| [1] |

贾兴文, 吴洲, 马英. 磷石膏建材资源化利用现状[J]. 材料导报, 2013, 27(23):139-141,146.

|

| [2] |

吴照洋, 张永兴, 张利珍, 等. β石膏相组成和杂质含量对其性能的影响[J]. 无机盐工业, 2021, 53(9):67-71.

|

| [3] |

ZHOU J, LI X, ZHAO Y, et al. Preparation of paper-free and fiber-free plasterboard with high strength using phosphogypsum[J]. Con-struction and Buliding Materials, 2020, 243.Doi: 10.1016/j.conbu-ildmat.2020.118091.

doi: 10.1016/j.conbu-ildmat.2020.118091

|

| [4] |

SHEN Y, QING J, CHAI J, et al. Calcium sulphoaluminate cements made with phosphogypsum:Production issues and material proper-ties[J]. Cement & Concrete Composites, 2014, 48:67-74.

|

| [5] |

YANG L, ZHANG Y, YAN Y. Utilization of original phosphogypsum as raw material for the preparation of self-leveling mortar[J]. Journal of Cleaner Production, 2016, 127:204-213.

doi: 10.1016/j.jclepro.2016.04.054

|

| [6] |

马丽萍. 磷石膏资源化综合利用现状及思考[J]. 磷肥与复肥, 2019, 34(7):5-9.

|

| [7] |

李逸晨, 杨再银. 磷石膏综合利用技术发展动态[J]. 磷肥与复肥, 2018, 33(2):1-6.

|

| [8] |

谭明洋, 张西兴, 相利学, 等. 磷石膏作水泥缓凝剂的研究进展[J]. 无机盐工业, 2016, 48(7):4-6.

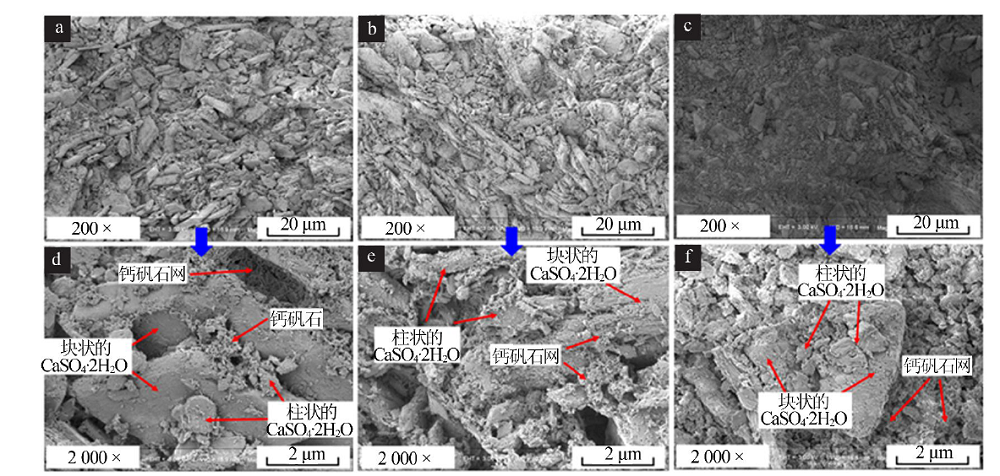

|

| [9] |

AMRANI M, TAHA Y, KCHIKACH A, et al. Phosphogypsum recycling:New horizons for a more sustainable road material application[J]. Journal of Building Engineering, 2020, 30.Doi: 10.1016/j.jobe.2020.101267.

doi: 10.1016/j.jobe.2020.101267

|

| [10] |

JIANG G, WU A, WANG Y, et al. Low cost and high efficiency utilization of hemihydrate phosphogypsum:Used as binder to prepare filling material[J]. Construction and Buliding Materials, 2018, 167(167):263-270.

|

| [11] |

孙世杰, 周贵云. 磷石膏制备β-半水建筑石膏技术研究[J]. 磷肥与复肥, 2019, 34(7):18-19,49.

|

| [12] |

张毅, 王小鹏, 李东旭. 利用原状磷石膏制备石膏基复合胶凝材料的力学性能[J]. 南京工业大学学报:自然科学版, 2011, 33(1):68-73.

|

| [13] |

HUA S, WANG K, YAO X, et al. Effects of fibers on mechanical properties and freeze-thaw resistance of phosphogypsum-slag based cementitious materials[J]. Construction and Buliding Materials, 2016, 121:290-299.

|

| [14] |

ZHOU S, LI X, ZHOU Y, et al. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill[J]. Journal of hazardous materials, 2020, 399.Doi: 10.1016/j.jhazmat.2020.122993.

doi: 10.1016/j.jhazmat.2020.122993

|

| [15] |

于万增, 潘俊廷, 朱会荣, 等. 原状磷石膏用作混凝土添加剂的性能研究[J]. 新型建筑材料, 2020, 47(4):28-30,42.

|

| [16] |

周灿灿, 郭小雨, 邓先功, 等. 原状磷石膏基水硬性胶凝材料的制备与性能表征[J]. 安徽工业大学学报:自然科学版, 2019, 36(1):29-34.

|

| [17] |

HUANG Y, LIN Z. Investigation on phosphogypsum-steel slag-granulated blast-furnace slag-limestone cement[J]. Construction and Buliding Materials, 2010, 24(7):1296-1301.

|

| [18] |

CHEN X, GAO J, LIU C, et al. Effect of neutralization on the setting and hardening characters of hemihydrate phosphogypsum plaster[J]. Construction and Buliding Materials, 2018, 190:53-64.

|

| [19] |

JIN Z, MA B, SU Y, et al. Effect of calcium sulphoaluminate cement on mechanical strength and waterproof properties of beta-hemihydrate phosphogypsum[J]. Construction and Buliding Materials, 2020, 242.Doi: 10.1016/j.conbuildmat.2020.118198.

doi: 10.1016/j.conbuildmat.2020.118198

|

| [20] |

罗双, 付汝宾, 孔德文, 等. 掺合料对磷石膏基复合胶凝材料耐水性及强度的影响综述[J]. 无机盐工业, 2020, 52(11):6-11.

|

| [21] |

姜关照, 吴爱祥, 王贻明, 等. 生石灰对半水磷石膏充填胶凝材料性能影响[J]. 硅酸盐学报, 2020, 48(1):86-93.

|

| [22] |

王健. 发泡磷石膏轻质材料的制备与基本性能[D]. 哈尔滨:哈尔滨工业大学, 2016.

|

| [23] |

兰文涛, 吴爱祥, 王贻明, 等. 基于正交实验的半水磷石膏充填配比优化[J]. 中国有色金属学报, 2019, 29(5):1083-1091.

|

| [24] |

ZHOU P, WU H, XIA Y. Influence of synthetic polymers on the mechanical properties of hardened β-calcium sulfate hemihydrate plasters[J]. Journal of Industrial and Engineering Chemistry, 2016, 33:355-361.

doi: 10.1016/j.jiec.2015.10.024

|

| [25] |

钱觉时, 余金城, 孙化强, 等. 钙矾石的形成与作用[J]. 硅酸盐学报, 2017, 45(11):1569-1581.

|

),LU Yuexian1,FU Rusong1,KONG Dewen1(

),LU Yuexian1,FU Rusong1,KONG Dewen1( ),FU Rubin2,HU Qun3

),FU Rubin2,HU Qun3