Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (4): 90-97.doi: 10.19964/j.issn.1006-4990.2023-0354

• Environment·Health·Safety • Previous Articles Next Articles

Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials

YU Zhou1( ), HE Zhaoyi2(

), HE Zhaoyi2( ), TANG Liang1, HE Sheng1, XIAO Haixin1, XIAO Yixun1

), TANG Liang1, HE Sheng1, XIAO Haixin1, XIAO Yixun1

- 1.School of Civil Engineering,Chongqing Jiaotong University,Chongqing 400074,China

2.School of Traffic & Transportation,Chongqing Jiaotong University,Chongqing 400074,China

-

Received:2023-07-05Online:2024-04-10Published:2024-04-18 -

Contact:HE Zhaoyi E-mail:995929765@qq.com;hzyzwb@cqjtu.edu

CLC Number:

Cite this article

YU Zhou, HE Zhaoyi, TANG Liang, HE Sheng, XIAO Haixin, XIAO Yixun. Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials[J]. Inorganic Chemicals Industry, 2024, 56(4): 90-97.

share this article

Table 1

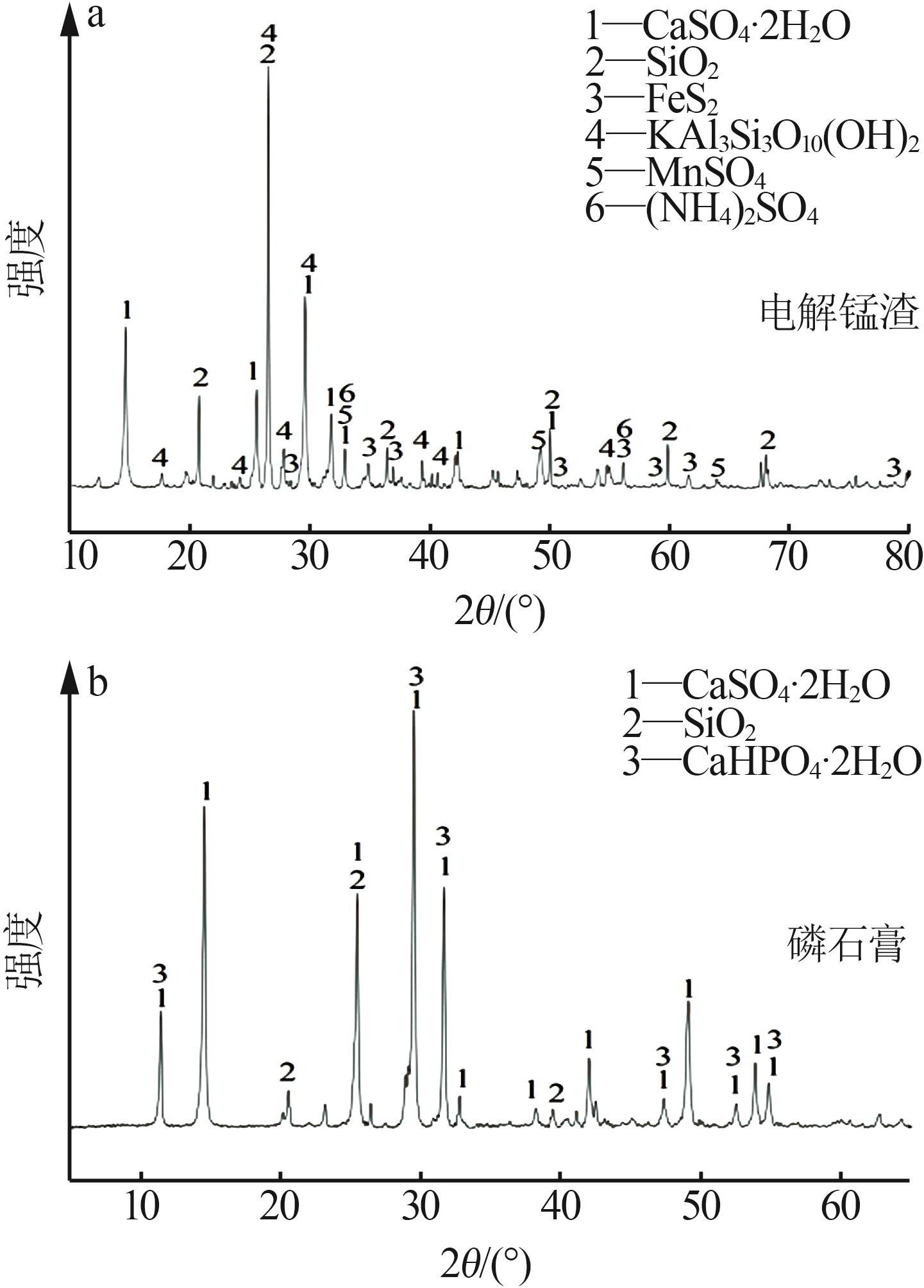

Main chemical compositions of EMR,PG and GGBS,P.O 42.5 %"

| 原料 | w(SiO2) | w(Al2O3) | w(Fe2O3) | w(CaO) | w(SO3) | w(MgO) | w(Na2O) | w(K2O) | w(MnO) | w(P2O5) | w(其他) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 电解锰渣 | 38.55 | 7.78 | 6.58 | 9.34 | 27.32 | 2.34 | 0.78 | 3.01 | 3.11 | — | 1.2 |

| 磷石膏 | 4.87 | 0.88 | 1.25 | 52.20 | 39.02 | 0.17 | 0.26 | 0.13 | — | 0.86 | 0.36 |

| 矿渣 | 32.49 | 19.22 | 0.52 | 35.28 | 1.62 | 8.76 | 0.61 | 0.40 | 0.19 | — | 1.1 |

| 水泥 | 19.88 | 5.22 | 2.75 | 65.66 | 3.47 | 0.49 | — | — | — | — | 1.59 |

Table 3

Leaching toxicity results of hardened body specimens"

| 组别 | 浸出毒性/(mg·L-1) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mn2+ | NH4+-N | PO | Hg2+ | Pb2+ | Cd2+ | Cr6+ | Cu2+ | Zn2+ | Ba2+ | Ni2+ | |

| 原始电解锰渣 | 1 220 | 149 | 0.001 2 | 0.001 2 | 0.013 2 | 0.073 2 | 0.025 2 | 0.464 | 1.7 | 0.498 | 0.974 |

| 原始磷石膏 | — | — | 300.27 | 0.013 | 0.012 | 0.004 | 0.079 | 0.201 | 0.143 | 0.486 | |

| A1B1 | 0.755 5 | 3.482 | 0.007 8 | 0.000 7 | 0.018 8 | 0.054 3 | 0.000 5 | 0.315 | 0.633 | 0.334 | 0.358 |

| A1B2 | 0.378 4 | 1.925 | 0.004 5 | 0.000 51 | 0.009 5 | 0.042 4 | 0.000 3 | 0.268 | 0.571 | 0.317 | 0.254 |

| A1B3 | 0.088 4 | 0.079 9 | 0.003 2 | 0.000 22 | 0.001 4 | 0.014 6 | 0.000 2 | 0.121 | 0.248 | 0.189 | 0.199 |

| GB 8978—1996 I类限值 | 2 | 15 | 0.5 | 0.05 | 1 | 0.1 | 0.5 | 0.5 | 2 | — | 1 |

| 1 |

何德军, 舒建成, 陈梦君, 等. 电解锰渣建材资源化研究现状与展望[J]. 化工进展, 2020, 39(10):4227-4237.

doi: 10.16085/j.issn.1000-6613.2020-0030 |

|

HE Dejun, SHU Jiancheng, CHEN Mengjun, et al. Current status and future prospects of electrolytic manganese residue reused as building materials[J]. Chemical Industry and Engineering Progress, 2020, 39(10):4227-4237.

doi: 10.16085/j.issn.1000-6613.2020-0030 |

|

| 2 | 金修齐, 黄代宽, 赵书晗, 等. 电解锰渣胶凝固化研究进展及其胶结充填可行性探讨[J]. 矿物岩石地球化学通报, 2020, 39(1):97-103. |

| JIN Xiuqi, HUANG Daikuan, ZHAO Shuhan, et al. Research progress in cementation/solidification and possibility of consolidated backfilling of the electrolytic manganese residue[J]. Bulletin of Mineralogy,Petrology and Geochemistry, 2020, 39(1):97-103. | |

| 3 |

CÁNOVAS C R, MACÍAS F, PÉREZ-LÓPEZ R, et al. Valorization of wastes from the fertilizer industry:Current status and future trends[J]. Journal of Cleaner Production, 2018, 174:678-690.

doi: 10.1016/j.jclepro.2017.10.293 |

| 4 | 张峻, 解维闵, 董雄波, 等. 磷石膏材料化综合利用研究进展[J]. 材料导报, 2023, 37(16):167-178. |

| ZHANG Jun, XIE Weimin, DONG Xiongbo, et al. Research progress on comprehensive utilization of phosphogypsum for materials:A review[J]. Materials Reports, 2023, 37(16):167-178. | |

| 5 |

WANG Jia, PENG Bing, CHAI Liyuan, et al. Preparation of electrolytic manganese residue-ground granulated blastfurnace slag cement[J]. Powder Technology, 2013, 241:12-18.

doi: 10.1016/j.powtec.2013.03.003 |

| 6 | 王继林, 龙广成, 董荣珍, 等. 掺电解锰渣砂浆的强度与微结构及碳排放分析[J]. 铁道科学与工程学报, 2023, 20(4):1382-1391. |

| WANG Jilin, LONG Guangcheng, DONG Rongzhen, et al. Analysis of strength,microstructure and carbon emission of mortar mixed with electrolytic manganese residue[J]. Journal of Railway Science and Engineering, 2023, 20(4):1382-1391. | |

| 7 | 胡修权, 张立, 张晋, 等. 非煅烧磷石膏基胶凝材料的改性实验[J]. 无机盐工业, 2022, 54(4):29-33. |

| HU Xiuquan, ZHANG Li, ZHANG Jin, et al. Modification experiment of non-calcined phosphogypsum based cementitious materials[J]. Inorganic Chemicals Industry, 2022, 54(4):29-33. | |

| 8 | LAM N N. A study on super-sulfated cement using Dinh Vu phosphogypsum[J]. IOP Conference Series:Earth and Environmental Science, 2018, 143: 012016. |

| 9 | 王星敏, 徐龙君, 胥江河, 等. 电解锰渣中锰的浸出条件及特征[J]. 环境工程学报, 2012, 6(10):3757-3761. |

| WANG Xingmin, XU Longjun, XU Jianghe, et al. Leaching conditions and characteristics of manganese from electrolytic manganese residue[J]. Chinese Journal of Environmental Engineering, 2012, 6(10):3757-3761. | |

| 10 | 杨洪友, 王家伟, 王海峰, 等. 某电解锰渣免烧砖的抗压抗折性能研究[J]. 非金属矿, 2019, 42(3):13-15. |

| YANG Hongyou, WANG Jiawei, WANG Haifeng, et al. Study on compressive and flexural properties of the baking-free brick made from an electrolytic manganese slag[J]. Non-Metallic Mines, 2019, 42(3):13-15. | |

| 11 | 谭明洋, 张西兴, 相利学, 等. 磷石膏作水泥缓凝剂的研究进展[J]. 无机盐工业, 2016, 48(7):4-6. |

| TAN Mingyang, ZHANG Xixing, XIANG Lixue, et al. Research progress of phosphorus gypsum as cement retarder[J]. Inorganic Chemicals Industry, 2016, 48(7):4-6. | |

| 12 |

JIANG Guanzhao, WU Aixiang, WANG Yiming, et al. Low cost and high efficiency utilization of hemihydrate phosphogypsum:Used as binder to prepare filling material[J]. Construction and Building Materials, 2018, 167:263-270.

doi: 10.1016/j.conbuildmat.2018.02.022 |

| 13 | 安树好. 高掺量矿渣水泥的研制及其早强激发机理的研究[D]. 唐山: 华北理工大学, 2008. |

| AN Shuhao. Development of high-slag cement and study on the activation mechanism of its early-strength[D]. Tangshan: North China University of Science and Technology, 2008. | |

| 14 | 张歆, 刘方, 朱健, 等. 基于电解锰渣-磷石膏复合胶凝材料的制备与表征[J]. 硅酸盐通报, 2021, 40(5):1610-1619. |

| ZHANG Xin, LIU Fang, ZHU Jian, et al. Preparation and characterization of composite cementitious material based on electrolytic manganese residue-phosphogypsum[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(5):1610-1619. | |

| 15 | 白敏, 龙广成. 大掺量电解锰渣制备生态型低强度水泥基材料[J]. 新型建筑材料, 2023, 50(6):55-60. |

| BAI Min, LONG Guangcheng. Preparation of ecological cement-based materials with low strength by mixing large amount of electrolytic manganese residue[J]. New Building Materials, 2023, 50(6):55-60. | |

| 16 | 万惠文, 王银, 戴鹏, 等. 磷石膏/矿粉复合过硫胶凝材料的制备研究[J]. 武汉理工大学学报, 2014, 36(3):23-27. |

| WAN Huiwen, WANG Yin, DAI Peng, et al. Study of phosphogysum/slag compound persulfate cementitious material[J]. Journal of Wuhan University of Technology, 2014, 36(3):23-27. | |

| 17 | 刘冬梅, 王玮琦, 彭艳周, 等. 磷石膏—磷渣基复合胶凝材料强度和水化特性研究[J]. 金属矿山, 2022(9):230-237. |

| LIU Dongmei, WANG Weiqi, PENG Yanzhou, et al. Study on the strength and hydration characteristics of phosphogypsum-phosphorus slag composite cementitious material[J]. Metal Mine, 2022(9):230-237. | |

| 18 |

XUE Fei, WANG Teng, ZHOU Min, et al. Self-solidification/stabilisation of electrolytic manganese residue:Mechanistic insigh-ts[J]. Construction and Building Materials, 2020, 255:118971.

doi: 10.1016/j.conbuildmat.2020.118971 |

| 19 | 石马刚, 柯国军, 邹品玉, 等. 碱-矿渣水泥的水化,力学及干缩性能研究进展[J]. 硅酸盐通报, 2022, 41(1):162-173. |

| SHI Magang, KE Guojun, ZOU Pinyu, et al. Research progress of hydration,mechanical and dry shrinkage properties of alkali-activated slag cement[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(1):162-173. | |

| 20 | 冯智广. 钛石膏基复合胶凝材料的性能研究与利用[D]. 杭州: 浙江大学, 2021. |

| FENG Zhiguang. Study and utilization of properties of titanium gypsum-based composite cementitious materials[D]. Hangzhou: Zhejiang University, 2021. | |

| 21 | 王智, 郭清春, 蒋小花, 等. 电解锰渣对粉煤灰火山灰活性的硫酸盐激发[J]. 非金属矿, 2011, 34(4):5-8. |

| WANG Zhi, GUO Qingchun, JIANG Xiaohua, et al. Sulphate activating of electrolytic manganese residue to fly ash[J]. Non-Metallic Mines, 2011, 34(4):5-8. |

| [1] | LI Keke, XUE Jiangwei, WANG Luwei, GUAN Xuemao. Effect of MgAl-layered double hydroxides on properties of high-iron low-calcium portland cement [J]. Inorganic Chemicals Industry, 2024, 56(4): 57-63. |

| [2] | ZHANG Guidong, YANG Xuejiao, GUO Xudong, YANG Lin. Study on hydration properties of type Ⅱ anhydrite prepared by calcination and atmospheric acidification [J]. Inorganic Chemicals Industry, 2024, 56(2): 104-110. |

| [3] | CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling. Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM [J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123. |

| [4] | WANG Yue, FANG Guoxiang, ZHANG Daoming, WANG Weicheng. Effect of nanosilica on gelling properties of hydraulic lime [J]. Inorganic Chemicals Industry, 2023, 55(7): 75-80. |

| [5] | XU Li, FANG Keneng, BI Yongxiang, YANG Min, CHEN Qianlin. Preparation of modified granular-like CaSO4 and its application in polyvinyl chloride [J]. Inorganic Chemicals Industry, 2023, 55(3): 104-112. |

| [6] | ZHANG Yanru, REN Changzai, SONG Zhanlong, ZHU Jianjun, ZHAO Baofeng, XIE Hongzhang, WANG Zhenjiang, QI Xiaole. Study on performance of biomass power plant ash as alternative to cement clinker in blended cements [J]. Inorganic Chemicals Industry, 2023, 55(10): 128-135. |

| [7] | CHEN Mingsheng,LIU Peng,KONG Dewen,LI Yuan,YU Ke,HUANG Yansen,WU Ningbo,CHANG Juanjuan. Effect of external admixtures on mechanical and thermal conductivity of phosphogypsum composite cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(9): 113-118. |

| [8] | ZHANG Taiyue,XIE Fan,GUO Junyuan. Study on performance optimization and mechanism of phosphogypsum based composite cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(9): 136-142. |

| [9] | XU Lihua,HUANG Zheng,ZHANG Xing,DU Huaiming,CHEN Xiaochao,HUANG Bin. Preparation and properties of composite materials from natural gas?based acetylene process produced carbon black and silica [J]. Inorganic Chemicals Industry, 2022, 54(5): 121-125. |

| [10] | MIAO Xun,LU Yuexian,FU Rusong,KONG Dewen,FU Rubin,HU Qun. Hemihydrate phosphogypsum as used to solidify the raw phosphogypsum to prepare composite cementitious material [J]. Inorganic Chemicals Industry, 2022, 54(4): 10-16. |

| [11] | WANG Yuan,WANG Zhi,QIN Hongyi. Study on properties of wet detoxification Fe-Cr slag as concrete admixture [J]. Inorganic Chemicals Industry, 2022, 54(3): 87-90. |

| [12] | LÜ Fangtao,ZHOU Yinsheng,KONG Dewen,CHEN Sihan,AN Hongfang,WANG Lingling. Effect of hybrid fiber on properties of desulfurized gypsum based composite cementitious material [J]. Inorganic Chemicals Industry, 2022, 54(10): 127-132. |

| [13] | LIU Junxia,LI Zhongyu,ZHANG Maoliang,HAI Ran. Research progress on magnesium phosphate cement modified by mineral admixtures [J]. Inorganic Chemicals Industry, 2022, 54(1): 18-23. |

| [14] | Liu Yuhong,Yin Chunlin,Ma Shunyou,Yan Xin,Yuan Xiaochao,Leng Jianjun,Zhang Jin. Preparation of colored zirconia ceramics by adding alumina-chrome slag from aluminothermic reduction [J]. Inorganic Chemicals Industry, 2021, 53(3): 78-83. |

| [15] | Wang Guosheng,Han Siyu,Tang Fengxiang,Xu Ronghui. Preparation and properties of modified basic magnesium chloride whisker/styrene butadiene rubber composites [J]. Inorganic Chemicals Industry, 2020, 52(3): 51-54. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||