Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (1): 46-55.doi: 10.19964/j.issn.1006-4990.2022-0098

• Development and utilization of lithium resources • Previous Articles Next Articles

Research progress of alumina coated cathode materials for lithium-ion batteries

XU Qianjin1( ),XU Jingang2,TIAN Peng1,2(

),XU Jingang2,TIAN Peng1,2( ),LIU Kunji1,GAO Tingting2,NING Guiling2

),LIU Kunji1,GAO Tingting2,NING Guiling2

- 1. Jiangxi Baohtech Science Co. ,Ltd. ,Yichun 331208,China

2. Dalian University of technology-Baohong technology lithium battery new material joint research center,Dalian University of technology,Dalian 116024,China

-

Received:2022-03-04Online:2023-01-10Published:2023-01-17 -

Contact:TIAN Peng E-mail:michael.xu@cremone.com;tianpeng@dlut.edu.cn

CLC Number:

Cite this article

XU Qianjin,XU Jingang,TIAN Peng,LIU Kunji,GAO Tingting,NING Guiling. Research progress of alumina coated cathode materials for lithium-ion batteries[J]. Inorganic Chemicals Industry, 2023, 55(1): 46-55.

share this article

Fig.2

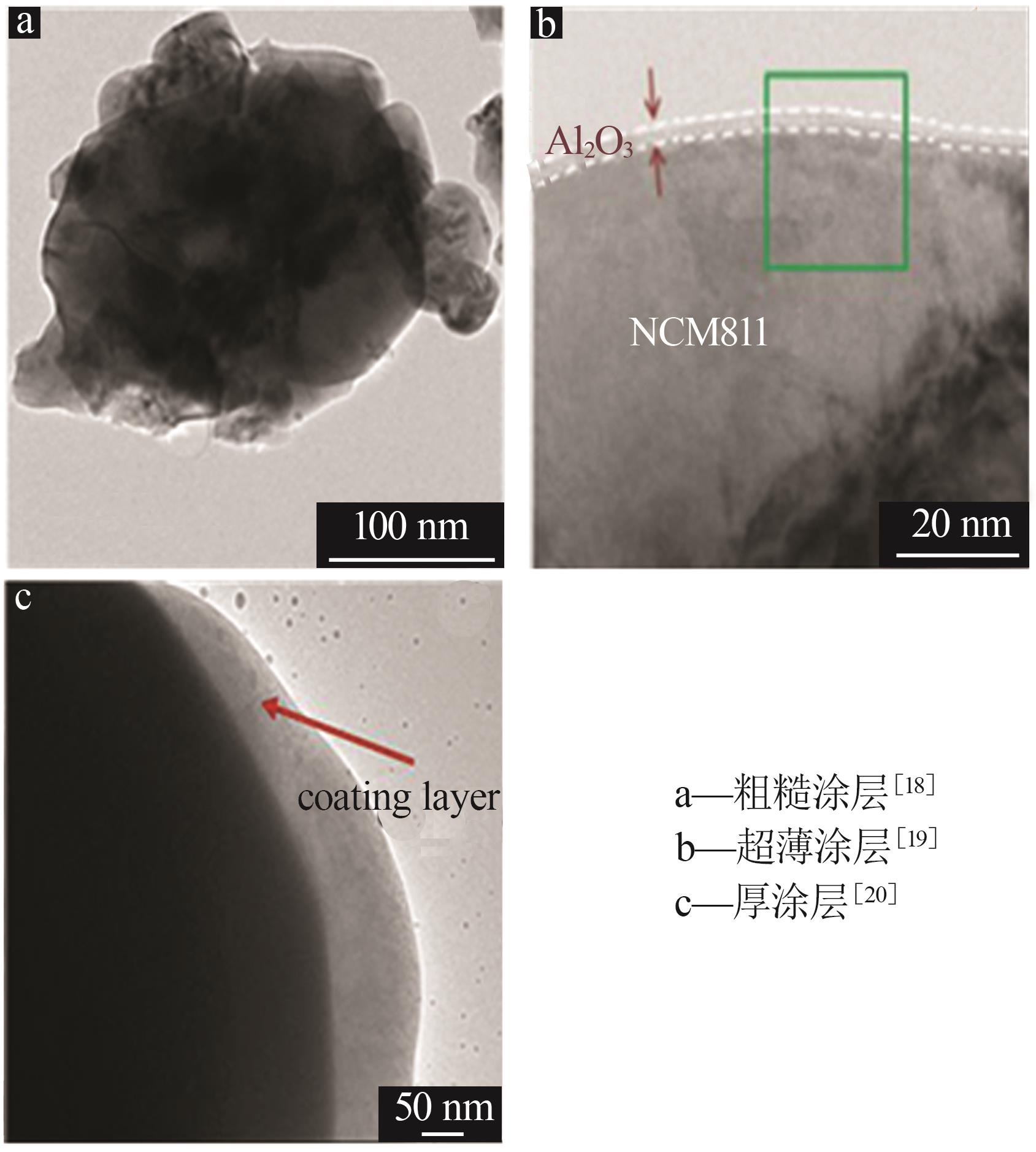

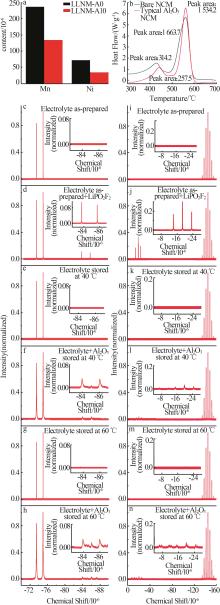

Dissolution of transition metal ions in uncoated and alumina coated LLNM samples[33](a);DSC profiles of uncoated NCM and alumin coated NCM electrode after 500 cycles[24](b);19F(c~h) and 31P(i~n) solution NMR spectra in electrolytes under different conditions,insets of expanded views of PO2F2- region[45]"

| 1 | TARASCON J M, ARMAND M. Issues and challenges facing rechargeable lithium batteries[J].Nature, 2001, 414(6861):359- 367. |

| 2 | SCHMUCH R, WAGNER R, HÖRPEL G, et al. Performance and cost of materials for lithium-based rechargeable automotive batteries[J].Nature Energy, 2018, 3(4):267-278. |

| 3 | WHITTINGHAM M S. Lithium batteries:50 years of advances to address the next 20 years of climate issues[J].Nano Letters, 2020, 20(12):8435-8437. |

| 4 | ARICÒ A S, BRUCE P, SCROSATI B, et al. Nanostructured materials for advanced energy conversion and storage devices[J].Nature Materials, 2005, 4(5):366-377. |

| 5 | TAO Haisheng, FENG Zhizhong, LIU Hao, et al. Reality and future of rechargeable lithium batteries[J].The Open Materials Science Journal, 2011, 5(1):204-214. |

| 6 | WANG Jiali, ZHAO Yu, ZHANG Xiaoqiang, et al. Trace molybdenum doped Li2RuO3 as a cathode material with enhanced performance for lithium ion batteries[J].Sustainable Energy & Fuels, 2019, 3(10):2697-2704. |

| 7 | LIU Jiequn, WANG Jian, CHEN Qingrong, et al. Mg-doped LiMnPO4/C cathode materials for enhanced lithium storage performance[J].Materials Technology, 2021, 36(3):153-158. |

| 8 | MA Ben, HUANG Xiao, LIU Zhaofeng, et al. Al2O3 coated single-crystalline hexagonal nanosheets of LiNi0.6Co0.2Mn0.2O2 cathode materials for the high-performance lithium-ion batteries[J].Journal of Materials Science, 2022, 57(4):2857-2869. |

| 9 | WANG Fangfang, HONG Ruoyu, LU Xuesong, et al. Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating[J].Nanotechnology Reviews, 2021, 10(1):210- 220. |

| 10 |

ZHAO Bing, XIE Jingwei, ZHUANG Hua, et al. Improved low-temperature performance of surface modified lithium-rich Li1.2Ni0.13Co0.13Mn0.54O2 cathode materials for lithium ion batteri-es[J].Solid State Ionics, 2020, 347.Doi:10.1016/j.ssi.2020.2020.115245.

doi: 10.1016/j.ssi.2020.2020.115245 |

| 11 | TAI Zige, ZHU Wei, SHI Ming, et al. Improving electrochemical performances of lithium-rich oxide by cooperatively doping Cr and coating Li3PO4 as cathode material for lithium-ion batteri-es[J].Journal of Colloid and Interface Science, 2020, 576:468-475. |

| 12 |

SUN Yongjiang, LIU Zhedong, CHEN Xiaochun, et al. Enhancing the stabilities and electrochemical performances of LiNi0.5Co0.2Mn0.3O2 cathode material by simultaneous LiAlO2 coat-ing and Al doping[J].Electrochimica Acta, 2021, 376.Doi:10.1016/j.electacta.2021.138038.

doi: 10.1016/j.electacta.2021.138038 |

| 13 | SUN Yanyun, LIU Sheng, HOU Yukun, et al. In-situ surface modification to stabilize Ni-rich layered oxide cathode with functional electrolyte[J].Journal of Power Sources, 2019, 410-411:115-123. |

| 14 |

LIU Yuan, LIN Xijie, SUN Yonggang, et al. Precise surface engineering of cathode materials for improved stability of lithium-ion batteries[J].Small:Weinheim an Der Bergstrasse, Germany,2019, 15(32).Doi:10.1002/smll.201901019.

doi: 10.1002/smll.201901019 |

| 15 | GUAN Peiyuan, ZHOU Lu, YU Zhenlu, et al. Recent progress of surface coating on cathode materials for high-performance lithium-ion batteries[J].Journal of Energy Chemistry, 2020, 43:220- 235. |

| 16 |

KALLURI S, YOON M,JO M,et al. Li-ion cells:Surface engineering strategies of layered LiCoO2 cathode material to realize high-energy and high-voltage Li-ion cells[J].Advanced Energy Materials, 2017, 7(1).Doi:10.1002/aenm.201770006.

doi: 10.1002/aenm.201770006 |

| 17 | NISAR U, MURALIDHARAN N, ESSEHLI R, et al. Valuation of surface coatings in high-energy density lithium-ion battery cathode materials[J].Energy Storage Materials, 2021, 38:309-328. |

| 18 | SETENI B, RAPULENYANE N, NGILA J C, et al. Coating effect of LiFePO4 and Al2O3 on Li1.2Mn0.54Ni0.13Co0.13O2 cathode surface for lithium ion batteries[J].Journal of Power Sources, 2017, 353:210-220. |

| 19 |

ZHU Wenchang, HUANG Xue, LIU Tingting, et al. Ultrathin Al2O3 coating on LiNi0.8Co0.1Mn0.1O2 cathode material for enhan-ced cycleability at extended voltage ranges[J].Coatings, 2019, 9(2).Doi:10.3390/coatings9020092.

doi: 10.3390/coatings9020092 |

| 20 |

ZHANG Hailin, XU Jiaqiang, ZHANG Jiujun. Surface-coated LiNi0.8Co0.1Mn0.1O2(NCM811) cathode materials by Al2O3,ZrO2,and Li2O-2B2O3 thin-layers for improving the performance of lithium ion batteries[J].Frontiers in Materials, 2019, 6.Doi:10.3389/fmats.2019.00309.

doi: 10.3389/fmats.2019.00309 |

| 21 | OH Y,AHN D,NAM S,et al. The effect of Al2O3-coating coverage on the electrochemical properties in LiCoO2 thin films[J].Journal of Solid State Electrochemistry, 2010, 14(7):1235-1240. |

| 22 | GRONER M D, ELAM J W, FABREGUETTE F H, et al. Electrical characterization of thin Al2O3 films grown by atomic layer deposition on silicon and various metal substrates[J].Thin Solid Films, 2002, 413(1/2):186-197. |

| 23 |

ZHAO Lini, CHEN Guorong, WENG Yuehua, et al. Precise Al2O3 coating on LiNi0.5Co0.2Mn0.3O2 by atomic layer deposition restrains the shuttle effect of transition metals in Li-ion capacitors[J].Che-mical Engineering Journal, 2020, 401.Doi:10.1016/j.cej.2020.126138.

doi: 10.1016/j.cej.2020.126138 |

| 24 | CAO Zhaoxia, LI Yanlei, SHI Mengjiao, et al. Improvement of the cycling performance and thermal stability of lithium-ion batteries by coating cathode materials with Al2O3 nano layer[J].Journal of the Electrochemical Society, 2017, 164(2):A475-A481. |

| 25 |

HAN J G, KIM K, LEE Y, et al. Scavenging materials to stabilize LiPF6-containing carbonate-based electrolytes for Li-ion batteries[J].Advanced Materials:Deerfield Beach, Fla.,2019, 31(20).Doi:10.1002/adma.201804822.

doi: 10.1002/adma.201804822 |

| 26 | WANG Qingsong, JIANG Lihua, YU Yan, et al. Progress of enhancing the safety of lithium ion battery from the electrolyte aspect[J].Nano Energy, 2019, 55:93-114. |

| 27 | YANG Hui, ZHUANG G V, ROSS P N Jr. Thermal stability of LiPF6 salt and Li-ion battery electrolytes containing LiPF6 [J].Journal of Power Sources, 2006, 161(1):573-579. |

| 28 | LIU Mingzhu, VATAMANU J, CHEN Xinli, et al. Hydrolysis of LiPF6-containing electrolyte at high voltage[J].ACS Energy Letters, 2021, 6(6):2096-2102. |

| 29 | LIU Jianyong, LIU Na, LIU Daotan, et al. Improving the performances of LiCoO2 cathode materials by soaking nano-alumina in commercial electrolyte[J].Journal of the Electrochemical Society, 2007, 154(1):55-63. |

| 30 | MYUNG S T, IZUMI K, KOMABA S, et al. Role of alumina coating on Li-Ni-Co-Mn-O particles as positive electrode material for lithium-ion batteries[J].Chemistry of Materials, 2005, 17(14):3695-3704. |

| 31 |

HU Die, DU Fanghui, CAO Haishang, et al. An effective strategy to control thickness of Al2O3 coating layer on nickel-rich cathode materials[J].Journal of Electroanalytical Chemistry, 2021, 880.Doi:10.1016/j.jelechem.2020.114910.

doi: 10.1016/j.jelechem.2020.114910 |

| 32 | ZHENG J M, ZHANG Z R, WU X B, et al. The effects of AlF3 coating on the performance of Li[Li0.2Mn0.54Ni0.13Co0.13]O2 positive electrode material for lithium-ion battery[J].Journal of the Electrochemical Society, 2008, 155(10):A775-A782. |

| 33 | LI Xiangnan, CAO Zhaoxia, DONG Hongyu, et al. Investigation of the structure and performance of Li[Li0.13Ni0.305Mn0.565]O2 Li-rich cathode materials derived from eco-friendly and simple coating techniques[J].RSC Advances, 2020, 10(6):3166-3174. |

| 34 | LAI Feiyan, ZHANG Xiaohui, WANG Hongqiang, et al. Three-dimension hierarchical Al2O3 nanosheets wrapped LiMn2O4 with enhanced cycling stability as cathode material for lithium ion batteries[J].ACS Applied Materials & Interfaces, 2016, 8(33):21656-21665. |

| 35 | WANG Q Y, LIU J, MURUGAN A V, et al. High capacity double-layer surface modified Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathode with improved rate capability[J].Journal of Materials Chemistry, 2009, 19(28):4965-4972. |

| 36 | DONG Mingxia, WANG Zhixing, LI Hangkong, et al. Metallurgy inspired formation of homogeneous Al2O3 coating layer to improve the electrochemical properties of LiNi0.8Co0.1Mn0.1O2 cathode material[J].ACS Sustainable Chemistry & Engineering, 2017, 5(11):10199-10205. |

| 37 | JUNG S C, HAN Y K. How do Li atoms pass through the Al2O3 coating layer during lithiation in Li-ion batteries?[J].The Journal of Physical Chemistry Letters, 2013, 4(16):2681-2685. |

| 38 | LIU Wen, LI Xifei, XIONG Dongbin, et al. Significantly improving cycling performance of cathodes in lithium ion batteries:The effect of Al2O3 and LiAlO2 coatings on LiNi0.6Co0.2Mn0.2O2 [J].Nano Energy, 2018, 44:111-120. |

| 39 | JUNG R, METZGER M, MAGLIA F, et al. Oxygen release and its effect on the cycling stability of LiNi x Mn y Co z O2(NMC) cathode materials for Li-ion batteries[J].Journal of the Electrochemical Society, 2017, 164(7):A1361-A1377. |

| 40 | JUNG R, STROBL P, MAGLIA F, et al. Temperature dependence of oxygen release from LiNi0.6Mn0.2Co0.2O2(NMC622) cathode materials for Li-ion batteries[J].Journal of the Electrochemical Society, 2018, 165(11):A2869-A2879. |

| 41 | JIANG Bing, LI Jingru, LUO Bi, et al. LiPO2F2 electrolyte additive for high-performance Li-rich cathode material[J].Journal of Energy Chemistry, 2021, 60:564-571. |

| 42 | WANG Chengyun, YU Le, FAN Weizhen, et al. Lithium difluorophosphate as a promising electrolyte lithium additive for high-voltage lithium-ion batteries[J].ACS Applied Energy Materials, 2018, 1(6):2647-2656. |

| 43 | LIU Q Q, MA Lin, DU C Y, et al. Effects of the LiPO2F2 additive on unwanted lithium plating in lithium-ion cells[J].Electrochimica Acta, 2018, 263:237-248. |

| 44 | LIU Lili, GU Shijie, WANG Shili, et al. A LiPO2F2/LiPF6 dual-salt electrolyte enabled stable cycling performance of nickel-rich lithium ion batteries[J].RSC Advances, 2020, 10(3):1704-1710. |

| 45 | HALL D S, GAUTHIER R, ELDESOKY A, et al. New chemical insights into the beneficial role of Al2O3 cathode coatings in lithi- |

| um-ion cells[J].ACS Applied Materials & Interfaces, 2019, 11(15):14095-14100. | |

| 46 | GUAN Dongsheng, JEEVARAJAN J A, WANG Ying. Enhanced cycleability of LiMn2O4 cathodes by atomic layer deposition of nanosized-thin Al2O3 coatings[J].Nanoscale, 2011, 3(4):1465-1469. |

| 47 |

ZUO Changjian, HU Zongxiang, QI Rui, et al. Double the capacity of manganese spinel for lithium-ion storage by suppression of cooperative Jahn-Teller distortion[J].Advanced Energy Materials, 2020, 10(34).Doi:10.1002/aenm.202070141.

doi: 10.1002/aenm.202070141 |

| 48 |

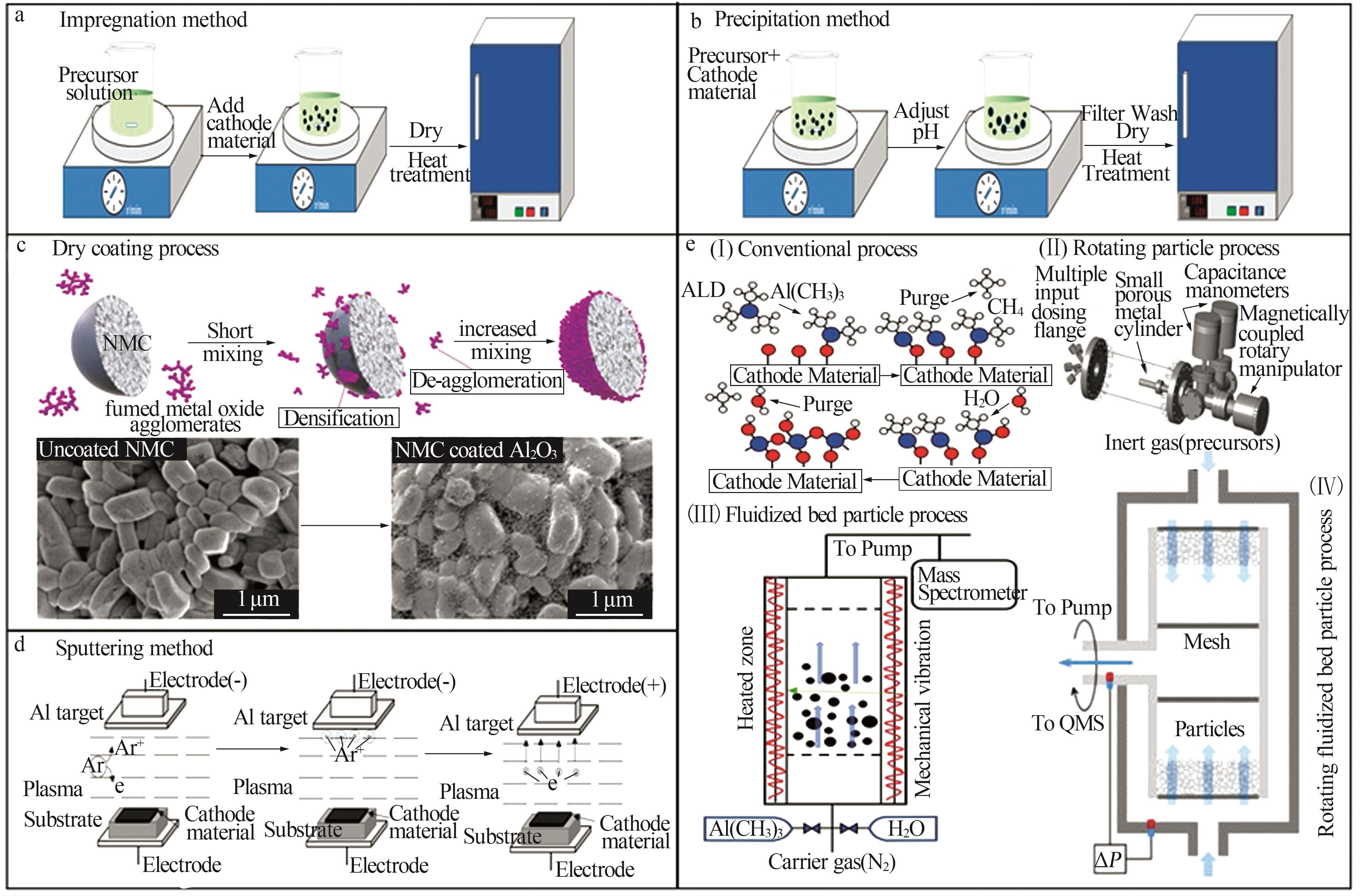

HERZOG M J, GAUQUELIN N, ESKEN D, et al. Facile dry coating method of high-nickel cathode material by nanostructured fumed alumina(Al2O3) improving the performance of lithium-ion batteries[J].Energy Technology, 2021, 9(4).Doi:10.1002/ente.202100028.

doi: 10.1002/ente.202100028 |

| 49 | MCCORMICK J A, CLOUTIER B L, WEIMER A W, et al. Rotary reactor for atomic layer deposition on large quantities of nanoparticles[J].Journal of Vacuum Science & Technology A:Vacuum, Surfaces,and Films,2007, 25(1):67-74. |

| 50 |

DUAN Chenlong, DENG Zhang, CAO Kun, et al. Surface passivation of Fe3O4 nanoparticles with Al2O3 via atomic layer deposition in a rotating fluidized bed reactor[J].Journal of Vacuum Science & Technology A:Vacuum, Surfaces,and Films,2016, 34(4).Doi:10.1116/1.4952401.

doi: 10.1116/1.4952401 |

| 51 | JUNG H, PARK W, HOLDER J, et al. Electrochemical properties of high nickel content Li(Ni0.7Co0.2Mn0.1)O₂ with an alumina thin-coating layer as a cathode material for lithium ion batteries[J].Journal of Nanoscience and Nanotechnology, 2020, 20(10):6505-6511. |

| 52 | CHANG Qian, WEI Aijia, LI Wen, et al. Structural and electrochemical characteristics of Al2O3-modified LiNi0.5Mn1.5O4 cathode materials for lithium-ion batteries[J].Ceramics International, 2019, 45(4):5100-5110. |

| 53 |

CAO Guolin, JIN Zhuomin, ZHU Jie, et al. A green Al2O3 metal oxide coating method for LiNi0.5Co0.2Mn0.3O2 cathode material to improve the high voltage performance[J].Journal of Alloys and Compounds, 2020, 832.Doi:10.1016/j.jallcom.2020.153788.

doi: 10.1016/j.jallcom.2020.153788 |

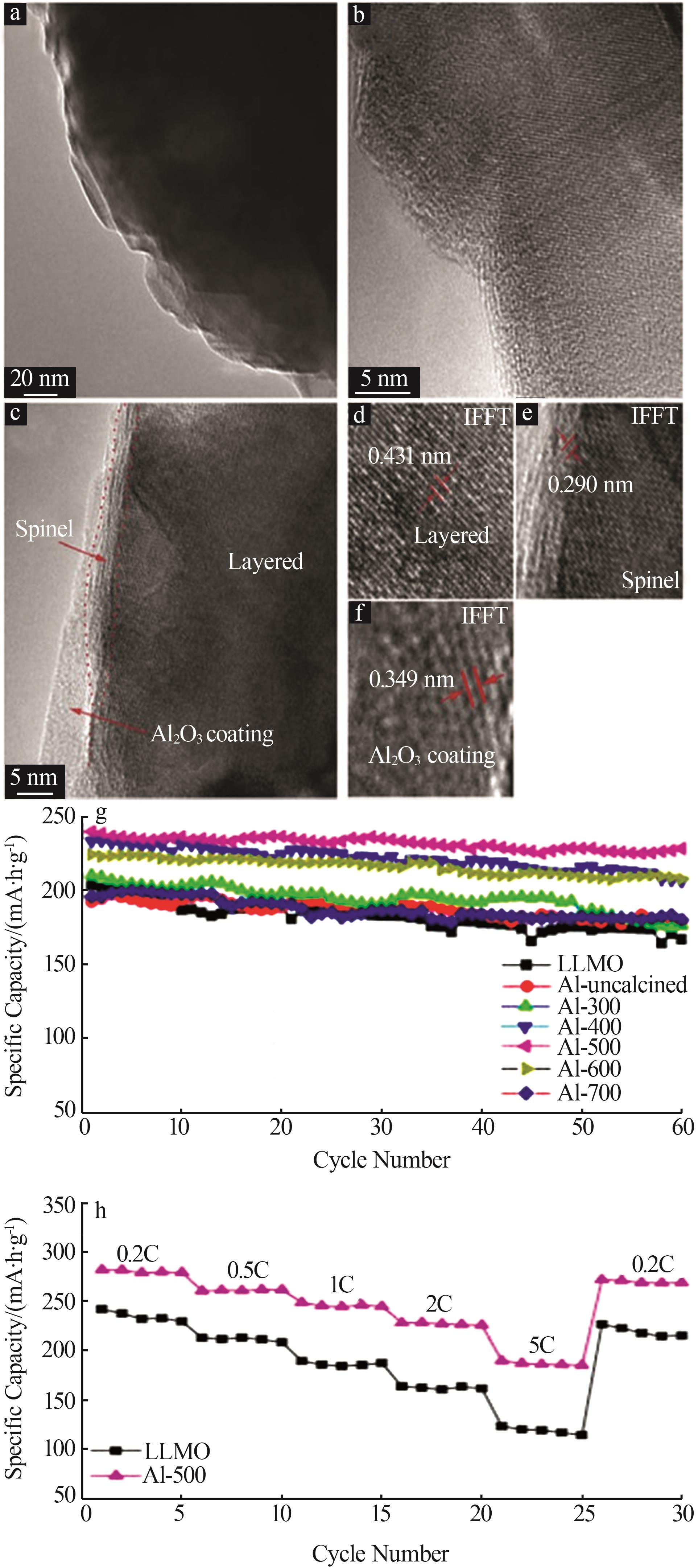

| 54 |

SUN Hao, REN Yurong, LIU Zhen, et al. Enhanced electrochemical properties of Li1.2Ni0.13Co0.13Mn0.54O2 coated with Al2O3 nano-film[J].Vacuum, 2021, 183.Doi:10.1016/j.vacuum.2021.109757.

doi: 10.1016/j.vacuum.2021.109757 |

| 55 |

LI Shiyou, LIANG Wenbiao, XIE Jing, et al. Synthesis of hollow microspheres LiNi0.5Mn1.5O4 coated with Al2O3 and characterization of the electrochemical capabilities[J].Journal of Electrochemical Energy Conversion and Storage, 2020, 17(3).Doi:10.1115/1.4045566.

doi: 10.1115/1.4045566 |

| 56 |

ZOU Tong, QI Weijing, LIU Xiaoshuo, et al. Improvement of the electrochemical performance of Li1.2Ni0.13Co0.13Mn0.54O2 cathode material by Al2O3 surface coating[J].Journal of Electroanalytical Chemistry, 2020, 859.Doi:10.1016/j.jelechem.2020.113845.

doi: 10.1016/j.jelechem.2020.113845 |

| 57 | SONG Chunlin, LU Junnan, LIU Yuan, et al. Enhanced electrochemical performance of spinel LiNi0.5Mn1.5O4 for Li-ion batteries with moderate Mn3+ concentration and nanosized thin Al2O3 coating[J].Journal of Materials Science:Materials in Electronics, 2020, 31(6):4815-4821. |

| 58 | PARMAR R, REZVANI S J, NOBILI F, et al. Electrochemical response and structural stability of the Li+ ion battery cathode with coated LiMn2O4 nanoparticles[J].ACS Applied Energy Materials, 2020, 3(9):8356-8365. |

| 59 | LI Shiyou, ZHU Konglei, ZHAO Dongni, et al. Porous LiMn2O4 with Al2O3 coating as high-performance positive materials[J].Ionics, 2019, 25(5):1991-1998. |

| 60 | HAN Binghong,KEY B, LAPIDUS S H, et al. From coating to dopant:How the transition metal composition affects alumina coatings on Ni-rich cathodes[J].ACS Applied Materials & Interfaces, 2017, 9(47):41291-41302. |

| 61 | HERZOG M J, ESKEN D, JANEK J. Improved cycling performance of high-nickel NMC by dry powder coating with nanostructured fumed Al2O3,TiO2,and ZrO2:A comparison[J].Batteries & Supercaps, 2021, 4(6):1003-1017. |

| 62 |

KIMURA N, SEKI E, TOOYAMA T, et al. STEM-EELS analysis of improved cycle life of lithium-ion cells with Al2O3-coated LiNi0.8Co0.1Mn0.1O2 cathode active material[J].Journal of Alloys and Compounds, 2021, 869.Doi:10.1016/j.jallcom.2021.159259.

doi: 10.1016/j.jallcom.2021.159259 |

| 63 | JEONG E, HONG Chan,TAK Y,et al. Investigation of interfacial resistance between LiCoO2 cathode and LiPON electrolyte in the thin film battery[J].Journal of Power Sources, 2006, 159(1):223-226. |

| 64 |

CHEN Yangyang, WANG Mingshan, CHEN Junchen, et al. Atomic layer deposition of Al2O3 on LiNi0.68Co0.10Mn0.22O2 for enhanced electrochemical performance[J].Materials Letters, 2020, 271.Doi:10.1016/j.matlet.2020.127771.

doi: 10.1016/j.matlet.2020.127771 |

| 65 | SHI Yang, ZHANG Minghao, QIAN Danna, et al. Ultrathin Al2O3 coatings for improved cycling performance and thermal stability of LiNi0.5Co0.2Mn0.3O2 cathode material[J].Electrochimica Acta, 2016, 203:154-161. |

| 66 | LEE Boyi, KRAJEWSKI M, HUANG M K, et al. Spinel LiNi0.5Mn1.5O4 with ultra-thin Al2O3 coating for Li-ion batteries:Investigation of improved cycling performance at elevated temperature[J].Journal of Solid State Electrochemistry, 2021, 25(10/11):2665-2674. |

| 67 | ZHOU M M, ZHAO J J, QIU S T, et al. Structural and electrochemical properties of Li1.2Ni0.16Mn0.54Co0.08O2-Al2O3 composite prepared by atomic layer deposition as the cathode material for LIBs[J].International Journal of Electrochemical Science, 2020, 15(11):10759-10771. |

| 68 | JUNG Y S, CAVANAGH A S, DILLON A C, et al. Enhanced stability of LiCoO2 cathodes in lithium-ion batteries using surface |

| modification by atomic layer deposition[J].Journal of the Electrochemical Society, 2010, 157(1):A75-A81. | |

| 69 |

TESFAMHRET Y, YOUNESI R, BERG E J. Influence of Al2O3 coatings on HF induced transition metal dissolution from lithium-ion cathodes[J].Journal of the Electrochemical Society, 2022, 169(1).Doi:10.1149/1945-7111/ac4ab1.

doi: 10.1149/1945-7111/ac4ab1 |

| 70 |

Yingchun LYU, WU Xia, WANG Kai, et al. An overview on the advances of LiCoO2 cathodes for lithium-ion batteries[J].Advanced Energy Materials, 2021, 11(2).Doi:10.1002/aenm.202000982.

doi: 10.1002/aenm.202000982 |

| 71 | KIM Y J, KIM H, KIM B, et al. Electrochemical stability of thin-film LiCoO2 cathodes by aluminum-oxide coating[J].Chemistry of Materials, 2003, 15(7):1505-1511. |

| 72 | ZHOU Aijun, LIU Qin, WANG Yi, et al. Al2O3 surface coating on LiCoO2 through a facile and scalable wet-chemical method towards high-energy cathode materials withstanding high cutoff voltages[J].Journal of Materials Chemistry A, 2017, 5(46):24361-24370. |

| 73 |

HUANG Yimeng, DONG Yanhao, LI Sa, et al. Lithium manganese spinel cathodes for lithium-ion batteries[J].Advanced Energy Materials, 2021, 11(2).Doi:10.1002/aenm.202000997.

doi: 10.1002/aenm.202000997 |

| 74 | WALLER G H, BROOKE P D, RAINWATER B H, et al. Structure and surface chemistry of Al2O3 coated LiMn2O4 nanostructured electrodes with improved lifetime[J].Journal of Power Sources, 2016, 306:162-170. |

| 75 | ZHANG H H, ZOU Z G, ZHANG S C, et al. A review of the doping modification of LiFePO4 as a cathode material for lithium ion batteries[J].International Journal of Electrochemical Science, 2020, 15(12):12041-12067. |

| 76 |

ZHAO Qunfang, ZHANG Shuqiong, HU Minyi, et al. Recent advances in LiFePO4 cathode materials for lithium-ion batteries.First-principles research[J].International Journal of Electrochemical Science, 2021, 16.Doi:10.20964/2021.12.11.

doi: 10.20964/2021.12.11 |

| 77 | SON J T. Surface treatment of LiFePO4 cathode material for lithium secondary battery[J].Journal of the Korean Electrochemical Society, 2010, 13(4):246-250. |

| 78 | WEN Xiaofeng, LIANG Kui, TIAN Lingyun, et al. Al2O3 coating on Li1.256Ni0.198Co0.082Mn0.689O2.25 with spinel-structure interface layer for superior performance lithium ion batteries[J].Electrochimica Acta, 2018, 260:549-556. |

| [1] | ZHOU Haitao, WEN Chengqin, ZHENG Ling, SUN Jie. Research on boron nitride modified film for cathode interface of metallic lithium battery [J]. Inorganic Chemicals Industry, 2024, 56(4): 85-89. |

| [2] | LIU Dexin, MA Tengyue, AN Jinling, LIU Jinrong, HE Weiyan. Study on cathode material design and electrochemical properties of manganese-based sodium ion battery [J]. Inorganic Chemicals Industry, 2024, 56(3): 51-55. |

| [3] | ZHOU Huang, HU Xiaoping, REN Wen, CAO Xinxin. Preparation and sodium storage properties of sulfur-doped Na3(VOPO4)2F cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(2): 30-37. |

| [4] | WANG Mengdi, LUO Jin, WU Wei, ZHOU Jinghui, WANG Jing, SUN Yanmin, YU Haibin. Study on preparation of γ-Al2O3 by microreaction and its properties for methyl orange adsorption [J]. Inorganic Chemicals Industry, 2023, 55(9): 66-74. |

| [5] | LUO Wenbo, LI Heng, LÜ Jun, YANG Linguang, ZHAO Xingfan, LONG Xiao. Study on recovery of silicon and aluminum from industrial silicon slag [J]. Inorganic Chemicals Industry, 2023, 55(9): 94-99. |

| [6] | FENG Zhun. Improvement of high temperature stability of high nickel single crystal cathode materials by B/Al/Zr synergistic strategy [J]. Inorganic Chemicals Industry, 2023, 55(8): 59-64. |

| [7] | KANG Le, JING Maoxiang, LI Donghong, HU Xinyu, JIA Chunyan. Study on preparation and electrochemical performance of lithium aluminate nanorods modified solid electrolyte [J]. Inorganic Chemicals Industry, 2023, 55(8): 65-70. |

| [8] | LU Junhao. Study on full element recycling process of retired ternary power lithium battery [J]. Inorganic Chemicals Industry, 2023, 55(6): 92-103. |

| [9] | PANG Fei, XU Yingrui, CHAI Chunling, SHEN Jingjing, BAI Liguang, ZHAO Xiaodong. Overview on recycling of waste activated alumina in production of hydrogen peroxide by anthraquinone process [J]. Inorganic Chemicals Industry, 2023, 55(6): 1-7. |

| [10] | ZHU Zhihong, ZHU Yongfang. Study on preparation and properties of silicon doped lithium manganate by self-propagating combustion [J]. Inorganic Chemicals Industry, 2023, 55(5): 66-70. |

| [11] | XU Jingyao,ZHOU Xiaoli,SUN Jinghui,CAO Alin,QING Peilin. Study on preparation of flake α-alumina based on mixed molten salt at low temperature [J]. Inorganic Chemicals Industry, 2023, 55(2): 73-78. |

| [12] | TIAN Peng, XU Jingang, XU Qianjin, LIU Kunji, PANG Hongchang, NING Guiling. Preparation of nano-alumina slurry and its application in modifying lithium-ion battery cathode material [J]. Inorganic Chemicals Industry, 2023, 55(12): 43-49. |

| [13] | GUO Xueqin, DENG Xiaochuan, ZHU Chaoliang, FU Xin, WANG Ruirui, MA Wanxia, FAN Jie, ZUO Fangtao, QING Binju. Study on preparation of modified diatomite loaded ammonium phosphomolybdate composite adsorbent and its adsorption performance of Cs+ [J]. Inorganic Chemicals Industry, 2023, 55(11): 19-26. |

| [14] | TIAN Peng, ZHOU Ruohui, XU Qianjin, LIU Kunji, PANG Hongchang, NING Guiling. Synthesis and dehydration dynamics of boehmite microcrystalline with different particle sizes [J]. Inorganic Chemicals Industry, 2023, 55(11): 27-36. |

| [15] | PENG Chenxi, LIU Jun. Research progress of layered transition metal oxides cathode materials for sodium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(10): 1-12. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||