Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (9): 94-99.doi: 10.19964/j.issn.1006-4990.2022-0664

• Environment·Health·Safety • Previous Articles Next Articles

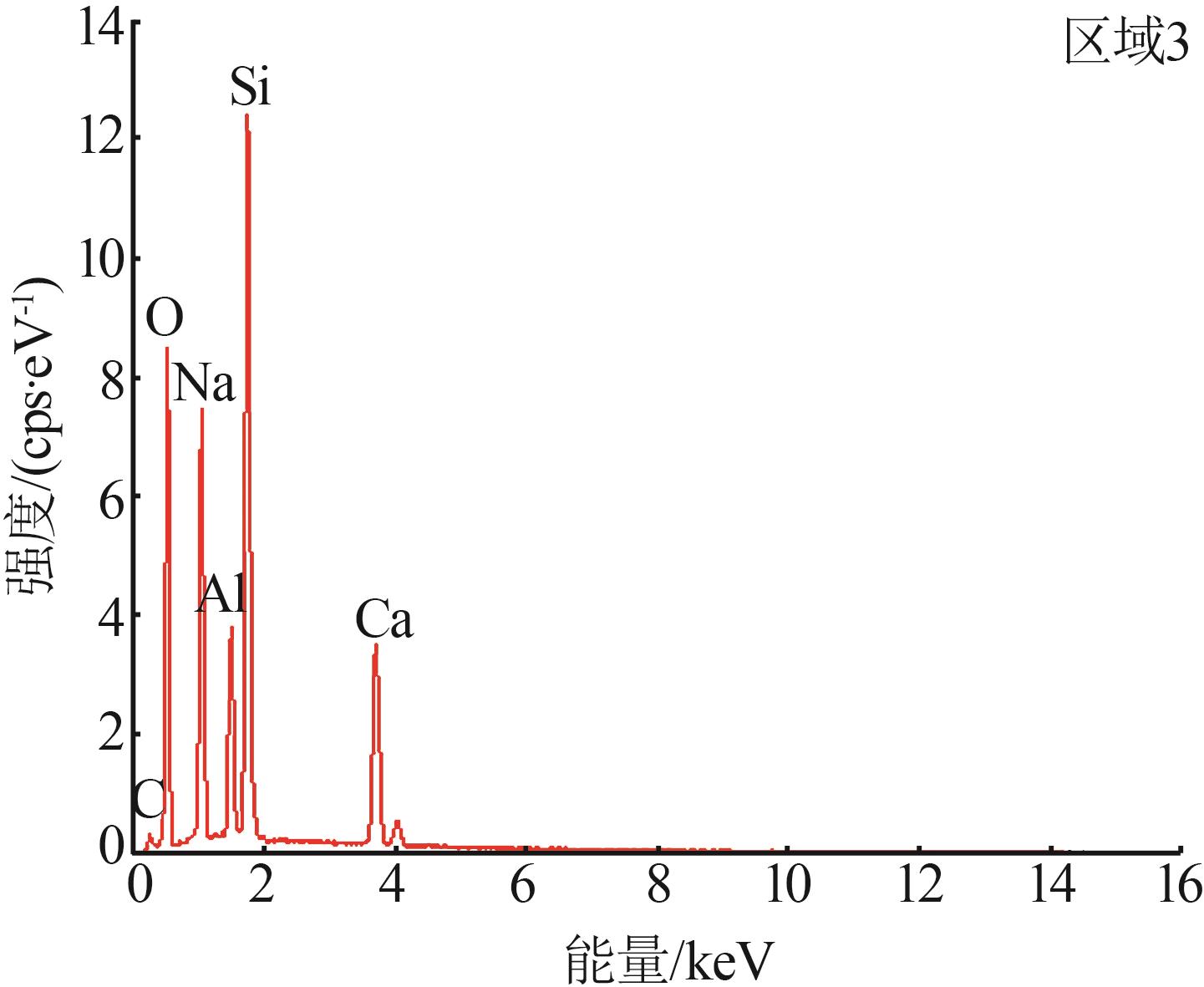

Study on recovery of silicon and aluminum from industrial silicon slag

LUO Wenbo1( ), LI Heng1, LÜ Jun2, YANG Linguang3, ZHAO Xingfan4, LONG Xiao1(

), LI Heng1, LÜ Jun2, YANG Linguang3, ZHAO Xingfan4, LONG Xiao1( )

)

- 1.Faculty of Materials and Energy Engineering,Guizhou Institute of Technology,Guiyang 550003,China

2.Mangshi Yonglong Ferroalloy Co. ,Ltd,Mangshi 678400,China

3.Yunnan Longling Longshan silicon Co. ,Ltd,Longling 678300,China

4.Longling Pengyue Technology Consulting Service Co. ,Ltd,Longling 678300,China

-

Received:2022-11-09Online:2023-09-10Published:2023-09-19 -

Contact:LONG Xiao E-mail:luowenbo@126.com;609412746@qq.com

CLC Number:

Cite this article

LUO Wenbo, LI Heng, LÜ Jun, YANG Linguang, ZHAO Xingfan, LONG Xiao. Study on recovery of silicon and aluminum from industrial silicon slag[J]. Inorganic Chemicals Industry, 2023, 55(9): 94-99.

share this article

| 1 | 郑通,翟双东,庄艳歆,等.从硅渣中回收提纯金属硅的研究[J].铁合金,2021,52(3):23-27. |

| ZHENG Tong, ZHAI Shuangdong, ZHUANG Yanxin,et al.Study on recovery and purification of metallic silicon from silicon slag[J].Ferro-Alloys,2021,52(3):23-27. | |

| 2 | HAN Shifeng, TAN Ning, WEI Kuixian,et al.Electromagnetic separation of silicon from metallurgical-grade silicon refined slag during the remelting process[J].Separation and Purification Technology,2022,280:119815. |

| 3 | 张藜,毕红兴,赵兴凡,等.工业硅渣重选试验研究[J].云南冶金,2019,48(1):30-34. |

| ZHANG Li, BI Hongxing, ZHAO Xingfan,et al.The gravity separation experimental study of industrial silicon slag[J].Yunnan Metallurgy,2019,48(1):30-34. | |

| 4 | 钱双凤,陈敏.从工业硅硅渣中分离金属硅的实验研究[J].有色金属设计,2017,44(3):18-22. |

| QIAN Shuangfeng, CHEN Min.Experimental study on separation of silicon from industrial silicon slag[J].Nonferrous Metals Design,2017,44(3):18-22. | |

| 5 | LIU Cheng, SONG Shaoxian, LI Hongqiang.Selective flotation of fluorite from barite using trisodium phosphate as a depressant[J].Minerals Engineering,2019,134:390-393. |

| 6 | 李昆,李春全,孙志明.粉煤灰制备NaA型分子筛及其对铅离子的吸附性能研究[J].矿业科学学报,2022,7(5):604-614. |

| LI Kun, LI Chunquan, SUN Zhiming.Preparation of NaA zeolite with fly ash and its adsorption properties for lead ions[J].Journal of Mining Science and Technology,2022,7(5):604-614. | |

| 7 | 何平.多孔材料成型体的制备及其吸附性能研究[D].长春:吉林大学,2020. |

| HE Ping.Study on preparation and adsorption properties of porous material molded body[D].Changchun:Jilin University,2020. | |

| 8 | 张浩洋,徐丽粉,常鑫瑜,等.以Mo-EDTA为钼源直接水热合成Mo-MFI分子筛及其催化环己烯环氧化性能[J].催化学报(英文),2021,42(12):2265-2274. |

| ZHANG Haoyang, XU Lifen, CHANG Xinyu,et al.Direct hydrothermal synthesis of Mo-containing MFI zeolites using Mo-EDTA complex and their catalytic application in cyclohexene epoxidati-on[J].Chinese Journal of Catalysis,2021,42(12):2265-2274. | |

| 9 | 马先赟,聂轶苗,陈阳,等.粉煤灰基沸石分子筛的合成及其结构性能研究现状[J].金属矿山,2022(8):82-93. |

| MA Xianyun, NIE Yimiao, CHEN Yang,et al.Research status of the synthesis and structural properties of fly ash-based zeolite molecular sieves[J].Metal Mine,2022(8):82-93. | |

| 10 | ZHANG Baoping, CHEN Yunlin, WEI Lin,et al.Preparation of molecular sieve X from coal fly ash for the adsorption of volatile organic compounds[J].Microporous and Mesoporous Materials,2012,156:36-39. |

| 11 | 李超,王丽萍,郭昭华,等.粉煤灰酸溶渣合成13X分子筛及其对铜离子吸附性能[J].无机盐工业,2018,50(9):63-66. |

| LI Chao, WANG Liping, GUO Zhaohua,et al.Synthesis of 13X zeolite by fly ash acid residue and its adsorption performance to copper ions[J].Inorganic Chemicals Industry,2018,50(9):63- 66. | |

| 12 | 孔德顺,蒋荣立.六盘水煤矸石酸浸渣制备NaP分子筛[J].非金属矿,2021,44(1):13-15. |

| KONG Deshun, JIANG Rongli.Preparation of NaP molecular sieve from acid leaching residue of coal gangue in Liupanshui[J].Non-Metallic Mines,2021,44(1):13-15. | |

| 13 | HAN Jinfeng, Ying HA, GUO Mingyu,et al.Synthesis of zeolite SSZ-13 from coal gangue via ultrasonic pretreatment combined with hydrothermal growth method[J].Ultrasonics Sonochemistry,2019,59:104703. |

| 14 | 王彬宇,李莉,李菁,等.用工业固体废料合成沸石分子筛的研究进展[J].高等学校化学学报,2021,42(1):40-59. |

| WANG Binyu, LI Li, LI Jing,et al.Recent progresses on the synthesis of zeolites from the industrial solid wastes[J].Chemical Journal of Chinese Universities,2021,42(1):40-59. | |

| 15 | 庄强,林国,崔群,等.锂矿渣制备FAU/LTA共晶分子筛的表征及性能[J].石油学报(石油加工),2014,30(2):348-352. |

| ZHUANG Qiang, LIN Guo, CUI Qun,et al.Characterization and performance of FAU/LTA Co-crystalline zeolite synthesized by lithium slag[J].Acta Petrolei Sinica(Petroleum Processing Section),2014,30(2):348-352. | |

| 16 | 卢艳龙.利用锆硅渣合成分子筛研究[D].淄博:山东理工大学,2013. |

| LU Yanlong.Study on synthesis of molecular sieve from zirconium silicon slag[D].Zibo:Shandong University of Technology,2013. | |

| 17 | 刘镇珲,王明华.廉价固体合成沸石分子筛的研究进展[J].材料研究与应用,2018,12(3):167-172. |

| LIU Zhenhui, WANG Minghua.The research development of zeolites preparation from cheap solid[J].Materials Research and Application,2018,12(3):167-172. | |

| 18 | 侯慧耀,陈永强,马保中,等.粉煤灰回收氧化铝工艺研究现状及进展[J].矿冶,2021,30(3):30-39. |

| HOU Huiyao, CHEN Yongqiang, MA Baozhong,et al.Research status and progress of alumina recovery from fly ash[J].Mining and Metallurgy,2021,30(3):30-39. |

| [1] | YU Zhou, HE Zhaoyi, TANG Liang, HE Sheng, XIAO Haixin, XIAO Yixun. Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials [J]. Inorganic Chemicals Industry, 2024, 56(4): 90-97. |

| [2] | WANG Jianrui, ZHANG Song, ZHANG Jie. Study on new process for beneficiation phosphate of low-grade phosphate rock leaching via lactic acid [J]. Inorganic Chemicals Industry, 2024, 56(3): 56-63. |

| [3] | WANG Ruting, ZHAO Xiaorong, HUANG Xuquan, WANG Haojie, XUE Fei, CAI Jiawei. Research on preparation and early performance of mixed phase phosphogypsum-based cementing materials [J]. Inorganic Chemicals Industry, 2024, 56(3): 98-104. |

| [4] | HUANG Tao, HUANG Zili, XIAO Shuo, ZHENG Jiemiao, LIU Xiaofeng, WU Jilong. Experimental study on preparation of polyferric chloride from iron tailings acid leaching solution [J]. Inorganic Chemicals Industry, 2024, 56(2): 121-126. |

| [5] | XIA Guiying, YANG Liuchun, YUAN Zhiye. Study on direct leaching of rare earth elements from phosphogypsum with sulfuric acid [J]. Inorganic Chemicals Industry, 2024, 56(1): 107-113. |

| [6] | XIANG Mengqi, MENG Hua, WANG Ye, MENG Xianzhang, BAI Yuhang, WANG Yujunyao, ZHANG Yidan. Study on kinetic of iron leaching from titanium gypsum and its cyclic acid leaching process [J]. Inorganic Chemicals Industry, 2024, 56(1): 114-120. |

| [7] | ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM [J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113. |

| [8] | DONG Xinyu, WANG Haifeng, HE Yue, YANG Pan, WANG Song, YANG Chunyuan, WANG Qin, HUANG Bifang, WANG Jiawei. Exleaching toxicity analysis and harmless treatment of electrolytic manganese residue [J]. Inorganic Chemicals Industry, 2023, 55(5): 85-90. |

| [9] | DONG Xiongwei, HAN Fenglan, HUA Wei, LI Maohui, AN Changcong, HUANG Yucai. Synthesis and characterization of silico-manganese slag zeolite [J]. Inorganic Chemicals Industry, 2023, 55(12): 128-132. |

| [10] | TENG Jiayang, FENG Qingge, ZHANG Xuan, QIN Fanghong, FENG Jinghang, HU Jiawen, CHEN Chaohong. Study on preparation of pseudo-boehmite from aluminum dross resource treatment [J]. Inorganic Chemicals Industry, 2023, 55(11): 130-138. |

| [11] | LI Huifang, WANG Xiao, BAI Youpeng, ZHANG Shixiang. Study on extraction of lithium from low grade high clay leaching solution by solvent extraction [J]. Inorganic Chemicals Industry, 2023, 55(10): 63-69. |

| [12] | LIU Darui,XU Lijun,LI Shichun,CAO Kun,TU Ya,LI Wenqing,LIU Qingliang. Research progress of recovery of strategic metal lithium from fly ash [J]. Inorganic Chemicals Industry, 2023, 55(1): 56-63. |

| [13] | ZHU Yue,QIU Shengbo,LIU Chenglin,YU Jianguo. Study on enhancement of spodumene phase reconstruction process by mechanical activation [J]. Inorganic Chemicals Industry, 2023, 55(1): 81-86. |

| [14] | YU Meng,LI Xiang,TIE Leilei,LI Zhiyuan,LIU Wenhui,WU Bao,Zheng Yufei. Research and evaluation of silicate composite viscoelastic oil displacement agent [J]. Inorganic Chemicals Industry, 2022, 54(9): 102-107. |

| [15] | FU Ziqi, ZHANG Cheng, SHENG Yong, JI Lijun. Study on preparation of phosphoric acid by leaching fluoride residue from wet-process phosphoric acid with organic solvents [J]. Inorganic Chemicals Industry, 2022, 54(7): 129-134. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||