Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (12): 43-49.doi: 10.19964/j.issn.1006-4990.2023-0062

• Research & Development • Previous Articles Next Articles

Preparation of nano-alumina slurry and its application in modifying lithium-ion battery cathode material

TIAN Peng1,2( ), XU Jingang1, XU Qianjin2, LIU Kunji2, PANG Hongchang1, NING Guiling1

), XU Jingang1, XU Qianjin2, LIU Kunji2, PANG Hongchang1, NING Guiling1

- 1. School of Chemical Engineering, Dalian University of Technology, Dalian 116023, China

2. Jiangxi Baohtech Science Co Ltd., Yichun 336000, China

-

Received:2023-02-10Online:2023-12-10Published:2023-12-14

CLC Number:

Cite this article

TIAN Peng, XU Jingang, XU Qianjin, LIU Kunji, PANG Hongchang, NING Guiling. Preparation of nano-alumina slurry and its application in modifying lithium-ion battery cathode material[J]. Inorganic Chemicals Industry, 2023, 55(12): 43-49.

share this article

Table 1

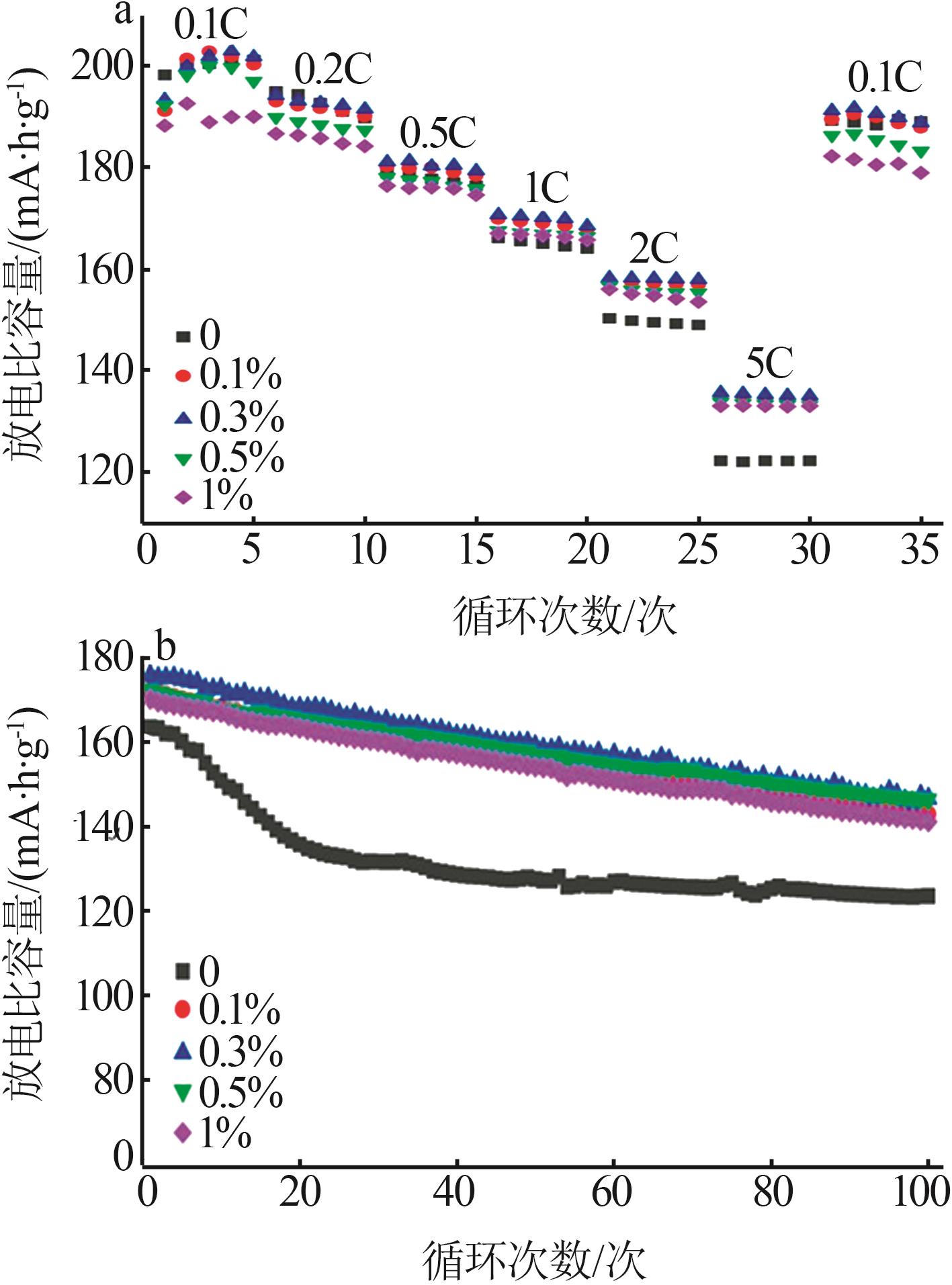

Comparison of effects of alumina modified lithium battery cathode materials by different methods"

| 正极材料 | 改性方法 | 循环容量保持率/% |

|---|---|---|

| NCM811[ | ALD | 73.87(0.1C,100次) |

| NCM811 [ | 溅射法 | 88.30(1C,100次) |

| NCM622 [ | 浸渍法 | 82.00(0.5C,100次) |

| NCM523[ | ALD | 76.80(1C,30次) |

| NCM622[ | 干法 | 85.00(1C,100次) |

| NCM[ | ALD | 84.70(1C/3,80次) |

| NCM811[ | 浸渍法 | 82.67(0.5C,100次) |

| NCM811(本工作) | — | 84.93(1C,100次) |

| 1 |

ZHAO Shuoqing, GUO Ziqi, YAN Kang, et al. Towards high-energy-density lithium-ion batteries:Strategies for developing high-capacity lithium-rich cathode materials[J]. Energy Storage Materials, 2021, 34:716-734.

doi: 10.1016/j.ensm.2020.11.008 |

| 2 |

SHAFIQ S, IRSHAD U BIN, AL-MUHAINI M, et al. Reliability evaluation of composite power systems:Evaluating the impact of full and plug-in hybrid electric vehicles[J]. IEEE Access, 2020, 8:114305-114314.

doi: 10.1109/ACCESS.2020.3003369 |

| 3 |

EL-HENDAWI M, WANG Zhanle, PARANJAPE R, et al. Electric vehicle charging model in the urban residential sector[J]. Energies, 2022, 15(13):4901.

doi: 10.3390/en15134901 |

| 4 |

WU Weitiao, LIN Yue, LIU Ronghui, et al. Online EV charge scheduling based on time-of-use pricing and peak load minimization:Properties and efficient algorithms[J]. IEEE Transactions on Intelligent Transportation Systems, 2022, 23(1):572-586.[LinkOut]

doi: 10.1109/TITS.2020.3014088 |

| 5 |

OR T, GOURLEY S W D, KALIYAPPAN K, et al. Recycling of mixed cathode lithium-ion batteries for electric vehicles:Current status and future outlook[J]. Carbon Energy, 2020, 2(1):6-43.

doi: 10.1002/cl2.v2.1 |

| 6 |

GOODENOUGH J B, PARK K S. The Li-ion rechargeable battery:A perspective[J]. Journal of the American Chemical Society, 2013, 135(4):1167-1176.

doi: 10.1021/ja3091438 |

| 7 |

ZHAO Shuoqing, YAN Kang, ZHANG Jinqiang, et al. Reaction mechanisms of layered lithium-rich cathode materials for high-energy lithium-ion batteries[J]. Angewandte Chemie International Edition, 2021, 60(5):2208-2220.

doi: 10.1002/anie.v60.5 |

| 8 | LEE W, MUHAMMAD S, SERGEY C, et al. Advances in the cathode materials for lithium rechargeable batteries[J]. Angewandte Chemie(International Ed.in English), 2020, 59(7):2578-2605. |

| 9 |

ZHOU Dingyanyan, GUO Xiaotian, ZHANG Qinyi, et al. Nickel-based materials for advanced rechargeable batteries[J]. Advanced Functional Materials, 2022, 32(12):2107928.

doi: 10.1002/adfm.v32.12 |

| 10 | YU Haifeng, WANG Shouliang, HU Yanjie, et al. Lithium-conductive LiNbO3 coated high-voltage LiNi0.5Co0.2Mn0.3O2 cathode with enhanced rate and cyclability[J]. Green Energy & Environment, 2022, 7(2):266-274. |

| 11 |

HU Qiao, HE Yufang, REN Dongsheng, et al. Targeted masking enables stable cycling of LiNi0.6Co0.2Mn0.2O2 at 4.6V[J]. Nano Energy, 2022, 96:107123.

doi: 10.1016/j.nanoen.2022.107123 |

| 12 |

KIM H K, KANG H S, SANTHOSHKUMAR P, et al. Surface modification of Ni-rich LiNi0.8Co0.1Mn0.1O2 with perovskite LaFeO3 for high voltage cathode materials[J]. RSC Advances, 2021, 11(35):21685-21694.

doi: 10.1039/D1RA00857A |

| 13 |

WOOD D L, WOOD M, LI Jianlin, et al. Perspectives on the relationship between materials chemistry and roll-to-roll electrode manufacturing for high-energy lithium-ion batteries[J]. Energy Storage Materials, 2020, 29:254-265.

doi: 10.1016/j.ensm.2020.04.036 |

| 14 | AMIN R, MURALIDHARAN N, PETLA R K, et al. Research advances on cobalt-free cathodes for Li-ion batteries-the high voltage LiMn1.5Ni0.5O4 as an example[J]. Journal of Power Sources, 2020,467. Doi:10.1016/j.jpowsour.2020.228318 . |

| 15 |

NISAR U, MURALIDHARAN N, ESSEHLI R, et al. Valuation of surface coatings in high-energy density lithium-ion battery cathode materials[J]. Energy Storage Materials, 2021, 38:309-328.

doi: 10.1016/j.ensm.2021.03.015 |

| 16 | 徐前进, 徐金钢, 田朋, 等. 氧化铝包覆锂离子电池正极材料的研究进展[J]. 无机盐工业, 2023, 55(1):46-55,117. |

| XU Qianjin, XU Jingang, TIAN Peng, et al. Research progress of alumina coated cathode materials for lithium-ion batteries[J]. Inorganic Chemicals Industry, 2023, 55(1):46-55,117. | |

| 17 |

MA Ben, HUANG Xiao, LIU Zhaofeng, et al. Al2O3 coated single-crystalline hexagonal nanosheets of LiNi0.6Co0.2Mn0.2O2 cathode materials for the high-performance lithium-ion batteries[J]. Journal of Materials Science, 2022, 57(4):2857-2869.

doi: 10.1007/s10853-021-06726-z |

| 18 |

LI Yan, LIU Xiang, REN Dongsheng, et al. Toward a high-voltage fast-charging pouch cell with TiO2 cathode coating and enhanced battery safety[J]. Nano Energy, 2020, 71:104643.

doi: 10.1016/j.nanoen.2020.104643 |

| 19 |

LI Yunyan, LI Xifei, HU Junhua, et al. ZnO interface modified LiNi0.6Co0.2Mn0.2O2 toward boosting lithium storage[J]. Energy & Environmental Materials, 2020, 3(4):522-528.

doi: 10.1002/eem2.v3.4 |

| 20 |

WEI Jian, LIANG Di, JI Yuxuan, et al. Enhanced electrochemical performance of cobalt oxide layers coated LiNi0.8Co 0.1Mn0.1O2by polyvinylpyrrolidone-assisted method cathode for Li-ion batteri-es[J]. Journal of Colloid and Interface Science, 2022, 616:520- 531.

doi: 10.1016/j.jcis.2022.02.095 pmid: 35228048 |

| 21 |

JUNG H, PARK W, HOLDER J, et al. Electrochemical properties of high nickel content Li(Ni0.7Co0.2Mn0.1)O2 with an alumina thin-coating layer as a cathode material for lithium ion batteries[J]. Journal of Nanoscience and Nanotechnology, 2020, 20(10):6505-6511.

doi: 10.1166/jnn.2020.18588 |

| 22 |

SUN Hao, REN Yurong, LIU Zhen, et al. Enhanced electrochemical properties of Li1.2Ni0.13Co0.13Mn0.54O2 coated with Al2O3 nano-film[J]. Vacuum, 2021, 183:109757.

doi: 10.1016/j.vacuum.2020.109757 |

| 23 |

HERZOG M J, ESKEN D, JANEK J. Improved cycling performance of high-nickel NMC by dry powder coating with nanostructured fumed Al2O3,TiO2,and ZrO2:A comparison[J]. Batteries & Supercaps, 2021, 4(6):1003-1017.

doi: 10.1002/batt.v4.6 |

| 24 | YU Han, HE Xiaoqing, LIANG Xinhua. AlF3-Al2O3 ALD thin-film-coated Li1.2Mn0.54Co0.13Ni0.13O2 particles for lithium-ion batteries:Long-term protection[J]. ACS Applied Materials & Interfaces, 2022, 14(3):3991-4003. |

| 25 |

KIM Y J, KIM H, KIM B, et al. Electrochemical stability of thin-film LiCoO2 cathodes by aluminum-oxide coating[J]. Chemistry of Materials, 2003, 15(7):1505-1511.

doi: 10.1021/cm0201403 |

| 26 | 胡继林, 刘琼, 罗祎格, 等. 球磨时间及测试条件对氧化铝粉体粒度分析的影响[J]. 无机盐工业, 2017, 49(4):64-67. |

| HU Jilin, LIU Qiong, LUO Yige, et al. Effects of milling time and testing conditions on particle size analysis of alumina powde-rs[J]. Inorganic Chemicals Industry, 2017, 49(4):64-67. | |

| 27 | 李仲谨, 王芬, 魏红, 等. 聚丙烯酸铵对氧化铝料浆分散行为的研究[J]. 陶瓷, 2002(5):27-30. |

| 28 |

CHEN Gang, PENG Biyou, HAN Rui, et al. A robust carbon coating strategy toward Ni-rich lithium cathodes[J]. Ceramics International, 2020, 46(13):20985-20992.

doi: 10.1016/j.ceramint.2020.05.160 |

| 29 |

YANG Chengsheng, LI Yuyu, ZHANG Xuanxuan, et al. Enhanced cyclic stability of LiNi0.8Co0.1Mn0.1O2(NCM811) by AlF3 coating via atomic layer deposition[J]. Ionics, 2022, 28(10):4547-4554.

doi: 10.1007/s11581-022-04691-4 |

| 30 |

陈良丹, 邹伟, 吴亮, 等. 纳米Al2O3包覆富锂锰基正极材料Li1.2Ni0.13Co0.13Mn0.54O2的性能研究[J]. 高等学校化学学报, 2020, 41(6):1329-1336.

doi: 10.7503/cjcu20190719 |

|

CHEN Liangdan, ZOU Wei, WU Liang, et al. Nano-Al2O3 coated Li-rich cathode material Li1.2Ni0.13Co0.13Mn0.54O2 for highly improved lithium-ion batteries[J]. Chemical Journal of Chinese Universities, 2020, 41(6):1329-1336.

doi: 10.7503/cjcu20190719 |

|

| 31 |

KIMURA N, SEKI E, TOOYAMA T, et al. STEM-EELS analysis of improved cycle life of lithium-ion cells with Al2O3-coated LiNi0.8Co0.1Mn0.1O2 cathode active material[J]. Journal of Alloys and Compounds, 2021, 869:159259.

doi: 10.1016/j.jallcom.2021.159259 |

| 32 | RAMASAMY H V, SINHA S, PARK J, et al. Enhancement of electrochemical activity of Ni-rich LiNi0.8Mn 0.1Co0.1O2by precisely controlled Al2O3 nanocoatings via atomic layer depositi-on[J]. Journal of Electrochemical Science and Technology, 2019, 10(2):196-205. |

| 33 | ZHANG Hailin, XU Jiaqiang, ZHANG Jiujun. Surface-coated LiNi0.8Co0.1Mn0.1O2(NCM811) cathode materials by Al2O3,ZrO2,and Li2O-2B2O3 thin-layers for improving the performance of lithium ion batteries[J]. Frontiers in Materials, 2019,6. Doi:10.3389/fmats.2019.00309 . |

| 34 |

KIM J H, PARK J S, CHO S H, et al. Stabilizing the surface of Ni-rich cathodes via facing-target sputtering for high-performance lithium-ion batteries[J]. Journal of Materials Chemistry A, 2022, 10(47):25009-25018.

doi: 10.1039/D2TA07322F |

| 35 |

CAO Guolin, JIN Zhuomin, ZHU Jie, et al. A green Al2O3 metal oxide coating method for LiNi0.5Co0.2Mn0.3O2 cathode material to improve the high voltage performance[J]. Journal of Alloys and Compounds, 2020, 832:153788.

doi: 10.1016/j.jallcom.2020.153788 |

| 36 | DONG Mingxia, WANG Zhixing, LI Hangkong, et al. Metallurgy inspired formation of homogeneous Al2O3 coating layer to improve the electrochemical properties of LiNi0.8Co0.1Mn0.1O2 cathode material[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(11):10199-10205. |

| 37 | ZHU Wenchang, HUANG Xue, LIU Tingting, et al. Ultrathin Al2O3 coating on LiNi0.8Co0.1Mn0.1O2 cathode material for enhanced cycleability at extended voltage ranges[J]. Coatings, 2019, 9(2). Doi:10.3390/coatings9020092 . |

| 38 |

WU Yingqiang, LI Mengliu, WAHYUDI W, et al. Performance and stability improvement of layered NCM lithium-ion batteries at high voltage by a microporous Al2O3 sol-gel coating[J]. ACS Omega, 2019, 4(9):13972-13980.

doi: 10.1021/acsomega.9b01706 pmid: 31497715 |

| 39 |

SHI Yang, ZHANG Minghao, QIAN Danna, et al. Ultrathin Al2O3 coatings for improved cycling performance and thermal stability of LiNi0.5Co0.2Mn0.3O2 cathode material[J]. Electrochimica Acta, 2016, 203:154-161.

doi: 10.1016/j.electacta.2016.03.185 |

| 40 |

ZHENG Lituo, HATCHARD T D, OBROVAC M N. A high-quality mechanofusion coating for enhancing lithium-ion battery cathode material performance[J]. MRS Communications, 2019, 9(1):245-250.

doi: 10.1557/mrc.2018.209 |

| 41 | ZHAI Haowei, GONG Tianyao, XU Bingqing, et al. Stabilizing polyether electrolyte with a 4 V metal oxide cathode by nanoscale interfacial coating[J]. ACS Applied Materials & Interfaces, 2019, 11(32):28774-28780. |

| 42 | 冯耀华. 高镍型锂离子电池正极材料LiNi0 .8Co 0.1Mn0.1O2制备及改性[D]. 兰州: 兰州理工大学,2020. |

| FENG Yaohua. Synthesis and modification of LiNi 0.8Co0.1Mn0. 1O2 rich nickel cathode materials for lithium-ion batteries[D]. Lanzhou: Lanzhou University of Technology, 2020. |

| [1] | FENG Zhun. Improvement of high temperature stability of high nickel single crystal cathode materials by B/Al/Zr synergistic strategy [J]. Inorganic Chemicals Industry, 2023, 55(8): 59-64. |

| [2] | LU Junhao. Study on full element recycling process of retired ternary power lithium battery [J]. Inorganic Chemicals Industry, 2023, 55(6): 92-103. |

| [3] | ZHU Zhihong, ZHU Yongfang. Study on preparation and properties of silicon doped lithium manganate by self-propagating combustion [J]. Inorganic Chemicals Industry, 2023, 55(5): 66-70. |

| [4] | ZHANG Chenhu, MA Yi, ZHU Shan, CHEN Peng, WANG Chengyong, LI Ziwen. Study on adsorption of heavy metal ions in mineral processing wastewater by chelating modified coal gangue [J]. Inorganic Chemicals Industry, 2023, 55(4): 97-103. |

| [5] | LIU Xueting, MAO Lingfeng, HU Yun, PENG Xi, FAN Xuemei, CHEN Yanlei, LIU Wenkui. Synergistic dispersion of SiO2 by dispersant and supershear [J]. Inorganic Chemicals Industry, 2023, 55(3): 71-77. |

| [6] | PENG Chenxi, LIU Jun. Research progress of layered transition metal oxides cathode materials for sodium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(10): 1-12. |

| [7] | YU Jianguo,SUN Qing,QIU Shengbo,ZHANG Yiren,CHEN Jun. Lithium resources development supporting national new energy strategy development [J]. Inorganic Chemicals Industry, 2023, 55(1): 1-14. |

| [8] | TANG Di,WANG Junxiong,CHEN Wen,JI Guanjun,MA Jun,ZHOU Guangmin. Research status and prospect on direct regeneration of cathode materials from retired lithium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(1): 15-25. |

| [9] | XU Qianjin,XU Jingang,TIAN Peng,LIU Kunji,GAO Tingting,NING Guiling. Research progress of alumina coated cathode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(1): 46-55. |

| [10] | HOU Shunli,ZHAO Duan,ZHOU Geng,WEI Shishi,LI Jian,WANG Jiatai. Research progress on doping modification of high nickel ternary nickel-cobalt-aluminum cathode material [J]. Inorganic Chemicals Industry, 2022, 54(8): 40-46. |

| [11] | LIANG Chao,LI Chunquan,SUN Zhiming,ZHENG Shuilin. Surface modification effect and mechanism of new organic modifiers on ground calcium carbonate [J]. Inorganic Chemicals Industry, 2022, 54(7): 70-77. |

| [12] | QIU Zhixu,ZHU Shaokuan,WEI Yuxiao,LONG Jiaying,HUANG Dongchuang,SHAO Jiaojing. Study on preparation and electrochemical performance of S/MCNT/Fe3O4 cathode materials [J]. Inorganic Chemicals Industry, 2022, 54(6): 73-77. |

| [13] | DONG Peng,ZHOU Yingjie,HOU Minjie,YANG Dongrong,DAI Yongnian,LIANG Feng. Research progress on Na3V2(PO4)3 cathode materials for sodium ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(5): 1-10. |

| [14] | WEI Chunguang,LIANG Yan,LI Tong,LÜ Wei. Research and industrialization progress of aqueous zinc ion battery [J]. Inorganic Chemicals Industry, 2022, 54(3): 18-22. |

| [15] | ZHANG Xinyi,DI Yuli,DONG Qi,CHEN Xingyu,ZHANG Zhengdong. Research progress on preparation of Li3V2(PO4)3 cathode material for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(3): 38-44. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||