Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (1): 136-143.doi: 10.19964/j.issn.1006-4990.2022-0230

• Environment·Health·Safety • Previous Articles Next Articles

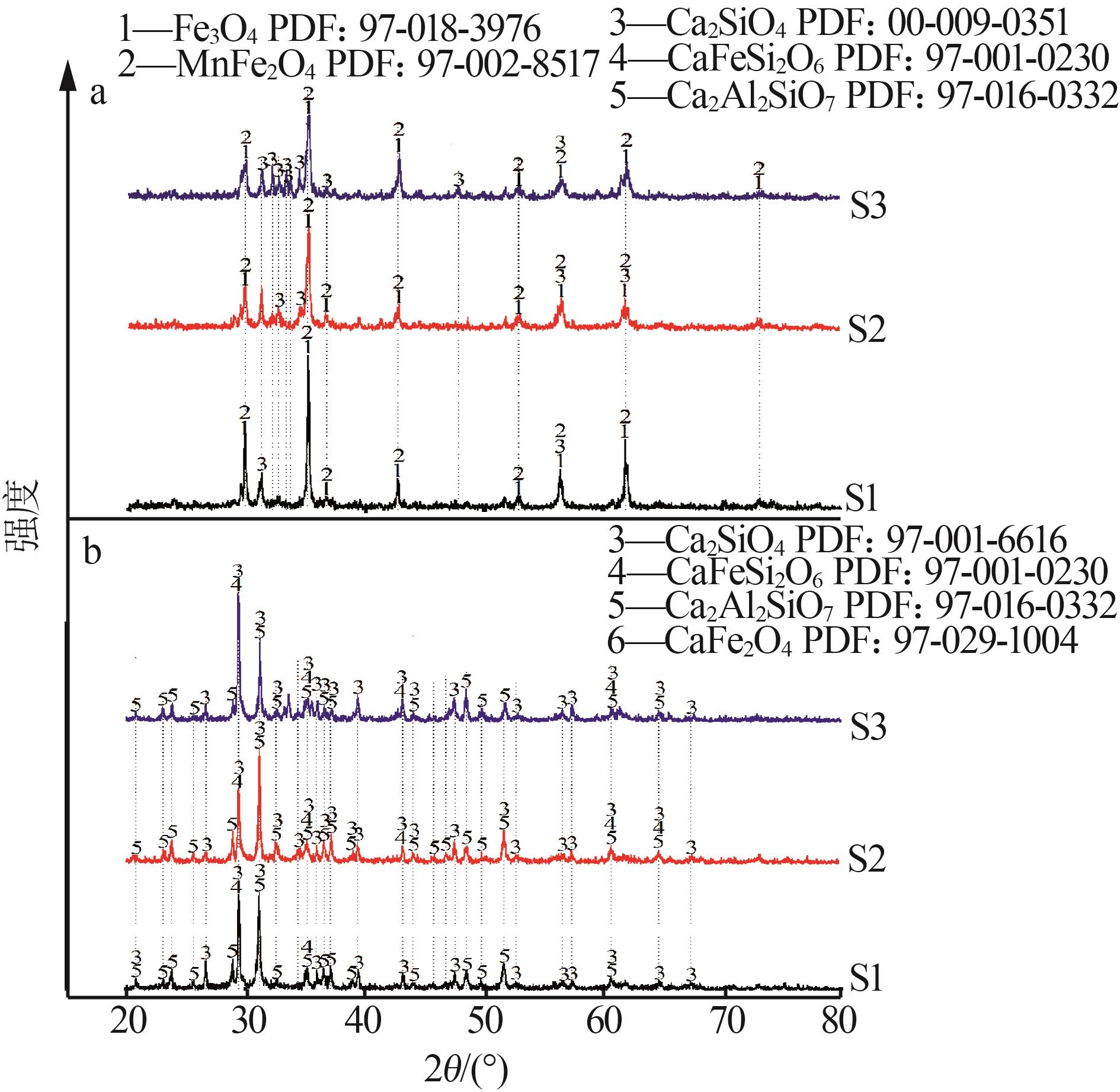

Study on reformation and extracting iron of copper slag and silicon-manganese water quenched slag composites

ZHENG Bin1( ),JIANG Liang2(

),JIANG Liang2( ),HAN Fenglan1,MA Hongru2,QI Zhihong2,SU Hui1

),HAN Fenglan1,MA Hongru2,QI Zhihong2,SU Hui1

- 1. School of Material Science and Engineering,North Minzu University,Yinchuan 750021,China

2. College of Mechanical Electrical Engineering,North Minzu University,Yinchuan 750021,China

-

Received:2022-04-21Online:2023-01-10Published:2023-01-17 -

Contact:JIANG Liang E-mail:20207330@stu.nun.edu.cn;jiangliang@nun.edu.cn

CLC Number:

Cite this article

ZHENG Bin,JIANG Liang,HAN Fenglan,MA Hongru,QI Zhihong,SU Hui. Study on reformation and extracting iron of copper slag and silicon-manganese water quenched slag composites[J]. Inorganic Chemicals Industry, 2023, 55(1): 136-143.

share this article

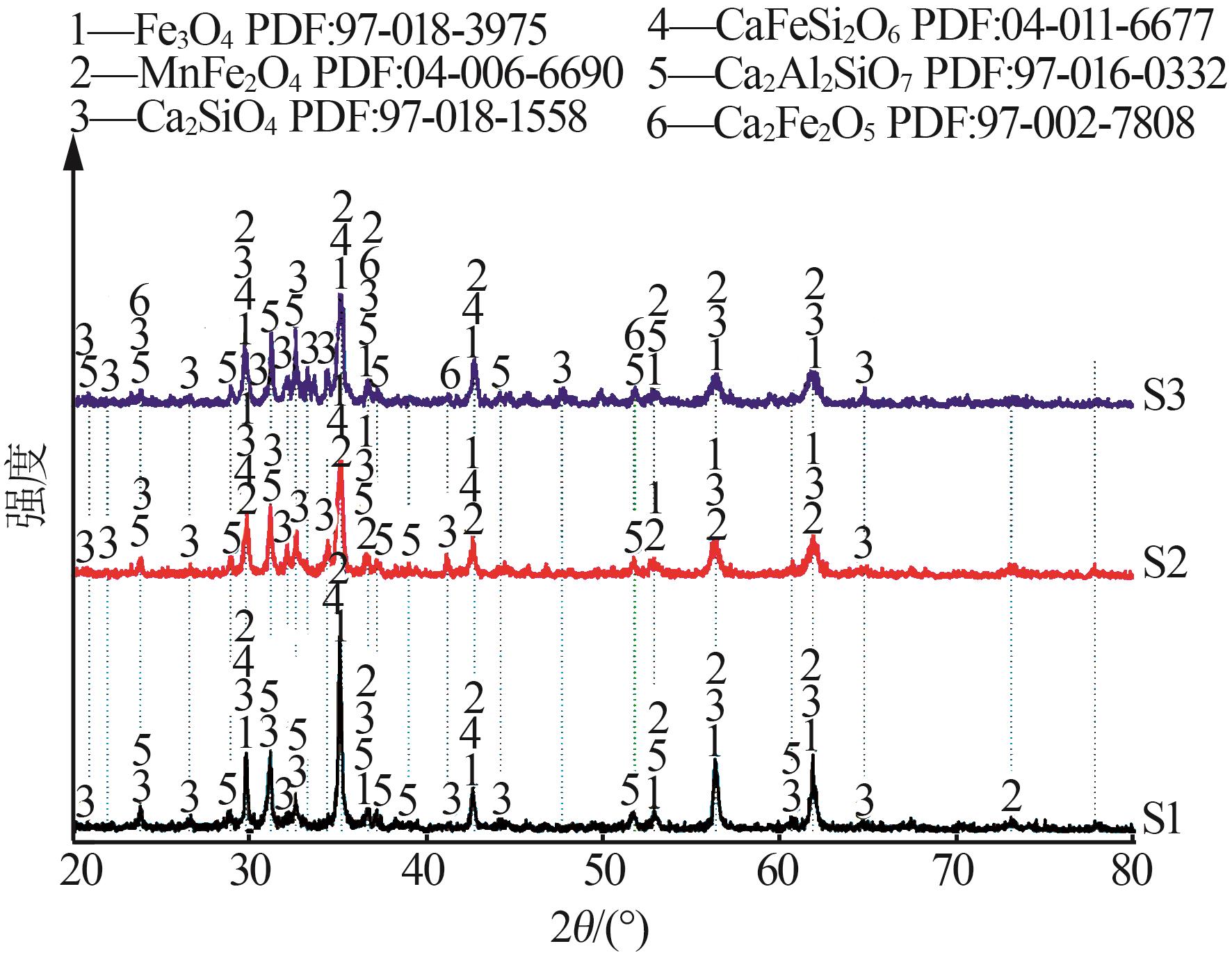

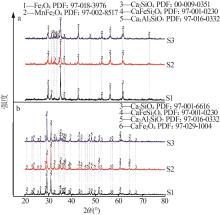

Table 2

Proportion of industrial copper slag compounded with silicon-manganese water quenching slag"

| 编号 | w(铜渣)∶w(硅锰水淬渣)∶ w(CaO)∶w(MnO) | 主要化学成分 | 碱度 | |||||

|---|---|---|---|---|---|---|---|---|

| w(SiO2)/% | w(Fe2O3)/% | w(Al2O3)/% | w(MnO)/% | w(MgO)/% | w(CaO)/% | |||

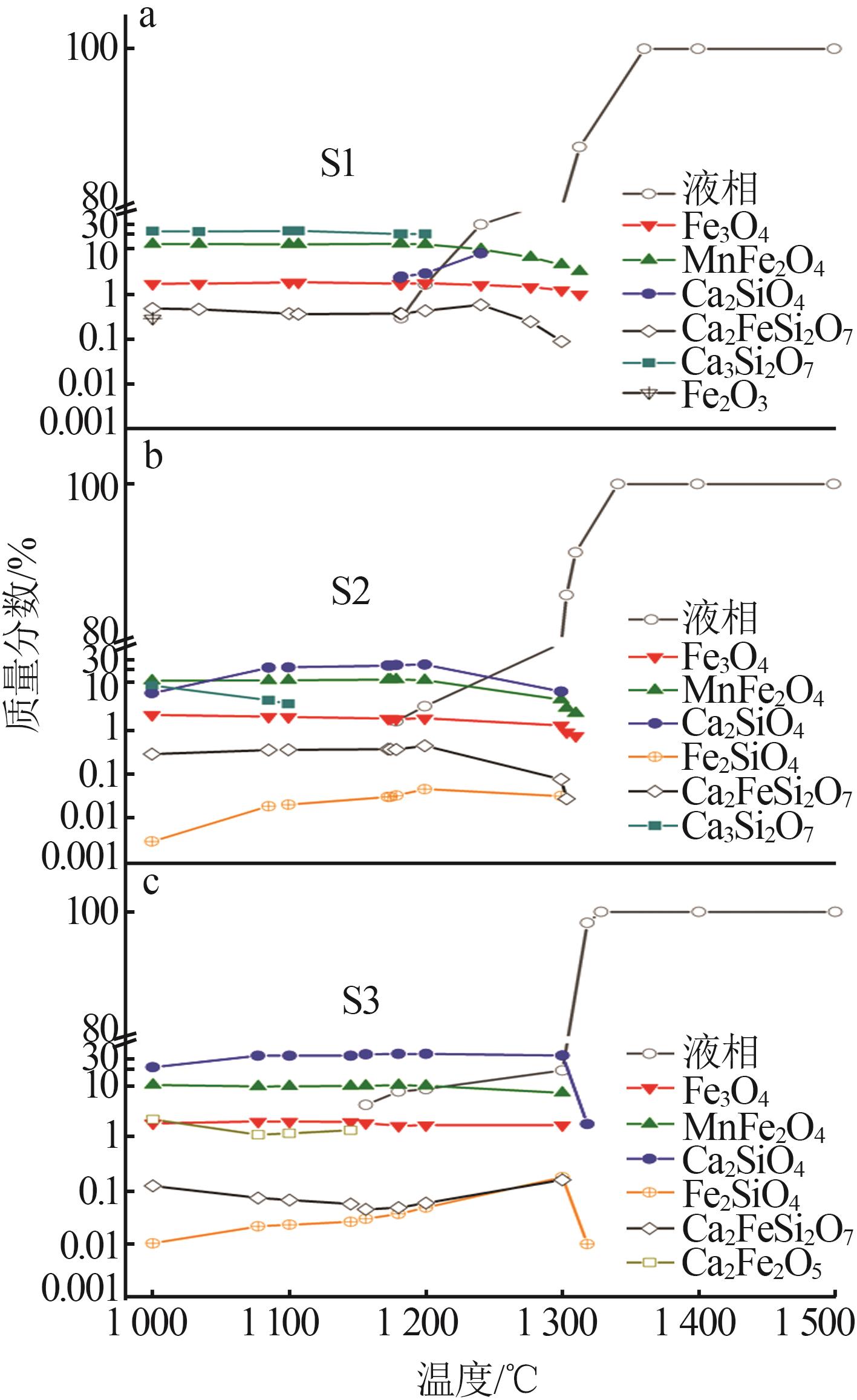

| S1 | 48%∶25%∶19%∶8% | 19.0 | 35.0 | 6.0 | 10 | 1.4 | 28.6 | 1.5 |

| S2 | 46%∶24%∶22%∶8% | 18.0 | 34.0 | 5.8 | 9.8 | 1.4 | 31 | 1.7 |

| S3 | 44%∶23%∶25%∶8% | 17.7 | 32.5 | 5.5 | 9.4 | 1.3 | 33.6 | 1.9 |

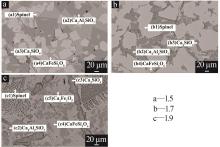

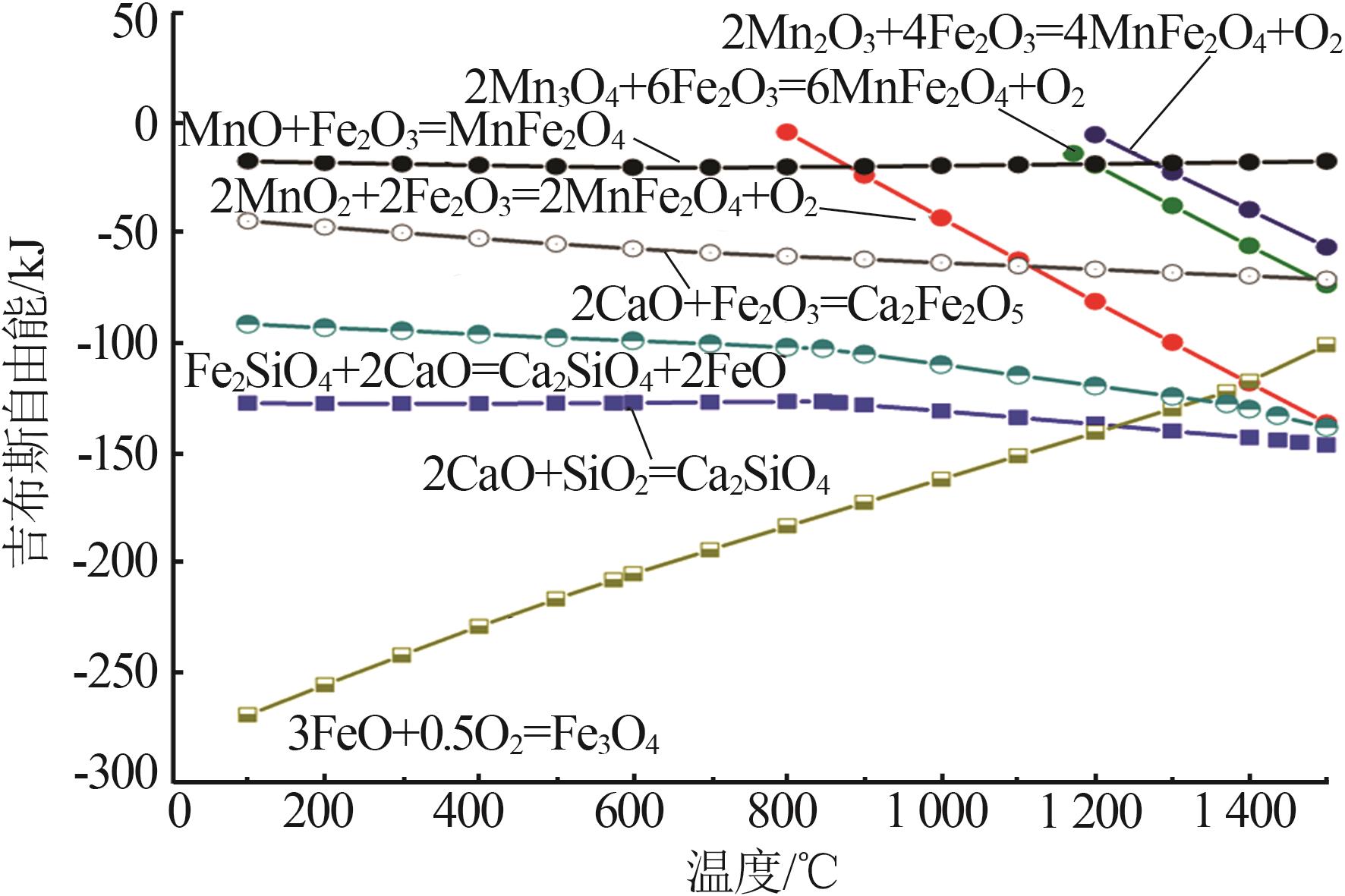

Table 3

EDS of main characteristic phases in Fig.5"

| 编号 | 可能存在 的物相 | a(O) | a(Si) | a(Al) | a(Ca) | a(Mn) | a(Mg) | a(Fe) |

|---|---|---|---|---|---|---|---|---|

| a1 | Spinel | 54.42 | 0.00 | 1.65 | 1.26 | 8.33 | 5.36 | 28.98 |

| a2 | Ca2Al2SiO7 | 59.82 | 9.42 | 8.94 | 14.99 | 0.00 | 0.75 | 6.07 |

| a3 | Ca2SiO4 | 52.04 | 16.8 | 0.00 | 31.05 | 0.00 | 0.00 | 0.00 |

| a4 | CaFeSi2O6 | 61.11 | 6.13 | 2.26 | 11.65 | 1.87 | 0.00 | 16.97 |

| b1 | Spinel | 55.56 | 0.00 | 3.16 | 1.33 | 7.9 | 6.35 | 25.7 |

| b2 | Ca2Al2SiO7 | 60.59 | 8.86 | 9.63 | 15.09 | 0.00 | 0.00 | 5.82 |

| b3 | Ca2SiO4 | 62.64 | 13.17 | 0.00 | 23.87 | 0.00 | 0.00 | 0.32 |

| b4 | CaFeSi2O6 | 60.12 | 6.80 | 1.89 | 10.58 | 1.80 | 1.32 | 17.42 |

| c1 | Spinel | 57.92 | 0.00 | 2.89 | 0.98 | 7.93 | 8.15 | 22.14 |

| c2 | Ca2Al2SiO7 | 61.29 | 8.14 | 11.07 | 14.4 | 0.00 | 0.23 | 4.86 |

| c3 | Ca2SiO4 | 66.57 | 11.54 | 0.00 | 21.5 | 0.13 | 0.00 | 0.26 |

| c4 | CaFeSi2O6 | 61.31 | 7.85 | 4.76 | 13.01 | 1.34 | 0.42 | 11.31 |

| c5 | Ca2Fe2O5 | 57.69 | 0.00 | 0.73 | 11.83 | 4.46 | 0.00 | 25.28 |

| 1 | National Bureau of Statistics of China. Monthly data[EB/OL].(2021-11-30)[2021-12-30]. |

| 2 | SHI Caijun, MEYER C, BEHNOOD A. Utilization of copper slag in cement and concrete[J].Resources,Conservation and Recycling, 2008, 52(10):1115-1120. |

| 3 | 苗希望, 白智韬, 卢光华, 等. 典型铁合金渣的资源化综合利用研究现状与发展趋势[J].工程科学学报, 2020, 42(6):663-679. |

| MIAO Xiwang, BAI Zhitao, LU Guanghua, et al. Review of comprehensive utilization of typical ferroalloy slags[J].Chinese Journal of Engineering, 2020, 42(6):663-679. | |

| 4 | 李宇, 刘月明. 我国冶金固废大宗利用技术的研究进展及趋势[J].工程科学学报, 2021, 43(12):1713-1724. |

| LI Yu, LIU Yueming. Progress and trend of bulk utilization technology of metallurgical solid wastes in China[J].Chinese Journal of Engineering, 2021, 43(12):1713-1724. | |

| 5 | 吴龙, 郝以党. 铜渣资源化利用现况及高效化利用探讨[J].中国有色冶金, 2015, 44(2):61-64. |

| WU Long, HAO Yidang. The investigation of utilization status of copper slag resources and efficient utilization[J].China Nonferrous Metallurgy, 2015, 44(2):61-64. | |

| 6 | 杨涛, 胡建杭, 王华, 等. 铜电炉冶炼贫化渣焙烧富集Fe3O4 [J].过程工程学报, 2011, 11(4):613-619. |

| YANG Tao, HU Jianhang, WANG Hua, et al. Concentration of Fe3O4 in roasted slag from copper impoverishment smelting[J].The Chinese Journal of Process Engineering, 2011, 11(4):613- 619. | |

| 7 | 许冬, 春铁军, 陈锦安. 铜渣高温快速还原焙烧-磁选回收铁的研究[J].矿冶工程, 2017, 37(1):89-91, 95. |

| XU Dong, CHUN Tiejun, CHEN Jinan. Iron recovery from copper slag by a combined technique of high-temperature reduction roasting and magnetic separation[J].Mining and Metallurgical Engineering, 2017, 37(1):89-91, 95. | |

| 8 | CHOI S, KIM J,OH S,et al. Hydro-thermal reaction according to the CaO/SiO2 mole-ratio in silico-manganese slag[J].Journal of Material Cycles and Waste Management, 2017, 19(1):374-381. |

| 9 | PAN De'an, LI Lili, WU Yufeng, et al. Characteristics and properties of glass-ceramics using lead fuming slag[J].Journal of Cleaner Production, 2018, 175:251-256. |

| 10 | SEMYKINA A, SHATOKHA V, IWASE M, et al. Kinetics of oxidation of divalent iron to trivalent state in liquid FeO-CaO-SiO2 slags[J].Metallurgical and Materials Transactions B, 2010, 41(6):1230-1239. |

| 11 | FILCENCO OLTEANU A, DOBRE T, PANTURU E, et al. Experimental process analysis and mathematical modeling for selective gold leaching from slag through wet chlorination[J].Hydrometallurgy, 2014, 144-145:170-185. |

| 12 | 薛超龙, 李慧, 梁精龙, 等. 铜渣资源回收的研究现状及展望[J].中国冶金, 2022, 32(2):108-114. |

| XUE Chaolong, LI Hui, LIANG Jinglong, et al. Research status and prospects of copper slag resource recovery[J].China Metallurgy, 2022, 32(2):108-114. | |

| 13 |

WANG Dengquan, WANG Qiang, HUANG Zongxian. Reuse of copper slag as a supplementary cementitious material:Reactivity and safety[J].Resources,Conservation and Recycling, 2020, 162.Doi:10.1016/j.resconrec.2020.105037.

doi: 10.1016/j.resconrec.2020.105037 |

| 14 |

SHARIFI Y, AFSHOON I, ASAD-ABADI S, et al. Environmental protection by using waste copper slag as a coarse aggregate in self-compacting concrete[J].Journal of Environmental Management, 2020, 271.Doi:10.1016/j.jenvman.2020.111013.

doi: 10.1016/j.jenvman.2020.111013 |

| 15 | 包焕均, 张晓雪, 王洪阳, 等. 铜渣中铁硅分离的研究进展[J].有色金属科学与工程, 2021, 12(5):30-38. |

| BAO Huanjun, ZHANG Xiaoxue, WANG Hongyang, et al. Research progress on the separation of iron and silicon from copper slag[J].Nonferrous Metals Science and Engineering, 2021, 12(5):30-38. | |

| 16 | SHU Q F, LIU Y. Effects of basicity,MgO and MnO on mineralogical phases of CaO-FeO x -SiO2-P2O5 slag[J].Ironmaking & Steelmaking, 2018, 45(4):363-370. |

| 17 | LI Siwei, PAN Jian, ZHU Deqing, et al. A novel process to upgrade the copper slag by direct reduction-magnetic separation with the addition of Na2CO3 and CaO[J].Powder Technology, 2019, 347:159-169. |

| 18 | 刘金生, 姜平国, 肖义钰, 等. 从铜渣中回收铁的研究现状及其新方法的提出[J].有色金属科学与工程, 2019, 10(2):19-24. |

| LIU Jinsheng, JIANG Pingguo, XIAO Yiyu, et al. Research status and new method of recovering iron from copper slag[J].Nonferrous Metals Science and Engineering, 2019, 10(2):19-24. | |

| 19 | 蒋亮, 吴婷, 马良富, 等. 改质转炉钢渣的易磨性研究[J].硅酸盐通报, 2018, 37(12):4034-4039. |

| JIANG Liang, WU Ting, MA Liangfu, et al. Research on grindability of modified BOF slag[J].Bulletin of the Chinese Ceramic Society, 2018, 37(12):4034-4039. | |

| 20 | 牛丽萍, 刘捷元, 宋锦波, 等. 熔融铜渣天然气还原过程的研究[J].材料与冶金学报, 2016, 15(3):200-204, 208. |

| NIU Liping, LIU Jieyuan, SONG Jinbo, et al. Study on reduction process of melting copper slag with natural gas[J].Journal of Materials and Metallurgy, 2016, 15(3):200-204, 208. | |

| 21 | ZHANG Xufang, NI Wen, WU Junyu, et al. Hydration mechanism of a cementitious material prepared with Si-Mn slag[J].International Journal of Minerals,Metallurgy,and Materials, 2011, 18(2):234-239. |

| 22 |

LI Jianli, MOU Qiqiang, ZENG Qiang, et al. Experimental study on precipitation behavior of spinels in stainless steel-making slag under heating treatment[J].Processes, 2019, 7(8).Doi:10.3390/pr7080487.

doi: 10.3390/pr7080487 |

| 23 | BALE C W. FactSage thermochemical software and databases:Recent developments[J].Calphad, 2009, 33(2):295-311. |

| 24 | JIANG Pingguo, LIU Jinsheng, XIAO Yiyu, et al. Recovery of iron from copper slag via modified roasting in CO-CO2 mixed gas and magnetic separation[J].Journal of Iron and Steel Research International, 2020, 27(7):796-806. |

| 25 | 高颖, 王伟赫, 陈萌, 等. 钢渣体积膨胀行为及改性方法研究进展[J].科学技术与工程, 2021, 21(33):14040-14048. |

| GAO Ying, WANG Weihe, CHEN Meng, et al. Research progress on bulk expansion behavior and modification methods of steel slag[J].Science Technology and Engineering, 2021, 21(33):14040-14048. | |

| 26 | 占寿罡, 许冬. 从铜渣选铜尾矿中回收铁的试验研究[J].中国有色冶金, 2015, 44(5):49-52. |

| ZHAN Shougang, XU Dong. Experimental study on recovery of Fe from flotation tailings of copper slag[J].China Nonferrous Metallurgy, 2015, 44(5):49-52. | |

| 27 |

CHEN Min, AVARMAA K, TASKINEN P, et al. An experimental study on the phase equilibria of FeO x -saturated iron silicate slags and metallic copper alloys at 1 200-1 300 ℃[J].Calphad, 2022, 77.Doi:10.1016/j.calphad.2022.102418.

doi: 10.1016/j.calphad.2022.102418 |

| 28 | 张琳, 刘先阳, 库建刚. 氧化钙在铜渣还原过程中的作用[J].中国冶金, 2019, 29(9):9-14, 28. |

| ZHANG Lin, LIU Xianyang, KU Jiangang. Effect of calcium oxide on reduction of copper slag[J].China Metallurgy, 2019, 29(9):9-14, 28. | |

| 29 |

KU Jiangang, ZHANG Lin, FU Weng, et al. Mechanistic study on calcium ion diffusion into fayalite:A step toward sustainable management of copper slag[J].Journal of Hazardous Materials, 2021, 410.Doi:10.1016/j.jhazmat.2020.124630.

doi: 10.1016/j.jhazmat.2020.124630 |

| 30 | 李磊, 胡建杭, 王华. 铜渣熔融还原炼铁过程研究[J].过程工程学报, 2011, 11(1):65-71. |

| LI Lei, HU Jianhang, WANG Hua. Study on smelting reduction ironmaking of copper slag[J].The Chinese Journal of Process Engineering, 2011, 11(1):65-71. | |

| 31 | 张淑会, 王宝勇, 兰臣臣, 等. 铜渣中有价金属元素回收技术的研究现状及展望[J].中国有色冶金, 2022, 51(3):84-93. |

| ZHANG Shuhui, WANG Baoyong, LAN Chenchen, et al. Current status and prospect of recovery technology of valuable metal elements in copper slag[J].China Nonferrous Metallurgy, 2022, 51(3):84-93. | |

| 32 | LI Qiuju, YANG Fanxi, WANG Ziyang, et al. Study on mechanism of oxidation modification of copper slag[J].Transactions of the Indian Institute of Metals, 2019, 72(12):3223-3231. |

| 33 | ISCHENKO V, Y-S JANG, KORMANN M, et al. The effect of SiC substrate microstructure and impurities on the phase formation in carbide-derived carbon[J].Carbon, 2011, 49(4):1189-1198. |

| 34 |

GUO Zhengqi, ZHU Deqing, PAN Jian, et al. Improving beneficiation of copper and iron from copper slag by modifying the molten copper slag[J].Metals, 2016, 6(4).Doi:10.3390/met6040086.

doi: 10.3390/met6040086 |

| 35 | ZUO Zongliang, YU Qingbo, LIU Junxiang, et al. Effects of CaO on reduction of copper slag by biomass based on ion and molecule coexistence theory and thermogravimetric experiments[J].ISIJ International, 2017, 57(2):220-227. |

| 36 | LI Jianli, XU Anjun, HE Dongfeng, et al. Effect of FeO on the formation of spinel phases and chromium distribution in the CaO-SiO2-MgO-Al2O3-Cr2O3 system[J].International Journal of Minerals,Metallurgy,and Materials, 2013, 20(3):253-258. |

| 37 | TURHDOGAN E T. 高温工艺物理化学[M].魏季,傅杰,译.北京:冶金工业出版社, 1988. |

| 38 |

DOS REIS SILVA D, VILELA A C F, HECK N C, et al. Solidification behavior of CaO-SiO2-Al2O3 mold fluxes containing MgO and low TiO2 content using single hot thermocouple technique(SHTT):Continuous-cooling-transformation(CCT) and viscosity analysis[J].Steel Research International, 2018, 89(2).Doi:10.1002/srin.201700246.

doi: 10.1002/srin.201700246 |

| 39 | GASKELL T. Self-diffusion in liquid metals:A generalized stokes-einstein equation[J].Journal of Non-Crystalline Solids, 1984, 61-62:913-918. |

| [1] | SHEN Xiaoqian, ZHOU Fei, LIU Wanchen, XU Lu, WU Junshu. Study on synthesis of FeS modified calcium silicate hydrate composites and their total Cr removal performance [J]. Inorganic Chemicals Industry, 2025, 57(2): 57-67. |

| [2] | ZHU Jicheng, YANG Qixin, LIANG Haoquan, WANG Zengkun, OUYANG Fugui, DI Jing, GAI Xikun. Effect of confined catalyst Ni@S2 on performance of methane dry reforming reaction [J]. Inorganic Chemicals Industry, 2025, 57(2): 138-146. |

| [3] | QIAN Zhihui, ZHU Qin, MA Jiao, GUO Yujiao, XIANG Mingwu, GUO Junming. Study on preparation and electrochemical properties of nano-sized LiNi0.05Mn1.95O4 cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(4): 50-56. |

| [4] | WANG Jianping, XUE Xujin, XUE Fengfeng. Study on new process of preparing high-purity aluminium fluoride from fluorosilicic acid [J]. Inorganic Chemicals Industry, 2024, 56(3): 86-90. |

| [5] | YAN Yu, ZHOU Wenyuan, YANG Yunfei, WU Junshu, WANG Jinshu, SUN Lingmin. Study on surface regulation of sodium ferric silicate photocatalyst and its enhanced Cr(Ⅵ) photoreduction properties [J]. Inorganic Chemicals Industry, 2024, 56(10): 141-150. |

| [6] | SONG Bo, PENG Hesong, LI Haibin, XU Lingfeng. Study on covering power of micro⁃nanoscale calcium silicate [J]. Inorganic Chemicals Industry, 2024, 56(10): 70-75. |

| [7] | LUO Wenbo, LI Heng, LÜ Jun, YANG Linguang, ZHAO Xingfan, LONG Xiao. Study on recovery of silicon and aluminum from industrial silicon slag [J]. Inorganic Chemicals Industry, 2023, 55(9): 94-99. |

| [8] | LI Tong, YIN Hongfeng. Study on controllable preparation of nickel phyllosilicate nanotubes catalysts and their catalytic performance [J]. Inorganic Chemicals Industry, 2023, 55(5): 128-136. |

| [9] | YU Meng,LI Xiang,TIE Leilei,LI Zhiyuan,LIU Wenhui,WU Bao,Zheng Yufei. Research and evaluation of silicate composite viscoelastic oil displacement agent [J]. Inorganic Chemicals Industry, 2022, 54(9): 102-107. |

| [10] | LU Yang,WANG Jing,HE Lijie,WANG Fudong,ZHANG Jiaming. Research progress on preparation of magnesium aluminate spinel powders and it in field of luminescent material [J]. Inorganic Chemicals Industry, 2022, 54(9): 39-46. |

| [11] | HU Zhongyang,SITU Yue,HUANG Hong,ZOU Jiantao. Spherical silica synthesized from cheap silicon and its particle size control [J]. Inorganic Chemicals Industry, 2022, 54(5): 79-83. |

| [12] | TANG Jianping,WANG Guosheng. Study on preparation technology and waterproof property of fused magnesia coating [J]. Inorganic Chemicals Industry, 2022, 54(5): 90-95. |

| [13] | HAN Dong,ZHANG Qiang,ZHANG Min. Study on recovery and utilization process of alkali containing sodium silicate solution [J]. Inorganic Chemicals Industry, 2022, 54(2): 106-110. |

| [14] | Sun Shuangshuang,Zhong Jianchu,Wang Hongzhi. Study on desiliconization process of copper smelting slag [J]. Inorganic Chemicals Industry, 2021, 53(9): 83-87. |

| [15] | Xie Tangfeng,Chen Ruokui,Gong Qinxue,Cai Luorong. Determination of silicon dioxide in crude sodium fluoride by potassium fluosilicate titrimetric method with microwave digestion [J]. Inorganic Chemicals Industry, 2021, 53(9): 92-96. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||