Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (4): 76-83.doi: 10.19964/j.issn.1006-4990.2022-0386

• Environment·Health·Safety • Previous Articles Next Articles

Preparation of poly-aluminum chloride from acid leaching liquor of red mud-coal gangue activated by sodium salt

WANG Lijuan1,2( ), YAN Kezhou1(

), YAN Kezhou1( ), GUO Zhiqiang1, ZHAO Zhonghe3, GUO Yanxia1,2, CHENG Fangqin1,2

), GUO Zhiqiang1, ZHAO Zhonghe3, GUO Yanxia1,2, CHENG Fangqin1,2

- 1. Institute of Resources and Environmental Engineering,State Environmental Protection Key Laboratory of Efficient Utilization Technology of Coal Waste Resources,Shanxi University,Taiyuan 030006,China

2. College of Environmental;and Resource Sciences of Shanxi University,Taiyuan 030006,China

3. Shanxi Dadi Environment;investment Holdings Company,Taiyuan 030032,China

-

Received:2022-06-24Online:2023-04-10Published:2023-04-13

CLC Number:

Cite this article

WANG Lijuan, YAN Kezhou, GUO Zhiqiang, ZHAO Zhonghe, GUO Yanxia, CHENG Fangqin. Preparation of poly-aluminum chloride from acid leaching liquor of red mud-coal gangue activated by sodium salt[J]. Inorganic Chemicals Industry, 2023, 55(4): 76-83.

share this article

| 1 | REDDY P S, REDDY N G, SERJUN V Z,et al.Properties and assessment of applications of red mud (bauxite residue):Current status and research needs[J].Waste and Biomass Valorization,2021,12(3):1185-1217. |

| 2 | WANG Shaohan, JIN Huixin, DENG Yong,et al.Comprehensive utilization status of red mud in China:A critical review[J].Journal of Cleaner Production,2021,289.Doi:10.1016/j.jclepro.2020. 125136 . |

| 3 | 石家力,黄自力,秦庆伟,等.二次铝灰制备聚合氯化铝试验研究[J].金属矿山,2021(7):206-210. |

| SHI Jiali, HUANG Zili, QIN Qingwei,et al.Experiment study on the preparation of polyaluminum chloride with secondary aluminum dross[J].Metal Mine,2021(7):206-210. | |

| 4 | 杜凯峰,吕帅帅,倪红军,等.铝灰渣与废盐酸制备聚合氯化铝的试验研究[J].功能材料,2020,51(1):1207-1213. |

| DU Kaifeng, Shuaishuai LYU, NI Hongjun,et al.Research on preparation of poly-aluminum chloride by aluminum ash and waste hydrochloric acid[J].Journal of Functional Materials,2020,51(1):1207-1213. | |

| 5 | LAN Wei, QIU Huiqin, ZHANG Jie,et al.Characteristic of a novel composite inorganic polymer coagulant-PFAC prepared by hydrochloric pickle liquor[J].Journal of Hazardous Materials,2009,162(1):174-179. |

| 6 | ZHAO Ying, ZHANG Lieyu, NI Fan,et al.Evaluation of a novel composite inorganic coagulant prepared by red mud for phosphate removal[J].Desalination,2011,273(2/3):414-420. |

| 7 | 胡文豪,张建波,李少鹏,等.煤气化渣制备聚合氯化铝工艺研究[J].洁净煤技术,2019,25(1):154-159. |

| HU Wenhao, ZHANG Jianbo, LI Shaopeng,et al.Study on the preparation of polyaluminium chloride from coal gasification residue[J].Clean Coal Technology,2019,25(1):154-159. | |

| 8 | 马方通,高利坤.赤泥制备无机高分子絮凝剂的研究进展[J].化学世界,2017,58(6):379-384. |

| MA Fangtong, GAO Likun.Progress of preparation of inorganic polymer flocculant from bauxite residues[J].Chemical World,2017,58(6):379-384. | |

| 9 | 赵恒,李望,牛泽鹏,等.赤泥制备聚合氯化铝铁及其吸附性能研究[J].稀有金属与硬质合金,2019,47(5):64-68,82. |

| ZHAO Heng, LI Wang, NIU Zepeng,et al.Preparation and adsorption properties of polyaluminum ferric chloride from red mud[J].Rare Metals and Cemented Carbides,2019,47(5):64-68,82. | |

| 10 | 王文杰,练伟,刘振英,等.微波水热煤矸石制备聚合氯化铝及其性能研究[J].安徽化工,2022,48(1):51-57. |

| WANG Wenjie, LIAN Wei, LIU Zhenying,et al.Preparation of polyaluminum chloride from coal gangue by microwave hydrothermal method and its performance[J].Anhui Chemical Industry,2022,48(1):51-57. | |

| 11 | GUO Yanxia, LI Jian, YAN Kezhou,et al.A prospective process for alumina extraction via the co-treatment of coal fly ash and bauxite red mud:Investigation of the process[J].Hydrometallurgy,2019,186:98-104. |

| 12 | 张吉元,柳丹丹,郭晓方,等.赤泥-煤矸石协同还原焙烧回收Fe、Al有价元素[J].环境工程学报,2021,15(10):3306-3315. |

| ZHANG Jiyuan, LIU Dandan, GUO Xiaofang,et al.Valuable element recovery of Fe and Al by reduction roasting of red mud and coal gangue[J].Chinese Journal of Environmental Engineering,2021,15(10):3306-3315. | |

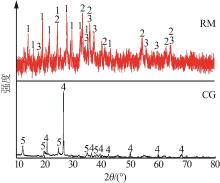

| 13 | 郭志强,燕可洲,张吉元,等.煤矸石/粉煤灰对赤泥钠化还原焙烧反应的影响机制[J].化工学报,2022,73(5):2194-2205. |

| GUO Zhiqiang, YAN Kezhou, ZHANG Jiyuan,et al.Influence mechanism of coal gangue/coal fly ash on the sodium reduction roasting reaction of red mud[J].CIESC Journal,2022,73(5):2194-2205. | |

| 14 | 郭玉梅,曹丽琼,郭彦霞,等.煤矸石和赤泥协同提取氧化铝过程矿相转变研究[J].化工学报,2019,70(4):1542-1549. |

| GUO Yumei, CAO Liqiong, GUO Yanxia,et al.Mineral transformation in process of combined extraction of alumina from coal gan-gue and red mud[J].CIESC Journal,2019,70(4):1542-1549. | |

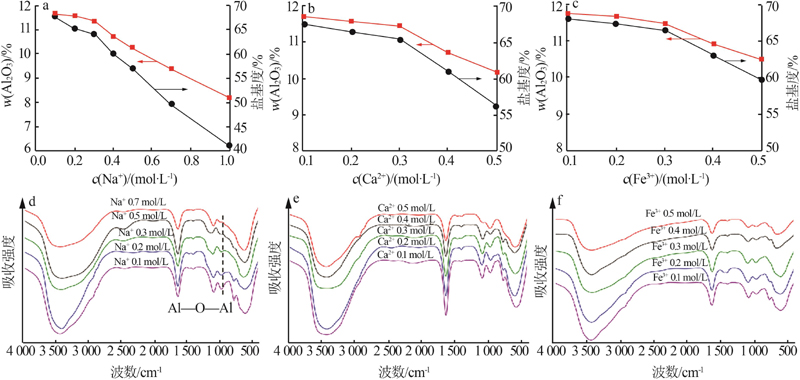

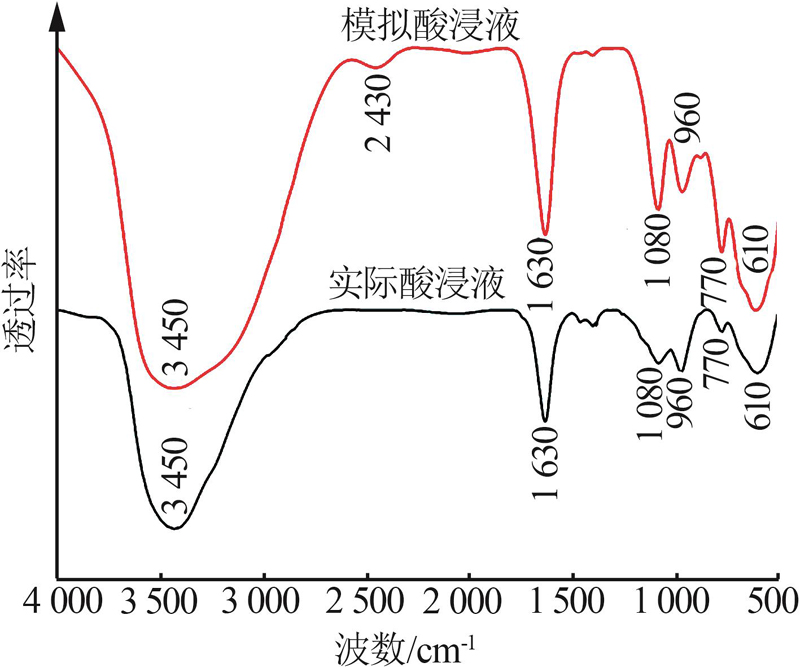

| 15 | 宁寻安,李凯,李润生,等.聚合氯化铝的红外光谱研究[J].环境化学,2008,27(2):263-264. |

| NING Xun'an, LI Kai, LI Runsheng,et al.Study on infrared spectrum of polyaluminum chloride[J].Environmental Chemistry,2008,27(2):263-264. | |

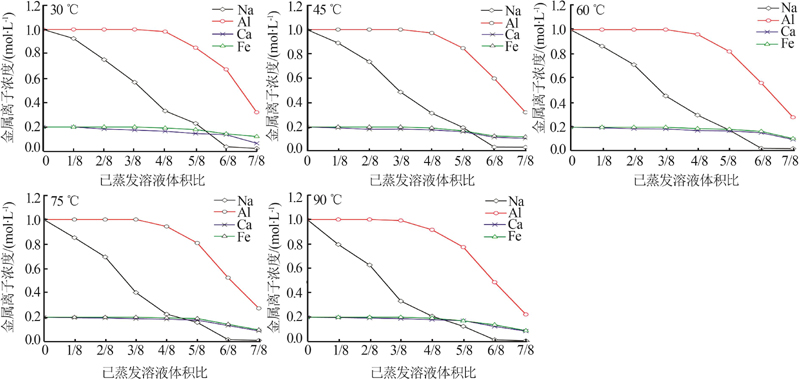

| 16 | 吕慧斌.粉煤灰酸浸液中AlCl3·6H2O的结晶分离研究[D].太原:山西大学,2017. |

| Huibin LÜ.Crystallization separation of AlCl3·6H2O from acid leaching liquor of coal fly ash[D].Taiyuan:Shanxi University,2017. | |

| 17 | 仵理想.粉煤灰盐酸浸取液相平衡及相分离的研究[D].太原:山西大学,2020. |

| WU Lixiang.Study on phase equilibrium and phase separation of hydrochloric acid leaching liquid of fly ash[D].Taiyuan:Shanxi University,2020. | |

| 18 | 刘吉龙,潘晓林,耿学哲,等.高铝粉煤灰酸浸废液制备聚合氯化铝铁及其应用[J].中南大学学报:自然科学版,2021,52(11):3792-3799. |

| LIU Jilong, PAN Xiaolin, GENG Xuezhe,et al.Preparation and application of polymeric aluminum ferric chloride from acidic-leaching waste liquor of high-alumina fly ash[J].Journal of Central South University:Science and Technology,2021,52(11):3792-3799. | |

| 19 | 丁舒航,周建民,张梦瑶,等.基于煤矸石制备的聚合氯化铝铁钛及其在二沉池出水处理中的应用[J].环境工程学报,2021,15(1):43-56. |

| DING Shuhang, ZHOU Jianmin, ZHANG Mengyao,et al.Preparation of polyaluminum iron titanium chloride from coal gangue and its application in the treatment of effluent from secondary sedimentation tank[J].Chinese Journal of Environmental Engineering,2021,15(1):43-56. | |

| 20 | LIU Beibei, GAO Baoyu, GUO Kangying,et al.The interactions between Al(Ⅲ) and Ti(Ⅳ) in the composite coagulant polyaluminum-titanium chloride[J].Separation and Purification Technology,2022,282.Doi:10.1016/j.seppur.2021.120148 . |

| 21 | 柴彬.聚合氯化铝制备条件优化与应用研究[D].成都:西南交通大学,2017. |

| CHAI Bin.Poly aluminium chloride preparation conditions optimization and application research[D].Chengdu:Southwest Jiaotong University,2017. | |

| 22 | 劳德平.粉煤灰与氧化铁皮制备复合型混凝剂及混凝性能研究[D].北京:北京科技大学,2019. |

| LAO Deping.Preparation of composite coagulant and coagulation performance with coal fly ash and iron scale[D].Beijing:University of Science and Technology Beijing,2019. | |

| 23 | 左选凤,蒋银峰,居银栋,等.高速分散均质技术制备无渣型聚合氯化铝[J].水处理技术,2019,45(4):68-71,77. |

| ZUO Xuanfeng, JIANG Yinfeng, JU Yindong,et al.Preparation of the ESM type polyaluminum chloride by the high-speed dispersion homogenization technology[J].Technology of Water Treatment,2019,45(4):68-71,77. | |

| 24 | NAKAMOTO K.Infrared and Raman spectra of inorganic and coordination compounds-Part A:Theory and applications in inorganic chemistry[M].5th ed.New York:John Wiley & Sons,1997. |

| 25 | KLOPROGGE J T, FROST R L.Raman and infrared spectroscopic investigation of the neutralisation of aluminium in the presence of monomeric orthosilicic acid[J].Spectrochimica Acta Part A:Molecular and Biomolecular Spectroscopy,1999,55(7/8):1359-1369. |

| 26 | DUXSON P, LUKEY G C, SEPAROVIC F,et al.Effect of alkali cations on aluminum incorporation in geopolymeric gels[J].Industrial & Engineering Chemistry Research,2005,44(4):832-839. |

| 27 | LIU Z, DUAN X, ZHAN P,et al.Coagulation performance and microstructural morphology of a novel magnetic composite coagulant for pre-treating landfill leachate[J].International Journal of Environmental Science and Technology,2017,14(11):2507-2518. |

| 28 | TZOUPANOS N D, ZOUBOULIS A I.Preparation,characterisation and application of novel composite coagulants for surface water treatment[J].Water Research,2011,45(12):3614-3626. |

| 29 | CHOUDHARY A K, KUMAR S, SHARMA C.Removal of chloro-organics and color from pulp and paper mill wastewater by polyaluminium chloride as coagulant[J].Desalination and Water Treatment,2015,53(3):697-708. |

| 30 | 张翔,段建榜,李瑞歌,等.炼钙还原渣和煤矸石制备聚合氯化铝的研究[J].无机盐工业,2016,48(4):66-68. |

| ZHANG Xiang, DUAN Jianbang, LI Ruige,et al.Preparation of polyaluminum chloride from calcium reducing slag and coal gangue[J].Inorganic Chemicals Industry,2016,48(4):66-68. | |

| 31 | CHEN Wei, LI Bo, LI Qiu,et al.Effect of polyaluminum chloride on the properties and hydration of slag-cement paste[J].Construction and Building Materials,2016,124:1019-1027. |

| 32 | 李文杰.粉煤灰基聚氯硫酸铝铁的制备及其性能研究[D].太原:山西大学,2021. |

| LI Wenjie.Enhanced metal leaching for preparation of polymeric aluminum ferric chloride sulfate(PAFCS) from circulating fluidized bed fly ash[D].Taiyuan:Shanxi University,2021. | |

| 33 | 孔德顺,王鲁凤,蒋荣立.高岭土制备聚合氯化铝及处理洗煤废水的研究[J].非金属矿,2020,43(4):80-83. |

| KONG Deshun, WANG Lufeng, JIANG Rongli.Study on the preparation of poly aluminum chloride from Kaolin and the treatment of coal washing waste water[J].Non-Metallic Mines,2020,43(4):80-83. | |

| 34 | 张帅,黄凯强,冯雪松,等.煤矸石制备无机高分子絮凝剂PAC及其絮凝性[J].化工技术与开发,2018,47(1):56-59,65. |

| ZHANG Shuai, HUANG Kaiqiang, FENG Xuesong,et al.Preparation of inorganic polymer flocculant of PAC with coal gangue and its flocculability[J].Technology & Development of Chemical Industry,2018,47(1):56-59,65. |

| [1] | ZHU Zuoqiao, SHI Mengyuan, MAO Rui, GUO Haining, SU Yuao. Study on treatment process of metallurgical fluorine-containing wastewater by coagulant sedimentation method [J]. Inorganic Chemicals Industry, 2024, 56(4): 118-124. |

| [2] | LIU Dexin, MA Tengyue, AN Jinling, LIU Jinrong, HE Weiyan. Study on cathode material design and electrochemical properties of manganese-based sodium ion battery [J]. Inorganic Chemicals Industry, 2024, 56(3): 51-55. |

| [3] | WANG Yizhou, HU Xiaomei, WANG Yongxiang, ZHANG Weimin. Study on preparation of nickel-iron-manganate sodium layered oxides and their properties [J]. Inorganic Chemicals Industry, 2024, 56(2): 57-64. |

| [4] | HAN Hongjing, ZHANG Jingze, LAMAO Zhuoma, HAN Jizhe, WU Yongmin, TANG Weiping. Preparation of Al-Co co-doped lithium manganese oxide and its adsorption performance of lithium [J]. Inorganic Chemicals Industry, 2023, 55(7): 38-44. |

| [5] | WANG Jianfang, YANG Heping, LI Kaibin, CONG Shiqiang, ZHANG Bojie, GUO Shan. Study on preparation of C3N4/MnCo2S4 composites and their capacitive properties [J]. Inorganic Chemicals Industry, 2023, 55(7): 70-74. |

| [6] | XU Xuetang, WANG Xukai, ZHANG Shenhe, HUANG Meixiang, NONG Shuliu, XU Nuo. Study on preparation and properties of vanadate doped NiCo-LDH electrode [J]. Inorganic Chemicals Industry, 2023, 55(5): 52-58. |

| [7] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [8] | ZHANG Chenhu, MA Yi, ZHU Shan, CHEN Peng, WANG Chengyong, LI Ziwen. Study on adsorption of heavy metal ions in mineral processing wastewater by chelating modified coal gangue [J]. Inorganic Chemicals Industry, 2023, 55(4): 97-103. |

| [9] | XU Wenzhen,LI Canhua,JI Hongfeng,LI Zimu,WU Zhaoyang,LI Minghui. Research progress of red mud in field of recycled metals and building materials [J]. Inorganic Chemicals Industry, 2023, 55(2): 10-18. |

| [10] | LI Songhong,ZHOU Songhua,ZHAO Aiming,DONG Wenyan,JIANG Chunyan,CAO Yang,AO Xianquan. Study on catalytic gasification reaction of distillers′grains under H2O/CO2 atmosphere [J]. Inorganic Chemicals Industry, 2023, 55(2): 132-140. |

| [11] | PAN Sicheng,XU Hongbin,ZHANG Hongling,DONG Yuming,ZHANG Hongjun,LOU Taiping. Study on preparation of metatitanic acid by hydrolysis of leaching solution of roasted mixture of red mud and ammonium sulfate [J]. Inorganic Chemicals Industry, 2023, 55(2): 85-91. |

| [12] | LU Jingjing,XIE Yan,LI Chen,MENG Mei,FENG Lunwei. Study on treatment of phosphorus-containing wastewater by lanthanum-loaded magnetized red mud [J]. Inorganic Chemicals Industry, 2023, 55(2): 99-105. |

| [13] | YUE Yuansui, CHENG Guanwen, XU Min, XU Xiaoyu, ZHANG Zhenlin, NONG Guowu. Function and effect of ferric chloride solution in alkaline regulation of red mud [J]. Inorganic Chemicals Industry, 2023, 55(11): 121-129. |

| [14] | HU Yue, MO Hengliang, LI Tianyu, PENG Wenjuan, SUN Guangdong, XIAO Hongkang, CHEN Yili, LI Suoding, TANG Yang. Study on spinning molding and performance of Ti-based lithium ion sieve powder and PVDF resin [J]. Inorganic Chemicals Industry, 2023, 55(11): 58-63. |

| [15] | LI Sen, WANG Jin, WANG Yingying, CAI Mingfang. Synthesis and modification of NaA zeolite and its application in polyurethane system [J]. Inorganic Chemicals Industry, 2023, 55(10): 78-85. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||