Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (2): 95-103.doi: 10.19964/j.issn.1006-4990.2023-0197

• Environment·Health·Safety • Previous Articles Next Articles

Study on preparation of low ash activated carbon by phosphoric acid method

ZHANG Li1( ), ZHANG Dan2, PAN Hongyan1(

), ZHANG Dan2, PAN Hongyan1( ), DONG Yonggang1(

), DONG Yonggang1( ), LI Wenfei2, QIN Hong2

), LI Wenfei2, QIN Hong2

- 1.School of Chemistry and Chemical Engineering, Guizhou University, Guiyang 550025, China

2.Guizhou Wengfu Chemical Co. , Ltd. , Guiyang 550002, China

-

Received:2023-04-06Online:2024-02-10Published:2024-02-06 -

Contact:PAN Hongyan, DONG Yonggang E-mail:3431183060@qq.com;cepanhongyan@163.com;ygdong@gzu.edu.cn

CLC Number:

Cite this article

ZHANG Li, ZHANG Dan, PAN Hongyan, DONG Yonggang, LI Wenfei, QIN Hong. Study on preparation of low ash activated carbon by phosphoric acid method[J]. Inorganic Chemicals Industry, 2024, 56(2): 95-103.

share this article

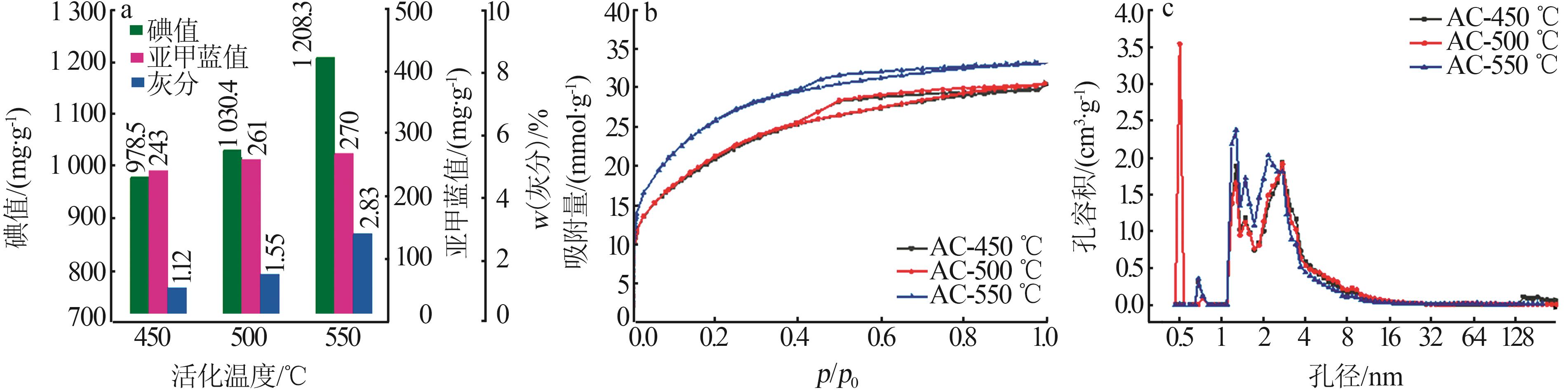

Table 1

Pore structure parameters of activated carbon prepared at different activation temperatures"

| 样品 | SBET/ (m2·g-1) | Smic/ (m2·g-1) | Smes/ (m2·g-1) | Vtotal/ (cm3·g-1) | Vmic/ (cm3·g-1) | Vmes/ (cm3·g-1) |

|---|---|---|---|---|---|---|

| AC-450 | 1 677 | 1 330 | 347 | 1.056 9 | 0.686 6 | 0.370 3 |

| AC-500 | 1 762 | 1 406 | 356 | 1.065 8 | 0.690 4 | 0.375 4 |

| AC-550 | 2 103 | 1 818 | 285 | 1.151 3 | 0.869 9 | 0.272 3 |

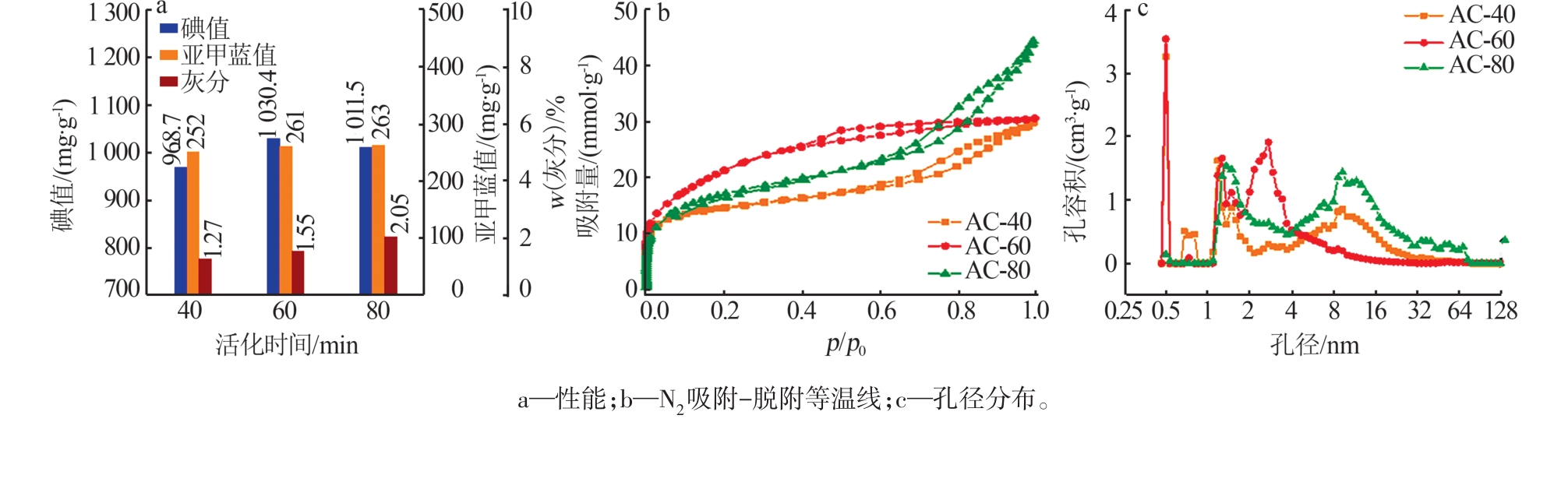

Table 2

Pore structure parameters of activated carbon prepared at different activation time"

| 样品 | SBET/ (m2·g-1) | Smic/ (m2·g-1) | Smes/ (m2·g-1) | Vtotal/ (cm3·g-1) | Vmic/ (cm3·g-1) | Vmes/ (cm3·g-1) |

|---|---|---|---|---|---|---|

| AC-40 | 1 483 | 1 230 | 253 | 0.985 9 | 0.676 6 | 0.309 3 |

| AC-60 | 1 762 | 1 406 | 356 | 1.065 8 | 0.690 4 | 0.375 4 |

| AC-80 | 1 625 | 1 294 | 331 | 1.183 2 | 0.654 1 | 0.529 1 |

Table 3

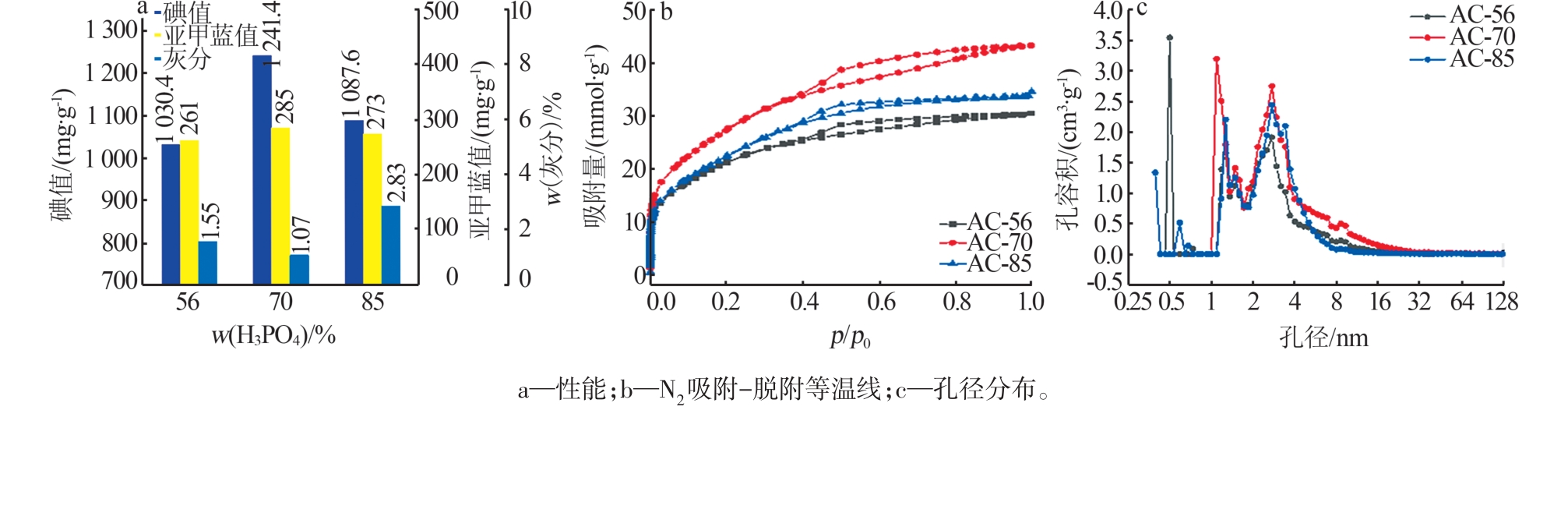

Pore structure parameters of activated carbon prepared at different phosphoric acid concentrations"

| 样品 | SBET/ (m2·g-1) | Smic/ (m2·g-1) | Smes/ (m2·g-1) | Vtotal/ (cm3·g-1) | Vmic/ (cm3·g-1) | Vmes/ (cm3·g-1) |

|---|---|---|---|---|---|---|

| AC-56 | 1 762 | 1 406 | 356 | 1.065 8 | 0.690 4 | 0.375 4 |

| AC-70 | 2 290 | 1 690 | 600 | 1.501 8 | 0.849 6 | 0.652 2 |

| AC-85 | 1 787 | 1 329 | 458 | 1.199 2 | 0.759 1 | 0.440 1 |

Table 4

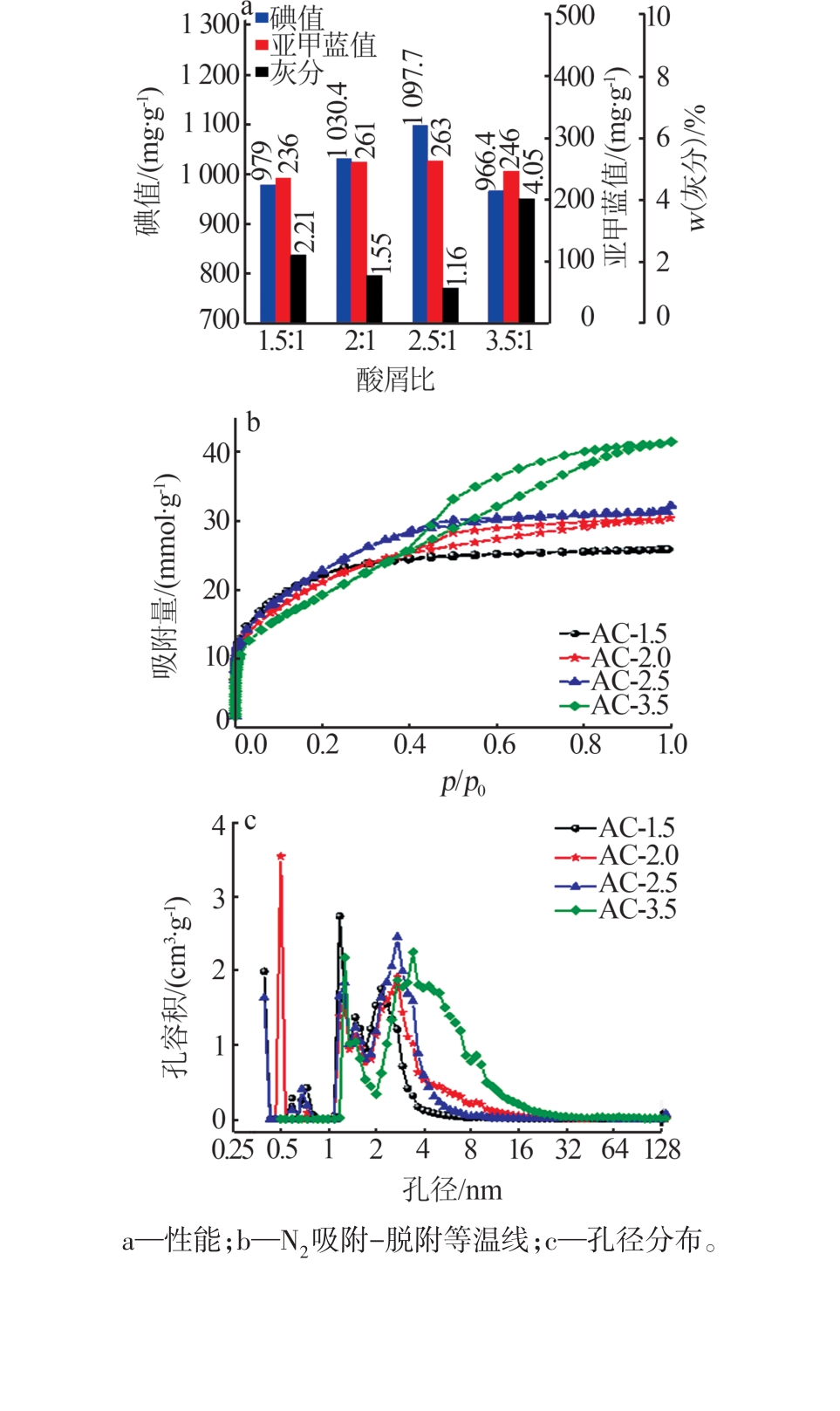

Pore structure parameters of activated carbon prepared at different acid chip mass ratios"

| 样品 | SBET/ (m2·g-1) | Smic/ (m2·g-1) | Smes/ (m2·g-1) | Vtotal/ (cm3·g-1) | Vmic/ (cm3·g-1) | Vmes/ (cm3·g-1) |

|---|---|---|---|---|---|---|

| AC-1.5 | 1 522 | 1 314 | 208 | 0.90 | 0.70 | 0.20 |

| AC-2.0 | 1 762 | 1 406 | 356 | 1.07 | 0.69 | 0.38 |

| AC-2.5 | 1 831 | 1 573 | 258 | 1.12 | 0.85 | 0.27 |

| AC-3.5 | 1 547 | 401 | 1 146 | 1.44 | 0.26 | 1.18 |

| 1 | 邓美玲.关于活性炭市场调研的建模分析[J].科技与创新,2022(20):109-111. |

| DENG Meiling.Modeling and analysis of activated carbon market research[J].Science and Technology & Innovation,2022(20):109-111. | |

| 2 | 任学勇,祁项超,曹畅,等.“双碳”战略下生物质活性炭材料生产与应用发展探析[J].林产工业,2022,59(4):48-51,63. |

| REN Xueyong, QI Xiangchao, CAO Chang,et al.Research on production and application of biomass activated carbon under “double carbon” strategy[J].China Forest Products Industry,2022,59(4):48-51,63. | |

| 3 | 孙昊,孙云娟,缪存标,等.我国活性炭产业发展典型案例分析:以福建元力活性炭股份有限公司为例[J].生物质化学工程,2021,55(1):1-9. |

| SUN Hao, SUN Yunjuan, MIAO Cunbiao,et al.A typical case analysis of activated carbon industry development in China:Fujian Yuanli active carbon Co.,Ltd.[J].Biomass Chemical Engineering,2021,55(1):1-9. | |

| 4 | 解强,张香兰,梁鼎成,等.煤基活性炭定向制备:原理·方法·应用[J].煤炭科学技术,2021,49(1):100-127. |

| XIE Qiang, ZHANG Xianglan, LIANG Dingcheng,et al.Directional preparation of coal-based activated carbon:Principles,approaches and applications[J].Coal Science and Technology,2021,49(1):100-127. | |

| 5 | 王硕,张健本,谢彩锋.生物质活性炭制备及吸附含硫化合物研究进展[J].应用化工,2022,51(12):3608-3613. |

| WANG Shuo, ZHANG Jianben, XIE Caifeng.Preparation and adsorption of sulfur compounds by biomass activated carbon[J].Applied Chemical Industry,2022,51(12):3608-3613. | |

| 6 | TRIFONOV S V, MURYGIN A V, TIKHOMIROV A A.Physical-chemical method for desalting organic waste for agricultural cycl-es[J].IOP Conference Series:Earth and Environmental Science,2021,839(4):042062. |

| 7 | 张会均,欧阳晚秋,陈琳莉.磷酸法茶渣活性炭的制备及吸附性能[J].应用化工,2019,48(12):2947-2950. |

| ZHANG Huijun, OUYANG Wanqiu, CHEN Linli.Characteristics and optimization of activated carbon from tea waste using H3PO4 [J].Applied Chemical Industry,2019,48(12):2947-2950. | |

| 8 | 郭奇,许伟,刘军利.磷酸法木质素基活性炭的制备及其电化学性能研究[J].林产化学与工业,2022,42(2):31-38. |

| GUO Qi, XU Wei, LIU Junli.Preparation and electrochemical performance of lignin-based activated carbon by phosphoric acid activation[J].Chemistry and Industry of Forest Products,2022,42(2):31-38. | |

| 9 | KAMAL S, AHMED B.Experimental tests of cadmium and trace metals adsorption on natural clays and activated carbon from wet phosphoric acid[J].Inorganic Chemistry Communications,2022,144:109866. |

| 10 | MUNAWAR I, MUHAMMAD S, ZAHID A,et al.Paracetamol and amoxicillin adsorptive removal from aqueous solution using phosphoric acid activated-carbon[J].Zeitschrift Für Physikalische Chemie,2023,237(3):257-271. |

| 11 | HIGAI D, HUANG Zhebin, QIAN E W.Preparation and surface characteristics of phosphoric acid-activated carbon from coconut shell in air[J].Environmental Progress & Sustainable Energy,2021,40(2):e13509. |

| 12 | 李文飞,王凤霞,杨坤.湿法净化磷酸与热法磷酸在微生物发酵应用中的差异研究[J].广州化工,2021,49(3):46-49. |

| LI Wenfei, WANG Fengxia, YANG Kun.Study on difference between purified wet phosphoric acid and thermal method phosphoric acid in microbial fermentation[J].Guangzhou Chemical Industry,2021,49(3):46-49. | |

| 13 | 马航,冯霄.基于湿、热法磷加工体系共生耦合的磷资源产业可持续性发展研究[J].无机盐工业,2018,50(11):1-6. |

| MA Hang, FENG Xiao.Study on sustainable development of phosphorus industry based on symbiotic coupling of wet and thermal phosphorus processing systems[J].Inorganic Chemicals Industry,2018,50(11):1-6. | |

| 14 | 梅毅,樊蕾,梁雪松,等.热法磷酸与湿法工业磷酸的技术经济分析[J].无机盐工业,2011,43(1):4-7. |

| MEI Yi, FAN Lei, LIANG Xuesong,et al.Techno-economic analysis on phosphoric acid by furnace process and phosphoric acid by wet process[J].Inorganic Chemicals Industry,2011,43(1):4-7. | |

| 15 | 王保明,吕中豪,李会勇,等.湿法磷酸制备磷酸脲的研究进展[J].无机盐工业,2020,52(11):1-5. |

| WANG Baoming, Zhonghao LÜ, LI Huiyong,et al.Research progress on preparation of urea phosphate with wet-process phosphoric acid[J].Inorganic Chemicals Industry,2020,52(11):1-5. | |

| 16 | 杜加磊,翟持,朱远蹠,等.基于分析的热法磷酸全热能回收技术模拟研究[J].化工学报,2021,72(11):5790-5799. |

| DU Jialei, ZHAI Chi, ZHU Yuanzhi,et al.Simulation study on heat energy recovery technology of furnace-process phosphoric acid process[J].CIESC Journal,2021,72(11):5790-5799. | |

| 17 | 齐亚兵,张思敬.湿法磷酸净化技术研究新进展及应用现状[J].应用化工,2022,51(9):2798-2804. |

| QI Yabing, ZHANG Sijing.New research progress and present application situation of purification technology for wet-process phosphoric acid[J].Applied Chemical Industry,2022,51(9):2798-2804. | |

| 18 | 王芳平,张劲斌,李晨阳,等.灰分对玉米芯基活性炭电化学性能的影响[J].现代化工,2020,40(5):190-193. |

| WANG Fangping, ZHANG Jinbin, LI Chenyang,et al.Effect of ash on electrochemical performance of corncob-based activated carbon[J].Modern Chemical Industry,2020,40(5):190-193. | |

| 19 | 刘菲.酸洗除灰分对活性炭性质的影响[J].石化技术,2019,26(5):212-213. |

| LIU Fei.Effect of acid cleaning and ash removal on properties of activated carbon[J].Petrochemical Industry Technology,2019,26(5):212-213. | |

| 20 | 邵远超,田华宇,王国睿,等.低灰分刺竹炭制备及性能表征[J].林业工程学报,2023,8(1):80-87. |

| SHAO Yuanchao, TIAN Huayu, WANG Guorui,et al.Study on preparation and characterization of low ash bambusa sinospinosa charcoal[J].Journal of Forestry Engineering,2023,8(1):80-87. | |

| 21 | 鲍建秀.磷酸法制备低灰分活性炭的研究[J].化学工程与装备,2019(4):19-20,42. |

| BAO Jianxiu.Study on preparation of low ash activated carbon by phosphoric acid method[J].Chemical Engineering & Equipment,2019(4):19-20,42. | |

| 22 | 徐茹婷,卢辛成,许伟,等.磷酸法玉米秸秆基活性炭的制备及其表征[J].生物质化学工程,2022,56(1):1-6. |

| XU Ruting, LU Xincheng, XU Wei,et al.Preparation and characterization of corn straw based activated carbon by phosphoric acid activation[J].Biomass Chemical Engineering,2022,56(1):1-6. | |

| 23 | 叶结旺,周志丹,金贞福.氮掺杂木质素基活性炭的制备、表征及其吸附性能研究[J].林产化学与工业,2023,43(1):127-132. |

| YE Jiewang, ZHOU Zhidan, JIN Zhenfu.Preparation,characterization and adsorption properties of nitrogen-doped lignin-based activated carbon[J].Chemistry and Industry of Forest Products,2023,43(1):127-132. | |

| 24 | 马名哲,孙昊,孙康,等.龙凤檀磷酸法活性炭的孔径分布与吸附性能的构效关系[J].林产化学与工业,2023,43(1):51-56. |

| MA Mingzhe, SUN Hao, SUN Kang,et al.The relationship between pore size distribution and adsorption properties of cumaru activated carbon prepared by phosphoric acid method[J].Chemistry and Industry of Forest Products,2023,43(1):51-56. | |

| 25 | MAGUANA Y EL, ELHADIRI N, BOUCHDOUG M,et al.Activated carbon from prickly pear seed cake:Optimization of preparation conditions using experimental design and its application in dye removal[J].International Journal of Chemical Engineering,2019,2019(12):1-12. |

| 26 | DENG Meigen, WANG Junlong, ZHANG Qi.Effect of freezing pretreatment on the performance of activated carbon from coconut shell for supercapacitor application[J].Materials Letters,2022,306:130934. |

| [1] | ZHAO Feiyan, ZHANG Xiaodong, DU Yanxia, WANG Qiang, LI Xiaoyan. Preparation technology and research progress of fly ash ceramsite [J]. Inorganic Chemicals Industry, 2024, 56(4): 16-23. |

| [2] | LI Kuai, LI Zhaoshuai, DONG Tingxuan, LI Dan, GUO Shengwei, HAN Fenglan. Study on effect of wet magnetic separation on distribution of Fe and heavy metal in fly ash [J]. Inorganic Chemicals Industry, 2024, 56(4): 98-104. |

| [3] | LI Qiaoyun, HUANG Xiuxing, WEI Wenye, CHEN Zhen. Study on adsorption of methylene blue by activated carbon with acid/alkali synergistically modified fly ash [J]. Inorganic Chemicals Industry, 2024, 56(3): 131-136. |

| [4] | ZHANG Ying, LI Jun, JIN Yang, HUANG Meiying. Study on pyrolysis regeneration of activated carbon for Tributyl phosphate decolorization [J]. Inorganic Chemicals Industry, 2024, 56(1): 59-66. |

| [5] | LU Junhao. Study on full element recycling process of retired ternary power lithium battery [J]. Inorganic Chemicals Industry, 2023, 55(6): 92-103. |

| [6] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [7] | ZHOU Qinglie, WANG Baoqi, ZHANG Zhiye, ZHANG Yinghu, WANG Jian, YANG Lin. Development of new process of removing metal cations from wet-process phosphoric acid by extraction [J]. Inorganic Chemicals Industry, 2023, 55(3): 84-91. |

| [8] | XU Rongsheng, MENG Ze, FENG Qian, WANG Ping, SUN Dong, LI Mei. Study on preparation of activated carbon from corn cob by zinc chloride and water vapor [J]. Inorganic Chemicals Industry, 2023, 55(12): 119-127. |

| [9] | SUN Zhigao, WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang. Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer [J]. Inorganic Chemicals Industry, 2023, 55(11): 139-146. |

| [10] | YANG Hongjun, WANG Min, GE Haiwen, QIAO Youmin, QIAO Ziyang. Study on recycling process of potassium from calcium aluminate fly ash [J]. Inorganic Chemicals Industry, 2023, 55(10): 121-127. |

| [11] | ZHANG Yanru, REN Changzai, SONG Zhanlong, ZHU Jianjun, ZHAO Baofeng, XIE Hongzhang, WANG Zhenjiang, QI Xiaole. Study on performance of biomass power plant ash as alternative to cement clinker in blended cements [J]. Inorganic Chemicals Industry, 2023, 55(10): 128-135. |

| [12] | HE Wenchao,XUE Jing,WANG Wei. Research on strength and creep characteristics of concrete containing fly ash microbead [J]. Inorganic Chemicals Industry, 2023, 55(1): 124-128. |

| [13] | LIU Darui,XU Lijun,LI Shichun,CAO Kun,TU Ya,LI Wenqing,LIU Qingliang. Research progress of recovery of strategic metal lithium from fly ash [J]. Inorganic Chemicals Industry, 2023, 55(1): 56-63. |

| [14] | WANG Zhiqiang,ZHANG Junjie,LIU Xiangcheng,JIN Wufeng. Study on adsorption kinetics model of modified activated carbon on SO2 with low?concentration [J]. Inorganic Chemicals Industry, 2022, 54(9): 69-76. |

| [15] | DU Bingxuan,LI Haichao,LIN Zezhong. Study on preparation of food?grade potassium chloride by one?step adsorption and purification [J]. Inorganic Chemicals Industry, 2022, 54(9): 96-101. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||