| [1] |

JIANG Songyan, HUA Hui, SHENG Hu, et al.Phosphorus footprint in China over the 1961-2050 period:Historical perspective and future prospect[J].Science of the Total Environment,2019,650:687-695.

|

| [2] |

LIANG Haijun, ZHANG P, JIN Zhen, et al.Rare earth and phosphorus leaching from a flotation tailings of Florida phosphate ro⁃ ck[J].Minerals,2018,8(9).Doi:10.3390/min8090416.

doi: 10.3390/min8090416.

|

| [3] |

傅英.简述磷酸渣酸资源化利用技术研究[J].山东化工,2017,46(5):151,154.

|

| [4] |

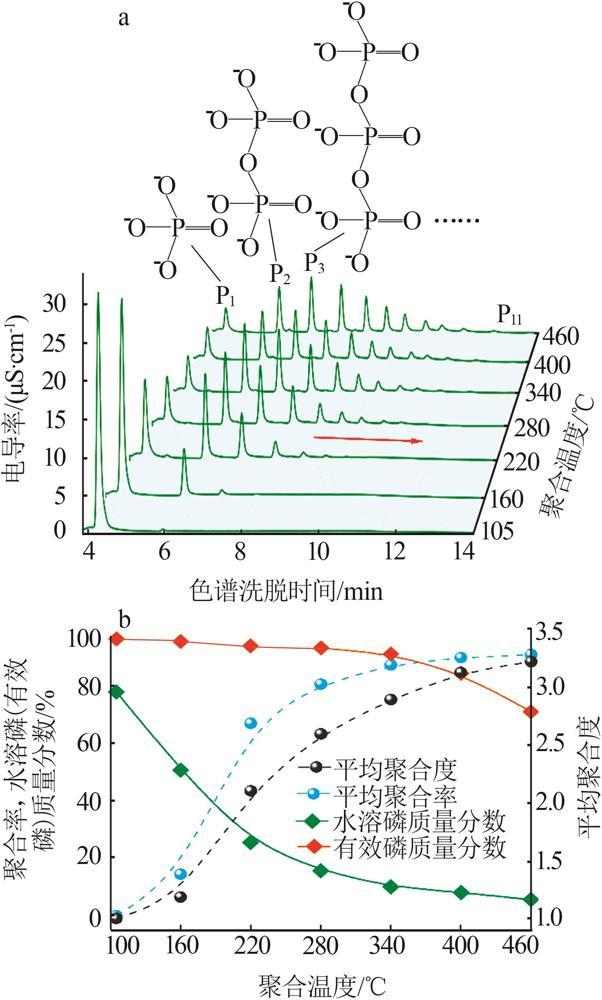

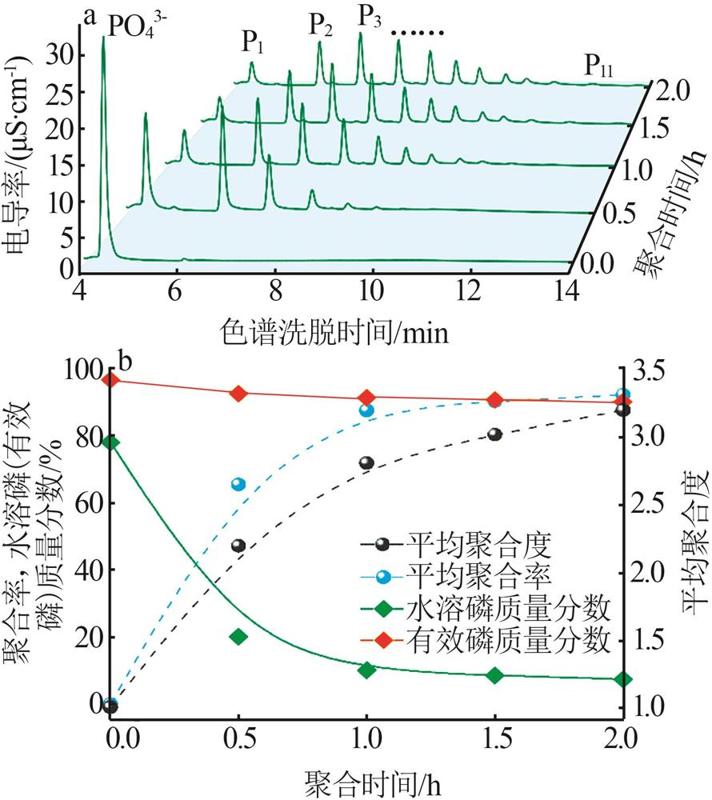

YANG Jingxu, KONG Xingjian, XU Dehua, et al.Evolution of the polydispersity of ammonium polyphosphate in a reactive extrusion process:Polycondensation mechanism and kinetics[J].Chemical Engineering Journal,2019,359:1453-1462.

|

| [5] |

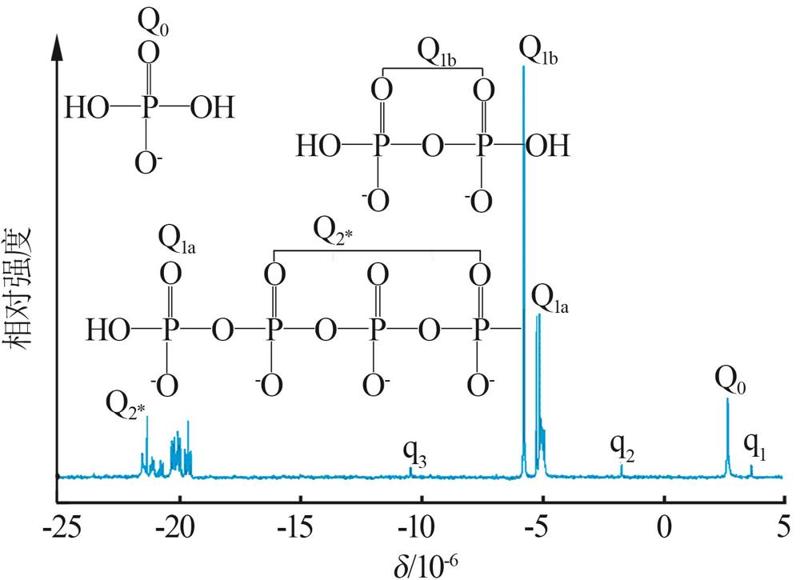

WANG Xuewei, GAO Yanju, HU Baowei, et al.Comparison of the hydrolysis characteristics of three polyphosphates and their effects on soil phosphorus and micronutrient availability[J].Soil Use and Management,2019,35(4):664-674.

|

| [6] |

凌浩瀚,王辛龙,许德华,等.不同聚合度水溶性聚磷酸铵螯合镁离子的研究[J].无机盐工业,2019,51(12):20-22,34.

|

|

LING Haohan, WANG Xinlong, XU Dehua, et al.Effect of water⁃soluble ammonium polyphosphate with different degree of polymerization on chelation of magnesium ion[J].Inorganic Chemicals Industry,2019,51(12):20-22,34.

|

| [7] |

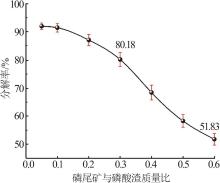

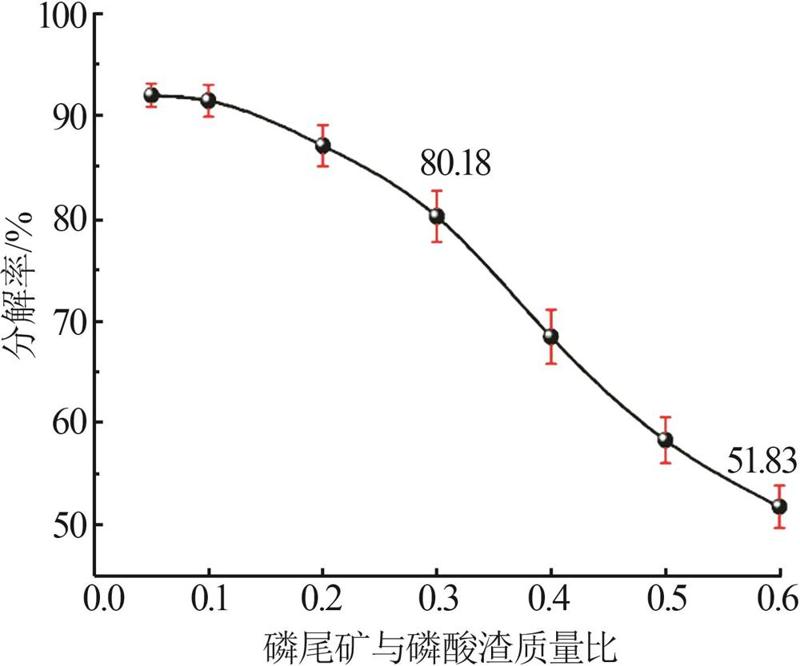

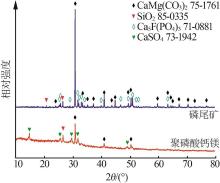

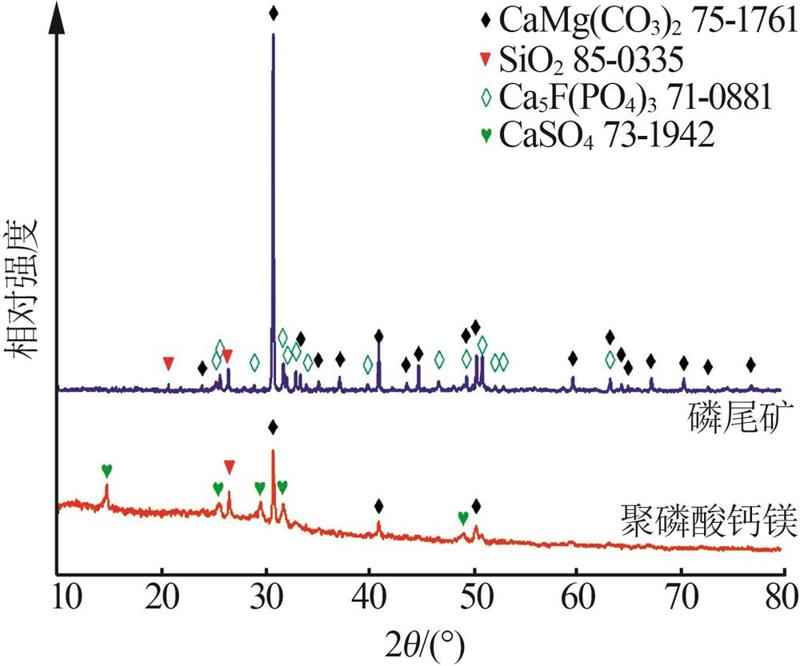

郑建国,于南树,刘永秀,等.磷酸活化磷尾矿制取聚合态钙镁磷肥的工艺条件研究[J].无机盐工业,2020,52(2):43-46.

|

|

ZHENG Jianguo, YU Nanshu, LIU Yongxiu, et al.Study on technological conditions of polymeric calcium magnesium phosphate fertilizer from phosphoric acid activated phosphate tailings[J].Inorganic Chemicals Industry,2020,52(2):43-46.

|

| [8] |

CHANDRA P K, GHOSH K, VARADACHARI C.A new slow⁃releasing iron fertilizer[J].Chemical Engineering Journal,2009,155(1/2):451-456.

|

| [9] |

尹伟,黄进,解田,等.磷酸高效分解磷矿实验研究[J].无机盐工业,2020,52(9):34-36.

|

|

YIN Wei, HUANG Jin, XIE Tian, et al.Experimental study on high efficiency decomposition of phosphate rock by phosphoric acid[J].Inorganic Chemicals Industry,2020,52(9):34-36.

|

| [10] |

邵一鑫,张泽强,黄朝德,等.工业磷酸分解磷矿影响因素及副产物性质研究[J].无机盐工业,2019,51(6):49-52.

|

|

SHAO Yixin, ZHANG Zeqiang, HUANG Chaode, et al.Research on influencing factors of industrial phosphoric acid decomposing phosphate rock and properties of by⁃products[J].Inorganic Che⁃micals Industry,2019,51(6):49-52.

|

| [11] |

YANG Jingxu, XIE Wenji, KONG Xingjian, et al.Reactive extrusion of ammonium polyphosphate in a twin-screw extruder:Polydispersity improvement[J].Chemical Engineering and Processing:Process Intensification,2018,133:58-65.

|

| [12] |

XIE Wenji, WANG Xinlong, LI Yongsheng, et al.Simultaneous determination of various phosphates in water⁃soluble ammonium polyphosphate[J].Chromatographia,2019,82(11):1687-1695.

|

| [13] |

郑君花,王修俊,冯廷萃,等.利用磷尾矿生产含磷有机肥料的固体发酵研究[J].广东农业科学,2014,41(14):61-65,79.

|

|

ZHENG Junhua, WANG Xiujun, FENG Tingcui, et al.Study on solid⁃state fermentation of producing phosphorus⁃containingorga⁃

|

|

nic fertilizer using phosphate tailings[J].Guangdong Agricultural Sciences,2014,41(14):61-65,79.

|

| [14] |

WALTER G, VOGEL J, HOPPE U, et al.Structural study of magnesium polyphosphate glasses[J].Journal of Non-Crystalline Solids,2003,320(1/2/3):210-222.

|

| [15] |

吴航,张丽芳,白威,等.聚合温度对聚磷酸钙聚合度及结构的影响[J].无机材料学报,2012,27(2):174-178.

|

|

WU Hang, ZHANG Lifang, BAI Wei, et al.Effect of polymerization temperature on polymerization degree and structure of calcium polyphosphate[J].Journal of Inorganic Materials,2012,27(2):174-178.

|

| [16] |

CHEN Fangping, WANG Kai, LIU Changsheng.Crystalline structure and its effects on the degradation of linear calcium polyphosphate bone substitute[J].Applied Surface Science,2008,255(2):270-272.

|

| [17] |

吕孝福,许德华,张志业,等.磷酸二氢铵-磷酸氢二铵-聚磷酸铵-水四元体系相平衡的实验与计算[J].过程工程学报,2021,21(1):64-70.

|

|

Xiaofu LÜ, XU Dehua, ZHANG Zhiye, et al.Experiment and calculation for phase equilibria in quaternary system of ammonium dihydrogen phosphate⁃diammonium hydrogen phosphate⁃ammonium polyphosphate⁃water[J].The Chinese Journal of Process Engineering,2021,21(1):64-70.

|

| [18] |

WEEKS JR J J, HETTIARACHCHI G M.A review of the latest in phosphorus fertilizer technology:Possibilities and pragmatism[J].Journal of Environmental Quality,2019,48(5):1300-1313.

|

),XU Miao,WANG Xinlong(

),XU Miao,WANG Xinlong( ),YAN Zhengjuan,XU Dehua,YANG Jingxu

),YAN Zhengjuan,XU Dehua,YANG Jingxu