| 1 |

武志富.纳米氧化铝形貌与性质之间的关系研究[J].人工晶体学报,2020,49(2):353-357.

|

|

WU Zhifu.Study on the relationship between the morphology and properties of nanoscale alumina[J].Journal of Synthetic Crystals,2020,49(2):353-357.

|

| 2 |

姚慧超,彭懋.片状氧化铝/聚合物复合材料的研究进展[J].材料科学与工程学报,2019,37(5):833-839.

|

|

YAO Huichao, PENG Mao.Progress of study of alumina platelets reinforced polymer composites[J].Journal of Materials Science and Engineering,2019,37(5):833-839.

|

| 3 |

苏界.新型片状Al2O3材料的可控制备及其在新一代珠光颜料中的应用研究[D].武汉:湖北大学,2017.

|

|

SU Jie.Controllable preparation of a new flake alumina materials and its application in the new generation of pearlescent pigment[D].Wuhan:Hubei University,2017.

|

| 4 |

楚肖莉,孙立军,查鲲鹏,等.片状氧化铝/球形氮化硼导热膏的制备及表征[J].青岛科技大学学报:自然科学版,2021,42(2):73-78,84.

|

|

CHU Xiaoli, SUN Lijun, ZHA Kunpeng,et al.Preparation and characterization of alumina platelets/spherical boron nitride thermal grease[J].Journal of Qingdao University of Science and Technology:Natural Science Edition,2021,42(2):73-78,84.

|

| 5 |

王玲,王千瑞,刘冲,等.片状氧化铝的发展历程与应用前景[J].陶瓷学报,2016,37(6):608-612.

|

|

WANG Ling, WANG Qianrui, LIU Chong,et al.Development process and application prospect of flaky aluminum oxide[J].Journal of Ceramics,2016,37(6):608-612.

|

| 6 |

杨岚婷,王兆文,杨酉坚,等.以粉煤灰为原料制备用于导热填料的板片状氧化铝[J].轻金属,2022(2):1-4,13.

|

|

YANG Lanting, WANG Zhaowen, YANG Youjian,et al.Preparation of plate-like alumina used as thermal conductive filler from fly ash[J].Light Metals,2022(2):1-4,13.

|

| 7 |

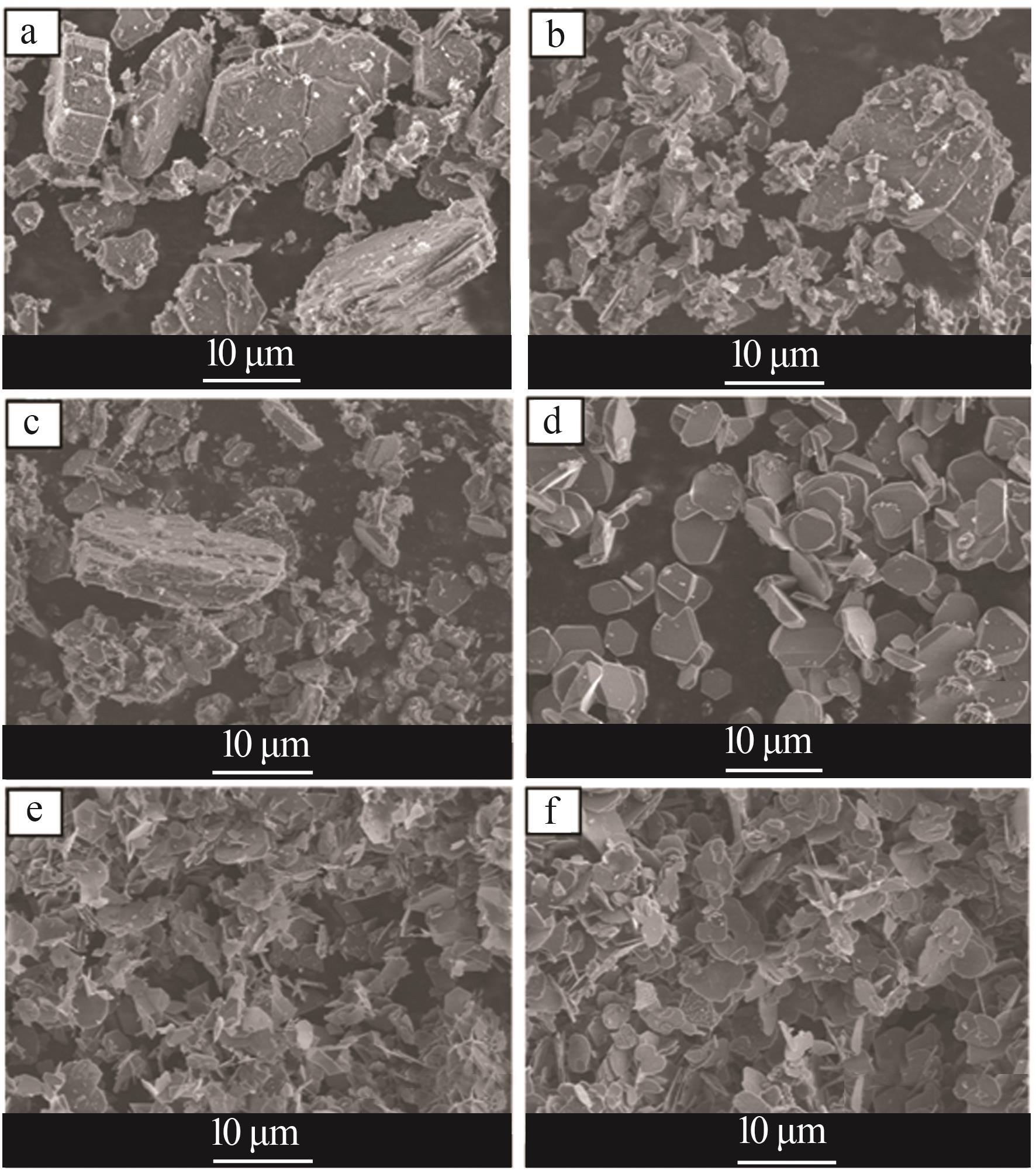

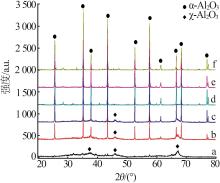

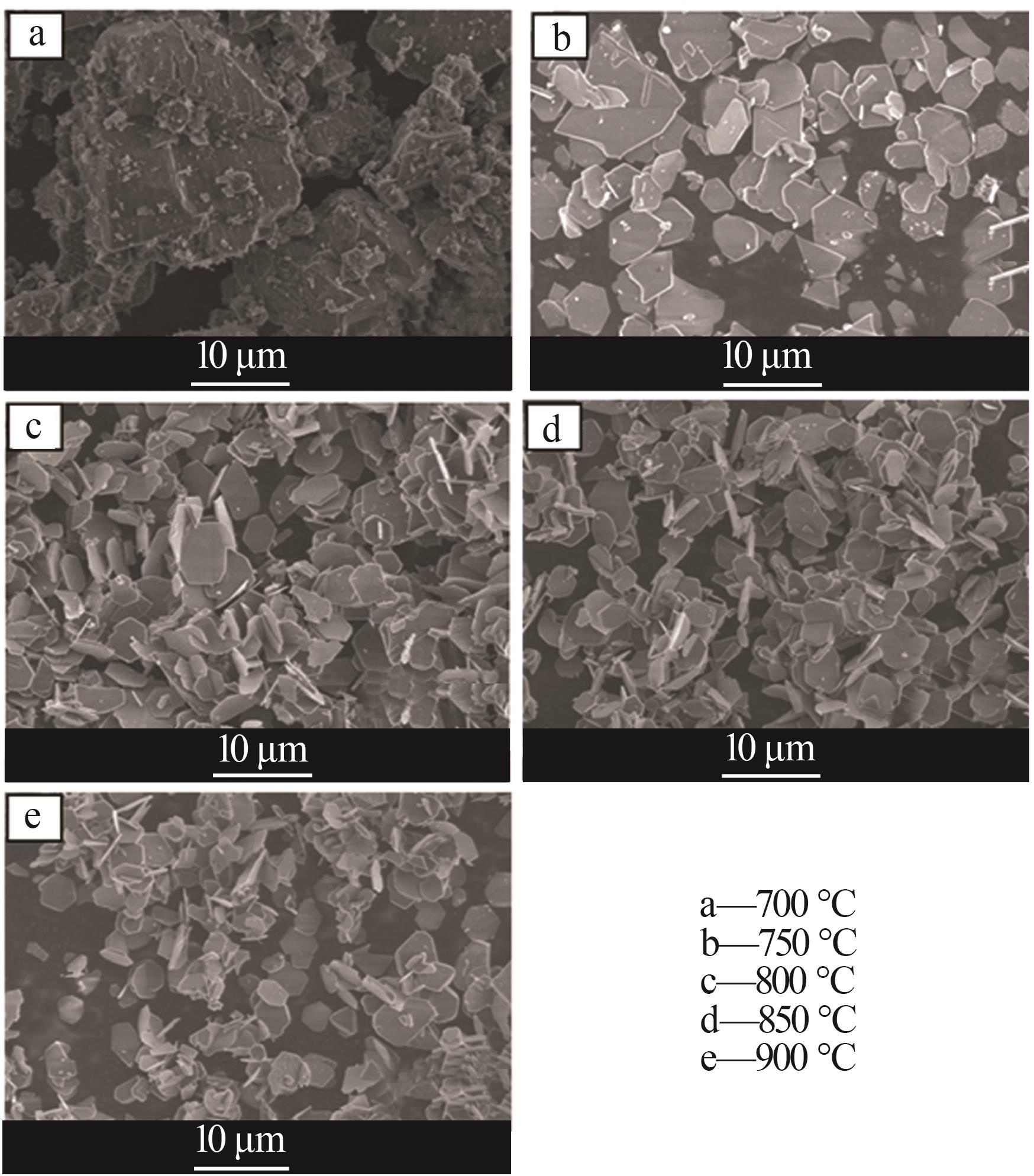

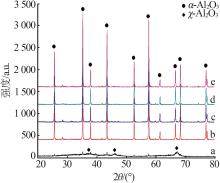

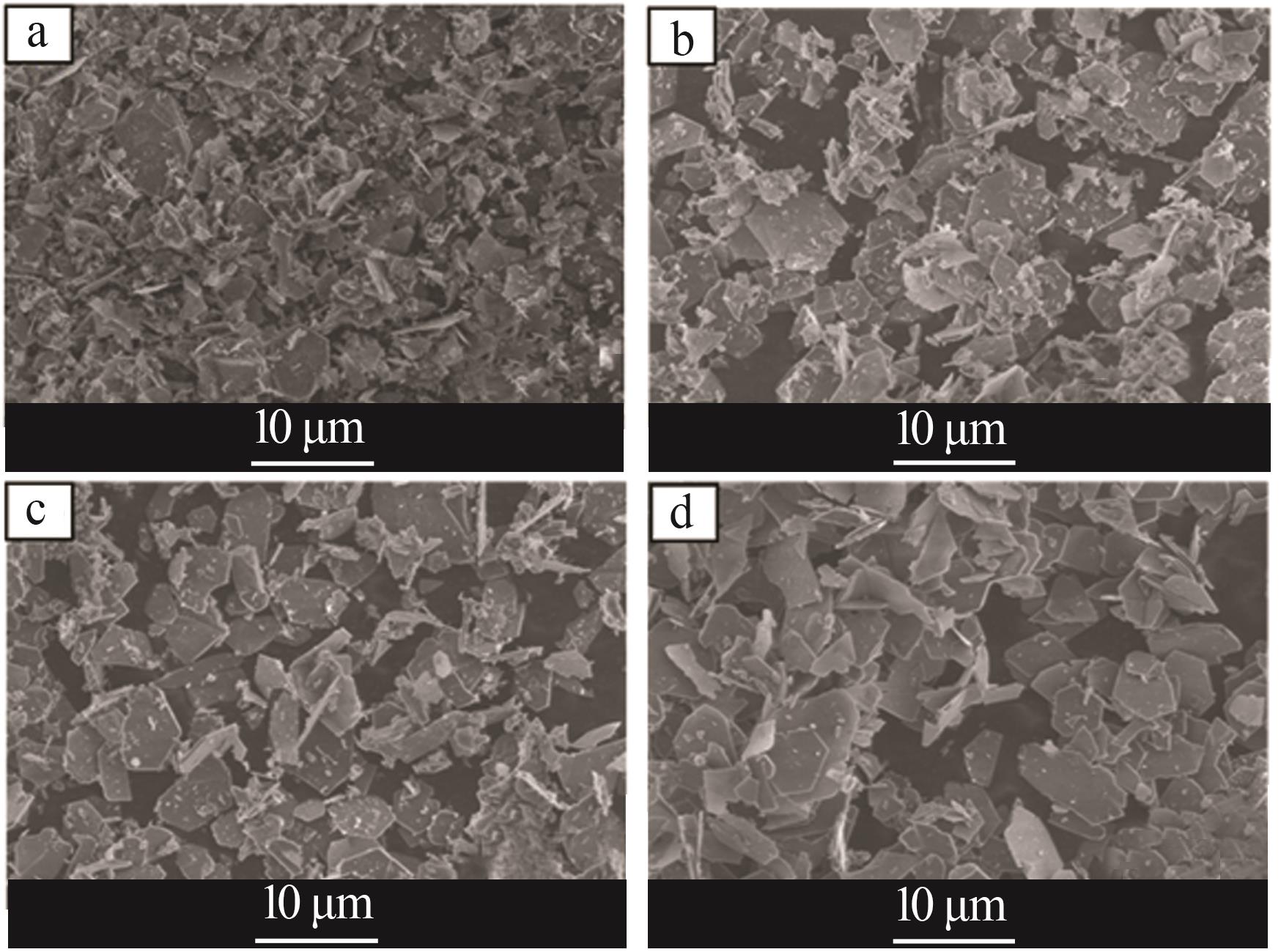

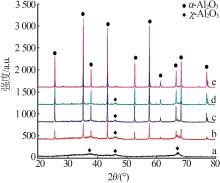

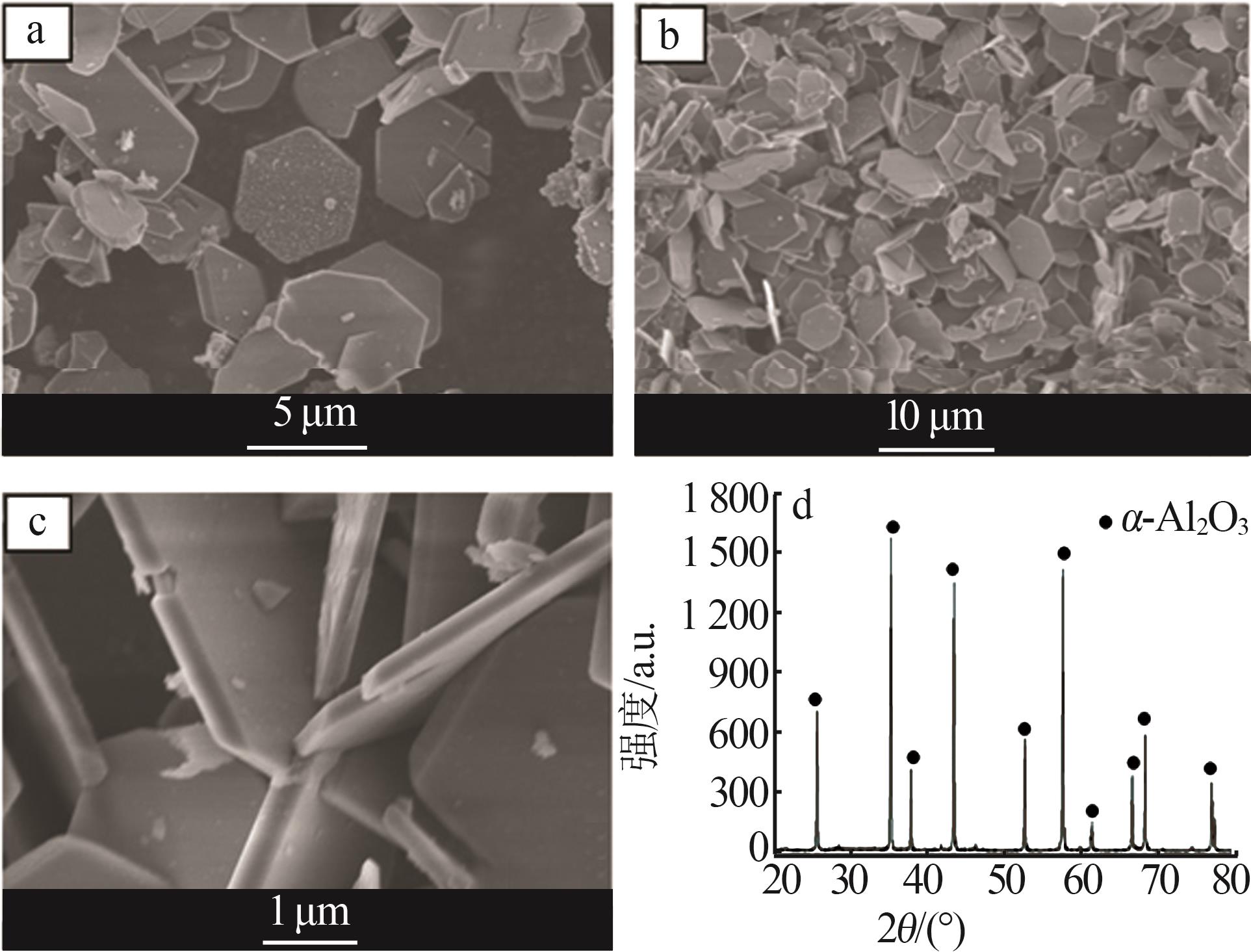

孙敬会,卿培林.高温固相法制备片状氧化铝[J].中国陶瓷,2021,57(12):34-38,52.

|

|

SUN Jinghui, QING Peilin.Preparation of flake aluminum oxide powder by high temperature solid phase method[J].China Ceramics,2021,57(12):34-38,52.

|

| 8 |

孙敬会,伊家飞,徐敬尧,等.基于薄膜技术制备超细片状氧化铝的研究[J].真空科学与技术学报,2018,38(12):1080- 1087.

|

|

SUN Jinghui, YI Jiafei, XU Jingyao,et al.Preparation of ultrafine lamellate alumina powder via chemical route[J].Chinese Journal of Vacuum Science and Technology,2018,38(12):1080-1087.

|

| 9 |

ZHANG Qianying, GENG Xun.Preparation of flaky alumina powder by molten salt synthesis method[J].Advanced Materials Research,2014,997:428-432.

|

| 10 |

张鹤,邵国强,史和邦,等.片状氧化铝的熔盐法制备关键参数[J].化工进展,2021,40(8):4187-4195.

|

|

ZHANG He, SHAO Guoqiang, SHI Hebang,et al.Key parameters of preparing flake alumina by molten salt method[J].Che-mical Industry and Engineering Progress,2021,40(8):4187-4195.

|

| 11 |

MIAO Zhuang, SHI Jiangong, ZHANG Wenping,et al.Effect of NH4F and nano-SiO2 on morphological control of α-Al2O3 platelets via solid-state reaction[J].China Petroleum Processing & Petrochemical Technology,2016,18(4):19-24.

|

| 12 |

张集发,程小苏,税安泽.高温固相法制备片状α-Al2O3粉体[J].硅酸盐通报,2015,34(S1):284-288,292.

|

|

ZHANG Jifa, CHENG Xiaosu, SHUI Anze.Preparation of flaky α-Al2O3 by high temperature solid phase method[J].Bulletin of the Chinese Ceramic Society,2015,34(S1):284-288,292.

|

| 13 |

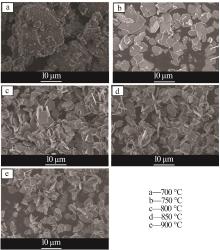

孙春晖,朱玲玲,李赛,等.前驱体预处理及卤化铵添加剂对α-氧化铝微粉颗粒形貌的影响[J].无机盐工业,2018,50(9):19-23.

|

|

SUN Chunhui, ZHU Lingling, LI Sai,et al.Effect of pretreated precursor and halogenated ammonia additives on the morphology of α-Al2O3 powders[J].Inorganic Chemicals Industry,2018,50(9):19-23.

|

| 14 |

李波,邵玲玲.氧化铝、氢氧化铝的XRD鉴定[J].无机盐工业,2008,40(2):54-57.

|

|

LI Bo, SHAO Lingling.Appraisal of alumina and aluminium hydroxide by XRD[J].Inorganic Chemicals Industry,2008,40(2):54-57.

|

| 15 |

FU Gaofeng, WANG Jing, KANG Jian.Influence of AlF3 and hydrothermal conditions on morphologies of α-Al2O3 [J].Transactions of Nonferrous Metals Society of China,2008,18(3):743- 748.

|

),ZHOU Xiaoli2,5(

),ZHOU Xiaoli2,5( ),SUN Jinghui1,CAO Alin1,3,4,QING Peilin1

),SUN Jinghui1,CAO Alin1,3,4,QING Peilin1