Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (9): 44-53.doi: 10.19964/j.issn.1006-4990.2023-0575

• Research & Development • Previous Articles Next Articles

Study on aluminum sol modified anode and cathode materials for lithium ion batteries

TIAN Peng1( ), ZHANG Haoran1, XU Jingang1, MOU Chenxi1, XU Qianjin2, NING Guiling1

), ZHANG Haoran1, XU Jingang1, MOU Chenxi1, XU Qianjin2, NING Guiling1

- 1.School of Chemical Engineering,Dalian University of Technology,Dalian 116023,China

2.Jiangxi Baohong Nano Technology Co.,Ltd.,Yichun 331208,China

-

Received:2023-11-30Online:2024-09-10Published:2024-02-18 -

Contact:TIAN Peng E-mail:tianpeng@dlut.edu.cn

CLC Number:

Cite this article

TIAN Peng, ZHANG Haoran, XU Jingang, MOU Chenxi, XU Qianjin, NING Guiling. Study on aluminum sol modified anode and cathode materials for lithium ion batteries[J]. Inorganic Chemicals Industry, 2024, 56(9): 44-53.

share this article

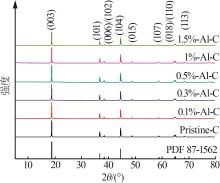

Table 1

Lattice parameters of NCM811 before and after alumina madification"

| 样品名 | a/Å | c/Å | c/a | I(003)/ I(104) | I(006+102)/ I(101) |

|---|---|---|---|---|---|

| Pristine-C | 2.872 | 14.194 | 4.942 | 1.786 | 0.417 |

| 0.1%-Al-C | 2.871 | 14.195 | 4.944 | 1.812 | 0.426 |

| 0.3%-Al-C | 2.872 | 14.200 | 4.944 | 1.846 | 0.415 |

| 0.5%-Al-C | 2.872 | 14.204 | 4.946 | 1.907 | 0.404 |

| 1%-Al-C | 2.872 | 14.203 | 4.945 | 1.814 | 0.413 |

| 1.5%-Al-C | 2.872 | 14.202 | 4.945 | 1.709 | 0.442 |

| 1 | OHZUKU T, BRODD R J.An overview of positive-electrode materials for advanced lithium-ion batteries[J].Journal of Power Sourc-es,2007,174(2):449-456. |

| 2 | RAN Qiwen, ZHAO Hongyuan, HU Youzuo,et al.Enhancing surface stability of LiNi0.8Co0.1Mn0.1O2 cathode with hybrid core-shell nanostructure induced by high-valent titanium ions for Li-ion batteries at high cut-off voltage[J].Journal of Alloys and Compounds,2020,834:155099. |

| 3 | LI Junhao, LIU Zhongqi, WANG Yifan,et al.Investigation of facial B2O3 surface modification effect on the cycling stability and high-rate capacity of LiNi1/3Co1/3Mn1/3O2 cathode[J].Journal of Alloys and Compounds,2020,834:155150. |

| 4 | WEISS M, RUESS R, KASNATSCHEEW J,et al.Fast charging of lithium-ion batteries:A review of materials aspects[J].Advanced Energy Materials,2021,11(33):2101126. |

| 5 | FU Chaochao, LI Guangshe, LUO Dong,et al.Nickel-rich layered microspheres cathodes:Lithium/nickel disordering and electrochemical performance[J].ACS Applied Materials & Interfaces,2014,6(18):15822-15831. |

| 6 | NOH H J, YOUN S, YOON C S,et al.Comparison of the structural and electrochemical properties of layered Li[Ni x Co y Mn z ]O2(x=1/3,0.5,0.6,0.7,0.8 and 0.85) cathode material for lithium-ion batteries[J].Journal of Power Sources,2013,233:121-130. |

| 7 | XU Tingting, LIU Cong, GUO Zhaoxin,et al.Improved rate and cyclic performance of potassium-doped nickel-rich ternary cathode material for lithium-ion batteries[J].Journal of Materials Science,2021,56(3):2399-2411. |

| 8 | POUILLERIE C, PERTON F, BIENSAN P,et al.Effect of magnesium substitution on the cycling behavior of lithium nickel cobalt oxide[J].Journal of Power Sources,2001,96(2):293-302. |

| 9 | HUANG Bing, YANG Xiaowei, XU Guodong,et al.Boron-doped single crystal LiNi0.6Mn0.2Co0.2O2 with improved electrochemical performance for lithium-ion batteries[J].Ionics,2019,25(12):5819-5827. |

| 10 | PENKI T R, GILADY S, NAYAK P K,et al.The effect of synthesis and zirconium doping on the performance of nickel-rich NCM622 cathode materials for Li-ion batteries[J].Journal of So-lid State Electrochemistry,2021,25(5):1513-1530. |

| 11 | WANG Jiale, NIE Yan, MIAO Chang,et al.Enhanced electrochemical properties of Ni-rich layered cathode materials via Mg2+ and Ti4+ co-doping for lithium-ion batteries[J].Journal of Colloid and Interface Science,2021,601:853-862. |

| 12 | 徐琛.锆掺杂三元NCM622锂离子电池研究[D].鞍山:辽宁科技大学,2022:35-41. |

| XU Chen.Electrochemical properties of LiNi0.6Co0.2Mn0.2O2 lithi-um-ion battery cathode materials with zirconium doped[D].Anshan:University of Science and Technology Liaoning,2022:35-41. | |

| 13 | NEUDECK S, MAZILKIN A, REITZ C,et al.Effect of low-temperature Al2O3 ALD coating on Ni-rich layered oxide composite cathode on the long-term cycling performance of lithium-ion batteries[J].Scientific Reports,2019,9:5328. |

| 14 | LIU Wen, LI Xifeng, XIONG Dongbin,et al.Significantly improving cycling performance of cathodes in lithium ion batteries:The effect of Al2O3 and LiAlO2 coatings on LiNi0.6Co0.2Mn0.2O2 [J].Nano Energy,2018,44:111-120. |

| 15 | LI Yan, LIU Xiang, REN Dongsheng,et al.Toward a high-voltage fast-charging pouch cell with TiO2 cathode coating and enhanced battery safety[J].Nano Energy,2020,71:104643. |

| 16 | SIM S J, LEE S H, JIN B S,et al.Use of carbon coating on LiNi0.8Co0.1Mn0.1O2 cathode material for enhanced performances of lithium-ion batteries[J].Scientific Reports,2020,10:11114. |

| 17 | SCHMUCH R, WAGNER R, HÖRPEL G,et al.Performance and cost of materials for lithium-based rechargeable automotive batteries[J].Nature Energy,2018,3:267-278. |

| 18 | GUO Jianguang, LU Shicheng, XIE Junran,et al.Preparation of mesophase pitch with domain textures by molecular regulation of ethylene tar pitch for boosting the performance of its carbon materials[J].Journal of Analytical and Applied Pyrolysis,2023,170:105932. |

| 19 | WANG Q.Novel spherical microporous carbon as anode material for Li-ion batteries[J].Solid State Ionics,2002,152-153:43-50. |

| 20 | FONG R, VON SACKEN U, DAHN J R.Studies of lithium intercalation into carbons using nonaqueous electrochemical cells[J].Journal of the Electrochemical Society,1990,137(7):2009. |

| 21 | WEYDANZ W J, WOHLFAHRT-MEHRENS M, HUGGINS R A.A room temperature study of the binary lithium-silicon and the ternary lithium-chromium-silicon system for use in rechargeable lithium batteries[J].Journal of Power Sources,1999,81-82:237-242. |

| 22 | IDOTA Y, KUBOTA T, MATSUFUJI A,et al.Tin-based amorphous oxide:A high-capacity lithium-ion-storage material[J].Science,1997,276(5317):1395-1397. |

| 23 | GUO Yanpeng, LI Huiqiao, ZHAI Tianyou.Reviving lithium-metal anodes for next-generation high-energy batteries[J].Advanced Materials,2017,29(29):1700007. |

| 24 | KIM J, PARK K,WOO H,et al.Selective removal of nanopores by triphenylphosphine treatment on the natural graphite anode[J].Electrochimica Acta,2019,326:134993. |

| 25 | MCDOWELL M T, LEE S W, NIX W D,et al.25th anniversary article:Understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries[J].Advanced Materials,2013,25(36):4966-4985. |

| 26 | SHEN Xiaohui, TIAN Zhanyuan, FAN Ruijuan,et al.Research progress on silicon/carbon composite anode materials for lithium-ion battery[J].Journal of Energy Chemistry,2018,27(4):1067-1090. |

| 27 | RYU I, CHOI J W, CUI Yi,et al.Size-dependent fracture of Si nanowire battery anodes[J].Journal of the Mechanics and Physics of Solids,2011,59(9):1717-1730. |

| 28 | YANG Jianping, WANG Yunxiao, LI Wei,et al.Amorphous TiO2 shells:A vital elastic buffering layer on silicon nanoparticles for high-performance and safe lithium storage[J].Advanced Materials,2017,29(48):1700523. |

| 29 | JUNG Y S, CAVANAGH A S, RILEY L A,et al.Ultrathin direct atomic layer deposition on composite electrodes for highly durable and safe Li-ion batteries[J].Advanced Materials,2010,22(19):2172-2176. |

| 30 | LIU Bo, CHUAN Yongming, ZHANG Yinyin,et al.The preparation of CuO@ZnO core-shell materials as high-stability anodes for lithium-ion batteries[J].International Journal of Electroche- mical Science,2019,14(9):8973-8985. |

| 31 | HY S, CHEN Y H, CHENG H M,et al.Stabilizing nanosized Si anodes with the synergetic usage of atomic layer deposition and electrolyte additives for Li-ion batteries[J].ACS Applied Materials & Interfaces,2015,7(25):13801-13807. |

| 32 | ZOU Tong, QI Weijing, LIU Xiaoshuo,et al.Improvement of the electrochemical performance of Li1.2Ni0.13Co0.13Mn0.54O2 cathode material by Al2O3 surface coating[J].Journal of Electroanalytical Chemistry,2020,859:113845. |

| 33 | HERZOG M J, ESKEN D, JANEK J.Improved cycling performance of high-nickel NMC by dry powder coating with nanostructured fumed Al2O3,TiO2,and ZrO2:A comparison[J].Batteries & Supercaps,2021,4(6):1003-1017. |

| 34 | GHOLIZADEH Z, ALIANNEZHADI M, GHOMINEJAD M,et al.Optical and structural properties of spherical-shaped boehmite and γ-alumina nanoparticles by ultrasonic-assisted hydrothermal method:The effects of synthesis route,calcination,and precursor concentration[J].Optical and Quantum Electronics,2023,55(10):880. |

| 35 | ZHA Guojun, OUYANG Chuying, YIN Shungao,et al.High cycling stability of the LiNi0.8Co0.1Mn0.1O2 cathode via surface modification with polyimide/multi-walled carbon nanotubes composite coating[J].Small,2021,17(47).Doi:10.1002/smll.202102981. |

| 36 | CHEN Gang, PENG Biyou, HAN Rui,et al.A robust carbon coating strategy toward Ni-rich lithium cathodes[J].Ceramics International,2020,46(13):20985-20992. |

| 37 | HOU Peiyu, LI Feng, SUN Yanyun,et al.Improving Li+ kinetics and structural stability of nickel-rich layered cathodes by heterogeneous inactive-Al3+ doping[J].ACS Sustainable Chemistry & Engineering,2018,6(4):5653-5661. |

| 38 | ZHENG Xiaobo, LI Xinhai, HUANG Zhenjun,et al.Enhanced electrochemical performance of LiNi0.6Co0.2Mn0.2O2 cathode materials by ultrasonic-assisted co-precipitation method[J].Journal of Alloys and Compounds,2015,644:607-614. |

| 39 | ARAVINDAN V, SUNDARAMURTHY J, SURESH KUMAR P,et al.Electrospun nanofibers:A prospective electro-active material for constructing high performance Li-ion batteries[J].Chemical Communications,2015,51(12):2225-2234. |

| 40 | TANG Daichun, Liubin BEN, SUN Yang,et al.Electrochemical behavior and surface structural change of LiMn2O4 charged to 5.1 V[J].J.Mater.Chem.A,2014,2(35):14519-14527. |

| 41 | TAO Fen, YAN Xiaoxia, LIU Junji,et al.Effects of PVP-assisted Co3O4 coating on the electrochemical and storage properties of LiNi0.6Co0.2Mn0.2O2 at high cut-off voltage[J].Electrochimica Acta,2016,210:548-556. |

| 42 | ZHANG Meiling, ZHAO Hongyuan, TAN Ming,et al.Yttrium chemical performance as high energy density cathode material at 4.5 V high voltage[J].Journal of Alloys and Compounds,2019,774:82-92. |

| 43 | DAN Jianglei, JIN Chenxin, WEN Lijun,et al.A double-layer-coated graphite anode material for high-rate lithium-ion batteri-es[J].Solid State Sciences,2023,141:107220. |

| 44 | XIAO Xingcheng, LU Peng,AHN D.Ultrathin multifunctional oxide coatings for lithium ion batteries[J].Advanced Materials,2011,23(34):3911-3915. |

| 45 | HAN Xiaogang, GONG Yunhui, FU Kun,et al.Negating interfacial impedance in garnet-based solid-state Li metal batteries[J].Nature Materials,2017,16:572-579. |

| 46 | QIU S, Yan W N, Wang L,et al.Facile synthesis of Si@LiAlO2 nanocomposites as anode for lithium-ion battery[J].Journal of Inorganic Chemistry,2022,38(8):1655-662. |

| 47 | 淡江雷.锂离子电池高倍率石墨负极材料改性技术研究[D].南昌:南昌大学,2022:45-65. |

| DAN Jianglei.Study on modification technologies of high-rate graphite anode materials for lithium-ion batteries[D].Nanchang:Nanchang University,2022:45-65. | |

| 48 | LIU Mingzhu, VATAMANU J, CHEN Xinli,et al.Hydrolysis of LiPF6-containing electrolyte at high voltage[J].ACS Energy Letters,2021,6(6):2096-2102. |

| 49 | LIU Jianyong, LIU Na, LIU Daotan,et al.Improving the performances of LiCoO2 cathode materials by soaking nano-alumina in commercial electrolyte[J].Journal of the Electrochemical Society,2007,154(1):A55. |

| 50 | OBROVAC M N, CHRISTENSEN L.Structural changes in silicon anodes during lithium insertion/extraction[J].Electrochemical and Solid-State Letters,2004,7(5):A93. |

| 51 | TAKEDA Y, YAMAMOTO O, IMANISHI N.Lithium dendrite formation on a lithium metal anode from liquid,polymer and solid electrolytes[J].Electrochemistry,2016,84(4):210-218. |

| 52 | VERMA P, MAIRE P, NOVÁK P.A review of the features and analyses of the solid electrolyte interphase in Li-ion batteries[J].Electrochimica Acta,2010,55(22):6332-6341. |

| 53 | LIU Kai, LIU Yayuan, LIN Dingchang,et al.Materials for lithium-ion battery safety[J].Science Advances,2018,4(6):eaas9820. |

| [1] | YANG Fu, XIE Yulong. Study on preparation and Na+ doping modification of ternary material LiNi0.65Co0.15Mn0.2O2 [J]. Inorganic Chemicals Industry, 2025, 57(3): 43-49. |

| [2] | SONG Jiaxi, JI Renfei, CHEN Jun, LIN Sen, YU Jianguo. Research on characteristics analysis and pretreatment on deeply deactivated power battery ternary cathode materials [J]. Inorganic Chemicals Industry, 2025, 57(2): 44-49. |

| [3] | ZHANG Shanshan, ZENG Yule, ZHANG Ting, LIN Sen, LIU Chenglin. Research progress of cathode pre-lithiation technology for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2025, 57(1): 1-13. |

| [4] | ZHANG Yanyan, LI Donghong, LIU Yonghe, ZHANG Yang, KANG Le, WANG Yi. Study on surface treatment of alumina filler [J]. Inorganic Chemicals Industry, 2025, 57(1): 77-82. |

| [5] | CHEN Xue, OUYANG Quansheng, SHAO Jiaojing. Recent research progress of lithium-sulfur batteries based on solid-solid reaction mechanism [J]. Inorganic Chemicals Industry, 2024, 56(9): 12-23. |

| [6] | SU Baocai, ZHANG Qin, XIE Yuanjian, CAI Pingxiong, PAN Yuanfeng. Advances in synthesis methods and structural modification of LiMnFePO4 materials [J]. Inorganic Chemicals Industry, 2024, 56(7): 28-36. |

| [7] | WANG Junting, MA Hang, ZHA Zuotong, WAN Banglong, ZHANG Zhenhuan. Research progress of iron phosphate industrial wastewater treatment process [J]. Inorganic Chemicals Industry, 2024, 56(6): 26-33. |

| [8] | ZHAO Tianting, ZHU Delun, YANG Lin, ZHOU Xinlei. Preparation and process optimization of porous silicon anode materials for lithium-ion battery [J]. Inorganic Chemicals Industry, 2024, 56(5): 31-38. |

| [9] | YANG En, SHEN Hongyan, LIU Youzhi. In situ modification of superfine magnesium hydroxide with silicon polyether [J]. Inorganic Chemicals Industry, 2024, 56(4): 42-49. |

| [10] | LIU Dexin, MA Tengyue, AN Jinling, LIU Jinrong, HE Weiyan. Study on cathode material design and electrochemical properties of manganese-based sodium ion battery [J]. Inorganic Chemicals Industry, 2024, 56(3): 51-55. |

| [11] | LI Yaguang, HAN Dongzhan, QI Lijuan. Recent research on pretreatment of waste lithium-ion batteries and electrolyte recovery technology [J]. Inorganic Chemicals Industry, 2024, 56(2): 1-10. |

| [12] | ZHOU Huang, HU Xiaoping, REN Wen, CAO Xinxin. Preparation and sodium storage properties of sulfur-doped Na3(VOPO4)2F cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(2): 30-37. |

| [13] | GE Jianhua, XIE Minyan, OUYANG Quansheng, SHAO Jiaojing. Advances in regeneration processes of cathode materials for spent power batteries [J]. Inorganic Chemicals Industry, 2024, 56(12): 79-87. |

| [14] | ZHAO Runze, QIAN A′niu. Research progress of lithium recovery for spent lithium-ion batteries and preparation in battery-grade lithium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(12): 70-78. |

| [15] | LIU Jiasheng, LUO Xiaoqiang, HOU Cuihong, XUE Lingwei. Effects of fluorine doping on electrochemical behavior of LiMn0.8Fe0.2PO4/C cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(11): 45-50. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||