| [1] |

WANG Peixiong, GONG Xiaomei, DING Jiaqi, CAO Hong.

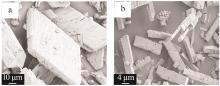

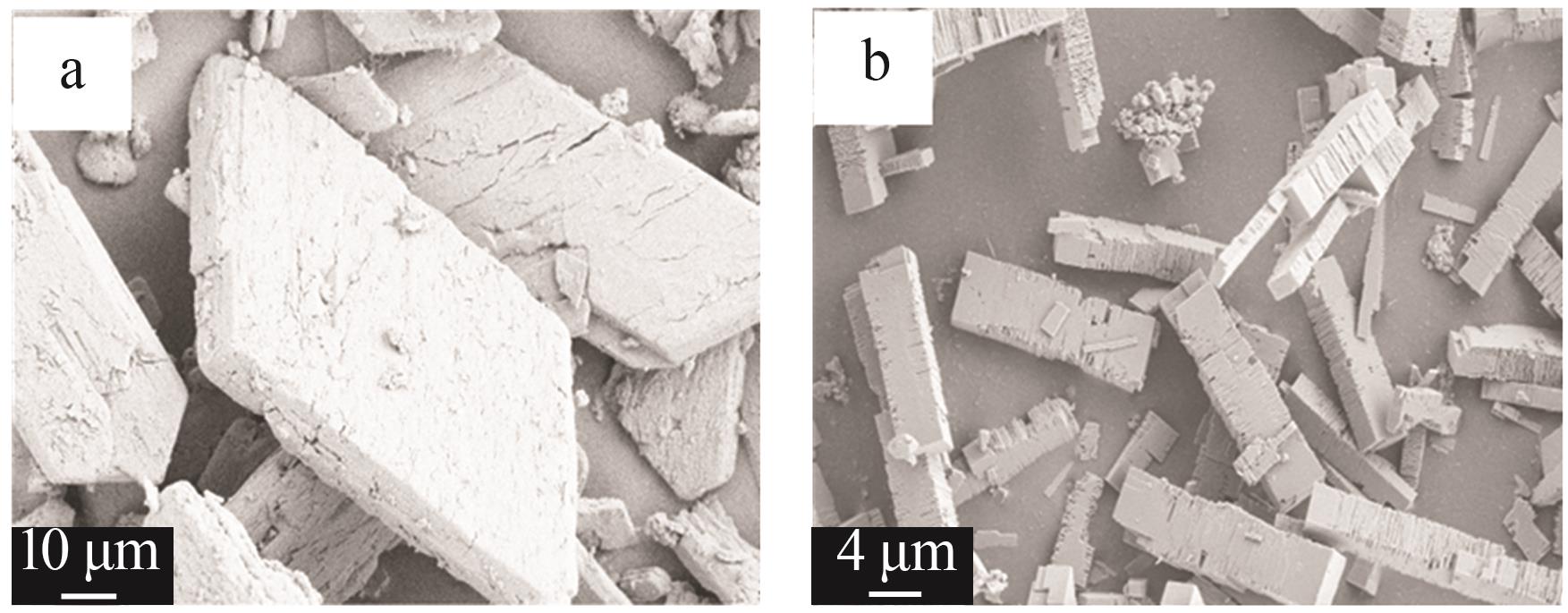

Effect of crystal modifier on preparation of α-hemihydrates gypsum from industrial gypsum

[J]. Inorganic Chemicals Industry, 2024, 56(4): 112-117.

|

| [2] |

YU Zhou, HE Zhaoyi, TANG Liang, HE Sheng, XIAO Haixin, XIAO Yixun.

Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials

[J]. Inorganic Chemicals Industry, 2024, 56(4): 90-97.

|

| [3] |

CHEN Feng, FENG Kang, LI Ming, SHEN Haojie, TIAN Chengtao, TANG Yuan, LI Zhili, HE Dongsheng.

Application of organically modified calcium sulfate whiskers in asphalt modification

[J]. Inorganic Chemicals Industry, 2024, 56(3): 125-130.

|

| [4] |

WANG Ruting, ZHAO Xiaorong, HUANG Xuquan, WANG Haojie, XUE Fei, CAI Jiawei.

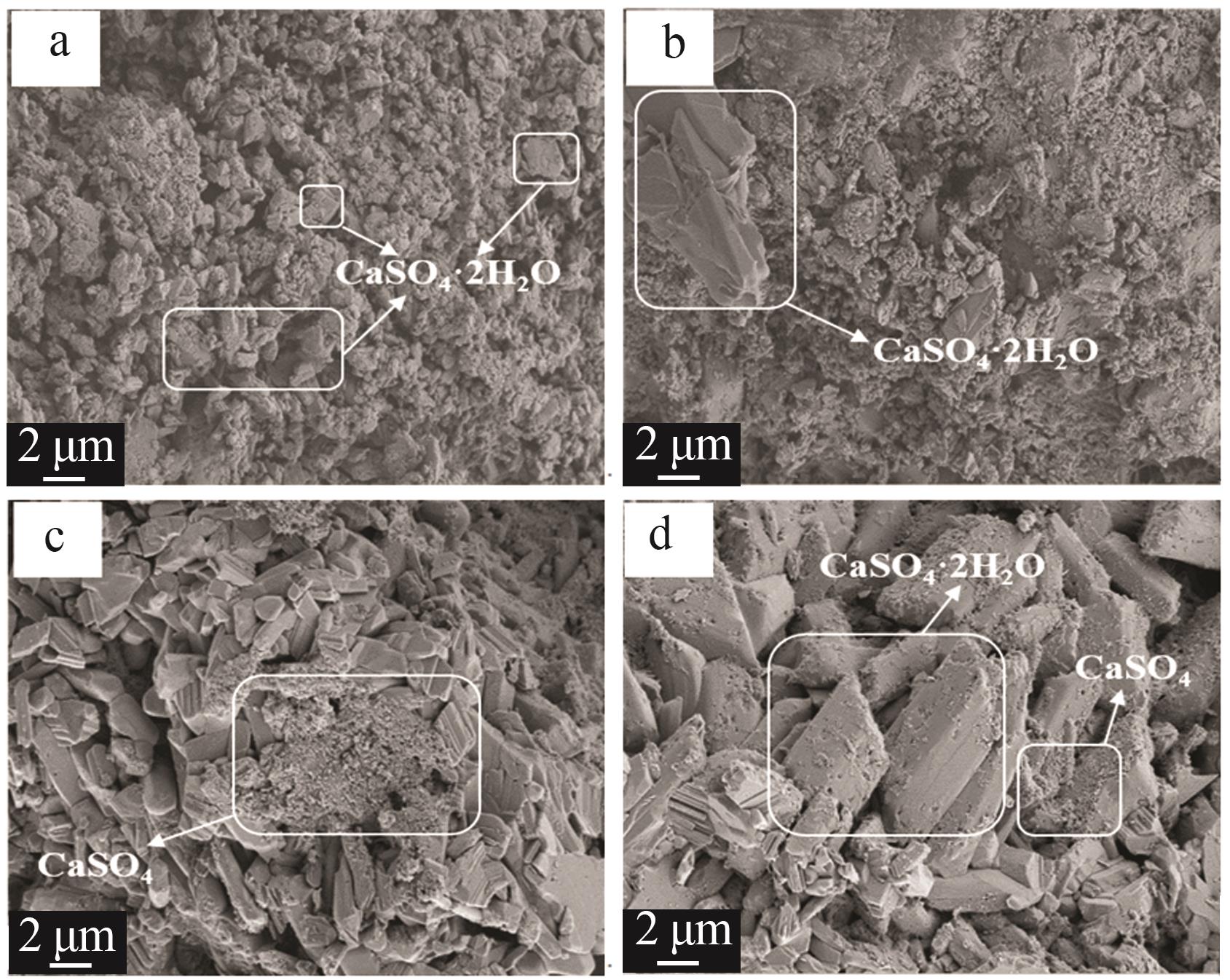

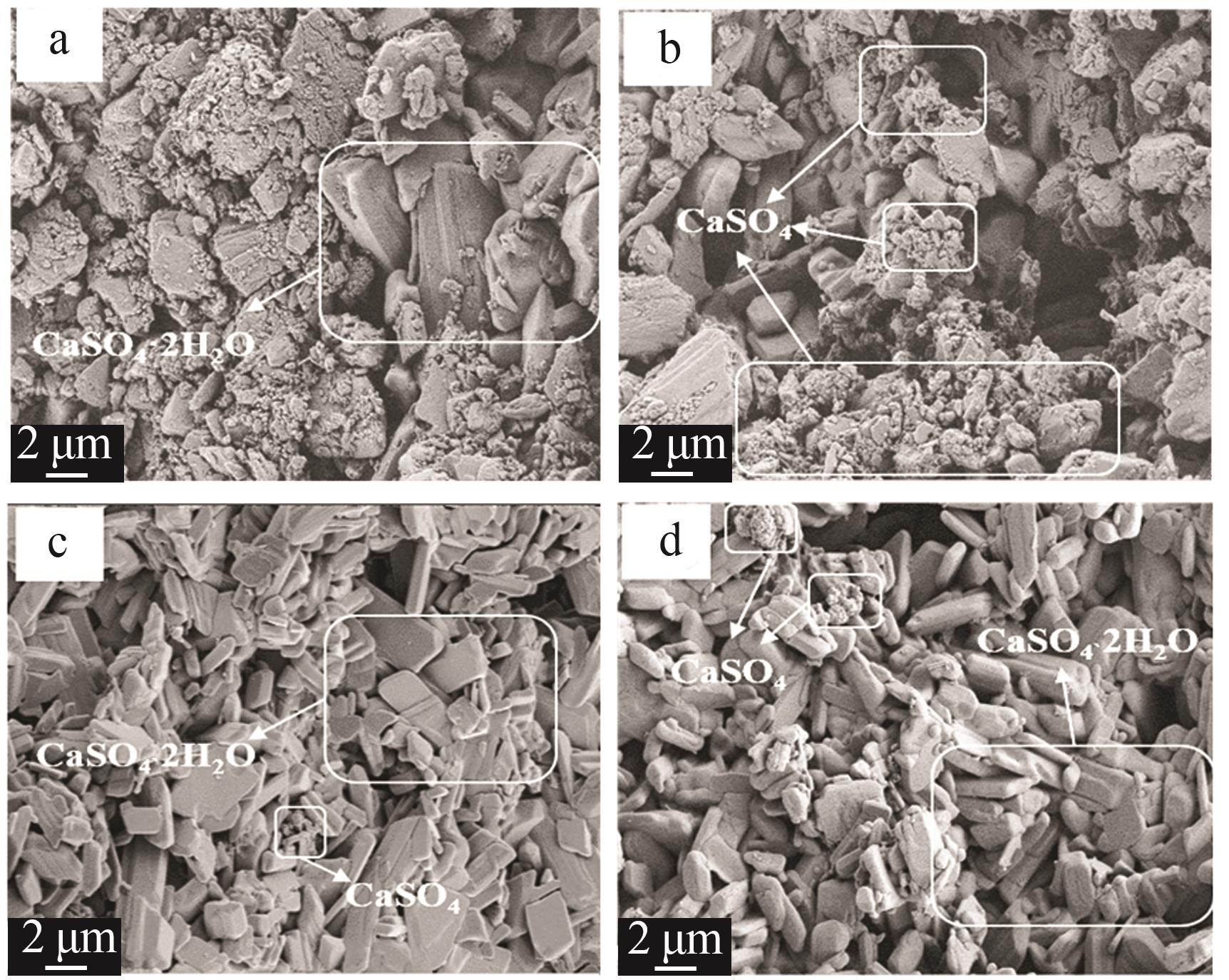

Research on preparation and early performance of mixed phase phosphogypsum-based cementing materials

[J]. Inorganic Chemicals Industry, 2024, 56(3): 98-104.

|

| [5] |

WANG Yanyu, GU Shouyu, HOU Cuihong, JING Hongquan, GUAN Hongling, ZHANG Hui.

Sulfur escape and slag physical phase analysis by carbon thermal reduction melting based on phosphogypsum ingredients

[J]. Inorganic Chemicals Industry, 2024, 56(2): 86-94.

|

| [6] |

DENG Hua, HOU Shuomin, LI Zhongjun, XU Gang, CHI Ru′an, XI Benjun.

Current situation and prospect of comprehensive utilization of phosphogypsum

[J]. Inorganic Chemicals Industry, 2024, 56(1): 1-8.

|

| [7] |

XIA Guiying, YANG Liuchun, YUAN Zhiye.

Study on direct leaching of rare earth elements from phosphogypsum with sulfuric acid

[J]. Inorganic Chemicals Industry, 2024, 56(1): 107-113.

|

| [8] |

XIANG Mengqi, MENG Hua, WANG Ye, MENG Xianzhang, BAI Yuhang, WANG Yujunyao, ZHANG Yidan.

Study on kinetic of iron leaching from titanium gypsum and its cyclic acid leaching process

[J]. Inorganic Chemicals Industry, 2024, 56(1): 114-120.

|

| [9] |

CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling.

Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM

[J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123.

|

| [10] |

LI Heng, ZHANG Hui, ZI Xuemin.

Analysis on calcination process progress of phosphogypsum

[J]. Inorganic Chemicals Industry, 2023, 55(6): 27-35.

|

| [11] |

ZHANG Lei, LI Meng, XIANG Wenguo, HU Jun, CHEN Shiyi, DUAN Lunbo.

Feasibility analysis of calcination and decomposition process of phosphogypsum in circulating fluidized bed

[J]. Inorganic Chemicals Industry, 2023, 55(6): 85-91.

|

| [12] |

XU Li, FANG Keneng, BI Yongxiang, YANG Min, CHEN Qianlin.

Preparation of modified granular-like CaSO4 and its application in polyvinyl chloride

[J]. Inorganic Chemicals Industry, 2023, 55(3): 104-112.

|

| [13] |

GUO Shuang, XING Dongxian, GUO Xiao, JI Xiaojie, TANG Jianwei, HUA Quanxian, WANG Baoming, LIU Yong.

Study on preparation and modification of phosphogypsum-based architectural gypsum

[J]. Inorganic Chemicals Industry, 2023, 55(12): 102-110.

|

| [14] |

LIU Chao, FAN Chuigang, LIU Runguo, YU Dongxue, LI Songgeng.

Preparation of α-hemihydrate gypsum from phosphogypsum by flotation and atmospheric trans-crystallization in solution

[J]. Inorganic Chemicals Industry, 2023, 55(11): 107-114.

|

| [15] |

SUN Zhigao, WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang.

Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer

[J]. Inorganic Chemicals Industry, 2023, 55(11): 139-146.

|

), YANG Xuejiao3, GUO Xudong3, YANG Lin1,2(

), YANG Xuejiao3, GUO Xudong3, YANG Lin1,2( )

)