| 1 |

黄锦.等离子体裂解煤制乙炔过程软测量方法研究[D].杭州:浙江大学,2020.

|

|

HUANG Jin.Study on soft sensor method for process in producting acetylene by pyrolysis of coal in plasma[D].Hangzhou:Zhejiang University,2020.

|

| 2 |

LI Yongzhi, WANG Gangding, YANG Hongyun,et al.New supercage metal⁃organic framework based on allopurinol ligands showing acetylene storage and separation[J].Chemistry-A European Journal,2020,26(69):16402-16407.

|

| 3 |

XU Zhu, ZHOU Shuzhen, ZHU Mingyuan.Ni catalyst supported on nitrogen⁃doped activated carbon for selective hydrogenation of acetylene with high concentration[J].Catalysis Communications,2021,149.Doi:10.1016/j.catcom.2020.106241 .

doi: 10.1016/j.catcom.2020.106241

|

| 4 |

ZENG Heng, XIE Mo, HUANG Yongliang,et al.Induced fit of C2H2 in a flexible MOF through cooperative action of open metal sites[J].Angewandte Chemie,2019,131(25):8603-8607.

|

| 5 |

TAKHT RAVANCHI M, SAHEBDELFAR S, KOMEILI S.Acetylene selective hydrogenation:A technical review on catalytic aspects[J].Reviews in Chemical Engineering,2018,34(2):215-237.

|

| 6 |

郭小虎,李凯华,苟远波,等.等离子体裂解煤制乙炔技术分析及展望[J].化工环保,2021,41(2):229-234.

|

|

GUO Xiaohu, LI Kaihua, GOU Yuanbo,et al.Analysis and prospect on plasma pyrolysis technology for coal⁃to⁃acetylene production[J].Environmental Protection of Chemical Industry,2021,41(2):229-234.

|

| 7 |

尹林虎,任小荣,马利云,等.乙炔生产工艺应用与推广[J].江西化工,2018(1):39-41.

|

|

YIN Linhu, REN Xiaorong, MA Liyun,et al.Application and po⁃

|

|

pularization acetylene production[J].Jiangxi Chemical Industry, 2018(1):39-41.

|

| 8 |

陆德芳,雍永祜.现代煤化工中的乙炔化工[J].化工进展,1989,8(5):9-13,8.

|

|

LU Defang, YONG Yonghu.Acetylene chemical industry in modern coal chemical industry[J].Chemical Industry and Engineering Progress,1989,8(5):9-13,8.

|

| 9 |

赵敏捷,方建军,张琳,等.煤等离子体裂解制乙炔技术研究现状[J].化学工程,2017,45(1):45-49.

|

|

ZHAO Minjie, FANG Jianjun, ZHANG Lin,et al.Present state of coal

|

|

pyrolysis to acetylene in plasma[J].Chemical Engineering(China), 2017,45(1):45-49.

|

| 10 |

王志方.天然气制乙炔工艺的氢能利用与多联产系统[D].北京:北京化工大学,2008.

|

|

WANG Zhifang.Polygeneration systems and hydrogen utilization of natural gas⁃based acetylene process[D].Beijing:Beijing University of Chemical Technology,2008.

|

| 11 |

游友惠.天然气部分氧化制乙炔副产炭黑综合利用探索[J].上海化工,2013,38(7):14-18.

|

|

YOU Youhui.Utilization of byproduct carbon black of methane partial combustion to acetylene[J].Shanghai Chemical Industry,2013,38(7):14-18.

|

| 12 |

路万里.关于天然气制乙炔装置副产炭黑处理技术探究[J].化工管理,2019(31):76-77.

|

|

LU Wanli.Study on treatment technology of by⁃product carbon black in acetylene plant from natural gas[J].Chemical Enterprise Management,2019(31):76-77.

|

| 13 |

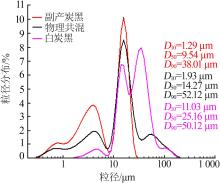

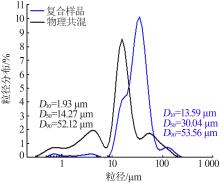

余尧,张俊毅,陈继凯,等.天然气制乙炔副产炭黑在天然橡胶中的应用研究[J].橡胶工业,2020,67(1):45-51.

|

|

YU Yao, ZHANG Junyi, CHEN Jikai,et al.Study on application of carbon black from natural gas based acetylene production in NR[J].China Rubber Industry,2020,67(1):45-51.

|

| 14 |

石太平.补强炭黑的改进及在带束层配方中的应用研究[D].哈尔滨:哈尔滨工业大学,2018.

|

|

SHI Taiping.Improvement of reinforcing carbon black and it's application in belt formulation[D].Harbin:Harbin Institute of Technology,2018.

|

| 15 |

FU Qingshan, CHEN Jian, YU Zuxiao,et al.Study on the structures and surface forces of different carbon blacks by atomic force microscopy[J].Applied Mechanics and Materials,2014,2948(496/497/498/499/500):106-109.

|

| 16 |

WANG Yanyan, TANG Meiyao, SHEN He,et al.Recyclable multifunctional magnetic mesoporous silica nanocomposite for ratiometric detection,rapid adsorption,and efficient removal of Hg(Ⅱ)[J].ACS Sustainable Chemistry & Engineering,2018,6(2):1744-1752.

|

),HUANG Zheng,ZHANG Xing,DU Huaiming,CHEN Xiaochao,HUANG Bin(

),HUANG Zheng,ZHANG Xing,DU Huaiming,CHEN Xiaochao,HUANG Bin( )

)