Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (6): 50-56.doi: 10.19964/j.issn.1006-4990.2022-0496

• Research & Development • Previous Articles Next Articles

Study on optimization of decalcification process of calcium and magnesium nitrate solution by response surface method

WU Yulin1,2( ), WU Junhu1,2, YANG Xiushan1,2(

), WU Junhu1,2, YANG Xiushan1,2( ), XU Dehua1,2, ZHANG Zhiye1,2

), XU Dehua1,2, ZHANG Zhiye1,2

- 1. Ministry of Education Research Center for Comprehensive Utilization and Clean Processing Engineering;of Phosphorus Resources,Chengdu 610065,China

2. College of Chemical Engineering,Sichuan University,Chengdu 610065,China

-

Received:2022-08-19Online:2023-06-10Published:2023-06-16 -

Contact:YANG Xiushan E-mail:3294127065@qq.com;yangxiushan3@163.com

CLC Number:

Cite this article

WU Yulin, WU Junhu, YANG Xiushan, XU Dehua, ZHANG Zhiye. Study on optimization of decalcification process of calcium and magnesium nitrate solution by response surface method[J]. Inorganic Chemicals Industry, 2023, 55(6): 50-56.

share this article

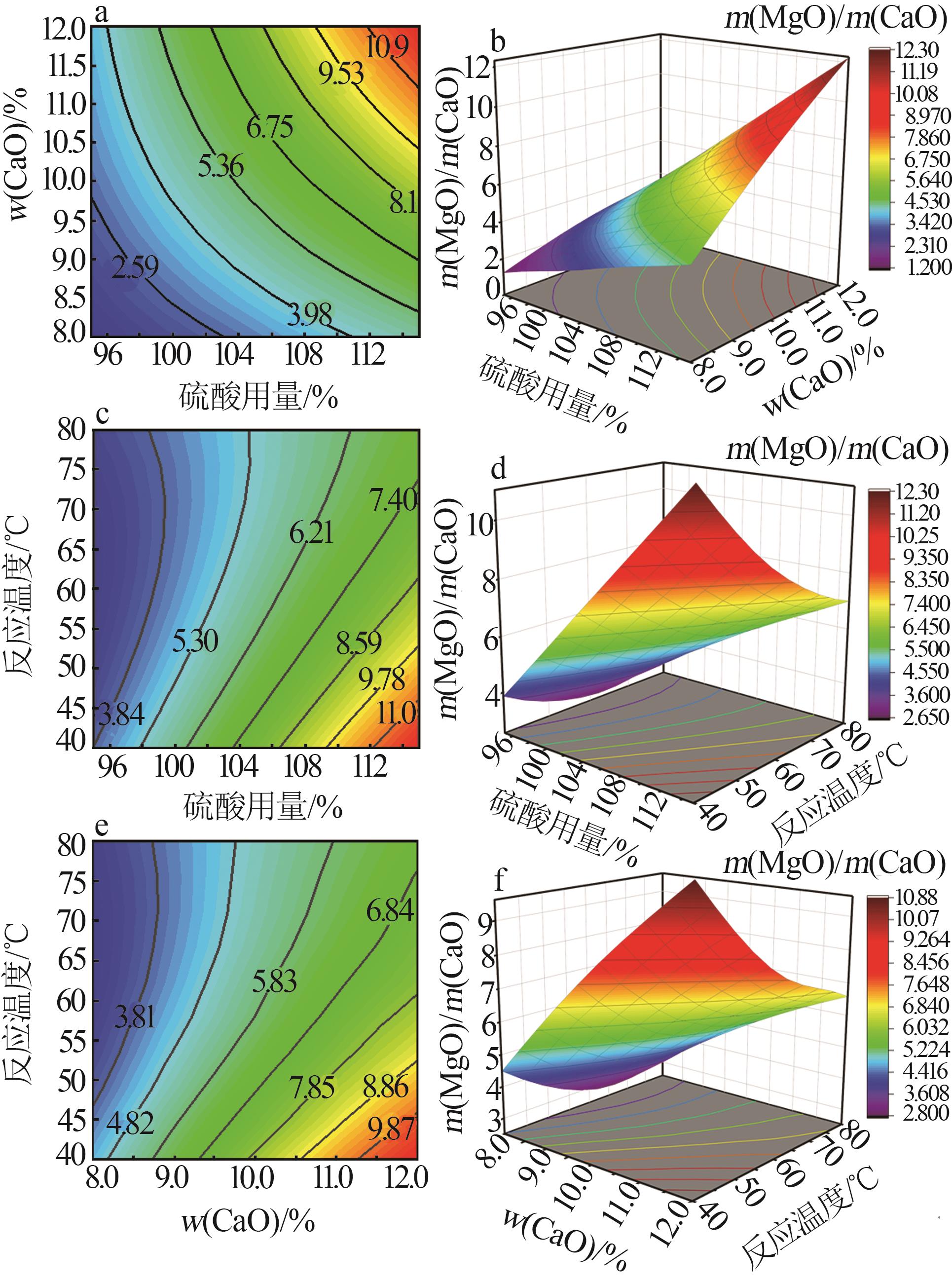

Table 3

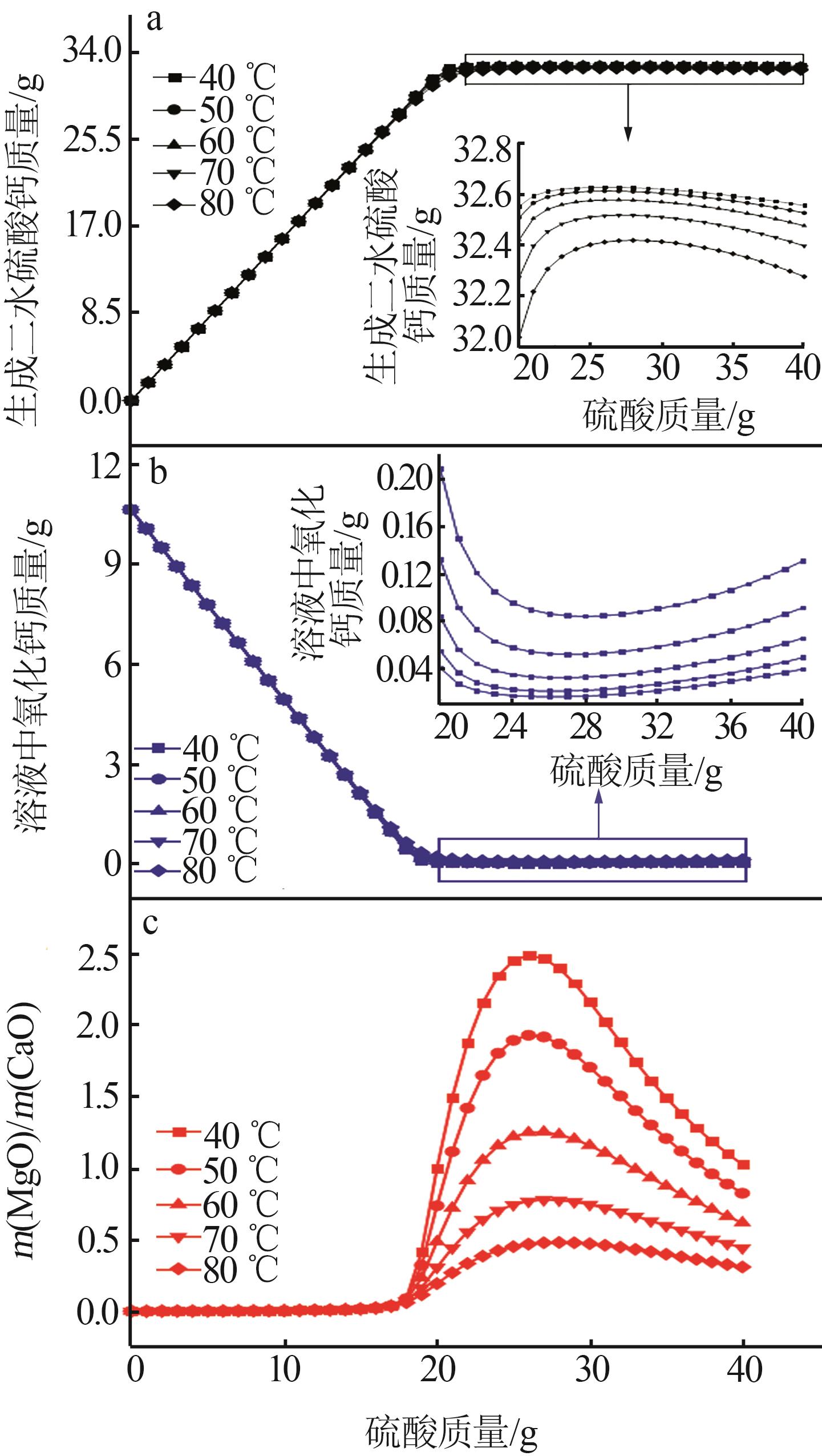

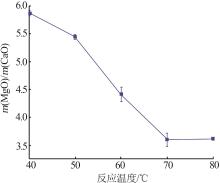

Experimental design and result of BBD"

| 序号 | A(硫酸 用量/%) | B(CaO质量 分数/%) | C(反应 温度/℃) | m(MgO)/m(CaO) | |

|---|---|---|---|---|---|

| 实验值 | 预测值 | ||||

| 1 | 105 | 10 | 60 | 5.95 | 5.74 |

| 2 | 105 | 10 | 60 | 5.27 | 5.74 |

| 3 | 105 | 10 | 60 | 5.96 | 5.74 |

| 4 | 105 | 10 | 60 | 5.94 | 5.74 |

| 5 | 105 | 10 | 60 | 5.58 | 5.74 |

| 6 | 105 | 12 | 80 | 6.99 | 6.58 |

| 7 | 105 | 8 | 80 | 3.47 | 3.01 |

| 8 | 105 | 12 | 40 | 10.42 | 10.88 |

| 9 | 105 | 8 | 40 | 4.08 | 4.49 |

| 10 | 115 | 10 | 80 | 6.61 | 7.01 |

| 11 | 95 | 10 | 80 | 2.74 | 3.20 |

| 12 | 115 | 10 | 40 | 12.61 | 12.14 |

| 13 | 95 | 10 | 40 | 4.24 | 3.84 |

| 14 | 115 | 12 | 60 | 12.26 | 12.26 |

| 15 | 95 | 12 | 60 | 3.59 | 3.54 |

| 16 | 115 | 8 | 60 | 4.55 | 4.61 |

| 17 | 95 | 8 | 60 | 1.24 | 1.23 |

Table 4

Regression model variance analysis results of Y"

| 项目 | 模型 | A | B | C | AB | AC | BC | A2 | B2 | C2 | 残差 | 失拟差 | 纯误差 | 总和 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 均方和 | 156.91 | 73.32 | 49.60 | 16.68 | 7.15 | 5.06 | 1.98 | 4.36×10-4 | 0.43 | 2.82 | 1.89 | 1.51 | 0.38 | 158.80 |

| 自由度 | 9.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 7.00 | 3.00 | 4.00 | 16.00 |

| 均方 | 17.43 | 73.32 | 49.60 | 16.68 | 7.15 | 5.06 | 1.98 | 4.36×10-4 | 0.43 | 2.82 | 0.27 | 0.50 | 0.096 | |

| F | 64.59 | 271.60 | 183.73 | 61.78 | 26.48 | 18.73 | 7.33 | 1.61×10-3 | 1.58 | 10.43 | 5.24 | |||

| P | <0.000 1 | <0.000 1 | <0.000 1 | 0.000 1 | 0.001 3 | 0.003 4 | 0.030 3 | 0.969 1 | 0.248 9 | 0.014 4 | 0.071 7 | |||

| 显著性分析 | 显著 | 不显著 |

| 1 | 闫成硕.钛白酸性废水用于中低品位胶磷矿脱镁及制取湿法磷酸工艺研究[D].上海:华东理工大学,2014. |

| YAN Chengshuo.Study on process of magnesium removal of low and medium-grade phosphate ores by acid drainage and wet-process phosphoric acid production[D].Shanghai:East China University of Science and Technology,2014. | |

| 2 | 肖勇,杨秀山,许德华,等.中低品位磷矿脱镁技术研究进展[J].化工矿物与加工,2021,50(5):42-48. |

| XIAO Yong, YANG Xiushan, XU Dehua,et al.Research progress on MgO removal technology for beneficiating middle to low P2O5 grade phosphate rock[J].Industrial Minerals & Processing,2021,50(5):42-48. | |

| 3 | 杨晓健,胡国涛,王诗瀚.中低品位磷矿脱镁技术研究进展[J].矿产保护与利用,2022,42(2):67-73. |

| YANG Xiaojian, HU Guotao, WANG Shihan.Research progress of magnesium removal technology from medium and low grade phosphate rocks[J].Conservation and Utilization of Mineral Resources, 2022,42(2):67-73. | |

| 4 | 肖勇,杨秀山,许德华,等.硝酸法处理中低品位高镁胶磷矿技术研究[J].无机盐工业,2022,54(1):71-76. |

| XIAO Yong, YANG Xiushan, XU Dehua,et al.Study on treatment of medium and low grade high magnesium collophanite by nitric acid method[J].Inorganic Chemicals Industry,2022,54(1):71- 76. | |

| 5 | 杨秀山,张志业,肖勇,等.磷矿预处理的方法:中国,110357054A[P].2019-10-22. |

| 6 | 杨秀山,张志业,肖勇,等.磷矿脱镁并联产碳酸镁和碳酸钙的方法:中国,110255591A[P].2019-09-20. |

| 7 | 李杰恩,何宾宾,杨秀山,等.中低品位磷矿预处理提磷降杂技术研究[J].无机盐工业,2020,52(4):33-36. |

| LI Jie'en, HE Binbin, YANG Xiushan,et al.Study on phosphorus extraction and impurity reduction technology for pretreatment of middle-low grade phosphate ore[J].Inorganic Chemicals Industry,2020,52(4):33-36. | |

| 8 | 周玉新,朱成,王健,等.磷矿脱镁废液制备纳米级氢氧化镁的工艺研究[J].化工矿物与加工,2019,48(1):27-30. |

| ZHOU Yuxin, ZHU Cheng, WANG Jian,et al.Study on process for preparation of nanometer magnesium hydroxide from phosphate rock demagnetization waste liquid[J].Industrial Minerals & Processing,2019,48(1):27-30. | |

| 9 | 杨俊,刘旭,陶绍程,等.磷矿化学脱镁后液相的处理研究[J].硫磷设计与粉体工程,2018(1):25-27,4. |

| YANG Jun, LIU Xu, TAO Shaocheng,et al.Study on treatment of liquid phase after chemically removing magnesium from phosphate rock[J].Sulphur Phosphorus & Bulk Materials Handling Related Engineering,2018(1):25-27,4. | |

| 10 | 成建,陈亚中,王晔,等.磷矿脱镁废液除杂并制备六水磷酸铵镁研究[J].合肥工业大学学报:自然科学版,2016,39(9):1266-1270. |

| CHENG Jian, CHEN Yazhong, WANG Ye,et al.Purification of de-magging waste liquor of phosphate ore and preparation of magnesium ammonium phosphate hexahydrate[J].Journal of Hefei University of Technology:Natural Science,2016,39(9):1266-1270. | |

| 11 | 金梦园.磷矿脱镁废液中镁的分离与回收[D].合肥:合肥工业大学,2013. |

| JIN Mengyuan.Separation and recovery of magnesium from demagging liquor of phosphate ore[D].Hefei:Hefei University of Technology,2013. | |

| 12 | 孔小雁,黄忠,余莹,等.磷矿脱镁废液制备氟化镁工艺研究[J].无机盐工业,2019,51(3):57-58,62. |

| KONG Xiaoyan, HUANG Zhong, YU Ying,et al.Study on the preparation of magnesium fluoride from demagging liquor of pho-sphate ore[J].Inorganic Chemicals Industry,2019,51(3):57-58,62. | |

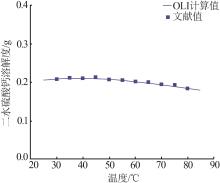

| 13 | ZHANG Yu, MUHAMMED M.Solubility of calcium sulfate dihydrate in nitric acid solutions containing calcium nitrate and phosphoric acid[J].Journal of Chemical & Engineering Data,1989,34(1):121-124. |

| 14 | 方伟成,程星星,孙常荣.响应曲面法优化污泥/粉煤灰复合陶粒滤料的制备[J].无机盐工业,2022,54(9):119-125,142. |

| FANG Weicheng, CHENG Xingxing, SUN Changrong.Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology[J].Inorganic Chemicals Industry,2022,54(9):119-125,142. | |

| 15 | 晋艳玲,谢海云,张培,等.基于响应曲面法的方铅矿表面改性参数优化[J].有色金属工程,2022,12(7):117-124. |

| JIN Yanling, XIE Haiyun, ZHANG Pei,et al.Optimization of surface modification parameters of galena based on response surface methodology[J].Nonferrous Metals Engineering,2022,12(7):117-124. | |

| 16 | 李朝荣,苏殊,许德华,等.磷酸二氢钙在硝酸钙-磷酸-水溶液体系中溶析结晶工艺[J].高校化学工程学报,2021,35(4):608-615. |

| LI Chaorong, SU Shu, XU Dehua,et al.Antisolvent crystallization of monocalcium phosphate in calcium nitratephosphoric acid-water solution system[J].Journal of Chemical Engineering of Chinese Universities,2021,35(4):608-615. | |

| 17 | 黄继明,刘润清,吴思展,等.响应面法优化氯化铵焙烧浸出低品位菱锰矿工艺[J].无机盐工业,2019,51(3):34-37. |

| HUANG Jiming, LIU Runqing, WU Sizhan,et al.Optimization of extraction process of chlorination roasting-water leaching process for low-grade rhodochrosite by response surface methodology[J].Inorganic Chemicals Industry,2019,51(3):34-37. | |

| 18 | 魏兰.响应曲面法优化聚合硫生产工艺参数[J].无机盐工业,2020,52(9):47-51. |

| WEI Lan.Response surface methodology for optimizing production process parameters of polysulfur[J].Inorganic Chemicals Industry,2020,52(9):47-51. |

| [1] | TANG Dongwu, YE Changwen, DENG Jie, AO Fang. Study on leaching rate of calcium and magnesium from phosphorus tailings based on thermodynamic analysis and response surface method [J]. Inorganic Chemicals Industry, 2024, 56(9): 98-106. |

| [2] | CHEN Junhui, LIU Xiang, HU Qingxi, TIAN Bangxin, CHEN Jiale. Study on leaching extraction of high purity potassium chloride from sintering machine head ash [J]. Inorganic Chemicals Industry, 2024, 56(6): 102-108. |

| [3] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [4] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [5] | ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM [J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113. |

| [6] | CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling. Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM [J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123. |

| [7] | WANG Yingnan, SHENG Linlin, HUANG Juan, HUANG Zhanbin. Study on adsorption performance of lead from water by coal-fired slag [J]. Inorganic Chemicals Industry, 2023, 55(8): 109-115. |

| [8] | TENG Jiayang, FENG Qingge, ZHANG Xuan, QIN Fanghong, FENG Jinghang, HU Jiawen, CHEN Chaohong. Study on preparation of pseudo-boehmite from aluminum dross resource treatment [J]. Inorganic Chemicals Industry, 2023, 55(11): 130-138. |

| [9] | ZHANG Zhiqiang, CUI Kangping, CHEN Xing, LI Haiyang. Optimization of preparation of ultrafine chromium oxide by carbothermal reduction of sodium dichromate by response surface methodology [J]. Inorganic Chemicals Industry, 2023, 55(10): 136-144. |

| [10] | FANG Weicheng,CHENG Xingxing,SUN Changrong. Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology [J]. Inorganic Chemicals Industry, 2022, 54(9): 119-125. |

| [11] | FU Ziqi, ZHANG Cheng, SHENG Yong, JI Lijun. Study on preparation of phosphoric acid by leaching fluoride residue from wet-process phosphoric acid with organic solvents [J]. Inorganic Chemicals Industry, 2022, 54(7): 129-134. |

| [12] | LU Youzhi,SU Limin,ZHAO Yi. Study on leaching of manganese from manganese dioxide ore with tannic acid?sulfuric acid system [J]. Inorganic Chemicals Industry, 2022, 54(6): 84-89. |

| [13] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| [14] | LI Yalin, HUANG Yu, Li Dongao, SUI Zhaoyi, HE Haiyang, LIU Haozhao. Preparation of Fe-impregnated biochar from food waste by solvothermal method [J]. Inorganic Chemicals Industry, 2022, 54(11): 96-103. |

| [15] | SHI Chenglong,MA Shuqing,QIN Yaru,LIU Bing,LI Haichao. Study on optimization of synergistic lithium extraction process of tributyl phosphate-ethyl butyrate system by response surface method [J]. Inorganic Chemicals Industry, 2022, 54(10): 37-41. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||