Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (2): 80-85.doi: 10.19964/j.issn.1006-4990.2023-0158

• Research & Development • Previous Articles Next Articles

Study on surface packaging and leakage prevention of high temperature molten salt/ceramic composite phase change thermal storage materials

LU Yunkun( ), TANG Xianyou, YIN Hang, ZHANG Yanan, ZHANG Shaojie

), TANG Xianyou, YIN Hang, ZHANG Yanan, ZHANG Shaojie

- China General Nuclear Power New Energy Holdings Co. ,Ltd. ,Beijing 100160,China

-

Received:2023-03-23Online:2024-02-10Published:2024-02-06

CLC Number:

Cite this article

LU Yunkun, TANG Xianyou, YIN Hang, ZHANG Yanan, ZHANG Shaojie. Study on surface packaging and leakage prevention of high temperature molten salt/ceramic composite phase change thermal storage materials[J]. Inorganic Chemicals Industry, 2024, 56(2): 80-85.

share this article

| 1 | 龚家竹,周桂民,吴宁兰,等.无机盐工业面临碳达峰碳中和的挑战与创新发展机遇[J].无机盐工业,2022,54(4):46-54. |

| GONG Jiazhu, ZHOU Guimin, WU Ninglan,et al.Challenges and innovative development opportunities of carbon peak and carbon neutralization faced by inorganic salt industry[J].Inorganic Chemi-Industry cals,2022,54(4):46-54. | |

| 2 | 李紫瑞,邢冬娴,汤建伟,等.磷石膏基复合相变材料的制备及储热性能研究[J].无机盐工业,2022,54(4):34-39. |

| LI Zirui, XING Dongxian, TANG Jianwei,et al.Study on preparation and heat storage performance of phosphogypsum-based composite phase change materials[J].Inorganic Chemicals Industry,2022,54(4):34-39. | |

| 3 | 郑天新,梁精龙,李慧,等.熔盐技术在新能源中的应用现状[J].无机盐工业,2018,50(3):11-15. |

| ZHENG Tianxin, LIANG Jinglong, LI Hui,et al.Application status of molten salt technology in new energy[J].Inorganic Chemicals Industry,2018,50(3):11-15. | |

| 4 | 杜志强,姚光源.用于储热新型低熔点二元无机盐特性研究[J].无机盐工业,2020,52(1):63-67. |

| DU Zhiqiang, YAO Guangyuan.Study on characteristics of novel low-melting binary inorganic salts for heat storage[J].Inorganic Chemicals Industry,2020,52(1):63-67. | |

| 5 | LENG Guanghui, QIAO Geng, JIANG Zhu,et al.Micro encapsulated & form-stable phase change materials for high temperature thermal energy storage[J].Applied Energy,2018,217:212-220. |

| 6 | JACOB R, BRUNO F.Review on shell materials used in the encapsulation of phase change materials for high temperature thermal energy storage[J].Renewable and Sustainable Energy Reviews,2015,48:79-87. |

| 7 | 李爱菊,王毅,张仁元.无机盐/陶瓷基复合相变储能材料的研究进展[J].材料导报,2007,21(5):29-31,39. |

| LI Aiju, WANG Yi, ZHANG Renyuan.Research development of inorganic salt/ceramic composite phase change energy storage material[J].Materials Review,2007,21(5):29-31,39. | |

| 8 | TIAN Heqing, WANG Weilong, DING Jing,et al.Thermal conductivities and characteristics of ternary eutectic chloride/expanded graphite thermal energy storage composites[J].Applied Energy,2015,148:87-92. |

| 9 | GE Zhiwei, HUANG Yun, DING Yulong.Eutectic composition-dependence of latent heat of binary carbonates(Na2CO3/Li2CO3)[J].Solar Energy Materials and Solar Cells,2018,179:202-206. |

| 10 | TAO Y B, LIN C H, HE Y L.Preparation and thermal properties characterization of carbonate salt/carbon nanomaterial composite phase change material[J].Energy Conversion and Management,2015,97:103-110. |

| 11 | LUO Jing, DENG Congkun, TARIQ N U H,et al.Corrosion behavior of SS316L in ternary Li2CO3-Na2CO3-K2CO3 eutectic mixture salt for concentrated solar power plants[J].Solar Energy Materials and Solar Cells,2020,217:110679. |

| 12 | GOKON N, NAKANO D, INUTA S,et al.High-temperature carbonate/MgO composite materials as thermal storage media for do-uble-walled solar reformer tubes[J].Solar Energy,2008,82(12):1145-1153. |

| 13 | GE Zhiwei, YE Feng, DING Yulong.Composite materials for thermal energy storage:Enhancing performance through microstructures[J].ChemSusChem,2014,7(5):1318-1325. |

| 14 | WEI Xiaolan, YIN Yue, QIN Bo,et al.Thermal conductivity improvement of liquid Nitrate and Carbonate salts doped with MgO particles[J].Energy Procedia,2017,142:407-412. |

| 15 | YE Feng, GE Zhiwei, DING Yulong,et al.Multi-walled carbon nanotubes added to Na2CO3/MgO composites for thermal energy storage[J].Particuology,2014,15:56-60. |

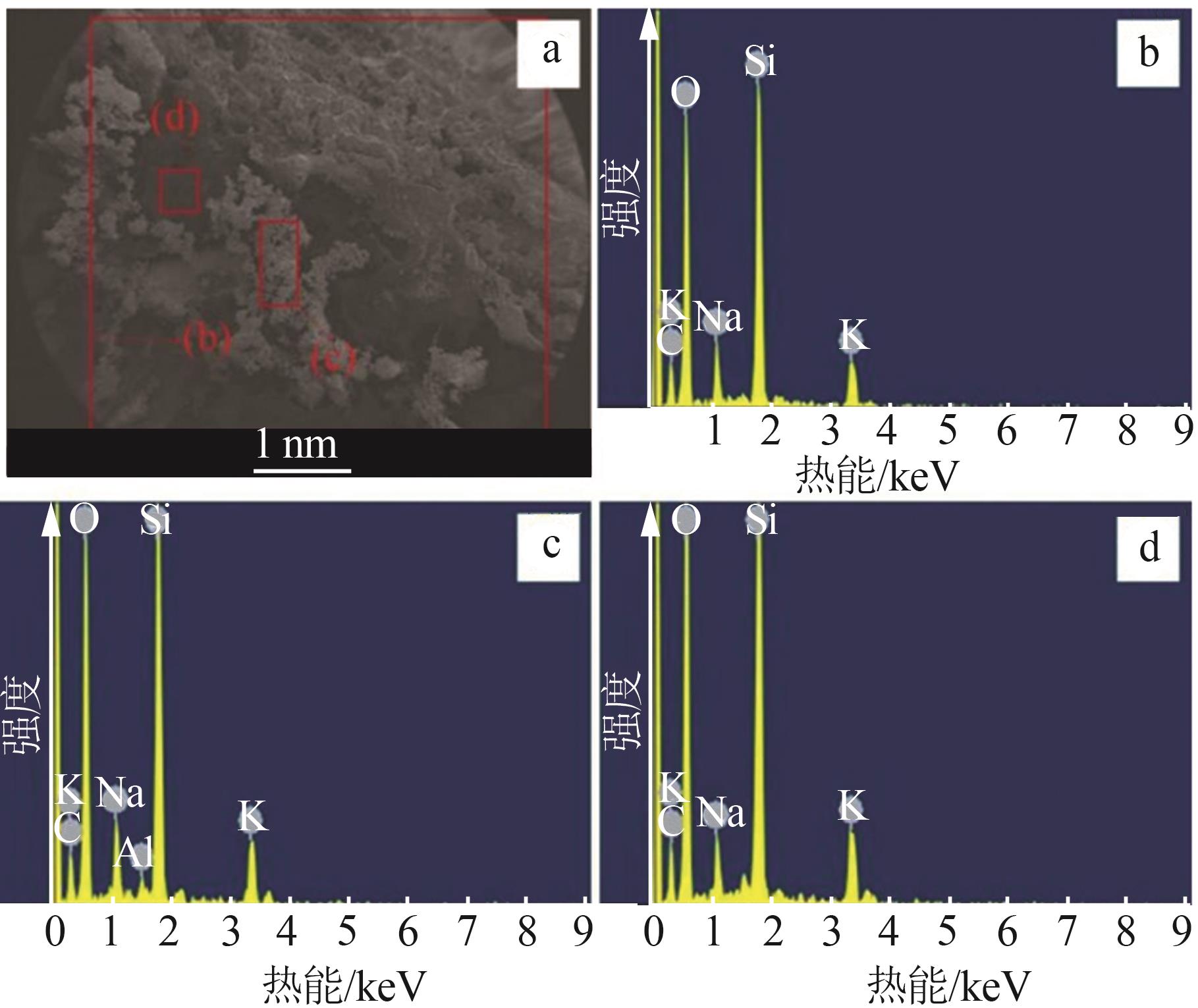

| 16 | LU Yunkun, ZHANG Gaoqun, HAO Junjie,et al.Fabrication and characterization of the novel shape-stabilized composite PCMs of Na2CO3-K2CO3/MgO/glass[J].Solar Energy,2019,189:228- 234. |

| 17 | CHERTKOVA N, YAMASHITA S. In situ spectroscopic study of water speciation in the depolymerized Na2Si2O5 melt[J].Chemical Geology,2015,409:149-156. |

| [1] | HU Jingrong, LI Xincong. Research on modified carbon aerogel/paraffin composite phase change thermal storage materials [J]. Inorganic Chemicals Industry, 2024, 56(5): 58-63. |

| [2] | DONG Mingzhe, LI Kexin, YE Xiushen, MA Zhen, LI Shengting, LI Quan, WU Zhijian. Study on electrochemical properties of magnesium chloride molten salt hydrates [J]. Inorganic Chemicals Industry, 2024, 56(2): 51-56. |

| [3] | LI Yuhang, WANG Yinbin, WEI Qiang. Preparation of Fe2O3-Co3O4 heterojunction by molten salt method and its hydrogen evolution performance [J]. Inorganic Chemicals Industry, 2023, 55(8): 51-58. |

| [4] | GUI Changqing, WANG Yajing, LING Changjian, WANG Huaiyou, TANG Zhongfeng. Research progress of preparation and modification of MgO-based CO2 adsorbents [J]. Inorganic Chemicals Industry, 2023, 55(8): 77-83. |

| [5] | LI Xun, JIA Yanhong, DOU Qiang, YANG Yang. Study on vacuum distillation purification technology for radioactive waste salt [J]. Inorganic Chemicals Industry, 2023, 55(7): 97-102. |

| [6] | YUAN Enxian, LI Jinpeng, LI Qian, ZHOU Meixia, JIAN Panming. Preliminary study on cyclohexane catalytic oxidation over magnesium-doped tricobalt tetraoxide [J]. Inorganic Chemicals Industry, 2023, 55(6): 136-141. |

| [7] | LUO Zhibo, WANG Huaiyou, WANG Min, DU Baoqiang. Effect of purity on thermo-physical properties of 60% NaNO3-40% KNO3 binary molten salt [J]. Inorganic Chemicals Industry, 2023, 55(6): 43-49. |

| [8] | XU Chunhui, WANG Feng, LING Changjian, WANG Zirui, TANG Zhongfeng. Research progress of CO2 capture by metal oxides modified by molten salts [J]. Inorganic Chemicals Industry, 2023, 55(5): 1-7. |

| [9] | PENG Shuang, CHEN Chaoyi, WANG Shiyu, BAI Yang, LI Tianpei, GU Wei. Study on preparation of titanium carbide derived carbon by electrolysis-etching in CaCl2 molten salt [J]. Inorganic Chemicals Industry, 2023, 55(3): 78-83. |

| [10] | XU Jingyao,ZHOU Xiaoli,SUN Jinghui,CAO Alin,QING Peilin. Study on preparation of flake α-alumina based on mixed molten salt at low temperature [J]. Inorganic Chemicals Industry, 2023, 55(2): 73-78. |

| [11] | YUAN Ziou, WANG Feng, QI Xingzhao, ZHANG Qi, MA Jianlong, TANG Zhongfeng. Thermal properties of sodium chloride-sodium sulfate/silicon-based phase change composites [J]. Inorganic Chemicals Industry, 2023, 55(10): 114-120. |

| [12] | LIANG Hai,YUAN Tianlong,WANG Wanting,YANG Yunhong,LIANG Wenjie,WANG Xiaomin,DENG Xinzhong. Synthesis of micron?tubular?magnesium oxide clusters and its adsorption performance for phosphate [J]. Inorganic Chemicals Industry, 2022, 54(9): 77-84. |

| [13] | XU Xiaobing,LI Xu,YANG Xu,XU Xiaoyong. Effect of firing temperature on properties of MgO-TiO2 composite inorganic ceramic microfilter membrane support [J]. Inorganic Chemicals Industry, 2022, 54(8): 85-89. |

| [14] | CHEN Feng,WEN Yuekai,GUO Yufeng,ZHENG Fuqiang,WANG Shuai,YANG Lingzhi,ZHENG Yu,LI Dongyue,REN Yuqiao. Research status of viscosity characteristics of chlorinated molten salt system [J]. Inorganic Chemicals Industry, 2022, 54(6): 1-5. |

| [15] | Feng Xiaoping,Hao Xuejun. Experimental study on enhanced heat transfer performance of ternary mixed molten salts [J]. Inorganic Chemicals Industry, 2021, 53(8): 66-70. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||