合成磷酸铁前驱体[J].有色金属工程,2023,13(7):61-68. |

| YUAN Wenlong, WANG Bixia, ZHAO Ying,et al.Synthesis of iron phosphate precursor from by-product ferrous sulfate of titanium dioxide[J].Nonferrous Metals Engineering,2023,13(7):61-68. | |

| [7] | DANG Leping, ZHANG Hongtao, XU Xin,et al.Preparation of spherical FePO4 by chemical co-precipitation combined with spray-drying[J].Transactions of Tianjin University,2020,26(1):57-66. |

| [8] | 马毅,沈文喆,袁梅梅,等.磷铁渣制备电池级纳米磷酸铁[J].化工进展,2019,38(11):5015-5023. |

| MA Yi, SHEN Wenzhe, YUAN Meimei,et al.Preparation of battery grade nano iron phosphate by using ferro-phosphorus as raw material[J].Chemical Industry and Engineering Progress,2019,38(11):5015-5023. | |

| [9] | 姚耀春,鲁劲华,马毅,等.用铁粉制备电池级材料磷酸铁的试验研究[J].湿法冶金,2019,38(2):140-144. |

| YAO Yaochun, LU Jinhua, MA Yi,et al.Preparation of battery grade ferric phosphate using iron powder[J].Hydrometallurgy of China,2019,38(2):140-144. | |

| [10] | GUO Ju, MO Xinliang, WU Fuyong,et al.A novel environment-friendly synthesis of high purity micron iron phosphate and its application as a precursor of lithium iron phosphate[J].Materials Research Express,2020,7(9):095504. |

| [11] | 刘烺,王鹏,周星辰,等.空气氧化法制备FePO4超细颗粒[J].中国粉体技术,2013,19(2):24-27,32. |

| LIU Lang, WANG Peng, ZHOU Xingchen,et al.Preparation of FePO4 ultrafine particles by air oxidation method[J].China Powder Science and Technology,2013,19(2):24-27,32. | |

| [12] | 唐涛,孙少先,应皆荣.空气和氧气氧化沉淀法制备FePO4·2H2O及LiFePO4 [J].电源技术,2020,44(1):17-20. |

| TANG Tao, SUN Shaoxian, YING Jierong.Preparation of FePO4·2H2O via air and oxygen oxidizing precipitation and downstream product LiFePO4 [J].Chinese Journal of Power Sources,2020,44(1):17-20. | |

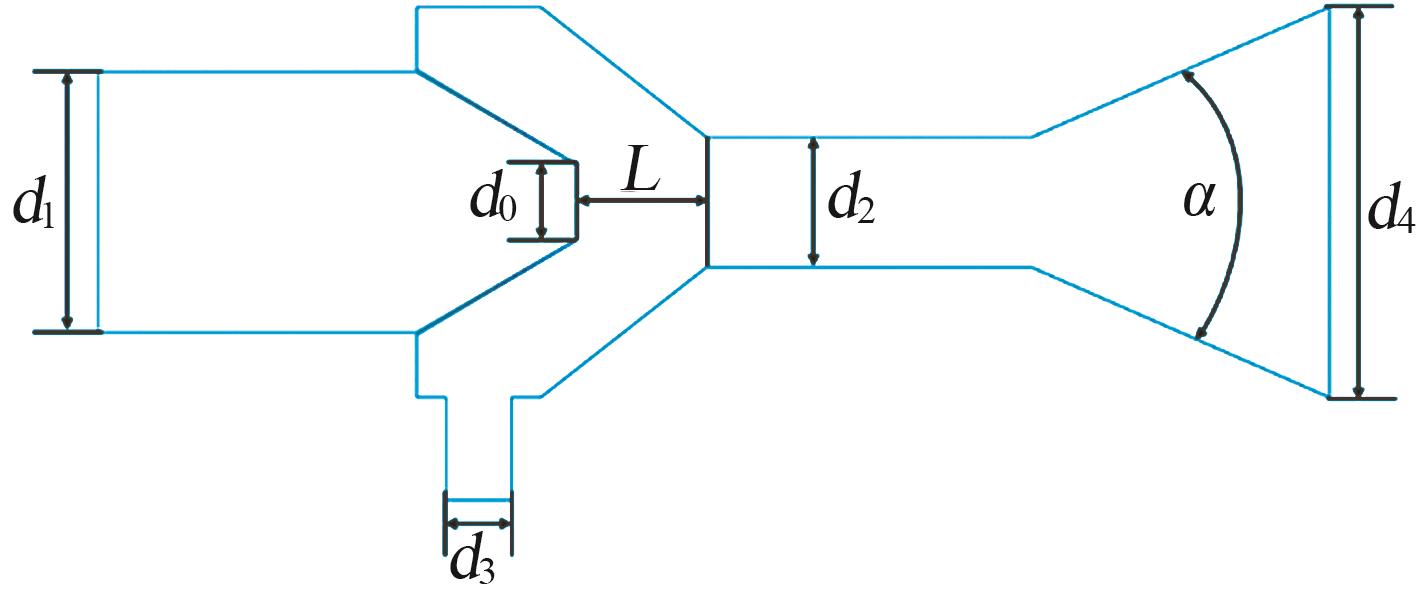

| [13] | 颜攀,黄正梁,王靖岱,等.文丘里气泡发生器的气泡尺寸及分布[J].浙江大学学报(工学版),2017,51(10):2070-2076. |

| YAN Pan, HUANG Zhengliang, WANG Jingdai,et al.Bubble size and its distribution for Venturi bubble generator[J].Journal of Zhejiang University(Engineering Science),2017,51(10):2070-2076. | |

| [14] | 褚付州,任腾,王德喜,等.制备磷酸铁的氧化反应器数值模拟分析[J].化学工程,2023,51(11):73-78,83. |

| CHU Fuzhou, REN Teng, WANG Dexi,et al.Numerical simulation analysis of oxidation reactor for preparation of iron phospha-te[J].Chemical Engineering(China),2023,51(11):73-78,83. | |

| [15] | 杨涵硕,王德喜,于红蕾,等.水力空化强化碳化反应制备碱式碳酸镁的实验研究[J].无机盐工业,2024,56(7):74-79. |

| YANG Hanshuo, WANG Dexi, YU Honglei,et al.Experimental study on hydrodynamic cavitation-enhanced carbothermic reduction process for production of magnesium carbonate hydromagnesite[J].Inorganic Chemicals Industry,2024,56(7):74-79. | |

| [16] | BARLAK M S, DEĞERMENCI N, CENGIZ İ,et al.Comparison of phenol removal with ozonation in jet loop reactor and bubble column[J].Journal of Environmental Chemical Engineering,2020,8(5):104402. |

| [17] | 崔丽丽.污水曝氧工艺适应性研究[J].中国石油和化工标准与质量,2023,43(15):166-168. |

| CUI Lili.Study on the adaptability of sewage aeration process[J].China Petroleum and Chemical Standard and Quality,2023,43(15):166-168. | |

| [18] | 刘彩,程先明,冯文平,等.电池级磷酸铁的合成工艺优化及其性能研究[J].盐科学与化工,2024,53(2):17-22. |

| LIU Cai, CHENG Xianming, FENG Wenping,et al.Study on process optimization and performance of the synthesis of battery-grade iron phosphate[J].Journal of Salt and Chemical Industry,2024,53(2):17-22. | |

| [19] | 章洪涛.球形磷酸铁前驱体的制备过程研究[D].天津:天津大学,2019. |

| ZHANG Hongtao.Study on preparation process of spherical iron phosphate precursor[D].Tianjin:Tianjin University,2019. |

| [1] | REN Genkuan, LUO Xin, ZHU Denglei, ZHANG Min. Thermodynamic analysis and experiment research on preparation of α-Fe2O3nanoparticles by solid-phase reduction method [J]. Inorganic Chemicals Industry, 2025, 57(4): 73-78. |

| [2] | LI Ping, LI Jun, CHEN Ming. Study on process of recovery of Fe(Ⅲ) from spent lithium extractant and preparation of battery grade iron phosphate [J]. Inorganic Chemicals Industry, 2024, 56(10): 28-37. |

| [3] | WANG Junting, MA Hang, ZHA Zuotong, WAN Banglong, ZHANG Zhenhuan. Research progress of iron phosphate industrial wastewater treatment process [J]. Inorganic Chemicals Industry, 2024, 56(6): 26-33. |

| [4] | CHEN Yuneng, CHEN Kunfeng, XUE Dongfeng. Research progress of preparation and device application of lithium niobate crystal ferroelectric domain [J]. Inorganic Chemicals Industry, 2024, 56(6): 1-13. |

| [5] | LI Kuai, LI Zhaoshuai, DONG Tingxuan, LI Dan, GUO Shengwei, HAN Fenglan. Study on effect of wet magnetic separation on distribution of Fe and heavy metal in fly ash [J]. Inorganic Chemicals Industry, 2024, 56(4): 98-104. |

| [6] | XU Li, ZHANG Qiang. Experimental study on properties of iron tailings powder cement-based materials [J]. Inorganic Chemicals Industry, 2023, 55(6): 116-123. |

| [7] | LIU Rui, GAO Wei, ZHANG Wenjing, AN Hongxue, LI Zaixing. Catalytic degradation of Rhodamine B by ferroferric oxide-loaded bacterial residue biochar [J]. Inorganic Chemicals Industry, 2023, 55(4): 111-119. |

| [8] | HU Luoxing,HUANG Qimao,QU Hongyou. Preparation of Fe3O4 from FeCl2 by-product of new process of titanium dioxide by hydrochloric acid [J]. Inorganic Chemicals Industry, 2023, 55(1): 118-123. |

| [9] | JIA Zhiqi,NIE Huimin,ZHAO Yongxiang. Fe0/C induced copper salt reduction coupled with chemical precipitation method to remove thiocyanate from wastewater [J]. Inorganic Chemicals Industry, 2023, 55(1): 129-135. |

| [10] | ZHENG Bin,JIANG Liang,HAN Fenglan,MA Hongru,QI Zhihong,SU Hui. Study on reformation and extracting iron of copper slag and silicon-manganese water quenched slag composites [J]. Inorganic Chemicals Industry, 2023, 55(1): 136-143. |

| [11] | ZHU Wanye,TANG Ding,CHI Heting,LIAO Xianghui,ZHUANG Rongchuan,WANG Qiankun,SHEN Qingfeng. Study on impurity removal rule of ferrous sulfate from by-product of titanium dioxide by crystallization purification [J]. Inorganic Chemicals Industry, 2022, 54(7): 105-109. |

| [12] | LU Zheng,CHEN Kunfeng,XUE Dongfeng. Study on large-scale preparation and electrochemical properties of high thermal stabilized α-Fe2O3 [J]. Inorganic Chemicals Industry, 2022, 54(3): 45-50. |

| [13] | WANG Xiaohuan,LI Shenghao,SHI Zhiming,WANG Jun,XINBA Yaer,LIU Liang. Research status of FeTiO3 materials [J]. Inorganic Chemicals Industry, 2022, 54(1): 12-17. |

| [14] | SONG Jin,WU Fenglong,WANG Yuejun. Study on preparation of Fe/modified MCM-41 catalyst with different loading methods and degradation of methylene blue [J]. Inorganic Chemicals Industry, 2021, 53(11): 122-128. |

| [15] | WANG Huijuan,WANG Chunyu,ZHANG Qiong. Research progress on the preparation of two-dimensional layered nanosheet materials and its application in electrolyzed water [J]. Inorganic Chemicals Industry, 2021, 53(11): 25-29. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||