| [1] |

WANG Linjian, CHANG Liming, CHEN Hang, SONG Xingfu.

Effect of air flow and temperature on DPNB froth properties in KCl flotation

[J]. Inorganic Chemicals Industry, 2023, 55(5): 39-44.

|

| [2] |

QIE Zhijia,DONG Weibing,DU Jingling,MA Shengkui,WANG Gang.

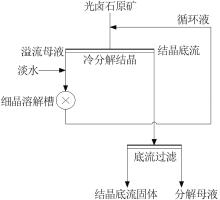

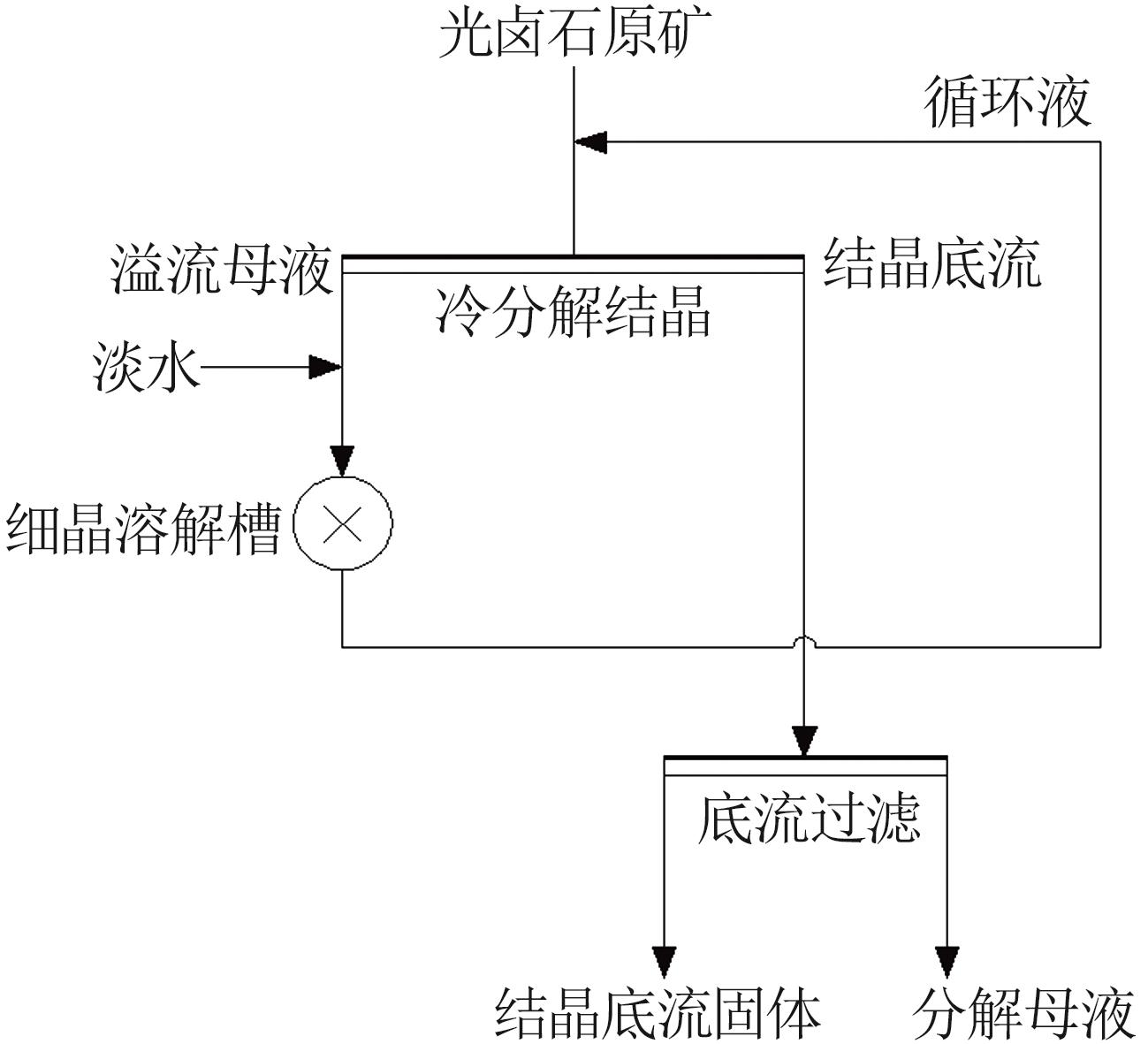

Study on yield of KCl prepared by cold crystallization of low?sodium carnallite

[J]. Inorganic Chemicals Industry, 2022, 54(5): 72-78.

|

| [3] |

CHEN Shuai,YANG Bo,CHEN Niancu,LUO Jun,REN Siying,ZENG Ying,YU Xudong.

Study on phase equilibria of ternary system NH4Cl+MgCl2+H2O at 323.2 K

[J]. Inorganic Chemicals Industry, 2022, 54(4): 100-103.

|

| [4] |

DU Jingling,DONG Weibing,QIE Zhijia,MA Shengkui,TIAN Hongbin,WANG Gang.

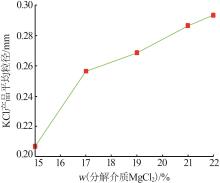

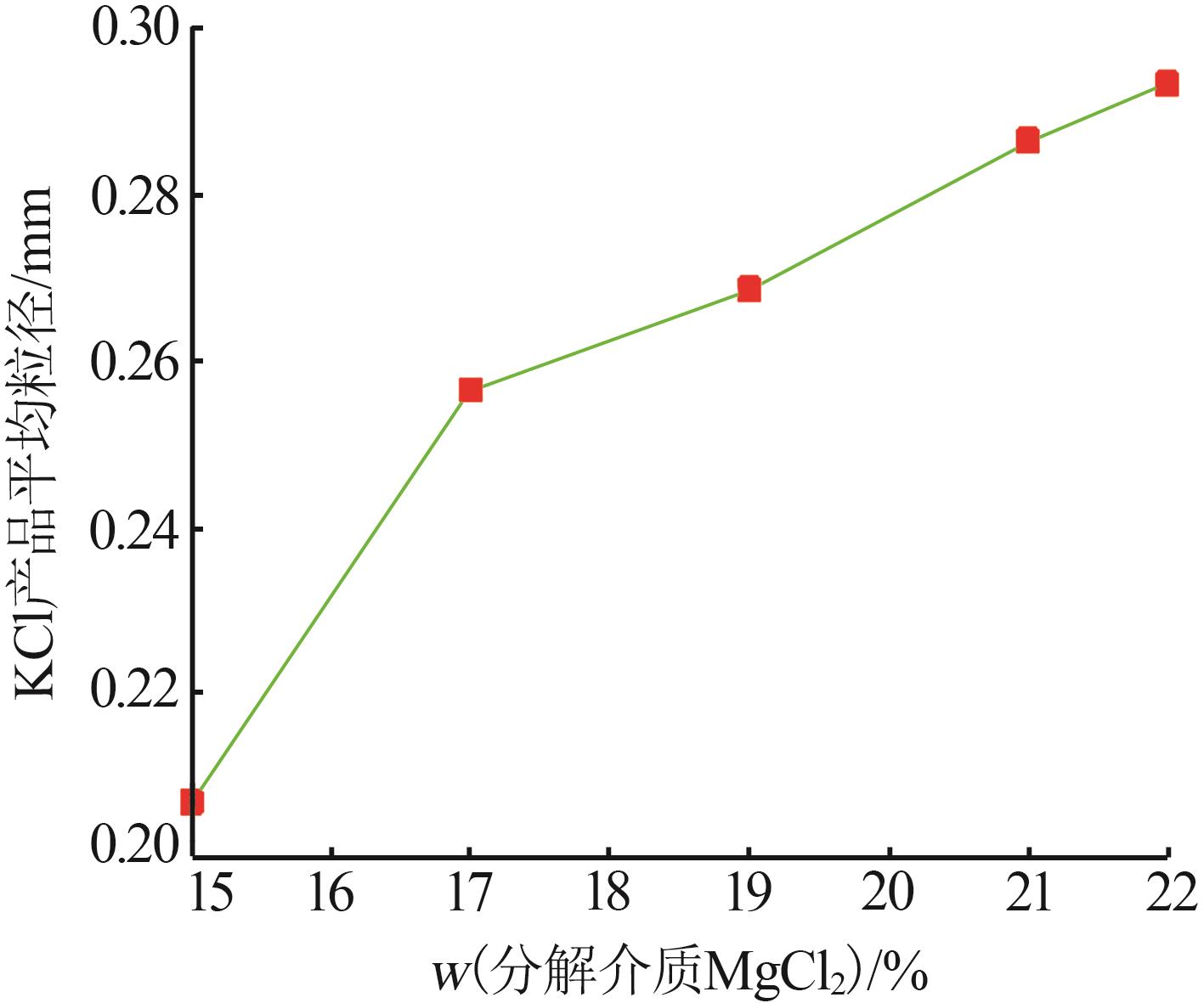

Study on effect of trisodium citrate on particle size of potassium chloride crystal prepared by decomposition of low sodium carnallite

[J]. Inorganic Chemicals Industry, 2022, 54(4): 112-118.

|

| [5] |

WU Sida,LIN Rushan,ZHANG Lei,JIA Yanhong.

Research progress on purification process for active crack elements in waste salt by dry post-treatment

[J]. Inorganic Chemicals Industry, 2022, 54(4): 81-87.

|

| [6] |

FAN Xiaojuan,ZHU Jing,DENG Wenqing,CHEN Yan,LI Tianxiang.

Study on phase equilibria of reciprocal quaternary system of K+,NH4+//Cl-,H2PO4--H2O at 313.15 K

[J]. Inorganic Chemicals Industry, 2022, 54(10): 102-108.

|

| [7] |

Xiong Jiaqing,Zhang Yu,Zhu Junguo.

Study on process of producing low-sodium carhalite by double brine mixing method

[J]. Inorganic Chemicals Industry, 2021, 53(8): 44-49.

|

| [8] |

Chen Xulong,Dong Weibing,Wan Junfeng,Wang Dongdong,Wang Gang.

Study on the crystallization process and agglomeration mechanism of spherical KCl

[J]. Inorganic Chemicals Industry, 2021, 53(7): 53-57.

|

| [9] |

Hou Yifei,Bai Ni,Sun Jian,Jiao Lina,Ju Dianchun.

Effects of ZrO2 on the physicochemical properties of NaCl-KCl molten salt system for the purification of crude ZrCl4

[J]. Inorganic Chemicals Industry, 2021, 53(7): 63-67.

|

| [10] |

Chen Mo,Sha Zuoliang.

Study on new process for producing potassium chloride using cold-decomposition-sieving method

[J]. Inorganic Chemicals Industry, 2021, 53(1): 65-67.

|

| [11] |

Zhang Liyuan,Wang Gang,Qi Meiling,Xie Yulong.

Effect of surfactants on metastable zone and induction period of KCl crystals in carnallite

[J]. Inorganic Chemicals Industry, 2020, 52(6): 46-49.

|

| [12] |

JIANG Cai-Li, ZHENG Shao-Cong, ZHENG Yuan-Li, WANG Zhi-Juan.

Preparation of potassium dihydrogen phosphate by triotylamine-isoamyl alcohol

organic solvent extraction

[J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(2): 44-.

|

| [13] |

XIE Bing-Jun, JI Lv, CHEN Gao-Qi, SUN Jin-He, JIA Yong-Zhong.

Effect of granularity on KCl distribution in flotation process

[J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(12): 38-.

|

| [14] |

GUO Jian-Feng, BIAN Hong-Li, CHENG Huai-Gang, CHENG Fang-Qin.

Study on preparation technology of carnallite from low grade potassium-bearing

brine by evaporation and crystallization

[J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(9): 18-.

|

| [15] |

LI Jin-Bin, SHA Zuo-Liang, WANG Yan-Fei.

Study on preparation of carnallite from mixed potassium salt

[J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(8): 18-.

|

), DING Ding2(

), DING Ding2( ), SUN Chenggao1, JIANG Shipeng1, GUAN Junfang2

), SUN Chenggao1, JIANG Shipeng1, GUAN Junfang2